Published online by Cambridge University Press: 08 June 2015

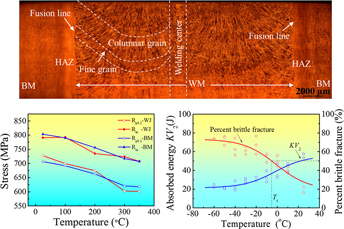

NiCrMoV steels used in nuclear rotor with heavy section were successfully fabricated by ultra-narrow gap submerged arc welding method. In this study, the mechanical properties including the tensile and impact toughness of the welded joints (WJs) with a wide temperature range were systematically investigated. Microstructural characterization indicated that the high-temperature tempered martensite and tempered bainite, as the main microstructure in WJ, were responsible for the improved comprehensive mechanical properties of the WJ. Microhardness across the WJ was measured as well, showing that the highest value of hardness occurred at the heat-affected zone which represents the appropriate lowest impact toughness of WJ. However, compared with the base metal, the ultimate tensile strength of the WJ displayed approximately equivalent values, while the yield strength was increased with increasing temperature. All the fracture of the WJ specimens occurred on the weld metal. In addition, the Charpy impact energy of weld metal was obtained at various temperatures, and the transition temperature (Tt) of welded metal was determined as 5 °C, which helps for the application design. The fractography indicated that the ductile fracture modes changed to quasi-cleavage ones gradually with decreasing temperature, and also the dimples became smaller and shallower.