Published online by Cambridge University Press: 18 April 2017

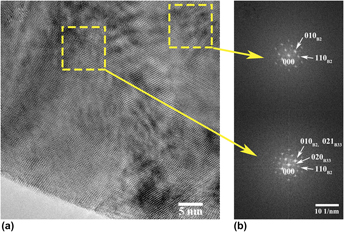

Zr–Co–Al alloys possess prospects of wide applications in the field of nuclear reactor cladding materials and biomedical materials. (Zr0.5Co0.5)100−x Al x (x = 1, 2, 3 at.%) alloys were prepared by the water-cooling copper mold suction casting technique, and the microstructure and compression mechanical properties of the alloys were investigated. The results showed that the as-cast Zr–Co–Al alloys mainly consisted of the B2 ZrCo phase with columnar or equiaxed grains and a small quantity of intermetallic compounds, i.e., Co2Zr and Zr2Co. The yield strength of Zr–Co–Al alloys increased with increasing Al content, but the plasticity decreased at the same time. The as-cast Zr49.5Co49.5Al1 alloy attained the highest ultimate compression strength up to 2.57 ± 0.02 GPa and the largest compression strain up to ∼54.7%. The B2 to B33 martensitic transformation that occurred during the deformation process was investigated using high resolution transmission electron microscopy. It was concluded that the enhanced plasticity of Zr49.5Co49.5Al1 alloy can be attributed to the transformation induced plasticity associated with the deformation-induced martensitic transformation.

Contributing Editor: Jörg F. Löffler