Published online by Cambridge University Press: 19 October 2018

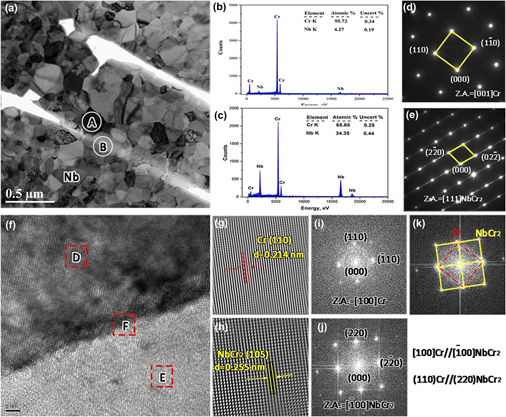

A bulk NbCr2 Laves phase matrix composite toughened with ductile Cr phase has been fabricated by spark plasma sintering (SPS) using pre-alloyed NbCr2 and Cr powders. The sintering behaviour and phase morphological evolution of the sintered alloy were investigated. The results show that a series of microstructure evolutions along the sintering temperature occurred: elongated Cr phase with uniform dispersion of fine NbCr2 and Cr phase → coarse Cr phase with matured fine NbCr2 and Cr → coarse Cr and Nb phases with lamellar eutectics. The microstructural evolution and phase transformation along the sintering temperature are analyzed by considering the inhomogenous temperature distribution and the accelerated atomic diffusion due to the pulsed electric current applied during SPS. The room temperature fracture toughness of the sintered samples is expected to be markedly improved due to the absence of lamellar or the occurrence of ductile Cr and Nb phases.