Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Tulyaganov, Dilshat U.

Reddy, Allu Amarnath

Kharton, Vladislav V.

and

Ferreira, José M.F.

2013.

Aluminosilicate-based sealants for SOFCs and other electrochemical applications − A brief review.

Journal of Power Sources,

Vol. 242,

Issue. ,

p.

486.

Abdoli, Hamid

Alizadeh, Parvin

Boccaccini, Dino

and

Agersted, Karsten

2014.

Effects of thermal aging on thermo-mechanical behavior of a glass sealant for solid oxide cell applications.

Journal of the European Ceramic Society,

Vol. 34,

Issue. 10,

p.

2525.

Hsu, Jen-Hsien

Kim, Cheol-Woon

and

Brow, Richard K.

2014.

Interfacial interactions between an alkali-free borosilicate viscous sealing glass and aluminized ferritic stainless steel.

Journal of Power Sources,

Vol. 250,

Issue. ,

p.

236.

Singh, Raj N.

2014.

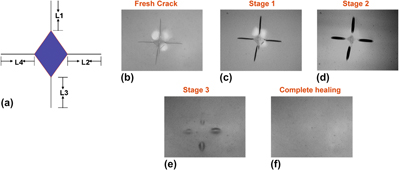

Kinetics of self-repair in inorganic glasses: modeling and experimental verification.

Journal of Materials Science,

Vol. 49,

Issue. 14,

p.

4869.

Hsu, Jen-Hsien

Kim, Cheol-Woon

Brow, Richard K.

Szabo, Joe

Crouch, Ray

and

Baird, Rob

2014.

An alkali-free barium borosilicate viscous sealing glass for solid oxide fuel cells.

Journal of Power Sources,

Vol. 270,

Issue. ,

p.

14.

Silva, Laís D.

Rodrigues, Alisson M.

Rodrigues, Ana Candida M.

Pascual, María J.

Durán, Alicia

and

Cabral, Aluísio A.

2017.

Sintering and crystallization of SrO-CaO-B2O3-SiO2 glass-ceramics with different TiO2 contents.

Journal of Non-Crystalline Solids,

Vol. 473,

Issue. ,

p.

33.

Lin, Dewei

Tan, Shengwei

Lin, Fen

Dong, Zhengwei

Yan, Jiajia

Tang, Dian

Yang, Hsiwen

Chen, Kongfa

and

Zhang, Teng

2018.

Improving the sealing performance of glass-ceramics for SOFCs applications by a unique ‘composite’ approach: A study on Na2O-SiO2 glass-ceramic system.

Journal of the European Ceramic Society,

Vol. 38,

Issue. 13,

p.

4488.

Hari, B.

Brouwer, J.P.

Dhir, A.

and

Steinberger-Wilckens, R.

2019.

A computational fluid dynamics and finite element analysis design of a microtubular solid oxide fuel cell stack for fixed wing mini unmanned aerial vehicles.

International Journal of Hydrogen Energy,

Vol. 44,

Issue. 16,

p.

8519.

Lenser, Christian

Udomsilp, David

Menzler, Norbert H.

Holtappels, Peter

Fujisaki, Takaya

Kwati, Leonard

Matsumoto, Hiroshige

Sabato, Antonio Gianfranco

Smeacetto, Federico

Chrysanthou, Andreas

and

Molin, Sebastian

2020.

Advanced Ceramics for Energy Conversion and Storage.

p.

387.

Ferraris, Monica

Casalegno, Valentina

Smeacetto, Federico

and

Salvo, Milena

2020.

Glass as a joining material for ceramic matrix composites: 25 years of research at Politecnico di Torino.

International Journal of Applied Glass Science,

Vol. 11,

Issue. 3,

p.

569.

Wang, Chu

Wang, Hongxiang

Liu, Zhichao

Zhang, Mingzhuang

Gao, Rui

Hou, Jing

and

Chen, Xianhua

2020.

Kinetic model and effect of surface impurities on the crack healing of BK7 glass.

Ceramics International,

Vol. 46,

Issue. 11,

p.

19069.

Liao, Yimin

Chen, Minghui

Feng, Min

Wang, Qunchang

Wang, Jinlong

Zhu, Shenglong

and

Wang, Fuhui

2021.

Thermal shock and self-healing behavior of the enamel composite coatings with addition of various nanoparticles at temperatures of 700 and 800 °C.

Corrosion Science,

Vol. 191,

Issue. ,

p.

109747.

Alencar, Maria V.S.

Bezerra, Glauco V.P.

Silva, Laís D.

Schneider, José F.

Pascual, M. Jesus

and

Cabral, Aluísio A.

2021.

Structure, Glass Stability and Crystallization Activation Energy of SrO-CaO-B2O3-SiO2 glasses doped with TiO2.

Journal of Non-Crystalline Solids,

Vol. 554,

Issue. ,

p.

120605.

Timurkutluk, Cigdem

Toruntay, Furkan

Onbilgin, Sezer

Atalmis, Gamze

and

Timurkutluk, Bora

2022.

Development of ceramic fiber reinforced glass ceramic sealants for microtubular solid oxide fuel cells.

Ceramics International,

Vol. 48,

Issue. 11,

p.

15703.

Barick, Prasenjit

and

Saha, Bhaskar

2023.

Effect of sintering parameters on the densification, microstructure, and mechanical properties of SrO-CaO-ZnO-Al2O3-B2O3-SiO2-TiO2 based glass sealant.

Science of Sintering,

Vol. 55,

Issue. 3,

p.

353.

Rao, Padmanapan

and

Singh, Raj N.

2023.

Sintering and thermal expansion behaviors of glass and glass–YSZ composites as self‐repairable seals for SOFC.

Journal of the American Ceramic Society,

Vol. 106,

Issue. 1,

p.

157.

Rao, Padmanapan

and

Singh, Raj N.

2023.

Kinetics of crack healing for self-repair in glass-yttria stabilized zirconia composites for solid oxide fuel cell.

Journal of Materials Research,

Vol. 38,

Issue. 10,

p.

2679.

Gao, Jianwei

Si, Xiaoqing

Li, Mingshen

Zhao, Wendi

Li, Chun

Qi, Junlei

and

Cao, Jian

2024.

A novel non-crystallizing Na2O-K2O-TiO2 silicate glass sealant for protonic ceramic fuel cell applications.

Ceramics International,

Vol. 50,

Issue. 23,

p.

49972.

Blaeß, Carsten

and

Müller, Ralf

2024.

Viscous crack healing in soda–lime–magnesium–silicate–ZrO2 glass matrix composites.

Journal of the American Ceramic Society,

Vol. 107,

Issue. 11,

p.

7212.

Salvador, Camilo A.F.

Rego, Jessica S.

Lopes, Thiago

Meneghini, Julio R.

Brandon, Nigel P.

and

Damasceno, Daniela A.

2025.

Materials selection of non-metallic glasses for planar solid-oxide fuel cell sealants.

Ceramics International,

Vol. 51,

Issue. 6,

p.

6867.