Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Hu, Wentao

Liu, Shaocun

Zhang, Yang

Xiang, Jianyong

Wen, Fusheng

Xu, Bo

He, Julong

Yu, Dongli

Tian, Yongjun

and

Liu, Zhongyuan

2012.

Annealing-Induced {011}-Specific Cyclic Twins in Tetragonal Zirconia Nanoparticles.

The Journal of Physical Chemistry C,

Vol. 116,

Issue. 39,

p.

21052.

Hu, Wentao

Tian, Yongjun

and

Liu, Zhongyuan

2013.

MAX Phases and Ultra-High Temperature Ceramics for Extreme Environments.

p.

478.

Hu, Wentao

Liu, Shaocun

Wen, Bin

Xiang, Jianyong

Wen, Fusheng

Xu, Bo

He, Julong

Yu, Dongli

Tian, Yongjun

and

Liu, Zhongyuan

2013.

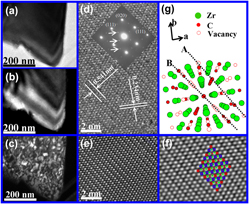

{111}-specific twinning structures in nonstoichiometric ZrC0.6with ordered carbon vacancies.

Journal of Applied Crystallography,

Vol. 46,

Issue. 1,

p.

43.

Hu, Wentao

Tian, Yongjun

and

Liu, Zhongyuan

2014.

Nanotechnology.

p.

667.

Liu, Shaocun

Hu, Wentao

Zhang, Yang

Xiang, Jianyong

Wen, Fusheng

Xu, Bo

He, Julong

Yu, Dongli

Tian, Yongjun

and

Liu, Zhongyuan

2014.

Metastable adaptive orthorhombic martensite in zirconia nanoparticles.

Journal of Applied Crystallography,

Vol. 47,

Issue. 2,

p.

684.

Zhang, Yanhui

Liu, Bin

and

Wang, Jingyang

2015.

Self-assembly of Carbon Vacancies in Sub-stoichiometric ZrC1−x.

Scientific Reports,

Vol. 5,

Issue. 1,

Xie, Congwei

Oganov, Artem R.

Li, Duan

Debela, Tekalign Terfa

Liu, Ning

Dong, Dong

and

Zeng, Qingfeng

2016.

Effects of carbon vacancies on the structures, mechanical properties, and chemical bonding of zirconium carbides: a first-principles study.

Physical Chemistry Chemical Physics,

Vol. 18,

Issue. 17,

p.

12299.

Li, Xiaopu

and

Hu, Wentao

2016.

Superfluous oxygen diffusion induced amorphization of ZrC0.6O0.4 and transformation of amorphous layer under electron beam irradiation.

Journal of Materials Research,

Vol. 31,

Issue. 1,

p.

137.

Zhang, Yanhui

Liu, Bin

Wang, Jiemin

and

Wang, Jingyang

2016.

Theoretical investigations of the effects of ordered carbon vacancies in ZrC1−x on phase stability and thermo-mechanical properties.

Acta Materialia,

Vol. 111,

Issue. ,

p.

232.

Ge, Haolong

Song, Quan

Hu, Wentao

Zhang, Bing

Jia, Yuanzhi

Liu, Yanguo

Ma, Mingzhen

and

Liu, Riping

2018.

Microstructures and mechanical properties of as-cast TiCuFeC alloys for biomedical applications.

Journal of Alloys and Compounds,

Vol. 750,

Issue. ,

p.

96.

Wei, Boxin

Wang, Yujin

Zhang, Haibin

Wang, Dong

Peng, Shuming

and

Zhou, Yu

2018.

Microstructure evolution of nonstoichiometric ZrC0.6 with ordered carbon vacancies under ion irradiation.

Materials Letters,

Vol. 228,

Issue. ,

p.

254.

Ushakov, Sergey V.

Navrotsky, Alexandra

Hong, Qi-Jun

and

van de Walle, Axel

2019.

Carbides and Nitrides of Zirconium and Hafnium.

Materials,

Vol. 12,

Issue. 17,

p.

2728.

Shabalin, Igor L.

2019.

Ultra-High Temperature Materials II.

p.

423.

Zhou, Yue

Heitmann, Thomas W.

Bohannan, Eric

Schaeperkoetter, Joseph C.

Fahrenholtz, William G.

and

Hilmas, Gregory E.

2020.

Carbon vacancy ordering in zirconium carbide powder.

Journal of the American Ceramic Society,

Vol. 103,

Issue. 4,

p.

2891.

Robin Chang, Yee Hui

and

Yoon, Tiem Leong

2020.

Effects of nitrogen addition and growth condition on the enhanced mechanical properties of transition metal carbides TMC (TM = Zr, Hf).

Ceramics International,

Vol. 46,

Issue. 1,

p.

1124.

Tunca, Bensu

Lapauw, Thomas

Callaert, Carolien

Hadermann, Joke

Delville, Remi

Caspi, El’ad N.

Dahlqvist, Martin

Rosén, Johanna

Marshal, Amalraj

Pradeep, Konda G.

Schneider, Jochen M.

Vleugels, Jozef

and

Lambrinou, Konstantina

2020.

Compatibility of Zr2AlC MAX phase-based ceramics with oxygen-poor, static liquid lead–bismuth eutectic.

Corrosion Science,

Vol. 171,

Issue. ,

p.

108704.

Davey, Theresa

Suzuki, Ken

Miura, Hideo

and

Chen, Ying

2021.

Stability and structural properties of vacancy-ordered and -disordered ZrCx.

RSC Advances,

Vol. 11,

Issue. 52,

p.

32573.

Huang, Shimin

Xu, Shuang

Xu, Yurong

Zhou, Zixiang

and

Li, Jun

2021.

Doping effects on mechanical and thermodynamic properties of zirconium carbide systems: a first-principles study.

Materials Research Express,

Vol. 8,

Issue. 6,

p.

065012.

Zhou, Yue

Fahrenholtz, William G.

Graham, Joseph

and

Hilmas, Gregory E.

2021.

From thermal conductive to thermal insulating: Effect of carbon vacancy content on lattice thermal conductivity of ZrC.

Journal of Materials Science & Technology,

Vol. 82,

Issue. ,

p.

105.

Korte-Kerzel, Sandra

Hickel, Tilmann

Huber, Liam

Raabe, Dierk

Sandlöbes-Haut, Stefanie

Todorova, Mira

and

Neugebauer, Jörg

2022.

Defect phases – thermodynamics and impact on material properties.

International Materials Reviews,

Vol. 67,

Issue. 1,

p.

89.