Published online by Cambridge University Press: 24 January 2011

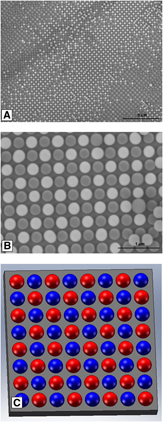

We demonstrate the formation of non-close-packed binary colloidal structures through a novel layer-by-layer directed self-assembly methodology. In this approach we deposit colloidal suspensions of particle concentration and controlled electrostatic potential onto a planar template with a periodic array of features that is able to trap the particles, nucleating ordered domains with a template-defined symmetry and periodicity that permits subsequent, sequential deposition to produce an ordered heterostructure. Specifically, a silicon template with a hole pattern formed by interference lithography that corresponds to [100] symmetry of a cubic system has been used. At low particle concentrations, and using a Debye length that is on the order of the particle diameter, ordered domains in which polystyrene (PS) particles occupy every other site in the template are formed. The remaining sites on the 2D template are then filled by identically sized silica particles using vertical deposition. This process is repeated to produce a second layer of the same structure. Upon removing the PS particles, a two-layer non-close-packed structure that is a half-unit-cell precursor to the diamond cubic structure is obtained. To our knowledge this is the first demonstration of colloidal self-assembly to obtain a non-close-packed multilayer structure. Challenges that remain in applying the approach to create extended three-dimensional structures are discussed.