Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Cai, Z.P.

Ai, B.Q.

Cao, R.

Lin, Q.

and

Chen, J.H.

2016.

Microstructure and properties of aluminum AA6061-T6 to copper (Cu)-T2 joints by cold metal transfer joining technology.

Journal of Materials Research,

Vol. 31,

Issue. 18,

p.

2876.

Vecchio, Kenneth S.

and

Jiang, Fengchun

2016.

Fracture toughness of Ceramic-Fiber-Reinforced Metallic-Intermetallic-Laminate (CFR-MIL) composites.

Materials Science and Engineering: A,

Vol. 649,

Issue. ,

p.

407.

Deshpande, Anagh

and

Hsu, Keng

2018.

Acoustoplastic metal direct-write: Towards solid aluminum 3D printing in ambient conditions.

Additive Manufacturing,

Vol. 19,

Issue. ,

p.

73.

Huang, Zhequn

Date, Kenji

Tatsugawa, Kiyoshi

and

Ando, Teiichi

2018.

Characterization of Al Skeletal Structures Fabricated by Ultrasonic Powder Consolidation.

Metallurgical and Materials Transactions A,

Vol. 49,

Issue. 12,

p.

6173.

Deshpande, Anagh

and

Hsu, Keng

2018.

Acoustic energy enabled dynamic recovery in aluminium and its effects on stress evolution and post-deformation microstructure.

Materials Science and Engineering: A,

Vol. 711,

Issue. ,

p.

62.

Hehr, Adam

and

Norfolk, Mark

2019.

A comprehensive review of ultrasonic additive manufacturing.

Rapid Prototyping Journal,

Vol. 26,

Issue. 3,

p.

445.

Deshpande, Anagh

Tofangchi, Alireza

and

Hsu, Keng

2019.

Microstructure evolution of Al6061 and copper during ultrasonic energy assisted compression.

Materials Characterization,

Vol. 153,

Issue. ,

p.

240.

Hehr, Adam

Norfolk, Mark

Sheridan, John

Davis, Matthew

Leser, William

Leser, Patrick

and

Newman, John A.

2019.

Spatial Strain Sensing Using Embedded Fiber Optics.

JOM,

Vol. 71,

Issue. 4,

p.

1528.

Ward, Austin A.

and

Cordero, Zachary C.

2020.

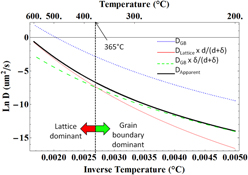

Junction growth and interdiffusion during ultrasonic additive manufacturing of multi-material laminates.

Scripta Materialia,

Vol. 177,

Issue. ,

p.

101.

Moisy, F.

Sauvage, X.

and

Hug, E.

2020.

Investigation of the early stage of reactive interdiffusion in the Cu-Al system by in-situ transmission electron microscopy.

Materialia,

Vol. 9,

Issue. ,

p.

100633.

Hehr, Adam

Norfolk, Mark

Wenning, Justin

Sheridan, John

Ahlfors, Magnus

Mastropietro, A. J.

Maghsoudi, Elham

and

Roberts, Scott N.

2021.

Hot Isostatic Pressing of Ultrasonic Additive Manufacturing Liquid Cold Plate Heat Exchangers.

Journal of Spacecraft and Rockets,

Vol. 58,

Issue. 3,

p.

910.

Pagan, Michael

Petrie, Christian

Leonard, Donovan

Sridharan, Niyanth

Zinkle, Steven

and

Babu, Sudarsanam Suresh

2021.

Interdiffusion of Elements During Ultrasonic Additive Manufacturing.

Metallurgical and Materials Transactions A,

Vol. 52,

Issue. 3,

p.

1142.

Massey, Caleb P.

Gussev, Maxim N.

Havrilak, Cody J.

Seibert, Rachel L.

Cakmak, Ercan

and

Nelson, Andrew T.

2022.

On the efficacy of post-build thermomechanical treatments to improve properties of Zirconium fabricated using ultrasonic additive manufacturing.

Additive Manufacturing,

Vol. 59,

Issue. ,

p.

103110.

Massey, Caleb P.

Bibhanshu, Nitish

Gussev, Maxim N.

Havrilak, Cody J.

and

Nelson, Andrew T.

2022.

Deformation and fracture characteristics of zirconium plate produced via ultrasonic additive manufacturing.

Journal of Materials Research,

Vol. 37,

Issue. 1,

p.

236.

Monaghan, T.

Harding, M. J.

Christie, S. D. R.

Harris, R. A.

and

Friel, R. J.

2022.

Complementary catalysis and analysis within solid state additively manufactured metal micro flow reactors.

Scientific Reports,

Vol. 12,

Issue. 1,

Zhou, Yanyuan

Chen, Jinyong

Wang, Zhenqiang

and

Jiang, Fengchun

2022.

Interfacial texture and bonding strength of Cu/Al laminate metal composite fabricated by ultrasonic additive manufacturing.

Science and Technology of Welding and Joining,

Vol. 27,

Issue. 7,

p.

501.

Pagan, Michael

Ohmura, Takahito

Wang, Ling

Zinkle, Steven

and

Babu, S. S.

2022.

Strengthening Effects at Dissimilar Metal Interfaces Created by Ultrasonic Additive Manufacturing.

Metallurgical and Materials Transactions A,

Vol. 53,

Issue. 10,

p.

3547.

Friel, Ross J.

2022.

Encyclopedia of Materials: Metals and Alloys.

p.

134.

Zhou, Yanyuan

Wang, Zhenqiang

Sun, Bin

Chong, Yan

and

Jiang, F. C.

2022.

Formation of Face-Centered Cubic Titanium During Ultrasonic Consolidation of Commercially Pure Titanium/Aluminium Dissimilar Metals.

SSRN Electronic Journal ,

Ward, Austin A.

Leonard, Donovan N.

König, Hans-Henrik

Lindwall, Greta

and

Cordero, Zachary C.

2022.

Ultrasonic additive manufacturing of nanocrystalline laminated composites.

Journal of Materials Research,

Vol. 37,

Issue. 1,

p.

247.