Article contents

An experimental investigation on B2 phase transfer and grain boundary character on mechanical properties of rapidly cooled Fe–6.5 wt% Si alloy

Published online by Cambridge University Press: 04 December 2017

Abstract

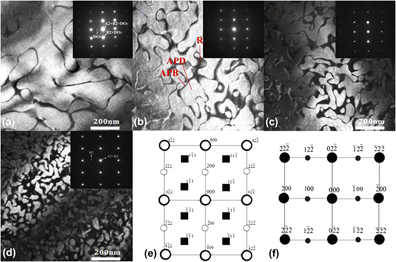

The combined effect of B2 phase transfer and grain boundary character on mechanical properties of the Fe–6.5 wt% Si alloy was investigated. The microstructures and textures of the Fe–6.5 wt% Si alloy under four cooling modes were characterized by X-ray diffraction, transmission electron microscope, and electron backscattered diffraction. The results reveal that the maximum nano-hardness value (8.9 GPa) results from the two-step air-cooling sample, while for the two-step water-cooling sample, the minimum value (5.3 GPa) is achieved. The transformation of the B2 phase affected by the water-cooling process is a critical factor in obtaining the lower APB energy and eliminating the brittlenes. A large fraction of the coincidence site lattice boundaries that formed on the sheet experienced the two-step water-cooling process due to a uniform and sharp γ-fiber recrystallization texture comprising the {111} 〈110〉 and {111} 〈112〉 components, which enhances resistance to intercrystalline effect and improves mechanical properties in comparison with the two-step air-cooling process.

Information

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 6

- Cited by