Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Long, Xu

Du, Chongyang

Hu, Bo

and

Li, Mingyu

2018.

Comparison of sintered silver micro and nano particles: from microstructure to property.

p.

1.

Long, Xu

Tang, Wenbin

Xu, Mengfei

Keer, Leon M.

and

Yao, Yao

2018.

Electric current-assisted creep behaviour of Sn–3.0Ag–0.5Cu solder.

Journal of Materials Science,

Vol. 53,

Issue. 8,

p.

6219.

Tang, Wenbin

Long, Xu

Liu, Yongchao

Du, Chongyang

Yao, Yao

Zhou, Cheng

Wu, Yanpei

and

Jia, Fengrui

2018.

Effect of Electric Current on Constitutive Behaviour and Microstructure of SAC305 Solder Joint.

p.

717.

Long, Xu

Tang, Wenbin

Wang, Shaobin

He, Xu

and

Yao, Yao

2018.

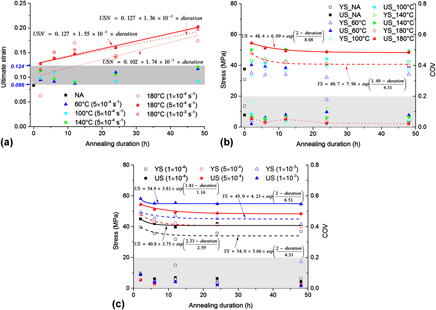

Annealing effect to constitutive behavior of Sn–3.0Ag–0.5Cu solder.

Journal of Materials Science: Materials in Electronics,

Vol. 29,

Issue. 9,

p.

7177.

Wang, Wenjie

Yao, Yao

Long, Xu

and

Zhu, Zhenghu

2018.

Material and structural optimization of fatigue life of PBGA under temperature cycling.

p.

477.

Long, Xu

Zhang, Xiaodi

Tang, Wenbin

Wang, Shaobin

Feng, Yihui

and

Chang, Chao

2018.

Calibration of a Constitutive Model from Tension and Nanoindentation for Lead-Free Solder.

Micromachines,

Vol. 9,

Issue. 11,

p.

608.

Wang, Wenjie

and

Long, Xu

2019.

Temperature and strain-rate dependent constitutive model for prediction of thermal cycling life.

IOP Conference Series: Materials Science and Engineering,

Vol. 531,

Issue. 1,

p.

012036.

Wang, W. J.

Long, X.

Du, C. Y.

Fu, Y. H.

Yao, Y.

and

Wu, Y. P.

2019.

Enhancement of the Unified Constitutive Model for Viscoplastic Solders in Wide Strain Rate and Temperature Ranges.

Strength of Materials,

Vol. 51,

Issue. 6,

p.

917.

Salita, D. S.

and

Polyakov, V. V.

2020.

Acoustic Emission during Plastic Deformation of Pb–Sn

Alloys.

Physical Mesomechanics,

Vol. 23,

Issue. 6,

p.

593.

Hammad, A.E.

and

Ragab, M.

2020.

Achieving microstructure refinement and superior mechanical performance of Sn-2.0Ag-0.5Cu-2.0Zn (SACZ) solder alloy with rotary magnetic field.

Microelectronics Reliability,

Vol. 113,

Issue. ,

p.

113932.

Long, Xu

Chen, Zubin

Wang, Wenjie

Fu, Yonghui

and

Wu, Yanpei

2020.

Parameterized Anand constitutive model under a wide range of temperature and strain rate: experimental and theoretical studies.

Journal of Materials Science,

Vol. 55,

Issue. 24,

p.

10811.

Liang, Tong

Yuan, Weike

and

Wang, Gangfeng

2021.

Influence of Equi-Biaxial Residual Stress on Spherical Indentation of Strain Hardening Materials.

International Journal of Applied Mechanics,

Vol. 13,

Issue. 05,

Tynchenko, Vadim

Kurashkin, Sergei

Tynchenko, Valeriya

Bukhtoyarov, Vladimir

Kukartsev, Vladislav

Sergienko, Roman

Kukartsev, Viktor

and

Bashmur, Kirill

2021.

Mathematical Modeling of Induction Heating of Waveguide Path Assemblies during Induction Soldering.

Metals,

Vol. 11,

Issue. 5,

p.

697.

Sobolewski, Maciej

Wojewoda-Budka, Joanna

Huber, Zbigniew

Zieba, Pawel

and

Wierzbicka-Miernik, Anna

2021.

Solder joints reliability of through hole assemblies with various land and hole design.

Microelectronics Reliability,

Vol. 125,

Issue. ,

p.

114368.

Yang, Yang

Xu, Tianyu

Guo, Junli

He, Zheng

and

Ma, Houbiao

2021.

Strength reserve assessment on pitting-corroded jacket offshore platforms based on the modified generalized constitutive model.

Thin-Walled Structures,

Vol. 169,

Issue. ,

p.

108494.

An, Qi

An, Rong

and

Wang, Chunqing

2022.

Interfacial Endogenous Stress-Induced Phase-Stress Partition in Tin-Lead Dual-Phase Alloy at Cryogenic Temperature.

SSRN Electronic Journal ,

Long, Xu

Li, Jiao

Shen, Ziyi

and

Su, Yutai

2022.

Dimensionless Analysis to Determine Elastoplastic Properties of Thin Films by Indentation.

Coatings,

Vol. 12,

Issue. 11,

p.

1768.

Salita, D. S.

and

Polyakov, V. V.

2022.

Violation of Kaiser effect in Pb–Sn alloys.

Vol. 2509,

Issue. ,

p.

020164.

Long, Xu

Dong, Ruipeng

Su, Yutai

and

Chang, Chao

2023.

Critical Review of Nanoindentation-Based Numerical Methods for Evaluating Elastoplastic Material Properties.

Coatings,

Vol. 13,

Issue. 8,

p.

1334.

Cong, Sen

Liu, Peng

Wang, Shaobin

and

Xiong, Jinghua

2023.

Reliability and prediction of Sn36Pb2Ag solder joints under thermal aging test.

Materials Research Express,

Vol. 10,

Issue. 4,

p.

046301.