Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Liu, Xinghang

Hou, Baofei

Wang, Gang

Cui, Zhenqi

Zhu, Xiang

and

Wang, Xianbao

2018.

Black titania/graphene oxide nanocomposite films with excellent photothermal property for solar steam generation.

Journal of Materials Research,

Vol. 33,

Issue. 6,

p.

674.

Mao, Zhou

Lin, Hua

Xu, Meng

Miao, Jie

He, Shijie

and

Li, Qing

2018.

Fabrication of co-doped CdSe quantum dot-sensitized TiO2 nanotubes by ultrasound-assisted method and their photoelectrochemical properties.

Journal of Applied Electrochemistry,

Vol. 48,

Issue. 2,

p.

147.

Li, Yuxin

Fu, Rong

Wang, Xiangdong

and

Guo, Xiaoling

2018.

Preparation of core–shell nanostructured black nano-TiO2 by sol–gel method combined with Mg reduction.

Journal of Materials Research,

Vol. 33,

Issue. 24,

p.

4173.

Li, Changxin

Liu, Yan

Zhang, Yanzong

Long, Lulu

Shen, Fei

Yang, Gang

Zhang, Xiaohong

He, Yan

Wang, Lilin

and

Deng, Shihuai

2019.

Electro-assisted ammonium persulfate activation to promote the introduction of N and S into TiO2 film: Enhancing its photoelectrocatalytic performance under solar.

Journal of Materials Research,

Vol. 34,

Issue. 20,

p.

3573.

Yu, Chengtao

Zhang, Jingyi

Yang, Hexu

Zhang, Ling

and

Gao, Yu

2019.

Enhanced photovoltaic conversion efficiency of a dye-sensitized solar cell based on TiO2 nanoparticle/nanorod array composites.

Journal of Materials Research,

Vol. 34,

Issue. 07,

p.

1155.

Gonçalves, Bruno S.

Silva, Lucas M.C.

de Souza, Tarcizo C.C.

de Castro, Vinícius G.

Silva, Glaura G.

Silva, Bruno C.

Krambrock, Klaus

Soares, Renata B.

Lins, Vanessa F.C.

Houmard, Manuel

and

Nunes, Eduardo H.M.

2019.

Solvent effect on the structure and photocatalytic behavior of TiO2-RGO nanocomposites.

Journal of Materials Research,

Vol. 34,

Issue. 23,

p.

3918.

Zhan, Feng

Xiong, Lei

Liu, Fang

and

Li, Chenying

2019.

Grafting Hyperbranched Polymers onto TiO2 Nanoparticles via Thiol-yne Click Chemistry and Its Effect on the Mechanical, Thermal and Surface Properties of Polyurethane Coating.

Materials,

Vol. 12,

Issue. 17,

p.

2817.

Sołtys-Mróz, Monika

Syrek, Karolina

Pierzchała, Joanna

Wiercigroch, Ewelina

Malek, Kamilla

and

Sulka, Grzegorz D.

2020.

Band gap engineering of nanotubular Fe2O3-TiO2 photoanodes by wet impregnation.

Applied Surface Science,

Vol. 517,

Issue. ,

p.

146195.

Khezami, Lotfi

Lounissi, Imen

Hajjaji, Anouar

Guesmi, Ahlem

Assadi, Aymen Amine

and

Bessais, Brahim

2021.

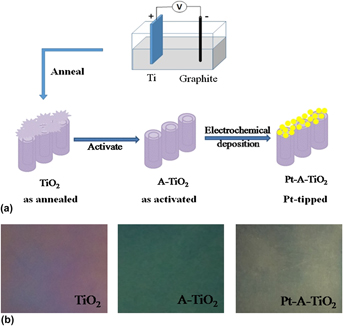

Synthesis and Characterization of TiO2 Nanotubes (TiO2-NTs) Decorated with Platine Nanoparticles (Pt-NPs): Photocatalytic Performance for Simultaneous Removal of Microorganisms and Volatile Organic Compounds.

Materials,

Vol. 14,

Issue. 23,

p.

7341.

Yurdakal, Sedat

Çetinkaya, Sıdıka

Özcan, Levent

Gök, Özer

and

Palmisano, Leonardo

2021.

Partial photoelectrocatalytic oxidation of 3-pyridinemethanol by Pt, Au and Pd loaded TiO2 nanotubes on Ti plate.

Catalysis Today,

Vol. 380,

Issue. ,

p.

248.

Navidpour, Amir H.

Hosseinzadeh, Ahmad

Zhou, John L.

and

Huang, Zhenguo

2023.

Progress in the application of surface engineering methods in immobilizing TiO2 and ZnO coatings for environmental photocatalysis.

Catalysis Reviews,

Vol. 65,

Issue. 3,

p.

822.

Hajjaji, M. A.

Missaoui, K.

Trabelsi, K.

Bouzaza, A.

Bessais, B.

Hajjaji, A.

and

Assadi, A. A.

2024.

Electrodeposited Platinum Nanoparticles on Highly Ordered Titanium Dioxide Nanotubes for Photocatalytic Application: Enhancement of Photocatalytic Degradation of Amido Black Dye.

Catalysis Letters,

Vol. 154,

Issue. 3,

p.

1242.