Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Weng, Fei

Chew, Youxiang

Zhu, Zhiguang

Yao, Xiling

Wang, Leilei

Ng, Fern Lan

Liu, Shibo

and

Bi, Guijun

2020.

Excellent combination of strength and ductility of CoCrNi medium entropy alloy fabricated by laser aided additive manufacturing.

Additive Manufacturing,

Vol. 34,

Issue. ,

p.

101202.

Bahadur, Fateh

Biswas, Krishanu

and

Gurao, N.P.

2020.

Micro-mechanisms of microstructural damage due to low cycle fatigue in CoCuFeMnNi high entropy alloy.

International Journal of Fatigue,

Vol. 130,

Issue. ,

p.

105258.

Sonkusare, Reshma

Biswas, Krishanu

Al-Hamdany, Nowfal

Brokmeier, H.G.

Kalsar, R.

Schell, Norbert

and

Gurao, N.P.

2020.

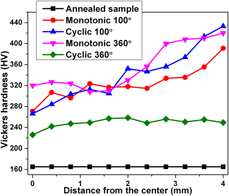

A critical evaluation of microstructure-texture-mechanical behavior heterogeneity in high pressure torsion processed CoCuFeMnNi high entropy alloy.

Materials Science and Engineering: A,

Vol. 782,

Issue. ,

p.

139187.

KARIMI, Mohammad Ali

SHAMANIAN, Morteza

and

ENAYATI, Mohammad Hossein

2021.

Microstructural and mechanical properties assessment of transient liquid phase bonding of CoCuFeMnNi high entropy alloy.

Transactions of Nonferrous Metals Society of China,

Vol. 31,

Issue. 10,

p.

3063.

Sinha, Subhasis

Sahu, Vivek K.

Beura, Vikrant

Sonkusare, Reshma

Kalsar, Rajib

Das, Aman K.L.

Basu, Joysurya

Gurao, Nilesh P.

and

Biswas, Krishanu

2021.

Initial texture dependence of nanocrystalline omega phase formation during high pressure torsion of commercially pure titanium.

Materials Science and Engineering: A,

Vol. 802,

Issue. ,

p.

140687.

Zhang, Yitan

Liu, Maowen

Sun, Jingyong

Li, Guodong

Zheng, Ruixiao

Xiao, Wenlong

and

Ma, Chaoli

2022.

Excellent thermal stability and mechanical properties of bulk nanostructured FeCoNiCu high entropy alloy.

Materials Science and Engineering: A,

Vol. 835,

Issue. ,

p.

142670.

Aydinyan, S.

Kirakosyan, H.

Sargsyan, A.

Volobujeva, O.

and

Kharatyan, S.

2022.

Solution combustion synthesis of MnFeCoNiCu and (MnFeCoNiCu)3O4 high entropy materials and sintering thereof.

Ceramics International,

Vol. 48,

Issue. 14,

p.

20294.

Nie, Xiaowu

Sheng, Mingqiang

and

Mabi, Awei

2022.

Effect of SPS Sintering Process on Compressive Strength and Magnetic Properties of CoCuFeMnNi Bulk Alloy.

JOM,

Vol. 74,

Issue. 7,

p.

2665.

Bibhanshu, Nitish

Prasad, Natasha

Nayan, Niraj

Avadhani, G.S.

Ray, R.K.

and

Suwas, Satyam

2022.

Mechanical response of as-cast equiatomic high entropy alloy CuFeCoNiMn.

Intermetallics,

Vol. 143,

Issue. ,

p.

107461.

Sabban, Rushikesh

Dash, K.

Suwas, S.

and

Murty, B. S.

2022.

Strength–Ductility Synergy in High Entropy Alloys by Tuning the Thermo-Mechanical Process Parameters: A Comprehensive Review.

Journal of the Indian Institute of Science,

Vol. 102,

Issue. 1,

p.

91.

Azzeddine, Hiba

Bradai, Djamel

Baudin, Thierry

and

Langdon, Terence G.

2022.

Texture evolution in high-pressure torsion processing.

Progress in Materials Science,

Vol. 125,

Issue. ,

p.

100886.

Biswas, Krishanu

Gurao, Nilesh Prakash

Maiti, Tanmoy

and

Mishra, Rajiv S.

2022.

High Entropy Materials.

p.

195.

Zhang, Baoyu

Zeng, Yuning

Pang, Xueqin

and

Deng, Wenjun

2023.

Fretting wear behaviour of ultrafine-grained copper produced by cryogenic temperature extrusion machining.

Materials Science and Technology,

Vol. 39,

Issue. 8,

p.

954.

Sonkusare, Reshma

Gurao, N.P.

Biswas, Krishanu

Basu, Joysurya

Sen, S.

Pradeep, K.G.

Praveena, Manimunda

Bhowmick, Sanjit

Bhowmick, Somnath

Kilmametov, A.

and

Palit, M.

2023.

Micro-mechanisms of deformation and strengthening during high pressure torsion of CoCuFeMnNi high entropy alloy.

Materialia,

Vol. 32,

Issue. ,

p.

101916.

Kumar, Jitesh

Jha, Saumya R.

Gurao, N. P.

and

Biswas, Krishanu

2023.

New Horizons in Metallurgy, Materials and Manufacturing.

p.

159.

Edalati, Parisa

Fuji, Masayoshi

and

Edalati, Kaveh

2023.

Superfunctional high-entropy alloys and ceramics by severe plastic deformation.

Rare Metals,

Vol. 42,

Issue. 10,

p.

3246.

Li, Shu-Cong

Wang, Qing-Lin

Yao, Yu

Sang, Dan-Dan

Zhang, Hai-Wa

Zhang, Guo-Zhao

Wang, Cong

and

Liu, Cai-Long

2023.

Application of high-pressure technology in exploring mechanical properties of high-entropy alloys.

Tungsten,

Vol. 5,

Issue. 1,

p.

50.

Edalati, Kaveh

Ahmed, Anwar Q.

Akrami, Saeid

Ameyama, Kei

Aptukov, Valery

Asfandiyarov, Rashid N.

Ashida, Maki

Astanin, Vasily

Bachmaier, Andrea

Beloshenko, Victor

Bobruk, Elena V.

Bryła, Krzysztof

Cabrera, José María

Carvalho, Amanda P.

Chinh, Nguyen Q.

Choi, In-Chul

Chulist, Robert

Cubero-Sesin, Jorge M.

Davdian, Gregory

Demirtas, Muhammet

Divinski, Sergiy

Durst, Karsten

Dvorak, Jiri

Edalati, Parisa

Emura, Satoshi

Enikeev, Nariman A.

Faraji, Ghader

Figueiredo, Roberto B.

Floriano, Ricardo

Fouladvind, Marjan

Fruchart, Daniel

Fuji, Masayoshi

Fujiwara, Hiroshi

Gajdics, Marcell

Gheorghe, Diana

Gondek, Łukasz

González-Hernández, Joaquín E.

Gornakova, Alena

Grosdidier, Thierry

Gubicza, Jenő

Gunderov, Dmitry

He, Liqing

Higuera, Oscar Fabian

Hirosawa, Shoichi

Hohenwarter, Anton

Horita, Zenji

Horky, Jelena

Huang, Yi

Huot, Jacques

Ikoma, Yoshifumi

Ishihara, Tatsumi

Ivanisenko, Yulia

Jang, Jae-il

Jorge, Alberto M.

Kawabata-Ota, Mie

Kawasaki, Megumi

Khelfa, Tarek

Kobayashi, Junya

Kommel, Lembit

Korneva, Anna

Kral, Petr

Kudriashova, Natalia

Kuramoto, Shigeru

Langdon, Terence G.

Lee, Dong-Hyun

Levitas, Valery I.

Li, Cong

Li, Hai-Wen

Li, Yongtao

Li, Zheng

Lin, Huai-Jun

Liss, Klaus-Dieter

Liu, Ying

Cardona, Diana Maritza Marulanda

Matsuda, Kenji

Mazilkin, Andrey

Mine, Yoji

Miyamoto, Hiroyuki

Moon, Suk-Chun

Müller, Timo

Muñoz, Jairo Alberto

Murashkin, Maxim Yu.

Naeem, Muhammad

Novelli, Marc

Olasz, Dániel

Pippan, Reinhard

Popov, Vladimir V.

Popova, Elena N.

Purcek, Gencaga

de Rango, Patricia

Renk, Oliver

Retraint, Delphine

Révész, Ádám

Roche, Virginie

Rodriguez-Calvillo, Pablo

Romero-Resendiz, Liliana

Sauvage, Xavier

Sawaguchi, Takahiro

Sena, Hadi

Shahmir, Hamed

Shi, Xiaobin

Sklenicka, Vaclav

Skrotzki, Werner

Skryabina, Nataliya

Staab, Franziska

Straumal, Boris

Sun, Zhidan

Szczerba, Maciej

Takizawa, Yoichi

Tang, Yongpeng

Valiev, Ruslan Z.

Vozniak, Alina

Voznyak, Andrei

Wang, Bo

Wang, Jing Tao

Wilde, Gerhard

Zhang, Fan

Zhang, Meng

Zhang, Peng

Zhou, Jianqiang

Zhu, Xinkun

and

Zhu, Yuntian T.

2024.

Severe plastic deformation for producing superfunctional ultrafine-grained and heterostructured materials: An interdisciplinary review.

Journal of Alloys and Compounds,

Vol. 1002,

Issue. ,

p.

174667.

Mahato, Swati

Chandrakar, Shirish

Biswas, Krishanu

and

Gurao, Nilesh P.

2024.

An experimental and crystal plasticity simulation study on kink band-assisted grain fragmentation during high-pressure torsion of (CrFeNi)99Si1 medium-entropy alloy.

Journal of Materials Science,

Vol. 59,

Issue. 14,

p.

6075.

Jha, Saumya Ranjan

Gurao, N. P.

and

Biswas, Krishanu

2025.

Micro-mechanisms of shear deformation during high-pressure torsion of equiatomic FeMnNi medium entropy alloy.

Journal of Materials Science,

Vol. 60,

Issue. 15,

p.

6688.