Article contents

Crystal plasticity modeling the deformation in nanodomained heterogenous structures

Published online by Cambridge University Press: 06 March 2019

Abstract

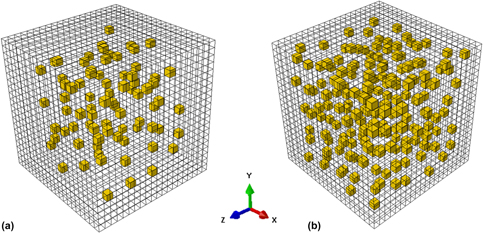

Nanodomained heterogenous structures characterized by randomly dispersed nanograins (NGs) embedded in the coarser grains (CGs) have demonstrated an exciting potential to break the strength–ductility trade-off, providing high strength without the loss of ductility. Here, using a combination of discrete crystal plasticity finite element (discrete-CPFE) model and dislocation density-based CPFE model, we study the effects of grain size, volume fraction of nanograins on the strength and deformation in nanodomained materials. Our analysis shows that the overall flow stresses of nanodomained samples are equal or higher than the strengths predicted by rule of mixtures. Smaller NGs or higher volume fraction of NGs can make the nanodomained samples stronger, as they can be more effective to promote the dislocation accumulations inside the CGs and eventually raise the critical resolved shear stress for each slip system during the plastic flow. Areas surrounding NGs stored higher dislocation densities and less plastic strain, due to the restricted dislocation motion. Furthermore, NGs grain embedded in the CGs can effectively reduce the anisotropy of strength in the nanodomained samples.

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 4

- Cited by