Article contents

Deformation mechanisms in submicron Be wires

Published online by Cambridge University Press: 21 August 2017

Abstract

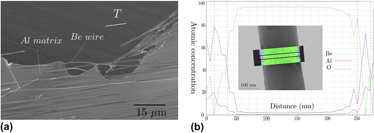

Plastic deformation of small metallic single crystals has focused a lot of attention because of their enhanced or specific mechanical properties. Here, submicron beryllium wires, obtained from selective etching of an Al/Be eutectic alloy, were deformed in tension in situ using a transmission electron microscope. Our observations indicate that wires oriented parallel to their 〈c〉 axis and containing almost no dislocations present a fragile-like behavior associated to a high stress level.  $\left\{ {10\bar 12} \right\}$ 〈1011〉 twins were also frequently observed near fractured wires, indicating that this deformation mode is important in small-scale Be. In a twinned area, a locally ductile behavior was observed due to the favorable orientation for prismatic slip. We also stress out the importance of a remaining outer layer, made of Al oxide, in the plastic deformation. On the basis of finite element modeling, we show that the deformation of the wire may involve dislocations moving along the wire axis, in or close to the Be/Al oxide interface, in agreement with in situ observations. Thus, even in naturally oxidized wires, the outer layer is supposed to play an important role in the deformation, not only in modifying a stress/strain field but also presumably in facilitating diffusional processes, such as dislocation climb or dislocation nucleation.

$\left\{ {10\bar 12} \right\}$ 〈1011〉 twins were also frequently observed near fractured wires, indicating that this deformation mode is important in small-scale Be. In a twinned area, a locally ductile behavior was observed due to the favorable orientation for prismatic slip. We also stress out the importance of a remaining outer layer, made of Al oxide, in the plastic deformation. On the basis of finite element modeling, we show that the deformation of the wire may involve dislocations moving along the wire axis, in or close to the Be/Al oxide interface, in agreement with in situ observations. Thus, even in naturally oxidized wires, the outer layer is supposed to play an important role in the deformation, not only in modifying a stress/strain field but also presumably in facilitating diffusional processes, such as dislocation climb or dislocation nucleation.

Information

- Type

- Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 24: Focus Issue: Mechanical Properties and Microstructure of Advanced Metallic Alloys—in Honor of Prof. Haël Mughrabi PART B , 28 December 2017 , pp. 4616 - 4625

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Mathias Göken

References

REFERENCES

- 3

- Cited by