Published online by Cambridge University Press: 28 October 2020

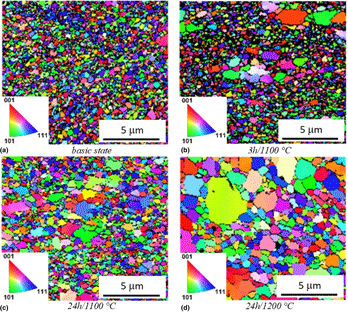

Fe–Al–O ODS alloy prepared via mechanical alloying was subjected to three different heat treatments. Material basic state exhibited a fine-grained (300–500 nm) microstructure with fine dispersion of aluminum oxide particles (60% up to 20 nm). Heat treatment at 1100 °C for 3 h resulted in local grain and particles coarsening. Prolongation of the heat treatment to 24 h resulted in further grain (50 % up to 5 μm) and particle (25 % with size 25–40 nm) coarsening. Annealing at 1200 °C for 24 h led to a bimodal microstructure (35 % of grains with size 100–250 μm and 45 % of particles with size 30–60 nm) and substantial oxide particle coarsening. Microstructural changes resulted in tensile strength decrease and ductility increase. Tensile tests at 800 °C revealed a 90% decrease of tensile strength while ductility increased 4–6 times when compared to the room temperature tests. The hardening ratio was below 10 % for all the alloys and both test temperatures.