Article contents

Dynamic recrystallization initiated by direct grain reorientation at high-angle grain boundary in α-titanium

Published online by Cambridge University Press: 15 May 2019

Abstract

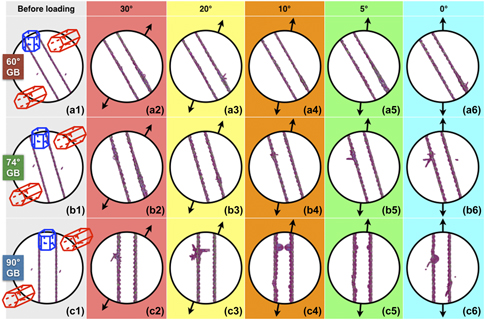

Employing atomic-scale simulations, the response of a high-angle grain boundary (GB), the soft/hard GB, against external loading was systematically investigated. Under tensile loading close to the hard orientation, strain-induced dynamic recrystallization was observed to initiate through direct soft-to-hard grain reorientation, which was triggered by stress mismatch, inhibited by surface tension from the soft-hard GB, and proceeded by interface ledges. Such grain reorientation corresponds with expansion and contraction of the hard grain along and perpendicular to the loading direction, respectively, accompanied by local atomic shuffling, providing relatively large normal strain of 8.3% with activation energy of 0.04 eV per atom. Tensile strain and residual dislocations on the hard/soft GB facilitate the initiation of dynamic recrystallization by lowering the energy barrier and the critical stress for grain reorientation, respectively.

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 8

- Cited by