Published online by Cambridge University Press: 07 August 2013

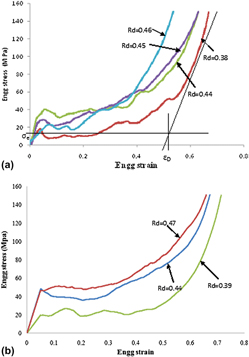

LM13 Al-alloy—cenosphere hybrid foam (HF) was made by foaming LM13 alloy–cenosphere mixture through a stir casting technique using CaCO3 as a foaming agent. In the melt mixture, 35 vol% of cenosphere was used and the foaming temperature was varied (660 and 690 °C). The foam contains microporosities as well as macroporosities and hence these are referred as HFs. The age-hardening characteristics and thereof deformation behavior of these foams have been examined using both microhardness and plateau stress measurements. It is further noted that energy absorption and plateau stress are maximum, and densification strain is minimum under peak-aged condition irrespective of the density of HF. Empirical relations are proposed to predict plateau stress, densification strain, and energy absorption as a function of aging time and relative density.