Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Li, Kemin

Huang, Zhifu

Zhang, Lei

Wang, Yiran

Shen, Yupeng

He, Lin

Zheng, Qiaoling

and

Li, Hui

2018.

Influence of Cr addition on tribological properties of bulk Fe2B under dry friction and water lubrication.

Materials Research Express,

Vol. 5,

Issue. 7,

p.

076506.

Jian, Yongxin

Huang, Zhifu

Xing, Jiandong

and

Gao, Yimin

2018.

Effects of chromium on the morphology and mechanical properties of Fe2B intermetallic in Fe-3.0B alloy.

Journal of Materials Science,

Vol. 53,

Issue. 7,

p.

5329.

Li, Kemin

Huang, Zhifu

Wang, Shaofei

Shen, Yupeng

Wang, Wenke

and

Jian, Yongxin

2019.

Effect of oxidation time on the short time oxidation behavior and tribological performance of bulk Fe2B.

Materials Research Express,

Vol. 6,

Issue. 10,

p.

106506.

Zhang, Jianjun

Liu, Jiachen

Liao, Huimin

Zeng, Ming

and

Ma, Sude

2019.

A review on relationship between morphology of boride of Fe-B alloys and the wear/corrosion resistant properties and mechanisms.

Journal of Materials Research and Technology,

Vol. 8,

Issue. 6,

p.

6308.

Ling, Zicheng

Chen, Weiping

Lu, Tiwen

Li, Bing

and

Zhang, Xianman

2019.

Interfacial morphology and tribo-corrosion behaviour of Fe-15.3 wt % Cr-3.1 wt % B-6.2 wt % Mo alloy in molten aluminium.

Wear,

Vol. 430-431,

Issue. ,

p.

81.

Jian, Yongxin

Huang, Zhifu

Xing, Jiandong

Sun, Liang

Gao, Yimin

and

Zheng, Qiaoling

2019.

Investigations on the mechanical properties and three-body wear behavior of pure Fe2B intermetallic with different chromium additions.

Wear,

Vol. 418-419,

Issue. ,

p.

273.

Otto, Johannes L.

Penyaz, Milena

Schmiedt-Kalenborn, Anke

Knyazeva, Marina

Ivannikov, Alexander

Kalin, Boris

and

Walther, Frank

2020.

Effect of phase formation due to holding time of vacuum brazed AISI 304L/NiCrSiB joints on corrosion fatigue properties.

Journal of Materials Research and Technology,

Vol. 9,

Issue. 5,

p.

10550.

Chen, Zhiguo

Miao, Sen

Kong, Lingnan

Wei, Xiang

Zhang, Feihong

and

Yu, Hongbin

2020.

Effect of Mo Concentration on the Microstructure Evolution and Properties of High Boron Cast Steel.

Materials,

Vol. 13,

Issue. 4,

p.

975.

Xu, Gaopeng

Wang, Kui

Dong, Xianping

Yang, Lei

Jiang, Haiyan

Wang, Qudong

and

Ding, Wenjiang

2020.

Effects of Titanium Addition on the Microstructural and Mechanical Property Evolution of FeCrB Alloys.

Metallurgical and Materials Transactions A,

Vol. 51,

Issue. 9,

p.

4610.

Ma, Teng

Yin, Yunyu

Hong, Fang

Zhu, Pinwen

and

Yu, Xiaohui

2021.

Magnetic, Electronic, and Mechanical Properties of Bulk ε-Fe2N Synthesized at High Pressures.

ACS Omega,

Vol. 6,

Issue. 19,

p.

12591.

Jian, Yongxin

Huang, Zhifu

Wang, Yu

Wu, Tonghai

and

Xing, Jiandong

2021.

Solidification process, microstructure, and mechanical properties of Cr-doped high boron Fe-based alloy.

Materials Chemistry and Physics,

Vol. 267,

Issue. ,

p.

124592.

Wang, Guangchi

Jiang, Yehua

Li, Zulai

Chong, Xiaoyu

and

Feng, Jing

2021.

Balance between strength and ductility of dilute Fe2B by high-throughput first-principles calculations.

Ceramics International,

Vol. 47,

Issue. 4,

p.

4758.

Jian, Yongxin

Ning, Haiyue

Huang, Zhifu

Wang, Yu

and

Xing, Jiandong

2021.

Three-body abrasive wear behaviors and mechanism analysis of Fe–B–C cast alloys with various Mn contents.

Journal of Materials Research and Technology,

Vol. 14,

Issue. ,

p.

1301.

Chen, Zhiguo

Zhang, Feihong

and

Wei, Xiang

2021.

Effect of Mo concentration on structural, mechanical, electronic and magnetic properties of Fe2B: a first-principles study.

Philosophical Magazine,

Vol. 101,

Issue. 13,

p.

1549.

Wang, Guangchi

Chong, Xiaoyu

Li, Zulai

Feng, Jing

and

Jiang, Yehua

2022.

Design of Fe2B-based ductile high temperature ceramics: First-principles calculations and experimental validation.

Ceramics International,

Vol. 48,

Issue. 18,

p.

27163.

Wei, Xiang

Chen, Zhiguo

Mao, Hong

Peng, Guangwei

Liu, Baogang

and

Wu, Jiwen

2023.

First‐principles study on stability, Debye temperature, mechanical, electronic and magnetic properties of Fe2B compounds.

International Journal of Quantum Chemistry,

Vol. 123,

Issue. 10,

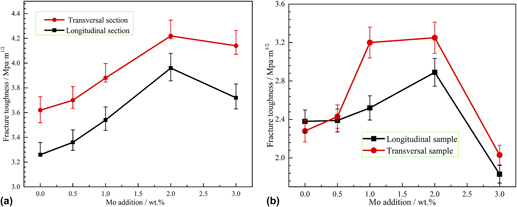

Jian, Yongxin

Peng, Weijian

Ning, Haiyue

Huang, Zhifu

Nie, Hongting

and

Hong, Jun

2024.

Microstructure evolution and mechanical properties of Fe–Cr–B alloys with varying Mo additions.

Journal of Materials Research and Technology,

Vol. 32,

Issue. ,

p.

1.

Wang, Guangchi

Chong, Xiaoyu

Li, Zulai

Feng, Jing

and

Jiang, Yehua

2024.

Strain-stiffening of chemical bonding enhance strength and fracture toughness of the interface of Fe2B/Fe in situ composite.

Materials Characterization,

Vol. 207,

Issue. ,

p.

113575.

Ma, Zhen

Yan, Yudong

Li, Qiang

Liu, Qicong

Chen, Chao

and

Zhuang, Minghui

2025.

The Effect of Cr Addition on the Microstructure Evolution and Mechanical Properties of Fe–B–Mo Alloy.

steel research international,