Article contents

Equal channel angular extrusion for bulk processing of Fe–Co–2V soft magnetic alloys, part II: Texture analysis and magnetic properties

Published online by Cambridge University Press: 04 June 2018

Abstract

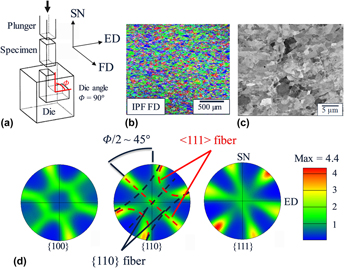

In Part I, equal channel angular extrusion (ECAE) was demonstrated as a novel, simple-shear deformation process for producing bulk forms of the low ductility Fe–Co–2V (Hiperco 50A®) soft ferromagnetic alloy with refined grain sizes. Microstructures and mechanical properties were discussed. In this Part II contribution, the crystallographic textures and quasi-static magnetic properties of ECAE-processed Hiperco were characterized. The textures were of a simple-shear character defined by partial {110} and 〈111〉 fibers inclined relative to the extrusion direction, in agreement with the expectations for simple-shear deformation textures of BCC metals. These textures were observed throughout all processing conditions and only slightly reduced in intensity by subsequent recrystallization heat treatments. Characterization of the magnetic properties revealed a lower coercivity and higher permeability for ECAE-processed Hiperco specimens relative to the conventionally processed and annealed Hiperco bar. The effects of the resultant microstructure and texture on the coercivity and permeability magnetic properties are discussed.

Information

- Type

- Article

- Information

- Journal of Materials Research , Volume 33 , Issue 15: Focus Issue: Soft Magnetic Materials: Synthesis, Characterization, and Applications , 13 August 2018 , pp. 2176 - 2188

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 6

- Cited by