Article contents

Extracting grain boundary motion in Cu–Al alloy from atomistic simulations

Published online by Cambridge University Press: 28 August 2020

Abstract

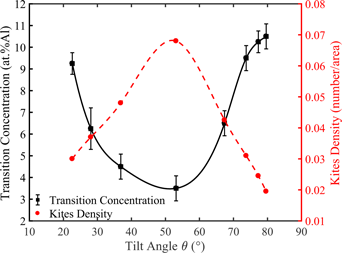

Grain boundary (GB) motions, such as migration, sliding and rotation, have been shown to play a vital role in the mechanical performance of polycrystalline metals. Despite extensive efforts have been made on the pure polycrystalline metals, few attentions have been paid to those in alloys. In this work, taking conventional nanoscale Cu–Al binary alloy system as an example, we intend to shed some light on understanding its GB motions under shear loading by means of molecular dynamics (MD) simulations. It is found that either shear-coupled GB migration or sliding motion can be observed, depending on GB tilt angles, temperatures and Al solute concentrations. By systematical MD simulations, the Al concentration required for transition between shear-coupled migration and sliding is found to decrease with increasing tilt angles (θ ≤ 50°) at fixed temperature, whereas it switches to the opposite trend for larger tilt angles. Furthermore, the GBs migrate much slower comparing with those in pure Cu, which shows the drag effects of the Al solutes in the alloy form. Moreover, the critical stress during shear loading shows a linear dependence on 2/3 power of the temperature.

Keywords

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 2

- Cited by