No CrossRef data available.

Published online by Cambridge University Press: 06 September 2019

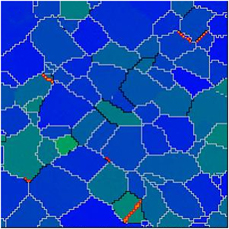

A novel solid-clad-by-liquid method was developed to form a 10-m long by 10-mm wide by 80-μm thick Ni–5 at.% W/Ni–9.3 at.% W/Ni–5 at.% W composite tape. Three deformation routes (cold rolling, cold rolling with intermediate annealing, and cold rolling combined with warm rolling) have been investigated in short Ni–5 at.% W/Ni–9.3 at.% W/Ni–5 at.% W composite substrate. To optimize the dynamic continuous annealing parameters for the long composite substrates, air-cooled and furnace-cooled annealing procedures were compared in short Ni–5 at.% W/Ni–9.3 at.% W/Ni–5 at.% W composite substrates. Improved cube texture of 98.7% in a 10-m long by 10-mm wide by 80-μm thick Ni–5 at.% W/Ni–9.3 at.% W/Ni–5 at.% W composite substrate was achieved via warm rolling deformation at 550 °C and two-step dynamic continuous annealing (750 °C for 1 h followed by 1200 °C for 1 h). The yield strength, Curie temperature, and saturation magnetization of 176 MPa, 324 K, and 18 emu/g, respectively, were obtained.