Article contents

Fracture resistance of Cu/Nb metallic nanolayered composite

Published online by Cambridge University Press: 15 May 2019

Abstract

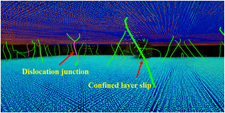

In this work, molecular dynamics simulations to explore the crack propagation and fracture behavior of Cu/Nb metallic nanolayered composites (MNCs) were performed. The results of this study are consistent with the previous experimental results, which illustrated that cracks in Cu and Nb layers may exhibit different propagation paths and distances under the isostrain loading condition. The analysis reveals that the interface can increase the fracture resistance of the Nb layer in Cu/Nb MNCs by providing the dislocation sources to generate the plastic strain at the front of the crack. Increasing the layer thickness can enhance the fracture resistance of both Cu and Nb layers, as the critical stress for activating the dislocation motion decreases with the increment of the layer thickness. In addition, grain boundaries (GBs) in polycrystalline Cu/Nb samples would decrease the fracture resistance of Nb layer by promoting the crack propagate along the GBs, i.e., intergranular fracture, while the effect of interface and layer thickness on the fracture resistance of MNCs will not be altered by introducing the GBs in MNCs.

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 6

- Cited by