Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Bieler, T.R.

Alizadeh, R.

Peña-Ortega, M.

and

Llorca, J.

2019.

An analysis of (the lack of) slip transfer between near-cube oriented grains in pure Al.

International Journal of Plasticity,

Vol. 118,

Issue. ,

p.

269.

Esteban-Manzanares, G.

Bellón, B.

Martínez, E.

Papadimitriou, I.

and

LLorca, J.

2019.

Strengthening of Al–Cu alloys by Guinier–Preston zones: Predictions from atomistic simulations.

Journal of the Mechanics and Physics of Solids,

Vol. 132,

Issue. ,

p.

103675.

Alizadeh, R.

Peña-Ortega, M.

Bieler, T.R.

and

LLorca, J.

2020.

A criterion for slip transfer at grain boundaries in Al.

Scripta Materialia,

Vol. 178,

Issue. ,

p.

408.

Haouala, S.

Alizadeh, R.

Bieler, T.R.

Segurado, J.

and

LLorca, J.

2020.

Effect of slip transmission at grain boundaries in Al bicrystals.

International Journal of Plasticity,

Vol. 126,

Issue. ,

p.

102600.

Haouala, S.

Lucarini, S.

LLorca, J.

and

Segurado, J.

2020.

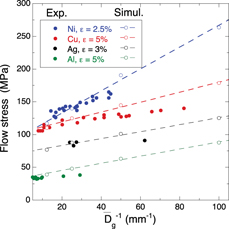

Simulation of the Hall-Petch effect in FCC polycrystals by means of strain gradient crystal plasticity and FFT homogenization.

Journal of the Mechanics and Physics of Solids,

Vol. 134,

Issue. ,

p.

103755.

Fomin, Eugeniy V.

and

Mayer, Alexander E.

2020.

Slip of low-angle tilt grain boundary (110) in FCC metals at perpendicular shear.

International Journal of Plasticity,

Vol. 134,

Issue. ,

p.

102843.

Shveykin, Alexey

Trusov, Peter

and

Sharifullina, Elvira

2020.

Statistical Crystal Plasticity Model Advanced for Grain Boundary Sliding Description.

Crystals,

Vol. 10,

Issue. 9,

p.

822.

Bellón, B.

Haouala, S.

and

LLorca, J.

2020.

An analysis of the influence of the precipitate type on the mechanical behavior of Al - Cu alloys by means of micropillar compression tests.

Acta Materialia,

Vol. 194,

Issue. ,

p.

207.

Motaman, S. Amir H.

and

Haase, Christian

2021.

The microstructural effects on the mechanical response of polycrystals: A comparative experimental-numerical study on conventionally and additively manufactured metallic materials.

International Journal of Plasticity,

Vol. 140,

Issue. ,

p.

102941.

Nguyen, Khanh

Zhang, Meijuan

Amores, Víctor Jesús

Sanz, Miguel A.

and

Montáns, Francisco J.

2021.

Computational Modeling of Dislocation Slip Mechanisms in Crystal Plasticity: A Short Review.

Crystals,

Vol. 11,

Issue. 1,

p.

42.

Li, Maojun

Wang, Zhuoling

and

Chen, Xu

2021.

Effects of Initial Equiaxed Crystal Ratio in As-Cast Slab on Texture Evolution and Formability of Ferritic Stainless Steel.

Journal of Materials Engineering and Performance,

Vol. 30,

Issue. 1,

p.

379.

Gélébart, Lionel

2021.

Grain size effects and weakest link theory in 3D crystal plasticity simulations of polycrystals.

Comptes Rendus. Physique,

Vol. 22,

Issue. S3,

p.

313.

Andrews, Miriam

Polcar, Tomas

Sofaer, Joanna

and

Pike, Alistair W. G.

2022.

The mechanised testing and sequential wear‐analysis of replica Bronze Age palstave blades.

Archaeometry,

Vol. 64,

Issue. 1,

p.

177.

Nieto-Valeiras, E.

Haouala, S.

and

LLorca, J.

2022.

On the effect of slip transfer at grain boundaries on the strength of FCC polycrystals.

European Journal of Mechanics - A/Solids,

Vol. 91,

Issue. ,

p.

104427.

Yousefi Mehr, Vahid

and

Toroghinejad, Mohammad Reza

2022.

On the texture evolution of aluminum-based composites manufactured by ARB process: a review.

Journal of Materials Research and Technology,

Vol. 21,

Issue. ,

p.

1095.

Chen, Ze

Wang, Chengcheng

Tang, Chao

Lek, Yung Zhen

Kandukuri, Sastry Yagnanna

Du, Hejun

Gao, Huajian

and

Zhou, Kun

2022.

Microstructure and mechanical properties of a Monel K-500 alloy fabricated by directed energy deposition.

Materials Science and Engineering: A,

Vol. 857,

Issue. ,

p.

144113.

Zhang, Xu

Zhao, Jianfeng

Kang, Guozheng

and

Zaiser, Michael

2023.

Geometrically necessary dislocations and related kinematic hardening in gradient grained materials: A nonlocal crystal plasticity study.

International Journal of Plasticity,

Vol. 163,

Issue. ,

p.

103553.

Wan, Wei

and

Tang, Changxin

2023.

Structures and energies of computed silicon (001) small angle mixed grain boundaries as a function of three macroscopic characters.

Acta Materialia,

Vol. 261,

Issue. ,

p.

119353.

Fomin, E.V.

2023.

STUDY OF THE TEMPERATURE DEPENDENCE OF THE SYMMETRICAL GRAIN BOUNDARY ENERGIES ON THE PLANE (110) IN ALUMINUM.

Челябинский физико-математический журнал,

Vol. 8,

Issue. 3,

p.

421.

Aghamohammadi, Hossein

and

Jamaati, Roohollah

2024.

Effect of cold single-roll drive rolling on the microstructural evolution and mechanical properties of ferritic stainless steel.

Journal of Materials Research and Technology,

Vol. 29,

Issue. ,

p.

2679.