Published online by Cambridge University Press: 13 March 2019

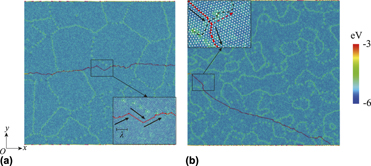

The stability of dynamic fracture is a fundamental and challenging problem in the field of materials science. The grain size effect on dynamic fracture instability in polycrystalline graphene under tear loading is explored via theoretical analysis and molecular dynamics simulations. The fracture stability phase diagram in terms of grain size and crack propagation velocity is obtained, and three regions of crack propagation are identified: stable, metastable, and unstable. For grain size above 2 nm, there exists a critical velocity beyond which fracture instability occurs, and this critical velocity depends linearly on grain size. Decreasing grain size leads to reduced characteristic time for correction of crack path deflection, which plays a dominant role in dynamic fracture instabilities. However, when grain size is below 2 nm, there does not exist a critical velocity for steady propagation of cracks due to discontinuous effects. Our results also provide a valuable insight into dynamic fracture of polycrystalline graphene as well as other 2D and quasi-2D materials.