Article contents

High-temperature low-cycle fatigue behavior and microstructural evolution of an improved austenitic ODS steel

Published online by Cambridge University Press: 01 June 2018

Abstract

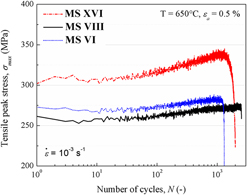

In this work, a high-temperature low-cycle fatigue (LCF) behavior of a newly developed austenitic oxide dispersion strengthened (ODS) steel is investigated. The LCF tests were performed in air at 650 °C under three different strain amplitudes (±0.4, ±0.5, and ±0.7%) with a nominal strain rate of 10−3 s−1. The measured cyclic stress response showed four distinct stages which include short initial stable cyclic response followed by a prolonged hardening with subsequent short saturation and finally crack initiation and growth stage. The rate of hardening and the duration of stages are a function of applied strain amplitude. Microstructural investigations were carried out to shed light on the deformation mechanisms. After cycling, the overall microstructure appears stable without any modifications in grain shape and size. In addition, twinning and stacking fault fractions remain unchanged. However, cyclic hardening is an aftermath of dislocation multiplication whose rate is also a function of applied strain amplitude. Furthermore, oxide particles, as well as fine grains, inhibit strain localization by restricting three-dimensional dislocation structure formation that are associated with the development of extrusions and intrusions and are readily observed in conventional austenitic non-ODS steels.

Information

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

Present address: Department of Mechanical Engineering, Johns Hopkins University, Baltimore, MD 21218, USA.

Present address: Oak Ridge National Laboratory, Oak Ridge, TN 37831, USA.

References

REFERENCES

- 8

- Cited by