Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Kakanuru, Padmalatha

and

Pochiraju, Kishore

2020.

Moisture Ingress and Degradation of Additively Manufactured PLA, ABS and PLA/SiC Composite Parts.

Additive Manufacturing,

Vol. 36,

Issue. ,

p.

101529.

Lee, Ching Hao

Padzil, Farah Nadia Binti Mohammad

Lee, Seng Hua

Ainun, Zuriyati Mohamed Asa’ari

and

Abdullah, Luqman Chuah

2021.

Potential for Natural Fiber Reinforcement in PLA Polymer Filaments for Fused Deposition Modeling (FDM) Additive Manufacturing: A Review.

Polymers,

Vol. 13,

Issue. 9,

p.

1407.

Shaik, Yousuf Pasha

Schuster, Jens

Shaik, Aarif

Mohammed, Mustafa

and

Katherapalli, Harshavardhan Reddy

2021.

Effect of Autoclave Pressure and Temperature on Consolidation of Layers and Mechanical Properties of Additively Manufactured (FDM) Products with PLA.

Journal of Manufacturing and Materials Processing,

Vol. 5,

Issue. 4,

p.

114.

Mohammadizadeh, Mahdi

and

Fidan, Ismail

2021.

Tensile Performance of 3D-Printed Continuous Fiber-Reinforced Nylon Composites.

Journal of Manufacturing and Materials Processing,

Vol. 5,

Issue. 3,

p.

68.

Tamburrino, F.

Barone, S.

Paoli, A.

and

Razionale, A. V.

2021.

Post-processing treatments to enhance additively manufactured polymeric parts: a review.

Virtual and Physical Prototyping,

Vol. 16,

Issue. 2,

p.

221.

Ehrmann, Guido

Brockhagen, Bennet

and

Ehrmann, Andrea

2021.

Shape-Memory Properties of 3D Printed Cubes from Diverse PLA Materials with Different Post-Treatments.

Technologies,

Vol. 9,

Issue. 4,

p.

71.

Tian, Xiaoyong

Todoroki, Akira

Liu, Tengfei

Wu, Lingling

Hou, Zhanghao

Ueda, Masahiro

Hirano, Yoshiyasu

Matsuzaki, Ryosuke

Mizukami, Koichi

Iizuka, Keisuke

Malakhov, Andrei V.

Polilov, Alexander N.

Li, Dichen

and

Lu, Bingheng

2022.

3D Printing of Continuous Fiber Reinforced Polymer Composites: Development, Application, and Prospective.

Chinese Journal of Mechanical Engineering: Additive Manufacturing Frontiers,

Vol. 1,

Issue. 1,

p.

100016.

Cao, Mengyu

Cui, Tianqi

Yue, Yuhang

Li, Chaoyu

Guo, Xue

Jia, Xin

and

Wang, Baojin

2022.

Investigation of Carbon Fiber on the Tensile Property of FDM-Produced PLA Specimen.

Polymers,

Vol. 14,

Issue. 23,

p.

5230.

Sun, Yufeng

Wang, Yapeng

Mu, Wenlong

Zheng, Zipeng

Yang, Bin

Wang, Jinwei

Zhang, Runkai

Zhou, Kaiyuan

Chen, Liang

Ying, Jilai

Liu, Xinping

and

Xu, Guangyin

2022.

Mechanical properties of 3D printed micro‐nano rice husk/polylactic acid filaments.

Journal of Applied Polymer Science,

Vol. 139,

Issue. 28,

Tran, Thang Q.

Ng, Feng Lin

Kai, Justin Tan Yu

Feih, Stefanie

and

Nai, Mui Ling Sharon

2022.

Tensile Strength Enhancement of Fused Filament Fabrication Printed Parts: A Review of Process Improvement Approaches and Respective Impact.

Additive Manufacturing,

Vol. 54,

Issue. ,

p.

102724.

Wang, Yanqing

Wang, Xin

Xie, Minghui

Zhou, Zheng

and

Xu, Huan

2022.

A surface modification of polylactic acid composites for additive manufacturing with modified chopped carbon fiber and modified nano‐hydroxyapatite.

Polymer Composites,

Vol. 43,

Issue. 11,

p.

7859.

Shaik, Yousuf Pasha

Schuster, Jens

Katherapalli, Harshavardhan Reddy

and

Shaik, Aarif

2022.

3D Printing under High Ambient Pressures and Improvement of Mechanical Properties of Printed Parts.

Journal of Composites Science,

Vol. 6,

Issue. 1,

p.

16.

Andreu, Alberto

Kim, Sanglae

Dittus, Jörg

Friedmann, Marco

Fleischer, Jürgen

and

Yoon, Yong-Jin

2022.

Hybrid material extrusion 3D printing to strengthen interlayer adhesion through hot rolling.

Additive Manufacturing,

Vol. 55,

Issue. ,

p.

102773.

Zhou, Mengnan

Chen, Bichi

Li, Yaozong

Jiang, Junjie

and

Zhai, Wentao

2023.

Enhanced Interfacial Adhesion and Increased Isotropy of 3D Printed Parts with Microcellular Structure Fabricated via a Micro‐Extrusion CO2‐Foaming Process.

Advanced Engineering Materials,

Vol. 25,

Issue. 8,

Hauschel, Adam B.

Carey, Daniel G.

Fishbeck, Blake J.

Coleman, Bryan J.

Carroll, Jacob M.

Mustafa, Mazin M.

Sarmah, Anubhav

Price, Carey D.

and

Green, Micah J.

2023.

Automated deposition and Joule heating of carbon ink for the generation of on-demand unique thermal patterns.

Journal of Materials Research,

Vol. 38,

Issue. 8,

p.

2137.

Figueiredo, Sara

Fernandes, Ana I.

Carvalho, Fátima G.

and

Pinto, João F.

2023.

Exploring Environmental Settings to Improve the Printability of Paroxetine-Loaded Filaments by Fused Deposition Modelling.

Pharmaceutics,

Vol. 15,

Issue. 11,

p.

2636.

Wang, Zhaogui

Yin, Xiuzeng

and

Wang, Lihan

2023.

Tensile properties of sandwich-designed carbon fiber filled PLA prepared via multi-material additive layered manufacturing and post-annealing treatment.

International Polymer Processing,

Vol. 38,

Issue. 3,

p.

343.

Ganapathy, Sakthi Balan

Sakthivel, Aravind Raj

Kandasamy, Jayakrishna

Khan, Tabrej

and

Aloufi, Mansour

2023.

Optimization of Printing Process Variables and the Effect of Post-Heat Treatments on the Mechanical Properties of Extruded Polylactic Acid–Aluminum Composites.

Polymers,

Vol. 15,

Issue. 24,

p.

4698.

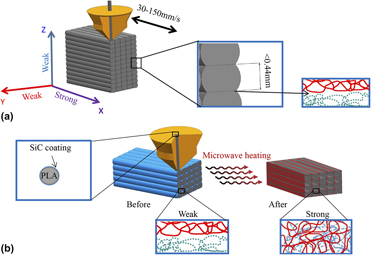

Antonio, Erik L. S.

Anik, Arefin M.

Kuksenok, Olga

and

Luzinov, Igor

2023.

Enhancement of Polypropylene 3D-Printed Structures via the Addition of SiC Whiskers and Microwave Irradiation.

ACS Applied Materials & Interfaces,

Vol. 15,

Issue. 33,

p.

40042.

Neijhoft, Jonas

Henrich, Dirk

Kammerer, Andreas

Janko, Maren

Frank, Johannes

and

Marzi, Ingo

2023.

Sterilization of PLA after Fused Filament Fabrication 3D Printing: Evaluation on Inherent Sterility and the Impossibility of Autoclavation.

Polymers,

Vol. 15,

Issue. 2,

p.

369.