Published online by Cambridge University Press: 28 September 2015

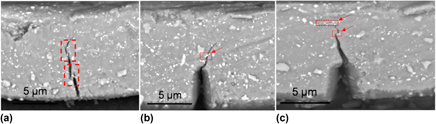

The influence of Pt layer thickness on the fracture behavior of PtNiAl bond coats was studied in situ using clamped micro-beam bend tests inside a scanning electron microscope (SEM). Clamped beam bending is a fairly well established micro-scale fracture test geometry that has been previously used in determination of fracture toughness of Si and PtNiAl bond coats. The increasing amount of Pt in the bond coat matrix was accompanied by several other microstructural changes such as an increase in the volume fraction of α-Cr precipitate particles in the coating as well as a marginal decrease in the grain size of the matrix. In addition, Pt alters the defect chemistry of the B2-NiAl structure, directly affecting its elastic properties. A strong correlation was found between the fracture toughness and the initial Pt layer thickness associated with the bond coat. As the Pt layer thickness was increased from 0 to 5 µm, resulting in increasing Pt concentration from 0 to 14.2 at.% in the B2-NiAl matrix and changing α-Cr precipitate fraction, the initiation fracture toughness (KIC) was seen to rise from 6.4 to 8.5 MPa·m1/2. R-curve behavior was observed in these coatings, with KIC doubling for a crack propagation length of 2.5 µm. The reasons for the toughening are analyzed to be a combination of material's microstructure (crack kinking and bridging due to the precipitates) as well as size effects, as the crack approaches closer to the free surface in a micro-scale sample.

Present address: Max Planck Institute for Iron Research, Max Planck Strasse-1, Duesseldorf 40237, Germany.

Contributing Editor: Yang-T. Cheng