Published online by Cambridge University Press: 27 April 2020

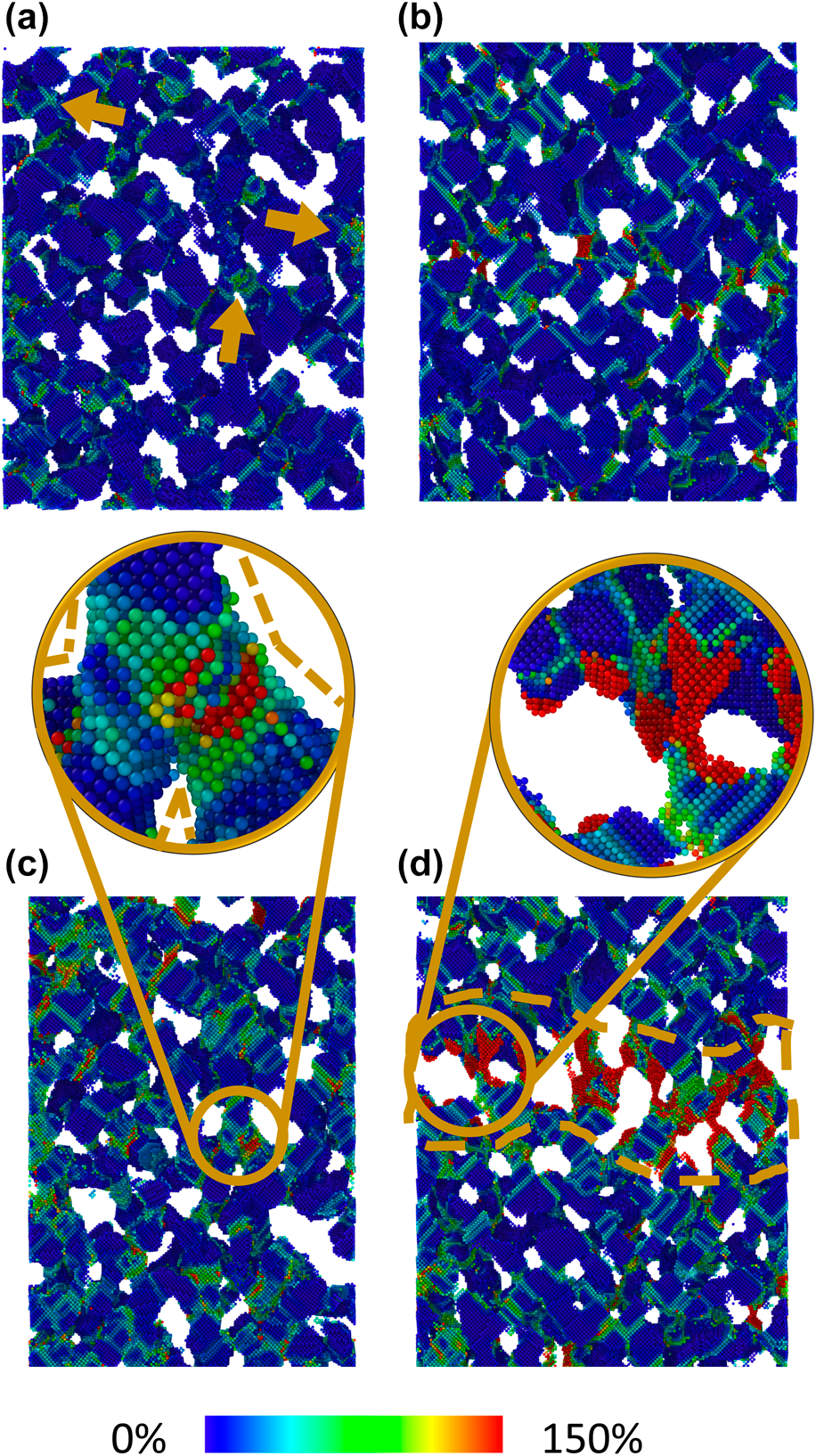

In this study, uniaxial tensile loading simulations were performed on several single crystalline copper nanoporous (NP) structures with varying relative density (RD) via molecular dynamics simulations. From the results, two distinctive deformation patterns were observed: structures with a low RD went through coarsening, and structures with a high RD did not. During coarsening, dislocations are nucleated because of the high surface stress induced by the thin ligaments. These dislocations drive the merging of ligaments as well as nodes and lead to an increase in the differences between the size of nodes and ligaments. The disproportional nodes and ligaments result in a lowered strength. In addition, larger nodes provide more favorable circumstances for the formation of sessile dislocations, which hinder the movement of other propagating Shockley partials and result in strain hardening. Subsequently, lower RD structures offer anomalously high strain-hardening potential, whereas high RD structures show better strength but poor deformability. These results help us in better understanding the plastic behavior of NP structures as a function of their RD.