No CrossRef data available.

Published online by Cambridge University Press: 10 September 2018

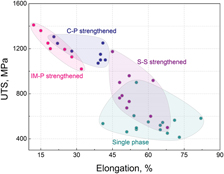

Classical alloy design strategies often aim to benefit from metastability. Examples are numerous: metastable transformation- and twinning-induced plasticity steels, cobalt or titanium based alloys, age hardenable aluminum alloys, and severe plastic deformed nanostructured copper. In each of these cases, superior engineering property combinations are achieved by exploring limits of stability. For the case of high-entropy alloys (HEAs), on the other hand, majority of present research efforts focus on exploring compositions that would yield stable single-phase structures. HEA metastability and its effects on microstructure and property development constitute only a relatively small fraction of ongoing work. To help motivate and guide a corresponding shift in HEA research efforts, here in this paper, we provide an overview of the research activities on metastability in HEAs. To this end, we categorize the past research on the topic into two groups based on their focus, namely, compositional and structural stability, and discuss the most relevant and exciting findings.

These authors contributed equally to this work.

This section of Journal of Materials Research is reserved for papers that are reviews of literature in a given area.