Article contents

Microstructural and mechanical inhomogeneity in the narrow-gap weld seam of thick GMA welded Al–Zn–Mg alloy plates

Published online by Cambridge University Press: 17 November 2016

Abstract

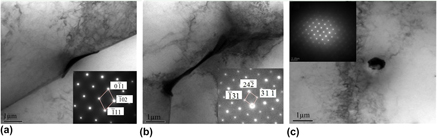

Inhomogeneity may lead to premature failure and operationally determines the lifetime estimation of thick weld joints. Considerable novelty of this paper was the achievement of the microstructural and mechanical inhomogeneity, especially along the thickness direction, in the narrow-gap weld seam of thick gas metal arc (GMA) welded Al–Zn–Mg alloy plates. The microstructure of the weld seam was investigated by means of optical metallography, scanning electron microscopy (SEM), transmission electron microscopy (TEM), and energy dispersive spectrum (EDS), after which the phase composition was ascertained according to the x-ray diffraction (XRD) analysis and selected area diffraction analysis by TEM (TEM-SAD). The generation of intergranular short rod-shaped MgZn2 particles changed the distribution of precipitates on the grain boundary with intragranular ellipsoidal MgZn2 particles simultaneously formed as the strengthening phase, which rendered preferable mechanical performances to the bottom layer of the weld seam. The above conclusion was farther affirmed by micro fractography and EDS test results on the fractured surface of the tensile samples. In addition, the effect of following weld passes on the microstructure and micro hardness profile of the finished weld pass was investigated.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 5

- Cited by