Published online by Cambridge University Press: 14 August 2018

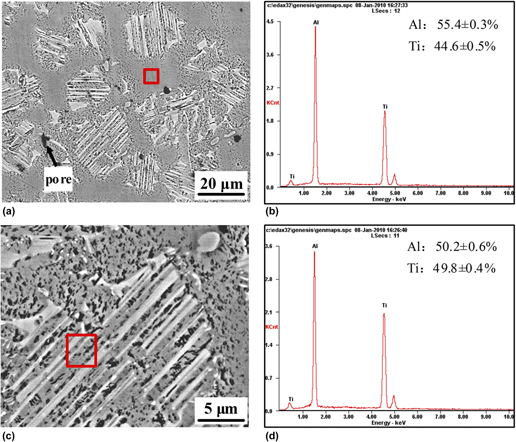

Ti–Al alloys are established as promising candidates for aerospace applications due to their lightweight, good elevated temperature strength, and decent corrosion resistance. In this study, a Ti–51Al (at.%) alloy is fabricated by spray deposition. The effects of temperature and strain rate on the deformation behavior of the spray-deposited Ti–Al alloy are investigated. The microstructural evolution of the Ti–Al alloy with different deformation temperatures is discussed in detail. A strain-dependent constitutive equation was proposed to predict the flow stresses at the elevated temperatures for the spray-deposited Ti–Al alloy. The microstructure of the as-deposited Ti–51Al alloy exhibits a α2/γ lamellar-structure with average size 25 ± 2 μm, due to the high cooling rate observed during solidification. The lamellar structure is embedded on a γ matrix. The amount of the α2/γ lamellar-structure reduces gradually with increasing the hot deformation temperature. After hot isostatic pressing at 1523 K, the microstructure is mainly comprised of the γ matrix.