No CrossRef data available.

Published online by Cambridge University Press: 20 October 2020

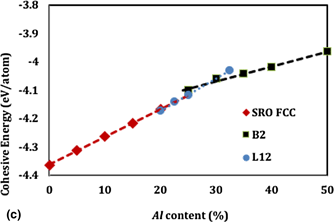

A set of embedded atom model (EAM) interatomic potentials was developed to represent highly idealized face-centered cubic (FCC) mixtures of Fe–Ni–Cr–Co–Al at near-equiatomic compositions. Potential functions for the transition metals and their crossed interactions are taken from our previous work for Fe–Ni–Cr–Co–Cu [D. Farkas and A. Caro: J. Mater. Res. 33 (19), 3218–3225, 2018], while cross-pair interactions involving Al were developed using a mix of the component pair functions fitted to known intermetallic properties. The resulting heats of mixing of all binary equiatomic random FCC mixtures not containing Al is low, but significant short-range ordering appears in those containing Al, driven by a large atomic size difference. The potentials are utilized to predict the relative stability of FCC quinary mixtures, as well as ordered L12 and B2 phases as a function of Al content. These predictions are in qualitative agreement with experiments. This interatomic potential set is developed to resemble but not model precisely the properties of this complex system, aiming at providing a tool to explore the consequences of the addition of a large size-misfit component into a high entropy mixture that develops multiphase microstructures.