Article contents

A multi-indent approach to detect the surface of soft materials during nanoindentation

Published online by Cambridge University Press: 30 August 2016

Abstract

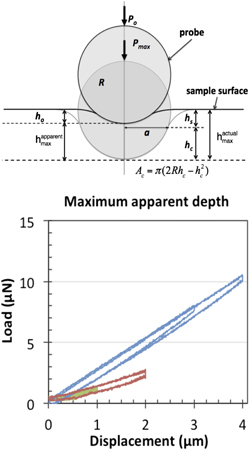

There is growing interest in using instrumented indentation to characterize mechanical properties of soft materials, including tissue properties related to damage and disease. However, sample surface detection has been a major challenge. The multi-indent approach (MIA) is a novel method to indirectly detect the surface using data from multiple indents to determine the preload-induced indentation depth. Elastic modulus and shear modulus determined by MIA were equivalent to bulk measurements for 19 and 49 kPa gels. However, the traditional Oliver–Pharr approach significantly overestimated these properties. MIA is also important to accurate characterization of poroelastic properties and allows for much smaller probes and indentation depths to be used for all measurements. This is particularly important for poroelasticity, where the relaxation time scales with the size of the indenter. The novel approach helps to resolve the long-standing challenge of surface detection and has the potential to broaden the use of instrumented indentation for soft materials.

Keywords

Information

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 11

- Cited by