Published online by Cambridge University Press: 17 February 2020

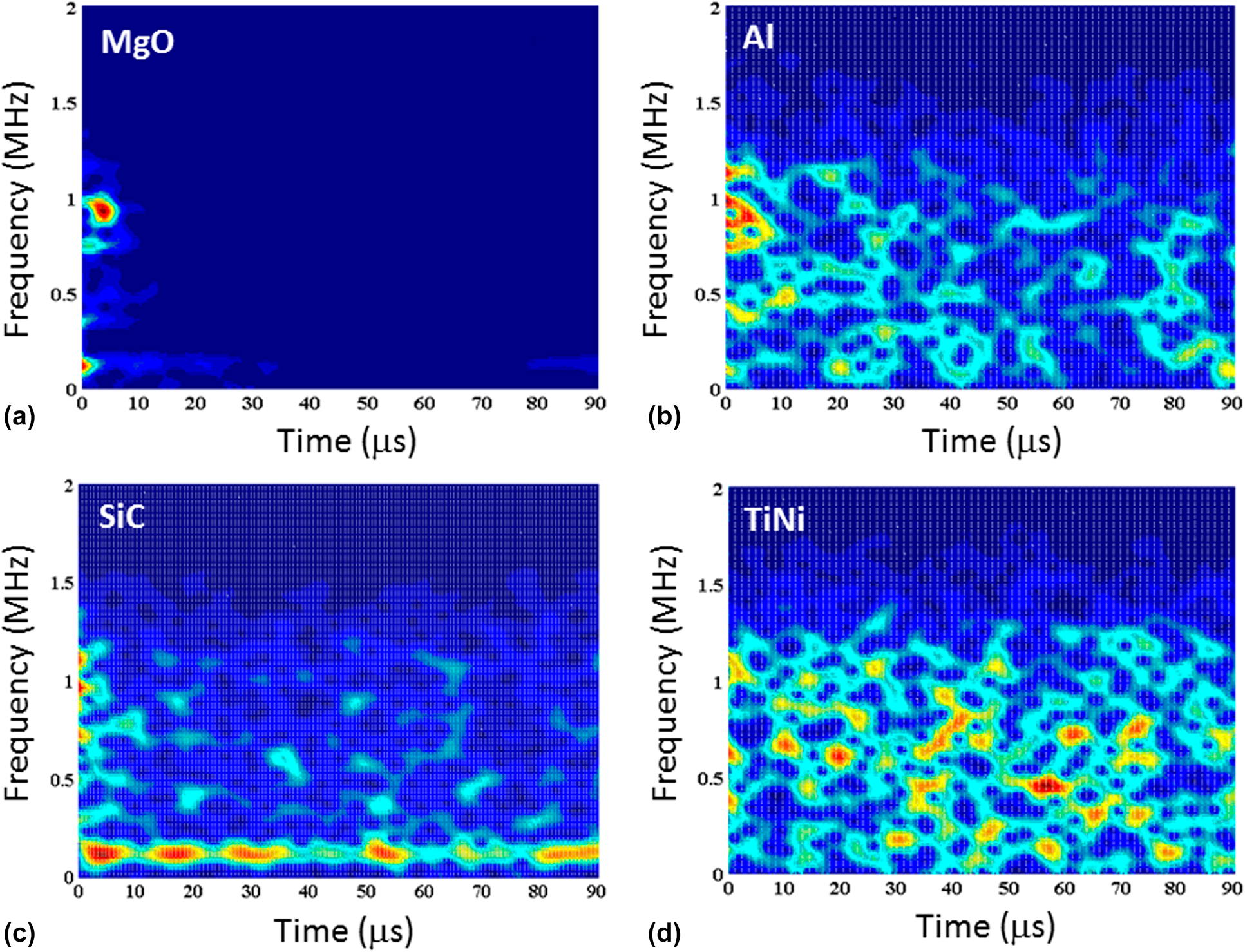

With the ever-increasing importance of nanoscale deformation phenomena in contemporary technologies, basic understanding of material behavior at the nanoscale has become of critical importance. Especially, nanomechanical testing that provides the capability to study fundamental nanoscale deformation and phase change phenomena in real time and under controlled loading conditions is essential for nanomaterial research. In this study, acoustic emission (AE) was used in situ to characterize nanoindentation-induced deformation, microfracture, and phase transformation processes intrinsic of bulk single-crystal MgO and polycrystalline Al, thin films of polycrystalline SiC, and thick films of austenitic TiNi shape-memory alloy. Scale-dependent plastic deformation and microfracture affected by the indenter tip radius and the applied normal load are interpreted in terms of the type and intensity of AE events revealed by abrupt displacement excursions in the loading response of the indented materials. The amplitudes of AE waveforms are used to examine characteristic deformation, microfracture, and phase change mechanisms in the time domain. Fast Fourier transformation and short-time Fourier transformation analyses provide further insight into the material behavior and structural changes due to indentation loading in the frequency and time-frequency domain, respectively. The methodology developed in this study represents an effective approach for nanomechanical testing and in situ characterization of nanoscale deformation, microfracture, and phase transformation phenomena.

Present address: International Institute for Urban Systems Engineering, Southeast University, Nanjing 210096, China.