Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Xu, Chang

Sun, Zhihong

and

Shao, Guowei

2021.

Prediction of Effective Thermal Conductivities of Four-Directional Carbon/Carbon Composites by Unit Cells with Different Sizes.

Applied Sciences,

Vol. 11,

Issue. 3,

p.

1171.

Xu, Chang

Dou, Jinzhen

Li, Xin

Shao, Guowei

and

Sun, Zhihong

2022.

Numerical study on thermal conductivities of spread tow woven pierced composites.

Textile Research Journal,

Vol. 92,

Issue. 23-24,

p.

4834.

Liu, Yang

Shan, Zhongde

Lv, Zhigang

Liu, Feng

Sun, Zheng

and

Li, Jiahua

2022.

Systematic deformation model of a square guide bar array in a flexible oriented 3D woven process.

Composite Structures,

Vol. 280,

Issue. ,

p.

114849.

Li, Biao

Huang, Dong

Li, Tongqi

Ye, Chong

Zhang, Ningyuan

Zhou, Xingming

Fan, Zhen

Liao, Gen

Han, Fei

Liu, Hongbo

and

Liu, Jinshui

2023.

The positive role of mesophase-pitch-based carbon fibers in enhancing thermal response behavior in Carbon/Carbon composites.

Materials Characterization,

Vol. 196,

Issue. ,

p.

112630.

Liu, Yang

Shan, Zhongde

Liu, Feng

and

Sun, Zheng

2023.

Out‐of‐plane compression properties and failure mechanism of gradient 3D woven composites.

Polymer Composites,

Vol. 44,

Issue. 9,

p.

5746.

Zhao, Xiaoyu

Guo, Fei

Li, Beibei

Wang, Guannan

and

Ye, Jinrui

2023.

Multiscale numerical modeling for thermal behavior of plain-woven composites with interfacial and internal defects.

International Journal of Heat and Mass Transfer,

Vol. 202,

Issue. ,

p.

123711.

Huang, Hao

Shan, Zhongde

Liu, Jianhua

Sun, Zheng

Guo, Zitong

Gong, Hao

Xia, Huanxiong

Jin, Peng

and

Chen, Chaozhong

2023.

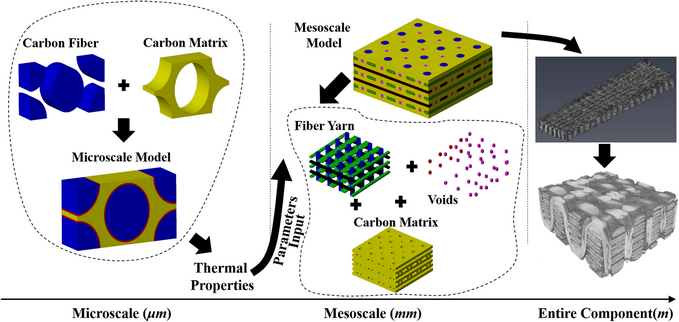

A unified trans-scale mechanical properties prediction method of 3D composites with void defects.

Composite Structures,

Vol. 306,

Issue. ,

p.

116574.

Liu, Yang

Shan, Zhongde

Lv, Zhigang

Sun, Zheng

and

Du, Wudi

2023.

Research on the thermal conductivity and ablation performance of gradient 3D woven carbon/carbon composite.

Ceramics International,

Vol. 49,

Issue. 11,

p.

16809.

Mi, Zhaoguo

Chen, Zhenhua

Yang, Weihua

and

Nawab, Yasir

2023.

Experimental and Numerical Analysis of the Thermal Conductivity of SiCf/SiC Composites.

Advances in Materials Science and Engineering,

Vol. 2023,

Issue. ,

p.

1.

Xu, Chang

Shao, Guowei

Li, Bin

and

Sun, Zhihong

2023.

Research into the thermal expansion behavior of spread tow woven pierced carbon/carbon composites at high temperature.

Textile Research Journal,

Vol. 93,

Issue. 19-20,

p.

4600.

Liu, Yang

Shan, Zhongde

Liu, Feng

and

Sun, Zheng

2024.

Optimization control of guide bar array deformation in flexible‐oriented 3D woven process.

Polymer Composites,

Vol. 45,

Issue. 6,

p.

5386.

Hu, Peili

Shan, Zhongde

Zang, Yong

Liu, Feng

Sun, Zheng

and

Wu, Xiaochuan

2024.

High‐Temperature Thermal Conductivity of Fiber Hybrid Ceramic Matrix Composites with Different Modes.

Advanced Engineering Materials,

Vol. 26,

Issue. 10,

Sun, Zheng

Shan, Zhongde

Huang, Hao

Wang, Dong

Wang, Wang

Liu, Jiale

Tan, Chenchen

and

Chen, Chaozhong

2024.

Multi-scale Modeling and Finite Element Analyses of Thermal Conductivity of 3D C/SiC Composites Fabricating by Flexible-Oriented Woven Process.

Chinese Journal of Mechanical Engineering,

Vol. 37,

Issue. 1,

Tan, Chenchen

Huang, Hao

Sun, Zheng

Shan, Zhongde

Guo, Zitong

Guo, Kehong

Bian, Jinshuai

and

Wang, Weihao

2025.

A comparative study of tensile fatigue life in various flexible-oriented three-dimensional woven process structures based on finite element models.

Composite Structures,

Vol. 352,

Issue. ,

p.

118680.

Wang, Weihao

Huang, Hao

Shan, Xuehao

Shan, Zhongde

Sun, Zheng

Guo, Zitong

and

Tan, Chenchen

2025.

A bending test and performance prediction study of large deformation braiding-needling composite preform.

Composites Part A: Applied Science and Manufacturing,

Vol. 194,

Issue. ,

p.

108851.

Li, Yaolan

Niu, Bo

Cai, Hongxiang

Zhang, Xuanfeng

Zhu, Xiaofei

Cao, Yu

Zhang, Yayun

and

Long, Donghui

2025.

A heat-transfer-inhibition strategy without compromising strengths for nanoporous phenolic composites: Designing hybrid carbon cloth/quartz felt needle-punched fabrics.

Composites Part A: Applied Science and Manufacturing,

Vol. 198,

Issue. ,

p.

109071.

Zhou, Zhengxi

Sun, Zheng

Shan, Zhongde

Guo, Kehong

Yang, Tianzheng

Yang, Haoda

Deng, Zuye

and

Guo, Zitong

2025.

Advanced composite preform forming technology for structures and its digitization: A review.

Thin-Walled Structures,

Vol. 211,

Issue. ,

p.

113053.

Du, Wudi

Shan, Zhongde

Liu, Feng

Wu, Xiaochuan

Chen, Zhe

and

Zou, Guisheng

2025.

Research on ultrasonic-assisted vibration multi-cycle compaction method of flexible guided 3D weaving.

Ultrasonics,

Vol. 145,

Issue. ,

p.

107461.