No CrossRef data available.

Published online by Cambridge University Press: 13 July 2017

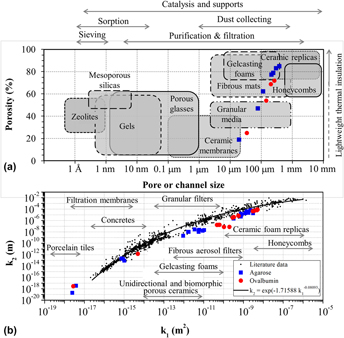

Alumina gel-cast foams were manufactured in a broad total porosity range (43–86%) by using agarose or ovalbumin as gelling agents. The foams were examined in terms of microstructural, permeability, and mechanical properties. For the achieved open porosity level (19–85%), the mean cell size (19–375 µm), and mean window size (8–77 µm) of the alumina foams manufactured using ovalbumin were slightly wider than those obtained using agarose (34–262 µm and 18–33 µm, respectively). By using different contents of agarose (0.3–1 wt%) or albumin (5 wt%) and solids (30–45.9 wt%), it was possible to vary the foaming yield from 1.6 to 4.4 and produce bodies with a very wide permeability level that included several classes of porous ceramics. Darcian (k1) and non-Darcian (k2) permeability coefficients displayed values in the range 3.2 × 10−18 to 4.3 × 10−9 m2 and 1.8 × 10−18 to 6.5 × 10−5 m respectively. Compressive strength of bodies was dependent upon the porosity level, with a variation of 8.5–149.7 MPa.

Contributing Editor: Paolo Colombo