Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

El-Atwani, Osman

Kim, Hyosim

Gigax, Jonathan G.

Harvey, Cayla

Aytuna, Berk

Efe, Mert

and

Maloy, Stuart A.

2021.

Stable, Ductile and Strong Ultrafine HT-9 Steels via Large Strain Machining.

Nanomaterials,

Vol. 11,

Issue. 10,

p.

2538.

Harvey, Cayla

Torrez, Avery J.

Lam, Sebastian

Kim, Hyosim

Maloy, Stuart A.

and

Gigax, Jonathan G.

2021.

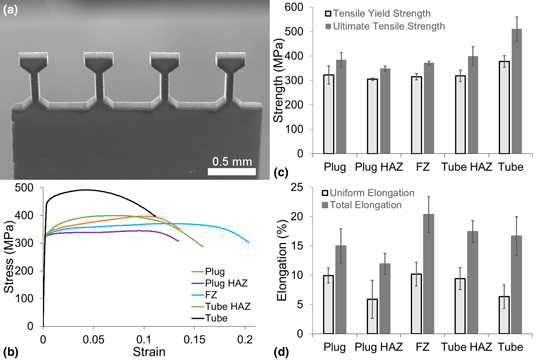

Demonstration of a High-Throughput Tensile Testing Technique Using Femtosecond Laser-Fabricated Tensile Bars in AISI 316 and Additively Manufactured Grade 91 Steel.

JOM,

Vol. 73,

Issue. 12,

p.

4240.

Dong, A.

Duckering, J.

Peterson, J.

Lam, S.

Routledge, D.

and

Hosemann, P.

2021.

Femtosecond Laser Machining of Micromechanical Tensile Test Specimens.

JOM,

Vol. 73,

Issue. 12,

p.

4231.

Bao, Weikang

Wang, Hao

Liu, Jizi

and

You, Zesheng

2022.

Microstructural and mechanical characterizations on Cu machined and sidewise polished by femtosecond laser.

Materials Science and Engineering: A,

Vol. 855,

Issue. ,

p.

143834.

Zhang, Yifan

Gigax, Jonathan G.

Nizolek, Thomas J.

Carpenter, John S.

Schneider, Matthew M.

Li, Nan

Capolungo, Laurent

and

McCabe, Rodney J.

2022.

Tensile and failure behaviors of Cu/Nb nanolaminates: the effects of loading direction, layer thickness, and annealing.

Acta Materialia,

Vol. 240,

Issue. ,

p.

118346.

Hong, JongDae

Ahn, Daehyeok

Jang, Dongchan

Oh, Hongryul

Kim, JaeYong

Kim, Hyochan

and

Ševeček, Martin

2023.

Measurement of local mechanical properties for Cr-coated accident tolerant fuel cladding.

Journal of Nuclear Materials,

Vol. 579,

Issue. ,

p.

154407.

Dong, A.

Vo, H.

Olivas, E.

Bickel, J.

Hardie, C.

Hosemann, P.

and

Maloy, S.

2023.

The effect of sample thickness on micro-mesoscale tensile properties of 304SS, HT-9, and CuCrZr.

Journal of Nuclear Materials,

Vol. 575,

Issue. ,

p.

154207.

Szabó, Péter Imre

Ugi, Dávid

Gilicze, Barnabás

Dankházi, Zoltán

Lipcsei, Sándor

Homik, Zsolt

and

Tóth, Zsolt

2023.

Micromachining using the high energy flat-top beam of a femtosecond pulse UV laser system: micropillar prefabrication.

Applied Physics A,

Vol. 129,

Issue. 6,

Mirmohammad, Hadi

Regmi, Abiral

Chang, Jiyoung

and

Kingstedt, Owen

2024.

Demonstration of an integrated-heating load frame for quantitatively assessing microscale tensile properties of copper and Zircaloy-2.

Journal of Nuclear Materials,

Vol. 601,

Issue. ,

p.

155339.

Sun, Tianyi

Niu, Tongjun

Shang, Zhongxia

Shen, Chao

Xie, Dongyue

Wang, Jian

Wang, Haiyan

and

Zhang, Xinghang

2024.

High‐Temperature Mechanical Behavior of Single‐Crystal FeCrAl Alloy Under In Situ Micropillar Compression.

Advanced Engineering Materials,

Vol. 26,

Issue. 21,

Niu, Tongjun

Lee, Ross

Lam, Sebastian

Hafen, Joseph

Lukow, Steven

Li, Nan

Hosemann, Peter

and

Gigax, Jonathan

2025.

A Novel Machine Learning-Driven Approach to High Throughput Mechanical Testing.

JOM,

Vol. 77,

Issue. 4,

p.

2121.