Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Borkar, Tushar

and

Banerjee, Rajarshi

2014.

Influence of spark plasma sintering (SPS) processing parameters on microstructure and mechanical properties of nickel.

Materials Science and Engineering: A,

Vol. 618,

Issue. ,

p.

176.

Borkar, Tushar

Mohseni, Hamidreza

Hwang, Junyeon

Scharf, Thomas W.

Tiley, Jaimie S.

Hong, Soon H.

and

Banerjee, Rajarshi

2015.

Excellent strength–ductility combination in nickel-graphite nanoplatelet (GNP/Ni) nanocomposites.

Journal of Alloys and Compounds,

Vol. 646,

Issue. ,

p.

135.

Borkar, Tushar

Mohseni, Hamidreza

Hwang, Junyeon

Scharf, Thomas

Tiley, Jaimie

Hong, Soon H.

and

Banerjee, Rajarshi

2015.

Advanced Composites for Aerospace, Marine, and Land Applications II.

p.

53.

Dong, Shuhong

Zhou, Jianqiu

Hui, David

and

Wang, Lu

2015.

Fracture toughness of nanocrystalline metal matrix composites reinforced by aligned carbon nanotubes.

Journal of Materials Research,

Vol. 30,

Issue. 21,

p.

3267.

Borkar, Tushar

Mohseni, Hamidreza

Hwang, Junyeon

Scharf, Thomas

Tiley, Jaimie

Hong, Soon H.

and

Banerjee, Rajarshi

2015.

Advanced Composites for Aerospace, Marine, and Land Applications II.

p.

53.

Wang, Pei

Zhang, Baicheng

Tan, Cheng Cheh

Raghavan, Srinivasan

Lim, Yee-Fun

Sun, Chen-Nan

Wei, Jun

and

Chi, Dongzhi

2016.

Microstructural characteristics and mechanical properties of carbon nanotube reinforced Inconel 625 parts fabricated by selective laser melting.

Materials & Design,

Vol. 112,

Issue. ,

p.

290.

Borkar, Tushar

Nag, Soumya

Tiley, Jaimie

and

Banerjee, Rajarshi

2016.

Proceedings of the 13th World Conference on Titanium.

p.

1311.

Minh, Thuyet-Nguyen

Hong, Hai-Nguyen

Kim, Won Joo

Kim, Ho Yoon

and

Kim, Jin-Chun

2016.

Fabrication and Mechanical Characteristics of Bulk Nickel/Carbon Nanotube Nanocomposites via the Electrical Explosion of Wire in Liquid and Spark Plasma Sintering Method.

Journal of Korean Powder Metallurgy Institute,

Vol. 23,

Issue. 3,

p.

213.

Aristizabal, Katherine

Katzensteiner, Andreas

Bachmaier, Andrea

Mücklich, Frank

and

Suarez, Sebastian

2017.

Study of the structural defects on carbon nanotubes in metal matrix composites processed by severe plastic deformation.

Carbon,

Vol. 125,

Issue. ,

p.

156.

Fu, Kai

Zhang, Xiang

Shi, Chunsheng

Liu, Enzuo

He, Fang

Li, Jiajun

Zhao, Naiqin

and

He, Chunnian

2018.

An approach for fabricating Ni@graphene reinforced nickel matrix composites with enhanced mechanical properties.

Materials Science and Engineering: A,

Vol. 715,

Issue. ,

p.

108.

Liu, Yongsheng

Liu, Ying

Zhang, Qian

Zhang, Caili

Wang, Jian

Wu, Yanxia

Han, Peide

Gao, Zhipeng

Wang, Liping

and

Wu, Xiaolei

2018.

Control of the microstructure and mechanical properties of electrodeposited graphene/Ni composite.

Materials Science and Engineering: A,

Vol. 727,

Issue. ,

p.

133.

Bundy, Vanessa

Chauhan, Mehul

Fitch, Cyrus

Modi, Prathmesh

and

Morsi, K.

2018.

Effect of Carbon Nanotube (CNT) Length on the Mechanical Milling of Ni-CNT Powders and Ni-CNT/Al Reactive Synthesis.

Metallurgical and Materials Transactions A,

Vol. 49,

Issue. 12,

p.

6351.

Baig, Zeeshan

Mamat, Othman

and

Mustapha, Mazli

2018.

Recent Progress on the Dispersion and the Strengthening Effect of Carbon Nanotubes and Graphene-Reinforced Metal Nanocomposites: A Review.

Critical Reviews in Solid State and Materials Sciences,

Vol. 43,

Issue. 1,

p.

1.

Zhou, Yu

Jiang, Wu-Gui

Li, Duo-Sheng

and

Qin, Qing-Hua

2019.

Study on Lightweight and Strengthening Effect of Carbon Nanotube in Highly Ordered Nanoporous Nickel: A Molecular Dynamics Study.

Applied Sciences,

Vol. 9,

Issue. 2,

p.

352.

Thuyet-Nguyena, Minh

and

Kim, Jin-Chun

2020.

Spark Plasma Sintering of the Ni-graphite Composite Powder Prepared by Electrical Explosion of Wire in Liquid and Its Properties.

Journal of Korean Powder Metallurgy Institute,

Vol. 27,

Issue. 1,

p.

14.

Carneiro, Íris

and

Simões, Sónia

2020.

Effect of Morphology and Structure of MWCNTs on Metal Matrix Nanocomposites.

Materials,

Vol. 13,

Issue. 23,

p.

5557.

Kurapova, Olga Yu

Lomakin, Ivan V.

Sergeev, Semen N.

Solovyeva, Elena N.

Zhilyaev, Alexander P.

Archakov, Ivan Yu

and

Konakov, Vladimir G.

2020.

Fabrication of nickel-graphene composites with superior hardness.

Journal of Alloys and Compounds,

Vol. 835,

Issue. ,

p.

155463.

Patil, Amit

Walunj, Ganesh

Torgerson, Tyler B.

Koricherla, Manindra V.

Khan, Mohammed U. F.

Scharf, Thomas W.

Gupta, Rajeev

and

Borkar, Tushar

2021.

Metal-Matrix Composites.

p.

3.

Patil, Amit

Nartu, Mohan Sai Kiran

and

Borkar, Tushar

2021.

Metal-Matrix Composites.

p.

111.

Patil, Amit

Nartu, Mohan Sai Kiran Kumar Yadav

Ozdemir, Furkan

Banerjee, Raj

Gupta, Rajeev Kumar

and

Borkar, Tushar

2021.

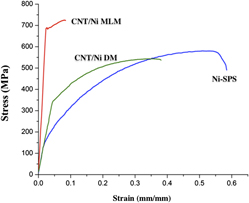

Strengthening effects of multi-walled carbon nanotubes reinforced nickel matrix nanocomposites.

Journal of Alloys and Compounds,

Vol. 876,

Issue. ,

p.

159981.