Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Haleem, Abid

and

Javaid, Mohd

2019.

Polyether ether ketone (PEEK) and its 3D printed implants applications in medical field: An overview.

Clinical Epidemiology and Global Health,

Vol. 7,

Issue. 4,

p.

571.

Sviridov, A

Lopatina, Iu

and

Kurganova, Iu

2019.

3D-printed polyether ether ketone samples mechanical properties estimation.

IOP Conference Series: Materials Science and Engineering,

Vol. 589,

Issue. 1,

p.

012021.

Haleem, Abid

and

Javaid, Mohd

2019.

Polyether ether ketone (PEEK) and its manufacturing of customised 3D printed dentistry parts using additive manufacturing.

Clinical Epidemiology and Global Health,

Vol. 7,

Issue. 4,

p.

654.

Wang, Jian

Huang, Ruiying

Chen, Haoxiang

Qiao, Xiaoyin

Shi, Xuelei

Wang, Xiaocheng

Cheng, Yanxiang

Tan, Weihong

and

Tan, Zhikai

2019.

Personalized Single‐Cell Encapsulation Using E‐Jet 3D Printing with AC‐Pulsed Modulation.

Macromolecular Materials and Engineering,

Vol. 304,

Issue. 4,

Ma, Jing

Xue, Yizebang

Liang, Xinyu

Liao, Chengzhu

Tan, Zhijie

and

Tang, Bin

2019.

Bi-directional regulatable mechanical properties of 3D braided polyetheretherketone (PEEK).

Materials Science and Engineering: C,

Vol. 103,

Issue. ,

p.

109811.

Choi, Jeongho

and

Lee, Sang-ik

2019.

Experimental validation of theoretical models for hypercube models made by fused deposition modelling technology.

Journal of Mechanical Science and Technology,

Vol. 33,

Issue. 12,

p.

5951.

Liao, Chengzhu

Li, Yuchao

and

Tjong, Sie Chin

2020.

Polyetheretherketone and Its Composites for Bone Replacement and Regeneration.

Polymers,

Vol. 12,

Issue. 12,

p.

2858.

Delaney, Lauren J.

Basgul, Cemile

MacDonald, Daniel W.

Fitzgerald, Keith

Hickok, Noreen J.

Kurtz, Steven M.

and

Forsberg, Flemming

2020.

Acoustic Parameters for Optimal Ultrasound-Triggered Release from Novel Spinal Hardware Devices.

Ultrasound in Medicine & Biology,

Vol. 46,

Issue. 2,

p.

350.

Gao, Xinshuai

Wang, Honghua

Zhang, Xu

Gu, Xinming

Liu, Yuzhe

Zhou, Guangyuan

and

Luan, Shifang

2020.

Preparation of Amorphous Poly(aryl ether nitrile ketone) and Its Composites with Nano Hydroxyapatite for 3D Artificial Bone Printing.

ACS Applied Bio Materials,

Vol. 3,

Issue. 11,

p.

7930.

Choi, Jeongho

2020.

Truss and Frames - Recent Advances and New Perspectives.

Zanjanijam, Ali Reza

Major, Ian

Lyons, John G.

Lafont, Ugo

and

Devine, Declan M.

2020.

Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships.

Polymers,

Vol. 12,

Issue. 8,

p.

1665.

Kulkarni, Arvind Gopalrao

Sagane, Shrikant S.

and

Kunder, Tushar Satish

2020.

Management of spondylolisthesis using MIS techniques: Recent advances.

Journal of Clinical Orthopaedics and Trauma,

Vol. 11,

Issue. 5,

p.

839.

Spece, H.

Yu, T.

Law, A.W.

Marcolongo, M.

and

Kurtz, S.M.

2020.

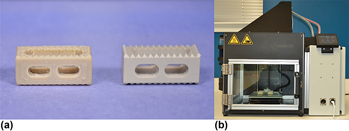

3D printed porous PEEK created via fused filament fabrication for osteoconductive orthopaedic surfaces.

Journal of the Mechanical Behavior of Biomedical Materials,

Vol. 109,

Issue. ,

p.

103850.

Lopatina, Y

and

Filippova, A

2020.

Research of composition porosity based on 3d-printed frames and impregnated with epoxy resin.

IOP Conference Series: Materials Science and Engineering,

Vol. 963,

Issue. 1,

p.

012031.

Elhattab, K.

Sikder, P.

Walker, J.M.

Bottino, M.C.

and

Bhaduri, S.B.

2020.

Fabrication and evaluation of 3-D printed PEEK scaffolds containing Macropores by design.

Materials Letters,

Vol. 263,

Issue. ,

p.

127227.

Choi, Jeongho

2020.

Proceedings of the 11th International Conference on Porous Metals and Metallic Foams (MetFoam 2019).

p.

59.

Basgul, Cemile

MacDonald, Daniel W.

Siskey, Ryan

and

Kurtz, Steven M.

2020.

Thermal localization improves the interlayer adhesion and structural integrity of 3D printed PEEK lumbar spinal cages.

Materialia,

Vol. 10,

Issue. ,

p.

100650.

Maguire, Alianna

Pottackal, Neethu

Saadi, M A S R

Rahman, Muhammad M

and

Ajayan, Pulickel M

2020.

Additive manufacturing of polymer-based structures by extrusion technologies.

Oxford Open Materials Science,

Vol. 1,

Issue. 1,

Kholgh Eshkalak, Saeideh

Rezvani Ghomi, Erfan

Dai, Yunqian

Choudhury, Deepak

and

Ramakrishna, Seeram

2020.

The role of three-dimensional printing in healthcare and medicine.

Materials & Design,

Vol. 194,

Issue. ,

p.

108940.

Vaes, Dries

and

Van Puyvelde, Peter

2021.

Semi-crystalline feedstock for filament-based 3D printing of polymers.

Progress in Polymer Science,

Vol. 118,

Issue. ,

p.

101411.