Article contents

Texture size control by mixing glass microparticles with alkaline solution for crystalline silicon solar cells

Published online by Cambridge University Press: 12 June 2018

Abstract

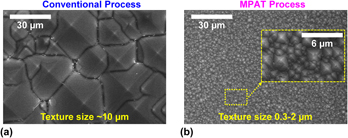

In this paper, we show a novel method to obtain small size textures usable in crystalline silicon (c-Si) solar cells. SiO2-based glass microparticles are mixed with a conventional KOH-based alkaline solution for making the textures. Using this mixing method, the texture size can be drastically reduced from 10 to ≤2 µm (0.3–2 µm). In addition, the process time and c-Si loss during the texture formation are reduced from 25 to 2 min and from 20 to 2 µm, respectively. Thus, the process is applicable to c-Si with thickness down to 50 µm. High-quality passivation showing the effective minority carrier lifetimes (τeff) larger than several ms and effective antireflection coating are possible on the new textures. The process is named “microparticle-assisted texturing (MPAT) process”, and its features are also demonstrated.

Keywords

- Type

- Invited Feature Paper

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

Present address: ULVAC, Inc. (ULVAC), Chigasaki, Kanagawa 253-8543, Japan.

This paper has been selected as an Invited Feature Paper.

References

REFERENCES

- 7

- Cited by