Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wang, Xiaofei

Xiang, Huimin

Sun, Xin

Liu, Jiachen

Hou, Feng

and

Zhou, Yanchun

2015.

Mechanical Properties and Damage Tolerance of Bulk Yb3Al5O12 Ceramic.

Journal of Materials Science & Technology,

Vol. 31,

Issue. 4,

p.

369.

Wang, Xiaofei

Xiang, Huimin

Liu, Jiachen

Hou, Feng

Sun, Yinjie

and

Zhou, Yanchun

2016.

Gelcasting of Yb3Al5O12 using a nontoxic water-soluble copolymer as both dispersant and gelling agent.

Ceramics International,

Vol. 42,

Issue. 1,

p.

421.

Wang, Xiaofei

Xiang, Huimin

Wang, Guigen

and

Zhou, Yanchun

2016.

A green fabrication strategy for porous Yb3Al5O12 ceramics with high strength and tunable gas permeability.

Journal of Materials Research,

Vol. 31,

Issue. 19,

p.

3078.

Lu, Ming‐Hui

Xiang, Hui‐Min

Feng, Zhi‐Hai

Wang, Xiao‐Ye

Zhou, Yan‐Chun

and

Smialek, J.

2016.

Mechanical and Thermal Properties of Yb2SiO5: A Promising Material for T/EBCs Applications.

Journal of the American Ceramic Society,

Vol. 99,

Issue. 4,

p.

1404.

Wei, Zhenbang

Jiang, Yong

Liu, Limeng

Wu, Laner

and

Huang, Zhenkun

2016.

Phase relations in the Si–Al–Yb–O–C system.

Journal of the European Ceramic Society,

Vol. 36,

Issue. 3,

p.

437.

Ding, Yingchun

Chen, Min

Wu, Wenjuan

and

Xu, Ming

2017.

Elasticity, Hardness and Thermal Conductivity of Si-Ge-Based Oxynitrides (SiGeN2O).

Journal of Electronic Materials,

Vol. 46,

Issue. 1,

p.

510.

Zhong, Xin

Niu, Yaran

Li, Hong

Zeng, Yi

Zheng, Xuebin

Ding, Chuanxian

and

Sun, Jinliang

2017.

Microstructure evolution and thermomechanical properties of plasma‐sprayed Yb2SiO5 coating during thermal aging.

Journal of the American Ceramic Society,

Vol. 100,

Issue. 5,

p.

1896.

Liu, Yuchen

Zhang, Wei

Wang, Banghui

Sun, Luchao

Li, Fangzhi

Xue, Zhenhai

Zhou, Guohong

Liu, Bin

and

Nian, Hongqiang

2018.

Theoretical and experimental investigations on high temperature mechanical and thermal properties of BaZrO3.

Ceramics International,

Vol. 44,

Issue. 14,

p.

16475.

Zhao, Zifan

Xiang, Huimin

Dai, Fu-Zhi

Peng, Zhijian

and

Zhou, Yanchun

2019.

(La0.2Ce0.2Nd0.2Sm0.2Eu0.2)2Zr2O7: A novel high-entropy ceramic with low thermal conductivity and sluggish grain growth rate.

Journal of Materials Science & Technology,

Vol. 35,

Issue. 11,

p.

2647.

Zhao, Zifan

Xiang, Huimin

Dai, Fu-Zhi

Peng, Zhijian

and

Zhou, Yanchun

2019.

(TiZrHf)P2O7: An equimolar multicomponent or high entropy ceramic with good thermal stability and low thermal conductivity.

Journal of Materials Science & Technology,

Vol. 35,

Issue. 10,

p.

2227.

Zhao, Zifan

Chen, Heng

Xiang, Huimin

Dai, Fu-Zhi

Wang, Xiaohui

Peng, Zhijian

and

Zhou, Yanchun

2019.

(La0.2Ce0.2Nd0.2Sm0.2Eu0.2)PO4: A high-entropy rare-earth phosphate monazite ceramic with low thermal conductivity and good compatibility with Al2O3.

Journal of Materials Science & Technology,

Vol. 35,

Issue. 12,

p.

2892.

Liu, Bin

Liu, Yuchen

Zhu, Changhua

Xiang, Huimin

Chen, Hongfei

Sun, Luchao

Gao, Yanfeng

and

Zhou, Yanchun

2019.

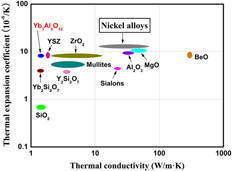

Advances on strategies for searching for next generation thermal barrier coating materials.

Journal of Materials Science & Technology,

Vol. 35,

Issue. 5,

p.

833.

Liu, Yuchen

Jia, Dechang

Zhou, Yu

Zhou, Yanchun

Zhao, Juanli

Li, Qian

and

Liu, Bin

2020.

Discovery of ABO4 scheelites with the extra low thermal conductivity through high-throughput calculations.

Journal of Materiomics,

Vol. 6,

Issue. 4,

p.

702.

Zhao, Zifan

Chen, Heng

Xiang, Huimin

Dai, Fu-Zhi

Wang, Xiaohui

Xu, Wei

Sun, Kuang

Peng, Zhijian

and

Zhou, Yanchun

2020.

(Y0.25Yb0.25Er0.25Lu0.25)2(Zr0.5Hf0.5)2O7: A defective fluorite structured high entropy ceramic with low thermal conductivity and close thermal expansion coefficient to Al2O3.

Journal of Materials Science & Technology,

Vol. 39,

Issue. ,

p.

167.

Chen, Heng

Zhao, Zifan

Xiang, Huimin

Dai, Fu-Zhi

Xu, Wei

Sun, Kuang

Liu, Jiachen

and

Zhou, Yanchun

2020.

High entropy (Y0.2Yb0.2Lu0.2Eu0.2Er0.2)3Al5O12: A novel high temperature stable thermal barrier material.

Journal of Materials Science & Technology,

Vol. 48,

Issue. ,

p.

57.

Mehboob, Ghazanfar

Liu, Mei-Jun

Xu, Tong

Hussain, Shahnwaz

Mehboob, Gohar

and

Tahir, Adnan

2020.

A review on failure mechanism of thermal barrier coatings and strategies to extend their lifetime.

Ceramics International,

Vol. 46,

Issue. 7,

p.

8497.

Shin, Sunmi

Wang, Qingyang

Luo, Jian

and

Chen, Renkun

2020.

Advanced Materials for High‐Temperature Thermal Transport.

Advanced Functional Materials,

Vol. 30,

Issue. 8,

Feng, Yang

Dong, Tian-shun

Fu, Bin-guo

Li, Guo-lu

Liu, Qi

and

Wang, Ran

2020.

Thermal shock resistance of double-layer thermal barrier coatings.

Journal of Materials Research,

Vol. 35,

Issue. 20,

p.

2808.

Zhao, Zifan

Chen, Heng

Xiang, Huimin

Dai, Fu-Zhi

Wang, Xiaohui

Xu, Wei

Sun, Kuang

Peng, Zhijian

and

Zhou, Yanchun

2020.

High-entropy (Y0.2Nd0.2Sm0.2Eu0.2Er0.2)AlO3: A promising thermal/environmental barrier material for oxide/oxide composites.

Journal of Materials Science & Technology,

Vol. 47,

Issue. ,

p.

45.

Vargas-Bernal, Rafael

and

Bermúdez-Reyes, Bárbara

2021.

Advanced Surface Coating Techniques for Modern Industrial Applications.

p.

88.