Published online by Cambridge University Press: 14 August 2018

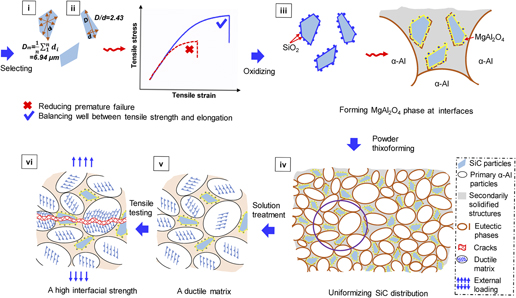

The powder thixoforming method was used to fabricate 10 vol% silicon carbide particle (SiCp) reinforced 6061 Al matrix composites with high mechanical performances successfully. Here, we demonstrated with proof that proper solution treatment could not only enhance tensile strength of the composite: its ultimate tensile strength and yield strength increased from 230 to 128 MPa in the as-fabricated state to 275 and 212 MPa solutionized at 808 K for 6 h but also improve composite’s tensile elongation significantly with an increment of 161.5% from 2.6% to 6.8%. Corresponding toughening mechanisms are mainly investigated from the perspective of both microstructure examination and total strain to failure calculation through a modified model. The theoretical predictions are in reasonably good agreement with the experimental data. This work may provide a practical way to alleviate the inverse strength–ductility relationship of particulate reinforced metal matrix composites and provide reference for the SF calculation of similar composites subjected to solution treatment.