Introduction

In 2016, people in the United States travelled more than 5.7 trillion miles in cars, trucks, buses, trains, and airplanes. In the same year, 14.9 million tons of freight were moved in the United States via road, rail, water, and air.1 However, all of this movement comes at a cost. In 2017, the transportation sector became the largest contributor to greenhouse gas emissions in the United States at 29% of the total 6.5 million metric tons of CO2 equivalent emitted.2 Because it takes less energy to move a lighter object, even small reductions in weight can have a significant effect on fuel consumption and emissions in the transportation sector.

Historically, ships, trains, trucks, and cars have been made of steel, which is a low-cost product with an established supply chain and manufacturing infrastructure. Dozens of steel grades are commercially available in product forms such as coils, plates, and ingots that can be manufactured in a variety of processes, including casting, forging, sheet forming, and roll forming to turn the steel into components. High volume assembly of steel components into vehicles primarily utilizes various forms of fusion welding, including arc welding with different shielding strategies, laser welding, and resistance welding. Fusion welding creates a metallurgical bond between the steel components via localized melting and results in a weldment that can have mechanical properties equivalent to the component steel. However, mild carbon steel has a density of 7.85 g/cc, which can result in substantial weight when fabricating large structures.

Airplanes have embraced lightweight materials since the Wright brothers built the Wright Flyer from wood and canvas with an aluminum engine in 1903. The huge increase in aluminum production during World War II allowed for more modern aircraft designs. Boeing’s 737 aircraft, designed in 1965 and still one of the most popular commercial airplanes, is made of 81% aluminum. Aircraft structures are primarily assembled using aluminum rivets, although steel rivets are also used when joining steel components to avoid galvanic corrosion. While the cost per pound of aluminum is approximately four times that of mild steel, it is also approximately one-third the density of steel. There are dozens of grades of aluminum alloys spanning a wide range of properties, which makes aluminum appealing for many component applications. The two most common aluminum alloys for aerospace, 2024 (Al-Cu) and 7075 (Al-Zn), have yield strengths of 345 and 500 MPa, respectively.

Advances in lightweight materials

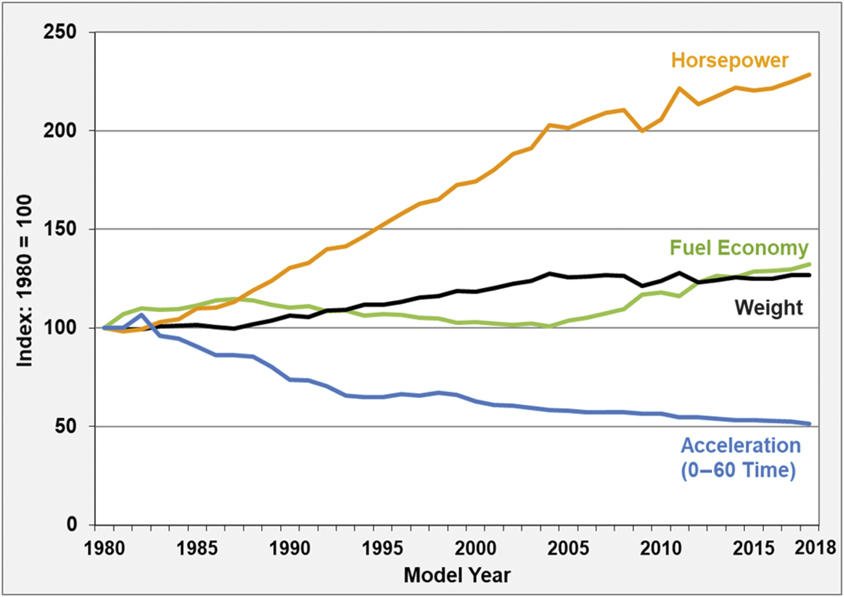

In the United States, the 1973 oil crisis spurred Congress to enact the Corporate Average Fuel Economy (CAFE) standards,3 which aimed to almost double the average fuel economy of all the cars and light trucks sold by model year 1985 and is still in effect today. Figure 14 shows the increase in fuel economy for new light vehicles for model years 1980–2018 and the inverse relationship between vehicle weight and fuel economy. In response to the regulation, the steel and automotive industries worked together to develop dual-phase (DP) and transformation induced plasticity (TRIP) steels, commonly referred to as advanced high-strength steels (AHSSs), with tensile strengths ranging from 550 to 1000 MPa.Reference Tamarelli5 The higher yield points of these materials allowed for reduced thickness of components, which reduced mass and also increased the crash safety of vehicles through improved energy absorption. Ultrahigh-strength boron and martensitic steels (UHSSs) have tensile strengths as high as 1500 MPaReference Tamarelli5 and are primarily used for the passenger compartment structure to keep occupants safe in a crash while also reducing weight. Third-generation AHSS alloys have been introduced in the last decade with tensile strengths comparable to those of UHSS while maintaining the ductility of DP and TRIP steels, allowing for increased formability and ease of manufacturing.Reference Nanda, Singh, Singh, Chakraborty and Sharma6

Figure 1. Horsepower, fuel economy, weight, and 0–60 time for new light vehicles, model years 1980–2018. The plot shows an increase in fuel economy for new light vehicles during this time period and the inverse relationship between vehicle weight and fuel economy.4

As the push for greater fuel economy continues, the automotive industry is also looking at lower density materials options, including aluminum alloys, carbon fiber composites, and magnesium alloys. Carbon fiber composites were introduced into the automotive industry in 1981 in McLaren’s MP4/1 Formula 1 car. High-performance consumer vehicles soon followed. Today, there are many methods of manufacturing components that take advantage of carbon fiber’s extremely high strength and stiffness though it is still primarily in low production volumes. Unidirectional continuous carbon fiber consists of multiple layers, called plies, of carbon fiber sheets that are pre-impregnated with a thermoset, often epoxy, resin. The placement and orientation of the plies provides for configurable properties, and the multilayer stack is placed into a mold under pressure and heated to set the resin. Continuous carbon fiber can also be braided, woven, and wound as a filament prior to curing. Discontinuous, or chopped, fiber can also be injection molded in a thermoplastic matrix or sheet molded in a thermoset matrix.7 The Boeing 787 aircraft incorporates 50% carbon fiber composite that provides a 20% reduction in weight as compared to aluminum and results in a 10–12% improvement in fuel efficiency.Reference Zhu, Li and Childs8

Magnesium alloysReference Luo and Sachdev9 are the lightest structural metals with a density of only 1.8 g/cc and yield strengths of up to 285 MPa. First used in automotive pistons in 1921, Mg die castings are used today for automotive components such as steering columns, instrument panels, and other interior components. It is more challenging to use Mg alloys as exterior components due to the metal’s propensity for corrosion and the formation of an unstable oxide layer that makes protective coatings a challenge. Presently, magnesium components are typically die cast and bolted on and rely on robust isolation strategies to prevent galvanic corrosion between the steel bolts and Mg base material. In recent years, there has been significant progress in the development of Mg alloys for sheets, which could be applied to body panels and closures with a corresponding weight reduction of up to 55% as compared to steel.

Multimaterial structures

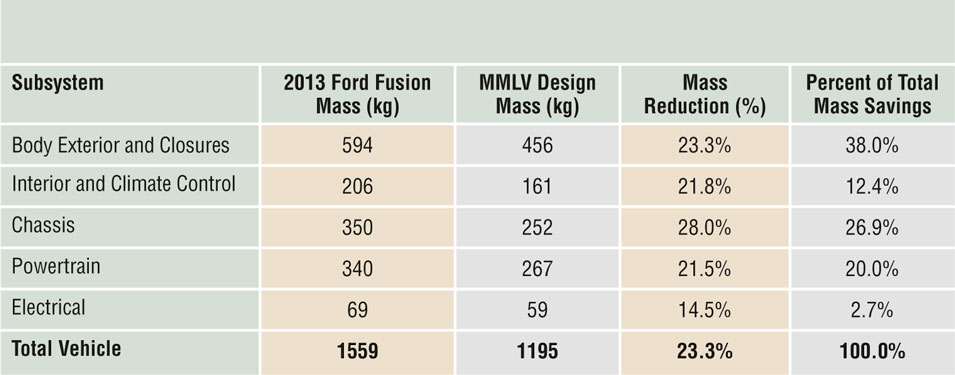

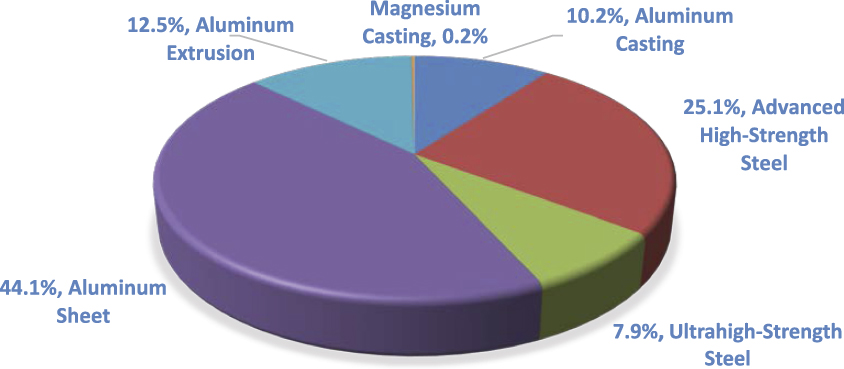

In 2015, a research team from Magna International and Ford Motor Company published the results of their Multimaterial Lightweight Vehicle design that weighed 23.3% less than the baseline vehicle, a 2013 Ford Fusion, while also meeting safety and performance targets.Reference Nanda, Singh, Singh, Chakraborty and Sharma6 Table I shows how the mass reductions were applied across the major subsystems of the vehicle.Reference Skszek, Zaluzec, Conklin and Wagner10 The design relied on commercially available materials and production processes; it was aluminum intensive, with steel, carbon fiber composite, and magnesium components as seen in Figure 2.Reference Skszek, Zaluzec, Conklin and Wagner10 The project used steel self-piercing rivets (SPRs), which is a type of rivet that doesn’t require a predrilled hole, as the primary joining technique with an epoxy structural adhesive applied for added strength and isolation to prevent galvanic corrosion.Reference Conklin, Beals and Brown11 Subsequently, a number of vehicles using lightweight materials and requiring dissimilar material joining have gone into production, including the 2013 BMW i3, 2015 Ford F-150, 2016 Cadillac CT6, and the 2017 Chrysler Pacifica.

Table I. Multimaterial Lightweight Vehicle (MMLV) mass reduction by subsystem and percent of total lightweighting.Reference Skszek, Zaluzec, Conklin and Wagner10

Figure 2. Material distribution for body and closure Multimaterial Lightweight Vehicle components.Reference Skszek, Zaluzec, Conklin and Wagner10

A key challenge in producing multimaterial structures is determining the best method to join the dissimilar material components. One of the primary considerations is how the joining method could affect the microstructure of the base materials and hence the resulting joint strength. Processes that rely on high temperatures to create joints may also cause melting of the materials and result in the formation of intermetallic compounds that could impact the strength of the joint. It is also important to account for the load path and geometry of the joint to ensure that the joint is robust to forces that act to peel the substrates apart and is able to withstand fatigue. Beyond the mechanical properties of the joint, the galvanic potential between the two materials may need to be mitigated through isolation, and the dimensional stability needs to be accounted for if there is a mismatch in the coefficients of thermal expansion. From a production point of view, access to the components to be joined may be from one or both sides, and for high volume production, the joining process needs to be completed in seconds. To reduce complexity, it is preferable to use the fewest number of joining methods for a given assembly line because introduction of a new joining method likely requires the installation of capital equipment and significant training for quality assurance and repair.

Joining solutions

Today’s multimaterial vehicles rely primarily on resistance spot welding and gas metal arc welding for similar material pairs, and SPRs or flow drill screws (FDSs) and adhesives for dissimilar material pairs. SPRs are one of the most common types of fasteners for joining aluminum to steel where the riveting head on the robot arm is able to simultaneously place the rivet on the front side of the joint and the die on the back side of the joint, commonly referred to as two-sided access. SPRs do not require the use of pilot holes and are a fast, automatable process. However, there are limitations on the strength of materials that can be joined using SPRs. High-strength steels with yield strengths above 590 MPa cannot be joined using the conventional self-piercing rivet and die because the rivet is not strong enough to penetrate the steel.Reference Abe, Kato and Mori12 FDS are another type of fastener that do not require pilot holes and only require one sided access. When designing for FDS, it is necessary to account for the projecting screw point on the back side of the joint. Structural adhesives are often used in conjunction with fasteners to provide isolation between dissimilar materials and prevent galvanic corrosion. The combination of fasteners and adhesive also acts to inhibit peel, which increases the joint strength as compared to use of an adhesive alone. Automotive adhesives are designed to cure during paint bake, which is one of the last steps in the assembly of a vehicle, so fasteners also provide important joint strength during the assembly process.

A typical midsize vehicle today has approximately 4500 spot joints and requires more than 300 robots in a body shop to create those welds.Reference Lippert13 Using the incumbent technology avoids the need for expensive capital investment and allows for earlier implementation. In their article in this issue, Carlson et al.Reference Carlson, Haselhuhn, Chen and Feng14 describe a new resistance spot welding technique, developed by General Motors (GM), that has demonstrated the ability to resistance spot weld aluminum to steel using a patented multiringed dome welding head geometry and a pulsed weld schedule. Unfortunately, the incumbent quality assurance technology, ultrasonic nondestructive evaluation, is not compatible with the features created in the weld by the multiringed dome. Consequently, GM is pursuing the use of infrared thermography to evaluate weld quality and enable the use of this joining technique to additional combinations of Al–steel alloys.

Adhesives are another incumbent technology that allow for the inclusion of materials with drastically different properties, such as carbon fiber-reinforced polymers. As discussed in the Banea article in this issue,Reference Banea15 in order to fully take advantage of the benefits of adhesives, it is important to be able to accurately model and understand the effects of joint geometry, adherend, and adhesive properties on the performance of the joint. Similarly, research efforts are underway to better account for differences in the coefficient of thermal expansion and to understand how adhesive properties evolve over the life of the vehicle.

Another solution to joining dissimilar materials, covered in the Ross et al. article in this issue,Reference Ross, Reza-E-Rabby, McDonnell and Whalen16 is friction stir welding (FSW), which uses frictional heat to soften the materials to be joined without melting and a rotational and translational movement to plastically deform and mix the materials. FSW is used today in shipbuilding, trains, and aerospace, and to a lesser extent, in the automotive industry. One use is in the fabrication of tailor welded blanks that reduce vehicle weight by butt welding sheets of differing thickness into a single sheet. When these sheets are then stamped into components, the areas of higher thickness provide increased strength and rigidity only to the portions of component that need it. FSW and its variants, including friction stir scribe welding, have proven successful at welding Al to steel and are showing promise in joining Al to Mg. In both of these cases, intermetallic compounds tend to form, which weakens the joint. Which compounds form and to what degree depends on the temperature of the materials at and near the weld. Pacific Northwest National Laboratory has developed a method for controlling the weld equipment in order to maintain a constant, desired temperature at the weld tip. In addition to ensuring better weld quality, the ability to control temperature during welding also helps to increase the combinations of alloys that can be welded and decrease the learning curve for implementing this technique.

Ultrasonic welding (USW) is another solid-state joining technique that creates bonds without melting of the base materials. As Chen et al. discuss in their article in this issue,Reference Chen, Lim, Huang, Feng and Sun17 USW utilizes high-frequency acoustic waves to vibrate workpieces against each other under pressure, which brings the metals into intimate contact and forms a bond. Used frequently for joining wires and battery tabs in automobiles, USW is also applied to sheet metals for structural joints. Oak Ridge National Laboratory is investigating the use of USW for joining Mg to itself and applying what is learned from this study to potential joints between Mg and steel, which would enable significant weight reduction. Using microdigital image correlation and high-speed infrared imaging, the temperature profile across the joint could be observed and correlated to the progression of weld formation. Similar to FSW, being able to measure and control the temperature of an ultrasonic weld is key to optimizing weld properties.

Other approaches to dissimilar material joining include impact welding, which can be initiated through vaporizing foil, magnetic pulses, and explosives. Vaporizing foil actuated welding (see the Thurston et al. article in this issueReference Thurston, Vivek, Nirudhoddi and Daehn18) uses the energy pulse from a vaporizing conductive foil to collide a flyer material into an offset plate. This technique has proven effective for a wide variety of metal combinations, including copper–titanium, copper–steel, aluminum–copper, aluminum–magnesium, and titanium–steel.Reference Vivek, Hansen, Liu and Daehn19 Solid-state joining techniques can also be combined with other joining methods such as mechanical fastening in the case of friction bit joining. This technique uses the frictional heat from a rotating bit to penetrate the top material and form a solid-state bond between the consumable bit and the bottom material.

Future challenges

While the number of joining techniques available to the transportation industries grows, for high volume production, there is a continued desire for a single joining method that can assemble AHSS, aluminum, magnesium, and composite materials consistently and robustly. The joint must be robust to corrosion, both general and galvanic, differences in coefficient of thermal expansion, and mechanical use and abuse over the life of the vehicle. Additionally, the joining process must be amenable to low cycle times and two and three thickness stacks of material, and be conducive to quality assurance evaluations. Currently, no joining method is able to meet all of these demands, but the research and development community continues to address each challenge with innovation and a determination to enable a more sustainable transportation system through lightweighting.

Sarah Kleinbaum is the technology manager for joining of dissimilar lightweight materials in the US Department of Energy’s Vehicle Technologies Office. She received her BS and MS degrees in materials engineering from Purdue University. She also serves as co-director of the LightMAT consortium, which seeks to enhance the collaboration between industry and national laboratories in order to accelerate the development and implementation of lightweight automotive materials. Previously, she managed the Materials Analysis and Approval Laboratory for North America at Whirlpool Corporation. Her research focuses on the challenges facing the automotive industry in implementing lightweight materials in vehicles, and she sponsors technical research projects led by academia, national laboratory, and industry partners to address these challenges. Kleinbaum can be reached by email at sarah.kleinbaum@ee.doe.gov.

Chonghua (Cindy) Jiang is the founder and principal engineer at AET Integration, Inc. She received her BS degree in welding engineering from Jilin University of Technology, China, with minors in mechanical engineering and materials science, and her MS degree in welding engineering from Harbin Research Institute of Welding, China. She received her MBA degree from Michigan State University and completed all courses and qualifying exams toward a PhD degree in welding engineering at The Ohio State University. Prior to founding AET in 2003, she was a welding specialist at US Steel Corporation, a senior welding research engineer at Caterpillar Technical Center, and a research manager at Harbin Research Institute of Welding. Her research focuses on joining technology development for new materials, dissimilar materials joining, weld metallurgy of ferrous and nonferrous materials, weld fatigue, hydrogen embrittlement in steels and steel structures, and failure analysis with production friendly process/product improvement guidance. Jiang can be reached by email at cindy.jiang@aet-int.com.

Stephen Logan is a senior project manager at AET Integration, Inc. He received his BS degree in mechanical engineering from The University of Oklahoma and his MS degree in automotive systems engineering from the University of Michigan. He retired from FCA/Chrysler in 2018, with more than 30 years of automotive engineering experience. At Chrysler, he led a group of engineers, designers, and suppliers to develop the world’s first ultra-lightweight magnesium die-cast intensive vehicle. He additionally led FCA’s participation in a number of industry collaborative research projects as well as FCA individual projects. His current research focuses on the joining of sheet magnesium as part of the United States Automotive Materials Partnership’s Low Cost Magnesium Sheet project. Logan can be reached by email at steve.logan@aet-int.com.