A group of researchers from University at Buffalo, The State University of New York and Temple University has developed a material that is both electrically conductive and can stretch like an accordion, as published in a recent issue of Advanced Materials (doi:10.1002/adma.201706390).

The material introduced by Ying-Shi Guan and co-workers is a combination of a stretchy polymer, termed TFB (poly[(9,9-dioctylfluorenyl-2,7-diyl)-co-(4,4′- (N-(4-sec-butylphenyl)diphenylamine)]), and a conductive polymer, termed P3BT (poly(3-butylthiophene-2,5-diyl)), together known as PthTFB. This hybrid material by itself is not sufficient for wearable electronics, but the implementation of three advances allows this material to gain the desired properties.

The first is a technique that allows the polymer molecules to self-assemble into a very flat and very uniform film, with a minimum thickness of ≈12 nm. This was achieved by dropping the solution of polymer molecules onto the surface of water, where the Marangoni effect (also responsible for causing wine to flow up the sides of glasses) stretches the droplet into a film. This thin film can be deposited on a surface and is moderately stretchable and weakly conductive. However, it becomes less conductive the more it is stretched.

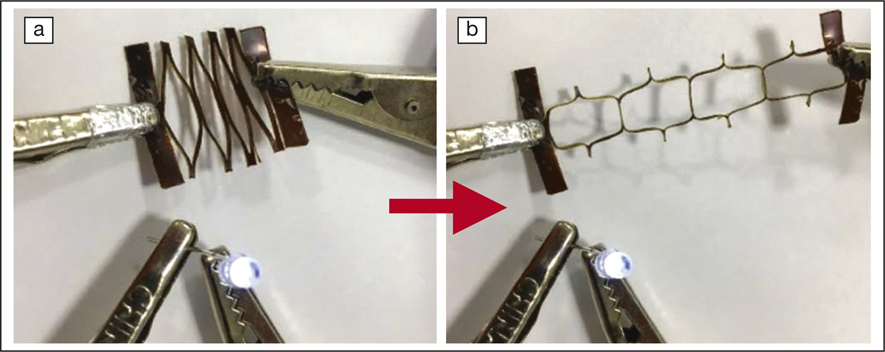

A kirigami polymer film (a) before and (b) after being stretched, as part of a circuit that lights an LED. Credit: Advanced Materials.

The second advance exploited the geometry of a type of origami called kirigami (Japanese for cut paper), which produces structures that can fold compactly and stretch immensely. The film by itself can stretch by an extra 15% of its length before breaking, and it becomes less conductive in the process. After the PthTBF is deposited on kirigami-cut paper, the film can be stretched by 2000% (20 times its length) without breaking, and it still conducts electricity just as well.

The conductive polymer in the film, P3BT, does not conduct well, and is thus not ideal for electronics. However, if iodine is included in the water when the film forms, iodine atoms can be incorporated within the film, boosting the transfer of charge between the polymers and significantly enhancing the electrical conductivity. The iodine-doped films conducted electricity at 4 S/cm, which is 8000 times better than the initial recipe, giving it an electrical conductivity 100× higher than that of seawater.

With these three developments, the material is foldable, stretchable, and electrically conductive. When asked about its implementation in consumer devices, researcher Shenqiang Ren says, “The development of stretchable materials and devices shown here can open up the development of new mechanically designed smart electronics, such as artificial skin, wearable electronics, and stretchable energy devices.” His research group has more in store besides wearable devices, with “ongoing efforts … to integrate energy transduction schemes into our systems, such as organic piezoelectrics, and photovoltaics, and thermoelectrics,” Ren says.

“This is a very interesting study with some promising results,” says Aaron Mascaro, a nanoelectronics researcher at McGill University. “This could definitely be implemented in wearable smart fabrics and stretchable sensor materials.”