I. INTRODUCTION

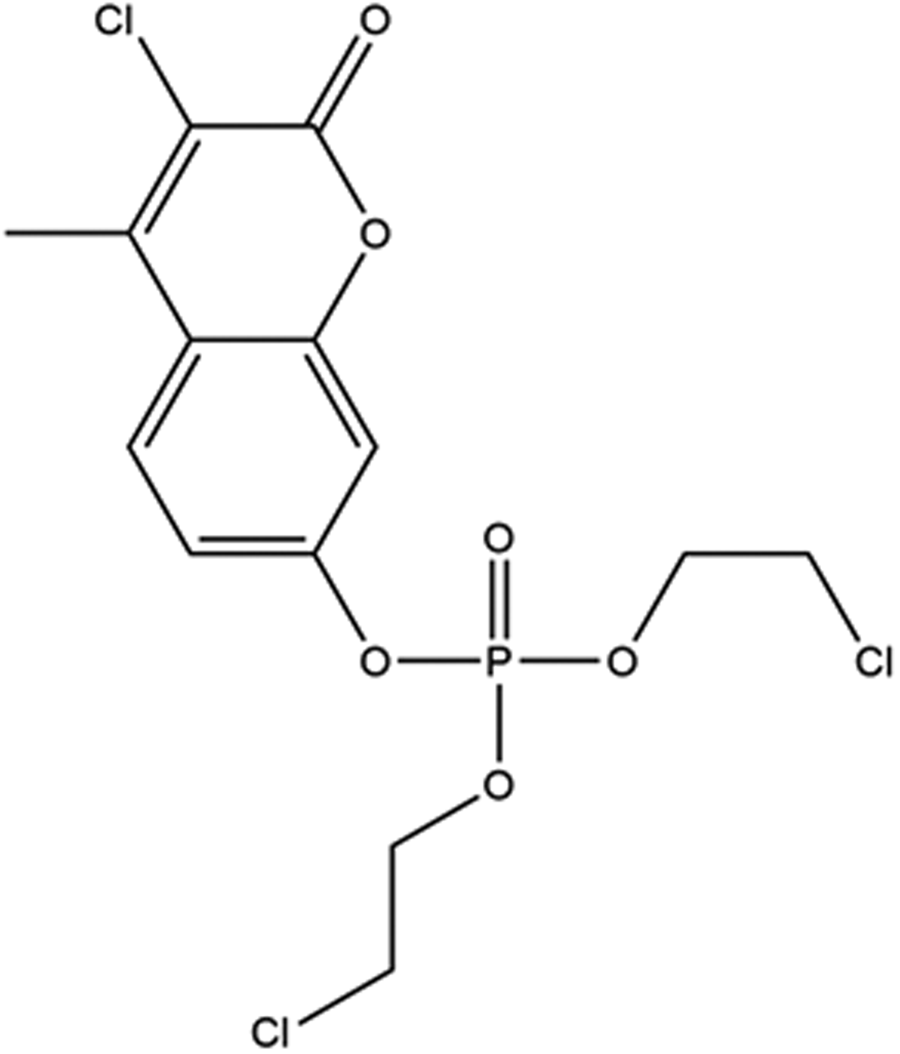

Haloxon (sold under the brand names Galloxon, Loxon, and Luxon among others) is an anthelminthic agent used in veterinary medicine to treat cattle. Haloxon is an antiparasitic drug that kills parasitic worms (helminths) and other internal parasites without causing significant damage to the host. The systematic name (CAS Registry Number 321-55-1) is bis(2-chloroethyl) (3-chloro-4-methyl-2-oxochromen-7-yl) phosphate. A two-dimensional molecular diagram is shown in Figure 1.

Figure 1. The 2D molecular structure of haloxon.

Haloxon was first mentioned by Brown et al. (Reference Brown, Hollinshead, Kingsbury and Malone1962). Several secondary sources indicate a Belgian patent BE610896, to Cooper, McDougall and Robertson, but we have been unable to obtain a copy, and are not aware of any published X-ray powder diffraction data on haloxon.

This work was carried out as part of a project (Kaduk et al., Reference Kaduk, Crowder, Zhong, Fawcett and Suchomel2014) to determine the crystal structures of large-volume commercial pharmaceuticals, and include high-quality powder diffraction data for them in the Powder Diffraction File (Gates-Rector and Blanton, Reference Gates-Rector and Blanton2019).

II. EXPERIMENTAL

Haloxon was a commercial reagent, purchased from Sigma (Lot #BO2641881), and was used as-received. The white powder was packed into a 1.5 mm diameter Kapton capillary and rotated during the measurement at ~50 Hz. The powder pattern was measured at 295 K at beamline 11-BM (Antao et al., Reference Antao, Hassan, Wang, Lee and Toby2008; Lee et al., Reference Lee, Shu, Ramanathan, Preissner, Wang, Beno, Von Dreele, Ribaud, Kurtz, Antao, Jiao and Toby2008; Wang et al., Reference Wang, Toby, Lee, Ribaud, Antao, Kurtz, Ramanathan, Von Dreele and Beno2008) of the Advanced Photon Source at Argonne National Laboratory using a wavelength of 0.458963(2) Å from 0.5 to 50° 2θ with a step size of 0.009984375 and a counting time of 0.1 s per step. The high-resolution powder diffraction data were collected using twelve silicon crystal analyzers that allow for high angular resolution, high precision, and accurate peak positions. A silicon (NIST SRM 640c) and alumina (SRM 676a) standard (ratio Al2O3:Si = 2:1 by weight) was used to calibrate the instrument and refine the monochromatic wavelength used in the experiment.

The pattern was indexed, using N-TREOR (Altomare et al., Reference Altomare, Cuocci, Giacovazzo, Moliterni, Rizzi, Corriero and Falcicchio2013), on a primitive monoclinic cell with a = 19.62613, b = 10.05116, c = 8.73551 Å, β = 92.725°, V = 1721.3 Å3, and Z = 4. A reduced cell search in the Cambridge Structural Database (Groom et al., Reference Groom, Bruno, Lightfoot and Ward2016) with the chemistry H, C, Cl, O, and P only yielded no hits. The suggested space group was P21/n, which was confirmed by successful solution and refinement of the structure. The structure was solved by direct methods using EXPO2104 (Altomare et al., Reference Altomare, Cuocci, Giacovazzo, Moliterni, Rizzi, Corriero and Falcicchio2013). Some of the atom types had to be reassigned manually.

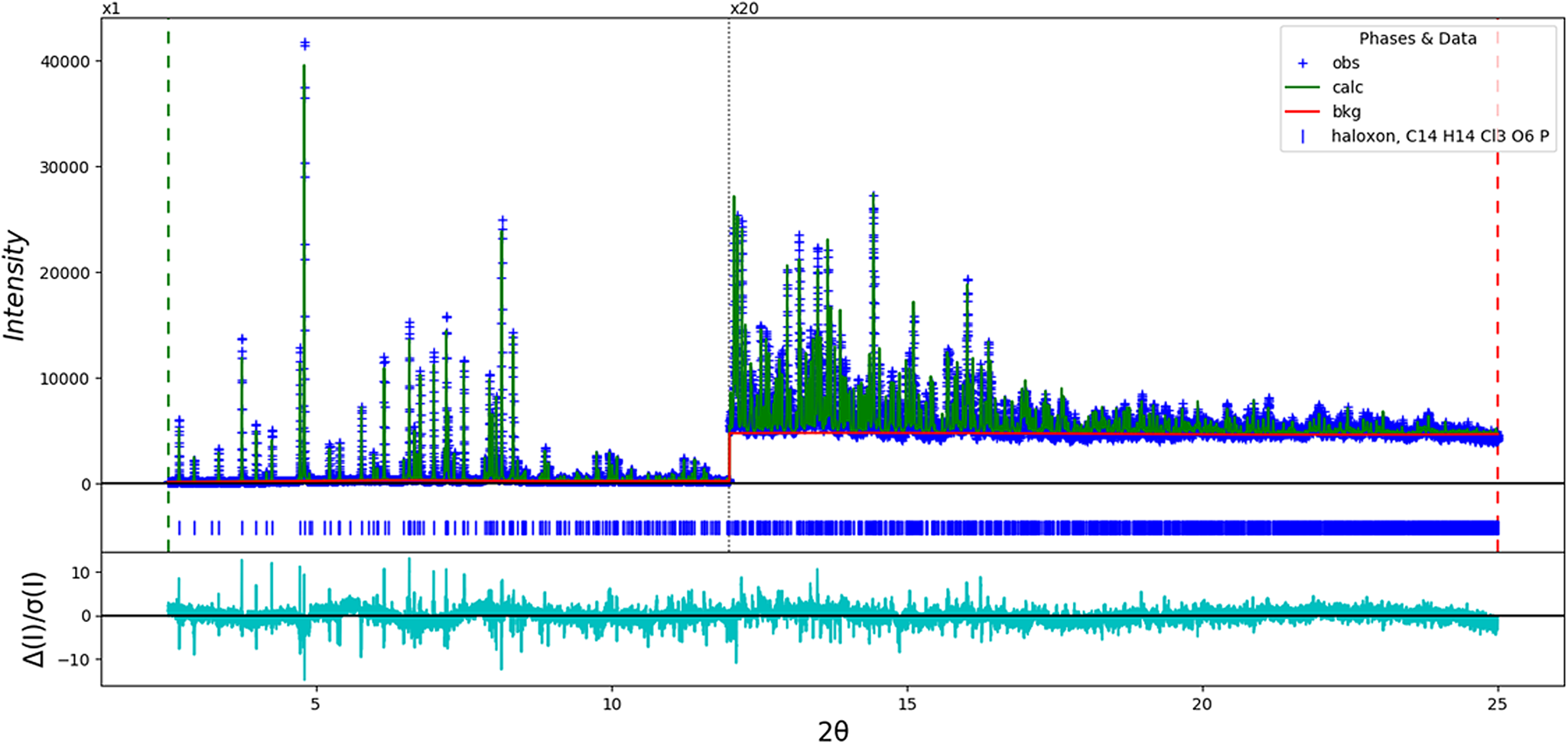

Rietveld refinement was carried out using GSAS-II (Toby and Von Dreele, Reference Toby and Von Dreele2013). Only the 2.5–25.0° portion of the pattern was included in the refinement (d min = 1.060 Å). All non-H bond distances and angles were subjected to restraints, based on a Mercury/Mogul Geometry Check (Bruno et al., Reference Bruno, Cole, Kessler, Luo, Motherwell, Purkis, Smith, Taylor, Cooper, Harris and Orpen2004; Sykes et al., Reference Sykes, McCabe, Allen, Battle, Bruno and Wood2011). The Mogul average and standard deviation for each quantity were used as the restraint parameters. The restraints contributed 6.4% to the final χ 2. The hydrogen atoms were included in calculated positions, which were recalculated during the refinement using Materials Studio (Dassault, 2021). The three Cl atoms were refined anisotropically. The U iso of the other heavy atoms were grouped by chemical similarity. The U iso for the H atoms were fixed at 1.3× the U iso of the heavy atoms to which they are attached. The peak profiles were described using the generalized microstrain model. The background was modeled using a 6-term shifted Chebyshev polynomial, and a peak at 6.28° 2θ to model the scattering from the Kapton capillary and any amorphous component.

The final refinement of 119 variables using 22 536 observations and 60 restraints yielded the residuals R wp = 0.0809 and GOF = 1.74. The largest peak (0.32 Å from C19) and hole (1.87 Å from Cl2) in the difference Fourier map were 0.56(13) and −0.48(13) eÅ−3, respectively. The largest errors in the difference plot (Figure 2) are in the shapes and intensities of some of the strong low-angle peaks, and may indicate subtle changes in the specimen during the measurement.

Figure 2. The Rietveld plot for the refinement of haloxon. The blue crosses represent the observed data points, and the green line is the calculated pattern. The cyan curve is the normalized error plot. The vertical scale has been multiplied by a factor of 20× for 2θ >120°. The row of blue tick marks indicates the calculated reflection positions.

The crystal structure was optimized using VASP (Kresse and Furthmüller, Reference Kresse and Furthmüller1996) (fixed experimental unit cell) through the MedeA graphical interface (Materials Design, 2016). The calculation was carried out on 16 2.4 GHz processors (each with 4 GB RAM) of a 64-processor HP Proliant DL580 Generation 7 Linux cluster at North Central College. The calculation used the GGA-PBE functional, a plane wave cutoff energy of 400.0 eV, and a k-point spacing of 0.5 Å−1 leading to a 2 × 2 × 1 mesh, and took ~21 h. A single-point density functional calculation (fixed experimental cell) and population analysis were carried out using CRYSTAL17 (Dovesi et al., Reference Dovesi, Erba, Orlando, Zicovich-Wilson, Civalleri, Maschio, Rerat, Casassa, Baima Salustro and Kirtman2018). The basis sets for the H, C, and O atoms in the calculation were those of Gatti et al. (Reference Gatti, Saunders and Roetti1994), and those for P and Cl were that of Peintinger et al. (Reference Peintinger, Vilela Oliveira and Bredow2013). The calculations were run on a 3.5 GHz PC using 8 k-points and the B3LYP functional, and took ~2.1 h.

III. RESULTS AND DISCUSSION

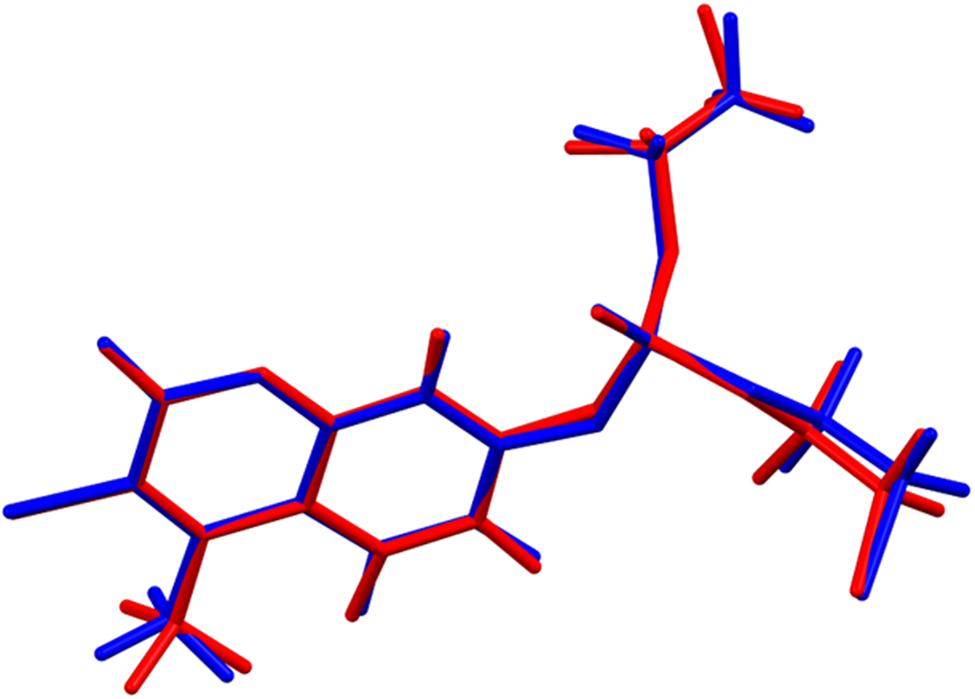

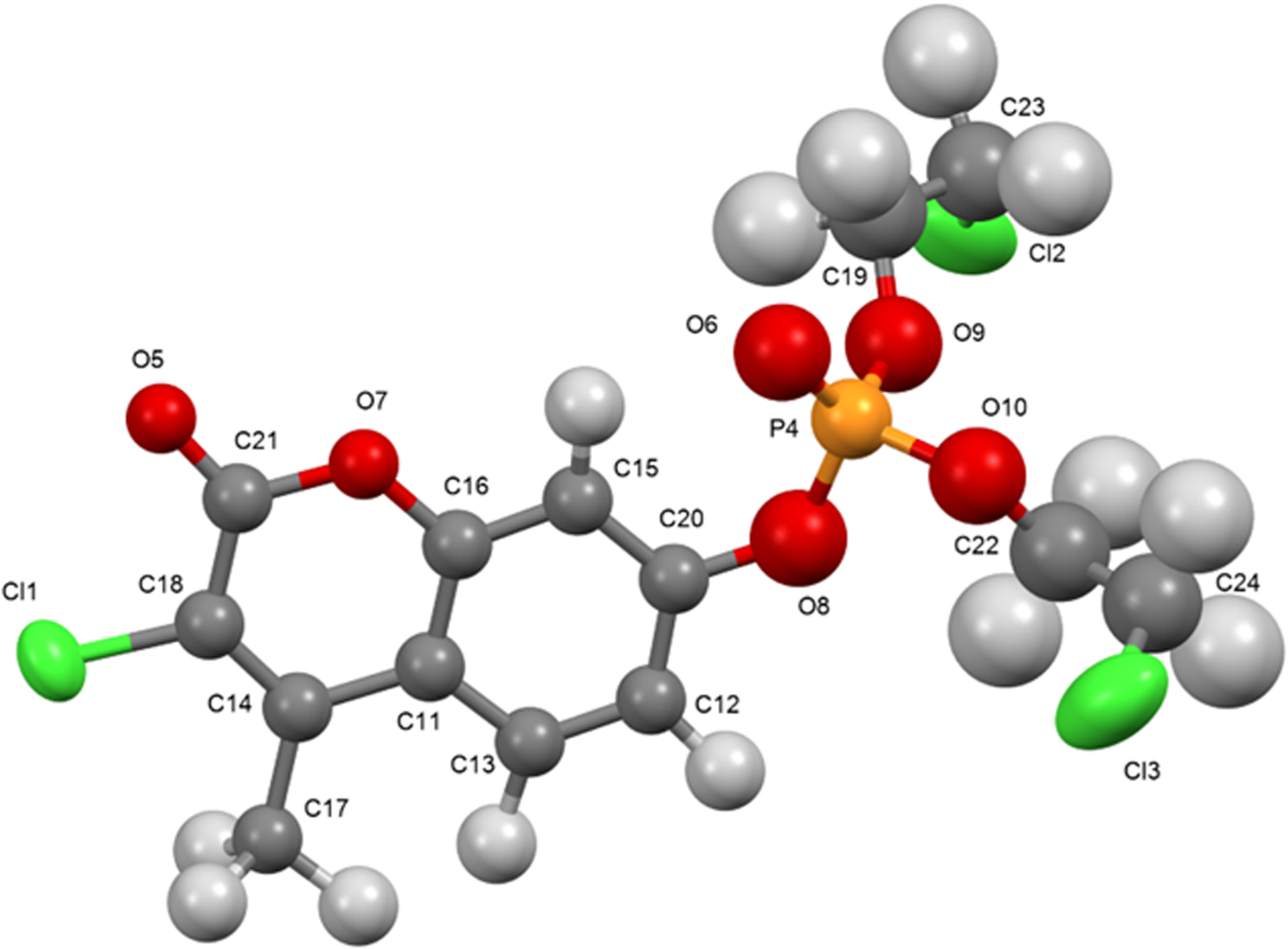

The root-mean-square (rms) Cartesian displacement between the Rietveld-refined and DFT-optimized structures of the haloxon molecule is 0.135 Å (Figure 3); the maximum difference is 0.353 Å at C24. The excellent agreement provides evidence that the refined structure is correct (van de Streek and Neumann, Reference van de Streek and Neumann2014). This discussion concentrates on the DFT-optimized structure. The asymmetric unit (with atom numbering) is illustrated in Figure 4. The best view of the crystal structure is down the b-axis (Figure 5). The structure consists of discrete molecules. The mean planes of the fused ring systems are approximately (0–11) and (011). The rings form staggered stacks perpendicular to these planes.

Figure 3. Comparison of the Rietveld-refined (red) and VASP-optimized (blue) structures of haloxon. The rms Cartesian displacement is 0.135 Å. Image generated using Mercury (Macrae et al., Reference Macrae, Sovago, Cottrell, Galek, McCabe, Pidcock, Platings, Shields, Stevens, Towler and Wood2020).

Figure 4. The asymmetric unit of haloxon, with the atom numbering. The atoms are represented by 50% probability spheroids/ellipsoids. Image generated using Mercury (Macrae et al., Reference Macrae, Sovago, Cottrell, Galek, McCabe, Pidcock, Platings, Shields, Stevens, Towler and Wood2020).

Figure 5. The crystal structure of haloxon, viewed down the b-axis. Image generated using Diamond (Crystal Impact, 2022).

All of the bond distances, bond angles, and torsion angles fall within the normal ranges indicated by a Mercury/Mogul Geometry Check (Macrae et al., Reference Macrae, Sovago, Cottrell, Galek, McCabe, Pidcock, Platings, Shields, Stevens, Towler and Wood2020). Quantum chemical geometry optimization of the haloxon cation (DFT/B3LYP/6-31G*/water) using Spartan ‘18 (Wavefunction, 2020) indicated that the observed conformation is 3.6 kcal mol−1 higher in energy than the local minimum. The major differences (rms Cartesian displacement = 0.564 Å) occur at the chloromethyl and methyl groups. A conformational analysis (MMFF force field) indicates that the minimum-energy conformation is 1.5 kcal mol−1 lower in energy. The major difference is that the phosphate ester group is rotated by ~180°; the molecule is thus fairly flexible. Although weak, the intermolecular interactions are important in determining the solid-state conformation.

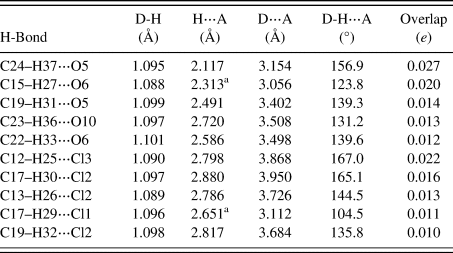

Analysis of the contributions to the total crystal energy of the structure using the Forcite module of Materials Studio (Dassault, 2021) suggests that the intramolecular deformation energy is dominated by angle deformation terms, as might be expected in a molecule containing a fused ring system. The intermolecular energy is dominated by electrostatic attractions, which in this force field analysis also include hydrogen bonds. The hydrogen bonds are better analyzed using the results of the DFT calculation. There are no traditional hydrogen bonds in the structure (Table I), but several C–H⋯O and C–H⋯Cl hydrogen bonds contribute to the crystal energy.

TABLE I. Hydrogen bonds (CRYSTAL17) in haloxon

a Intramolecular.

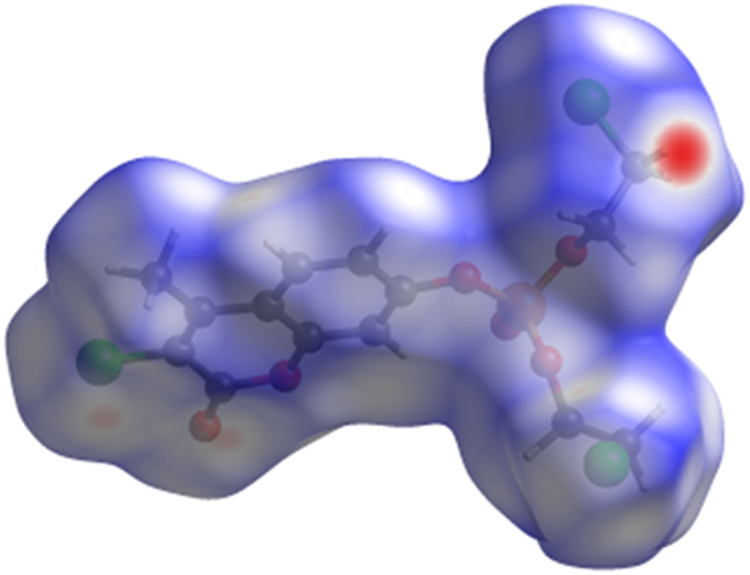

The volume enclosed by the Hirshfeld surface of haloxon (Figure 6; Hirshfeld, Reference Hirshfeld1977; Turner et al., Reference Turner, McKinnon, Wolff, Grimwood, Spackman, Jayatilaka and Spackman2017) is 421.82 Å3, 98.09% of 1/4 the unit cell volume. The packing density is thus fairly typical. The only significant-close contacts (red in Figure 6) involve the hydrogen bonds. The volume/non-hydrogen atom is 17.9 Å3.

Figure 6. The Hirshfeld surface of haloxon. Intermolecular contacts longer than the sums of the van der Waals radii are colored blue, and contacts shorter than the sums of the radii are colored red. Contacts equal to the sums of radii are white.

The Bravais–Friedel–Donnay–Harker (Bravais, Reference Bravais1866; Friedel, Reference Friedel1907; Donnay and Harker, Reference Donnay and Harker1937) morphology suggests that we might expect blocky morphology for haloxon, with perhaps {100} as major faces. A second-order spherical harmonic model was included in the refinement. The texture index was 1.003(0), indicating that preferred orientation was slight in this rotated capillary specimen. The powder pattern of haloxon from this synchrotron dataset has been submitted to ICDD for inclusion in the Powder Diffraction File.

IV. DEPOSITED DATA

The Crystallographic Information Framework (CIF) files containing the results of the Rietveld refinement (including the raw data) and the DFT geometry optimization were deposited with the ICDD. The data can be requested at pdj@icdd.com.

ACKNOWLEDGEMENTS

The use of the Advanced Photon Source at Argonne National Laboratory was supported by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357. This work was partially supported by the International Centre for Diffraction Data. We thank Lynn Ribaud and Saul Lapidus for their assistance in the data collection.

CONFLICT OF INTEREST

The authors have no conflict of interest to declare.