INTRODUCTION

The seismic event that hit the Emilian plain in 2012 caused extensive damage to the region’s historical and artistic heritage (Decanini et al. Reference Decanini, Liberatore, Liberatore and Sorrentino2012; Dolce et al. Reference Dolce, Nicoletti, Ammirati, Bianconi, Filippi, Gorini, Marcucci, Palma, Zambonelli, Lavecchia, de Nardis, Brozzetti, Boncio, Cirillo, Romano, Costa, Gallo, Tiberi, Zoppé, Suhadolc, Ponziani and Formica2012; Indirli et al. Reference Indirli, Marghella and Marzo2012; Andreini et al. Reference Andreini, De Falco, Giresini and Sassu2014; Graziani et al. Reference Graziani, Bernardini, Castellano, Del Mese, Ercolani, Rossi, Tertulliani and Vecchi2015). The condition of the UNESCO World Heritage Site of Modena, and in particular the cathedral vaults, was alarming (Baraccani et al. Reference Baraccani, Palermo, Silvestri, Gasparini, Trombetti and Silvestri2015; Baraccani et al. Reference Baraccani, Gasparini, Palermo, Silvestri and Trombetti2017; Baraccani et al. Reference Baraccani, Palermo, Trombetti, DeJong, Aguilar, Torrealva, Moreira, Pando and Ramos2019). An anti-seismic reinforcement project was planned with the aim of determining the vulnerability of the cathedral and analyzing the damage suffered in the past. Since historical documents leave unclear issues regarding the chronology of the construction phases, absolute dating of building materials represents the only way to obtain reliable data. The study and dating of the building materials of the cathedral were previously carried out by analyzing other parts of the building (Lubritto et al. Reference Lubritto, Caroselli, Lugli, Marzaioli, Nonni, Marchetti Dori and Terrasi2015; Panzeri et al. Reference Panzeri, Caroselli, Galli, Lugli, Martini and Sibilia2019).

The construction phases of the Modena cathedral are a subject for discussion (Silvestri Reference Silvestri2013), but the vaults were progressively added to the main framework during the 15th century (Dondi Reference Dondi1896; Baracchi and Giovannini Reference Baracchi and Giovannini1988; Baracchi Reference Baracchi1993).

Our survey carried out on the extrados (upper/convex surface) of the vault revealed unexpected data: the vaults were built using either a gypsum or a lime binder and carry the scars of several earthquakes, repaired using different binders, which resulted in a complex patchwork of lime and gypsum mortars (Figure 1).

Figure 1 Modena Cathedral: vaults extrados plan with sampling points of the vaults S9 and N8. (Please see electronic version for color figures.)

The main objectives of the project were to date the original vaults’ construction, restoring portions built after the main earthquakes and correlating them to the earthquake chronology deduced from the historic catalog (Rovida et al. Reference Rovida, Locati, Camassi, Lolli and Gasperini2016). Several damaging, moment magnitude (Mw) and high peak ground acceleration (PGA) value earthquakes occurred after the vaults were constructed, with epicenters located in various areas during the following years: 1474 (Modena, Mw 4.30, PGA 0.232), 1501 (Emilian Apennines, Mw 5.82, PGA 0.187), 1505 (Bologna, Mw 5.41, PGA 0.055), 1584 (Tuscan-Emilian Apennines, Mw 5.99, PGA 0.025), 1586 (Spilamberto, Mw 4.53, PGA 0.091), 1660 (Modena, Mw 4.25, PGA 0.172), 1671 (Rubiera, Mw 5.23, PGA 0.110), 1688 (Romagna, Mw 5.85, PGA 0.028), 1828 (Staffora Valley. Mw 5.55, PGA 0.012), and 1850 (Modena, MW 4.53, PGA 0.144).

We applied an integrated approach using three different techniques to date the construction of the vaults’ repair phases: radiocarbon (14C) of mortars by sequential dissolution (Lindroos et al. Reference Lindroos, Ringbom, Heinemeier, Hodgins, Sonck-Koota, Sjöberg, Lancaste, Kaisti, Brock, Ranta, Caroselli and Lugli2018), optically stimulated luminescence (OSL) of the mortar sand aggregate, and thermoluminescence (TL) of the bricks bound by the analyzed mortars (Panzeri et al. Reference Panzeri, Caroselli, Galli, Lugli, Martini and Sibilia2019). This paper reviews the preliminary results from two vaults (Figure 1).

MATERIALS AND METHODS

Petrographic Analysis

The mortar samples were consolidated with epoxy resin in order to obtain thin sections for optical microscope observations. The UNI-Normal 11176 document was used as reference for the petrographic characterization of mortar in order to determine the aggregate composition, the grain size and the texture, the type of binder, the presence of underburned and over-burned limestone fragments and “lime lumps” (Nawrocka et al. Reference Nawrocka, Michniewicz, Pawlyta and Pazdur2005; Elsen Reference Elsen2006; Pesce et al. Reference Pesce, Ball, Quarta and Calcagnile2012; Michalska and Pawlyta Reference Michalska and Pawlyta2019).

Image analysis of thin sections was also carried out to evaluate the binder/aggregate ratio, the aggregate grain size (Carò and Di Giulio Reference Carò and Di Giulio2004: Hayen et al. Reference Hayen, Van Strydonck, Fontaine, Boudin, Lindroos, Heinemeier, Ringbom, Michalska, Hajdas, Hueglin, Marzaioli, Terrasi, Passariello, Capano, Maspero, Panzeri, Galli, Artioli, Addis, Secco, Boaretto, Moreau, Guibert, Urbanova, Czernik, Goslar and Caroselli2017; Michalska et al. Reference Michalska, Czernik and Goslar2017), and for the identification of the supply sources of the aggregate (Lugli et al. Reference Lugli, Marchetti Dori, Fontana, Arribas, Critelli and Johnsson2007).

14C Dating of Mortars: Sequential Dissolution

Two lime mortar samples from the vaults N8 and S9 were prepared for 14C dating following the sequential dissolution methodology. This procedure is fundamental in order to identify the contaminants that could occur in historic mortar. Underburned limestone fragments and carbonate aggregate could contaminate the 14C dating results and provide older ages, while a rejuvenation effect can be induced by the presence of secondary calcite within the calcareous binder, produced by later exchange with the atmospheric CO2. The dissolution method is described in detail in Lindroos et al. (Reference Lindroos, Heinemeier, Ringbom, Braskén and Sveinbjörnsdóttir2007). The bulk mortars were carefully crushed and dry sieved into decreasing grain-size fractions ranging between 75–500 µm. The grain-size fraction <100 μm was subsequently wet sieved and, since the dissolution time decreases with grain size, a narrow grain-size window (46–75 µm) was isolated and dried for 14C dating. After the mechanical separation, cathodoluminescence (CL, see e.g. Marshall Reference Marshall1988) analysis was carried out to identify the possible contaminants from limestone grains added in the aggregate sand and the alkalinity test with phenolphthalein (1%) dissolved in alcohol was performed on the coarser grain size fraction (301–500 μm). An alkaline reaction may indicate the presence of calcium hydroxide, which will react with the modern CO2 in the atmosphere, leading to a younger age. Therefore, alkaline samples are rejected for AMS dating.

The chemical separation was done in a vacuum system with 85% phosphoric acid in order to release CO2 for dating. The mortar sample S9-4M was analyzed in two CO2 fractions, while the 14C dating of the sample N8-1M was performed only on a soft lime lump (Pesce et al. Reference Pesce, Ball, Quarta and Calcagnile2012) crushed before hydrolysis and analyzed in two CO2 fractions.

The vials containing CO2 gas were submitted to the AMS 14C Dating Centre at Aarhus University and ETH Zurich. The conventional 14C dates were calibrated using OxCal v4.3.2 program (Bronk Ramsey Reference Bronk Ramsey2017).

All calibrated results are reported at the 95% confidence level (2 sigma).

OSL Dating of Mortars

OSL dating was performed on the same lime mortar selected for 14C dating: N8-1M and S9-4M. Mortars were sampled using a chisel and hammer under dim red light and they were put into a black plastic bag. In the laboratory, the surface layer was removed and the inner part was used for luminescence analysis. All the laboratory procedures were carried out under dim red light. The measurements were performed using the quartz inclusion technique (180–250 µm; Fleming 1970) with the single aliquot regenerative (SAR) protocol (Murray and Wintle Reference Murray and Wintle2000). Both multi-grain (MG) and single grain (SG) techniques were applied. OSL measurement were performed with TL-DA-20 Risø reader and photons were detected by a bialkali photomultiplier tube (EMI 9235QB) coupled to a 7.5 mm Hoya U-340 filter. More details on OSL application to mortars are discussed elsewhere (Galbraith et al. Reference Galbraith, Roberts, Laslett, Yoshida and Olley1999; Zacharias et al. Reference Zacharias, Mauz and Michael2002; Stella et al. Reference Stella, Almeida, Basilio, Pasquale, Dinis, Almeida and Gueli2018; Panzeri et al. Reference Panzeri, Cantù, Martini and Sibilia2017; Urbanovà et al. Reference Urbanová, Michel, Cantin, Guibert, Lanos, Dufresne and Garnier2018; Panzeri et al. Reference Panzeri, Caroselli, Galli, Lugli, Martini and Sibilia2019, Reference Panzeri, Maspero, Galli, Sibilia and Martini2020, in this volume and other references therein).

TL Dating of Bricks

We analyzed two brick fragments for each of the two vaults (N8-1L, N8-2L, S9-1L, S9-4L). The outer layer of the brick fragments was removed in the laboratory. The polymineral fine grain technique was used and the multiple aliquot additive dose (MAAD) protocol was applied (Aitken Reference Aitken1985). TL dating was performed using an in-house system equipped with a photomultiplier tube (EMI 9235QB) coupled to a blue filter (Corning BG12).

Dose Rate Determination

For dose-rate determination, 238U and 232Th concentrations were derived from alpha counting using ZnS (Ag) scintillator discs and assuming a Th/U concentration ratio equal to 3.16 (Aitken Reference Aitken1985). The contribution due to 40K content was obtained from the total concentration of K measured by flame photometry. The attenuation of the beta particles in coarse grain quartz used for mortar dating was taken into account (Bell Reference Bell1979). For dose rate calculations, an amount of water corresponding to 20 ± 5% of saturation was assumed. The external dose rate was evaluated on site with an ionization chamber for environmental dosimetry, to avoid the problem of inhomogeneity of the building materials around the samples.

Parameters used for age determination are reported in Table 1.

Table 1 Parameters used for age determination of OSL and TL dating.

RESULTS AND DISCUSSION

Petrographic Analysis of Lime Mortars

The sample S9-4M is a non-hydraulic lime-based mortar with underburned particles up to 3 mm in size. Lime lumps are scarce and small (< 1 mm). The binder/aggregate ratio is 2.2. The aggregate grain size is very fine to fine sand and moderately well sorted. The sand composition is: micritic limestone and sparry calcite, quartz, feldspar, siltstone, rare fossil fragments, serpentinite fragments, biotite, iron oxide and/or hydroxide. The provenance is probably from the Panaro River (Lugli et al. Reference Lugli, Marchetti Dori, Fontana, Arribas, Critelli and Johnsson2007; Figure 2a).

Figure 2 (a) photomicrograph in crossed polars of the mortar sample S9-4M. F: fossil fragments, L: lime lump, M: micritic limestone, S: sparry calcite, U: underburned fragment; (b) photomicrograph in crossed polars of the mortar sample N8-1M. M: micritic limestone, Q: quartz, S: sparry calcite, U: underburned fragment.

The sample N8-1M is a non-hydraulic lime-based mortar with underburned particles up to 4 mm in size. Lime lumps are frequent and up to 2 mm across. They are soft and white and of the type that Pesce et al. (Reference Pesce, Ball, Quarta and Calcagnile2012) and Lindroos et al. (Reference Lindroos, Ringbom, Heinemeier, Hodgins, Sonck-Koota, Sjöberg, Lancaste, Kaisti, Brock, Ranta, Caroselli and Lugli2018) recommend for dating. The binder/aggregate ratio is 1.3. The aggregate grain size is very fine to medium sand and moderately well sorted. The sand composition is as follows: micritic limestone and sparry calcite, quartz, feldspar, siltstone, fossil fragments, serpentinite fragments, biotite, iron oxide and/or hydroxide, glauconite. The provenance is probably from the Panaro River (Lugli et al. Reference Lugli, Marchetti Dori, Fontana, Arribas, Critelli and Johnsson2007; Figure 2b).

14C Dating

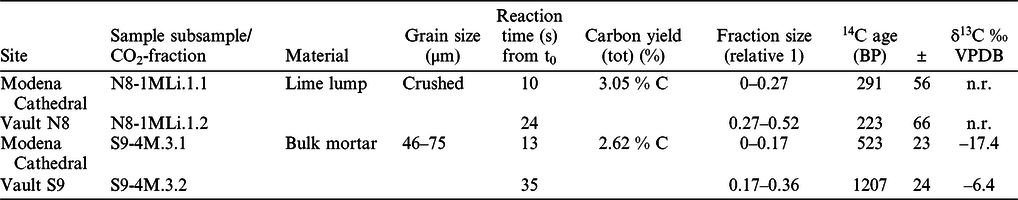

The 14C dating results are listed in Table 2. The alkalinity test reveals that the samples result with a low alkalinity and therefore are suitable to be dated. CL inspection was performed on the selected grain size fraction (46–75 μm) after sieving and on the same powder after sequential dissolution of the sample S9-4M. The powder before dissolution contained carbonate contaminants and part of silicic aggregates, while after the dissolution, the aggregate was only visible since the binder and the carbonate contaminants were dissolved.

Table 2 Hydrolysis data, 14C results and δ13C values for the dated samples.

Carbon yield (tot) (%) = total carbon yield after about 1-hr dissolution.

n.r. = not reported.

The 14C profile of the sample S9-4M is shown in Figure 3a. It displays an increasing slope, characterized by rapidly dissolving mortar binder and slowly dissolving contaminants. The 14C age of the first CO2 fraction (523 ± 23 BP) of the sample S9-4M gave a calibrated calendar age 1328–1341 AD (5.2%) and 1396–1439 AD (90.2%), matching with the age provided by historical documents (1404–1433 AD, Baracchi and Giovannini Reference Baracchi and Giovannini1988, Figure 3b). It follows that despite the presence of carbonate grains in the aggregate and unburned limestone fragments, the sequential dissolution procedure succeeded in eliminating the possible contaminant effect, which would have given an older age than that provided by documents.

Figure 3 (a) 14C age profile of the samples S9-4M. F is the fraction of reactive material transformed from carbonate to carbon dioxide. The horizontal gray bars along the x-axis denote the size of the extracted CO2 fractions relative to the total carbon yield (=1); (b) calibrated result of the bulk mortar S9-4M, 1328–1341 (5.2%) and 1396–1439 (90.2%). The date coincides with the historical documents age (1404–1433) marked as a green rectangle; (c) 14C age profile of sample N8-1M. F is the fraction of reactive material transformed from carbonate to carbon dioxide. The horizontal gray bars along the x-axis denote the size of the extracted CO2 fractions relative to the total carbon yield (=1); (d) calibrated result of the lime lump N8-1MLi, 1487–1681 (79.2%), 1739–1743 (0.4%), 1763–1802 (12.4%), >1938 (3.5%). The dates are younger than the historical documents age (1433–1454) marked as a green rectangle. Several earthquakes, marked as red vertical lines, overlap with the 14C age, indicating later repair after significant seismic damage.

As show in Figure 3c, the 14C profile of the sample N8-1MLi reveals that the dates seem to be inverted i.e. fraction 1 produced an age slightly older than fraction 2. However, CO2 fractions 1 and 2 have overlapping ages and according to the Criterion I (Heinemeier et al. Reference Heinemeier, Ringbom, Lindroos and Sveinbjörnsdóttir2010; Ringbom et al. Reference Ringbom, Heinemeier, Lindroos and Brock2011; Lindroos et al. Reference Lindroos, Ringbom, Heinemeier, Hodgins, Sonck-Koota, Sjöberg, Lancaste, Kaisti, Brock, Ranta, Caroselli and Lugli2018) if the first two CO2 fractions agree within the given error margins (and so the ages are overlapping), it demonstrates an absence of contamination and is considered a reliable result. In this case the combined calibration is assumed to give the true age of the mortar. The combined age of the CO2 fractions 1 and 2 yields the 14C age 263 ± 43 BP corresponding with a calibrated calendar age 1487–1681 AD (79.2%), 1739–1743 AD (0.4%), 1763–1802 AD (12.4%), >1938 AD (3.5%), younger than the documented construction age (1433–1454 AD, Baracchi and Giovannini Reference Baracchi and Giovannini1988, Figure 3d), indicating a later re-construction after significant damage. The catalog of earthquakes reports several seismic events that occurred after the vaults’ construction. Four damaging earthquakes in 1474, 1501, 1660, and 1671 overlap with the 14C dating, and they may be the cause of the reparation works, which are not documented in the historical records. In Table 3 we report the calibrated ages and their interpretation in comparison with the TL and OSL dating results.

Table 3 Results of absolute dating of the vaults S9 and N8.

OSL Dating

The OSL dating results are listed in Table 3. Mortar OSL dating gives results incompatible with the construction phases. The OSL ages obtained are much older than expected, regardless of the techniques used, indicating a poor and uncomplete bleaching (Sawakuchi et al. Reference Sawakuchi, Blair, DeWitt, Faleiros, Hyppolito and Guedes2011).

TL Dating

Table 3 lists the TL dating results. They provide information about the construction timing and restoration of the vaults, especially for those cases where gypsum binder was used. In these cases, the TL of bricks is the only possible dating technique. The results from vault S9 suggest that the bricks were manufactured in the 13th century (1245 ± 65 and 1235 ± 80, 1250 ± 80) and were reused later in both lime and gypsum portions of the vault.

The dates obtained from the vault N8 reveal that the lime portion of the vault was built with reused bricks from the 11th century, whereas bricks from the gypsum portion are younger (1740 ± 20, 1740 ± 30, 1805 ± 20) than the original construction phase of the vault. These data suggest that significant restoration works were carried out using gypsum mortar in the 18th and 19th centuries after the damaging earthquakes of 1671, 1688, 1828, and 1850.

CONCLUSION

A detailed survey of the 15th century vaults of the Modena medieval cathedral revealed a complex and unexpected structure consisting of different mortars used for multiple modifications.

The dating of mortars and bricks clarifies the chronology of the construction phases and the history of complex restorations, which are probably related to damage suffered after earthquakes.

Absolute dating results suggest that the vault S9 was originally built in 1404–1433 using lime mortar and older bricks, and was subsequently partially reconstructed with gypsum mortar and reused bricks. As gypsum mortar can not be directly dated, the reuse of older bricks does not allow us pinpoint the timing of the reconstruction and the possible triggering earthquake.

Two different restoration phases were recognized on the vault N8. A first repair by lime mortar, and reused bricks, was carried out immediately after the original construction, possibly as a result of the 1474, 1501, 1660, and 1671 earthquakes. A second intervention was then necessary to repair damage probably caused by the 1671, 1688, 1828, and 1850 earthquakes. As building materials for this second repair, new bricks were used, kept together by a gypsum mortar. The preliminary results of this study demonstrate that the vaults suffered much larger damage induced by earthquakes than previously assessed by mapping fracture and crack networks alone.