Introduction

Force feedback has been repeatedly proved to greatly improve the quality of a teleoperation scenario, for example, in the case of remote interaction (Yip et al., Reference Yip, Tavakoli and Howe2011). Indeed, beneficial applications of haptic interfaces to teleoperation can be found in several fields, from telesurgery (Guthart and Salisbury, Reference Guthart and Salisbury2000), to space (Imaida et al., Reference Imaida, Yokokohji, Doi, Oda and Yoshikawa2004) and underwater exploration (Khatib et al., Reference Khatib, Yeh, Brantner, Soe, Kim, Ganguly, Stuart, Wang, Cutkosky, Edsinger, Mullins, Barham, Voolstra, Salama, L’Hour and Creuze2016), as well as disaster response (Klamt et al., Reference Klamt, Rodriguez, Baccelliere, Chen, Chiaradia, Cichon, Gabardi, Guria, Holmquist, Kamedula, Karaoguz, Kashiri, Laurenzi, Lenz, Leonardis, Hoffman, Muratore, Pavlichenko, Porcini, Ren, Schilling, Schwarz, Solazzi, Felsberg, Frisoli, Gustmann, Jensfelt, Nordberg, Roßmann, Süss, Tsagarakis and Behnke2019a).

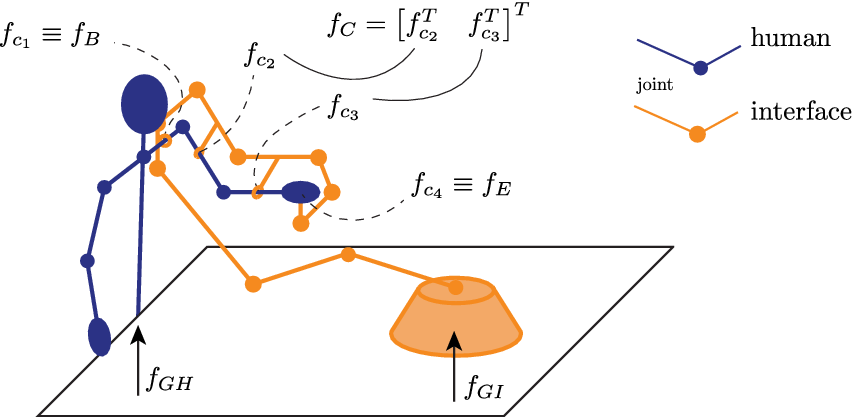

Numerous kinesthetic haptic displays (KHDs) have been proposed to deliver a feedback by acting in the domain of forces and displacements. Usually, these assume that the interaction with the remote environment occurs through one main contact interface, that is, the end effector, which can correspond to the palm/back of the hand or a fingertip of the operator and aim at rendering the wrench corresponding to the total of all the forces and torques exchanged through that contact interface. The way a KHD returns this wrench depends mainly on its kinematics and on its coupling with the operator, and the choice of both these elements can strongly influence the outcome of the teleoperation experience. The motivation behind this aspect can be understood with the help of the general user-interface scheme in Figure 1, where a KHD addressing the whole arm workspace is represented.

Figure 1. Scheme of generalized interaction between operator and kinesthetic haptic display. ![]() $ {f}_{c_i},i=1,\dots, 4 $ are the exchanged forces between the human and the interface at the contact points (assumed to be 4 for simplicity). The force exchanged through the first contact point

$ {f}_{c_i},i=1,\dots, 4 $ are the exchanged forces between the human and the interface at the contact points (assumed to be 4 for simplicity). The force exchanged through the first contact point ![]() $ {f}_{c_1} $ is also called

$ {f}_{c_1} $ is also called ![]() $ {f}_B $, whereas the last (

$ {f}_B $, whereas the last (![]() $ {f}_{c_4} $) is called

$ {f}_{c_4} $) is called ![]() $ {f}_E $. The second and third are then collected in the vector

$ {f}_E $. The second and third are then collected in the vector ![]() $ {f}_C={\left[{f}_{c_2}^T\;{f}_{c_3}^T\right]}^T $.

$ {f}_C={\left[{f}_{c_2}^T\;{f}_{c_3}^T\right]}^T $. ![]() $ {f}_{GH} $ and

$ {f}_{GH} $ and ![]() $ {f}_{GI} $ denote the contact forces with the ground of the human and the mechanism, respectively.

$ {f}_{GI} $ denote the contact forces with the ground of the human and the mechanism, respectively.

Traditionally, KHDs were implemented in the form of robotic system with a grounded base (G), to not burden the heavy weight of the system on the operator. With respect to the scheme of Figure 1, G-KHDs always present a ground reaction force ![]() $ {f}_{GI} $. More recently, thanks to the achievements in miniaturization and the use of lightweight materials, engineers started proposing wearable devices (W), that ditch the direct ground connection (

$ {f}_{GI} $. More recently, thanks to the achievements in miniaturization and the use of lightweight materials, engineers started proposing wearable devices (W), that ditch the direct ground connection (![]() $ {f}_{GI} $ absent) to improve portability of the device and mobility of the user. Please note that the following classification based on the device kinematics and its coupling with the user is just one of the possible topologies. Other classifications can be based, for example, on the used actuation, sensing method, and device control. We will not analyze these last, as they are not the focus of this work and have been already analyzed in existing literature, as Rosen and Ferguson (Reference Rosen and Ferguson2020) and Pacchierotti et al. (Reference Pacchierotti, Sinclair, Solazzi, Frisoli, Hayward and Prattichizzo2017).

$ {f}_{GI} $ absent) to improve portability of the device and mobility of the user. Please note that the following classification based on the device kinematics and its coupling with the user is just one of the possible topologies. Other classifications can be based, for example, on the used actuation, sensing method, and device control. We will not analyze these last, as they are not the focus of this work and have been already analyzed in existing literature, as Rosen and Ferguson (Reference Rosen and Ferguson2020) and Pacchierotti et al. (Reference Pacchierotti, Sinclair, Solazzi, Frisoli, Hayward and Prattichizzo2017).

The majority of existing systems, both grounded and wearable, are designed as exoskeletons that follow the motion of the operator, link by link, with kinematic joints accommodating for the human articulations. We will refer to these designs as “joint-space” (JS). An important characteristic of JS-KHD is that the kinematics of the human and the device are designed to be, as much as possible, equal. Following this assumption, the torque exerted by each joint of the interface is directly mapped on the corresponding joint of the human, through the various intermediate contact forces (see Figure 1), a hypothesis that heavily simplifies the control of the device. However, the hypothesis of matching kinematics is hardly achievable in reality. Indeed, human joints are not easy to reproduce with a mechanical counterpart. Although they are often approximated with pin joints, their motion is never really purely rotational, nor they are exactly the same across different people. Moreover, their alignment with the KHD joints tend to be always imperfect. Also, a rigid and precise attachment between the two is challenging, due to the compliance of human tissues. As a consequence, undesired relative movements and contact forces outside the image space of the expected wrench can occur. The majority of JS systems live with this problem, accepting the generation of such undesired forces, even if they downgrade the interface performance and the quality of the haptic rendering. Finally, a fundamental limitation of JS-KHD is that they cannot render a desired wrench ![]() $ {W}_d $ exactly, as they only render its projection onto the space of the joint torques, and transfer it to the operator through the actuatable contact forces.

$ {W}_d $ exactly, as they only render its projection onto the space of the joint torques, and transfer it to the operator through the actuatable contact forces.

Plenty of examples of grounded, joint-space displays (GJS-KHD) can be found in literature, involving one or more fingers (Agarwal et al., Reference Agarwal, Fox, Yun, O’Malley and Deshpande2015), wrist (Gupta et al. Reference Gupta, O’Malley, Patoglu and Burgar2008; Pehlivan et al. Reference Pehlivan, Lee and O’Malley2012; Martinez et al. Reference Martinez, Ng, Lu, Campagna and Celik2013; Andrikopoulos et al. Reference Andrikopoulos, Nikolakopoulos and Manesis2015; Pezent et al. Reference Pezent, Rose, Deshpande and O’Malley2017; Basteris et al. Reference Basteris, Contu, Plunkett, Kuah, Konczak, Chua and Masia2018; Lee et al. Reference Lee, Song and Yang2018; Pezent et al. Reference Pezent, Fani, Clark, Bianchi and O’Malley2019), and full-arm (Frisoli et al., Reference Frisoli, Rocchi, Marcheschi, Dettori, Salsedo and Bergamasco2005; Gupta and O’Malley, Reference Gupta and O’Malley2006; Mallwitz et al., Reference Mallwitz, Will, Teiwes and Kirchner2015; Barsotti et al., Reference Barsotti, Stroppa, Mastronicola, Marcheschi and Frisoli2018). Several are also the wearable, joint-space solutions (WJS-KHD), in which ![]() $ {f}_{GI} $ is not present, and therefore all the weight of the structure has to be compensated by the user (the interface represented in Figure 1 would start from the contact point corresponding to the force

$ {f}_{GI} $ is not present, and therefore all the weight of the structure has to be compensated by the user (the interface represented in Figure 1 would start from the contact point corresponding to the force ![]() $ {f}_{c_1}\equiv {f}_B $). Nonetheless, wearable devices tend to be lighter than the grounded ones, and, ideally, can be carried and used wherever desired. Similarly to GJS-KHDs, WJS-KHDs can involve different portions of the operator limb. There are some examples of full-arm exoskeletons for teleoperation (Letier et al., Reference Letier, Avraam, Veillerette, Horodinca, De Bartolomei, Schiele and Preumont2008; Schiele and Hirzinger, Reference Schiele and Hirzinger2011; Klamt et al., Reference Klamt, Schwarz, Lenz, Baccelliere, Buongiorno, Cichon, DiGuardo, Droeschel, Gabardi, Kamedula, Kashiri, Laurenzi, Leonardis, Muratore, Pavlichenko, Periyasamy, Rodriguez, Solazzi, Frisoli, Gustmann, Roßmann, Süss, Tsagarakis and Behnke2019b), and some of hand devices as well (Leonardis et al., Reference Leonardis, Barsotti, Loconsole, Solazzi, Troncossi, Mazzotti, Castelli, Procopio, Lamola, Chisari, Bergamasco and Frisoli2015; Gabardi et al., Reference Gabardi, Solazzi, Leonardis and Frisoli2018). On the contrary, there are relatively few wearable JS-KHDs for the wrist and, to the best of the author’s knowledge, almost all of them are designed for application in rehabilitation (Hope and McDaid Reference Hope and McDaid2017; Lambelet et al. Reference Lambelet, Lyu, Woolley, Gassert and Wenderoth2017; Buongiorno et al. Reference Buongiorno, Sotgiu, Leonardis, Marcheschi, Solazzi and Frisoli2018). Note that in both wearable and grounded JS categories, there are several examples of solutions in which particular attention has been put in designing structures that aims to reduce or even remove the macromisalignment issues, as Schiele and Van Der Helm (Reference Schiele and Van Der Helm2006), Sergi et al. (Reference Sergi, Accoto, Tagliamonte, Carpino, Galzerano and Guglielmelli2012), and Jarrassé and Morel (Reference Jarrassé and Morel2011). In Esmaeili et al. (Reference Esmaeili, Guy, Dailey, Burdet and Campolo2013), for example, a wrist exoskeleton with customizable joint parameters has been proposed for such purpose.

$ {f}_{c_1}\equiv {f}_B $). Nonetheless, wearable devices tend to be lighter than the grounded ones, and, ideally, can be carried and used wherever desired. Similarly to GJS-KHDs, WJS-KHDs can involve different portions of the operator limb. There are some examples of full-arm exoskeletons for teleoperation (Letier et al., Reference Letier, Avraam, Veillerette, Horodinca, De Bartolomei, Schiele and Preumont2008; Schiele and Hirzinger, Reference Schiele and Hirzinger2011; Klamt et al., Reference Klamt, Schwarz, Lenz, Baccelliere, Buongiorno, Cichon, DiGuardo, Droeschel, Gabardi, Kamedula, Kashiri, Laurenzi, Leonardis, Muratore, Pavlichenko, Periyasamy, Rodriguez, Solazzi, Frisoli, Gustmann, Roßmann, Süss, Tsagarakis and Behnke2019b), and some of hand devices as well (Leonardis et al., Reference Leonardis, Barsotti, Loconsole, Solazzi, Troncossi, Mazzotti, Castelli, Procopio, Lamola, Chisari, Bergamasco and Frisoli2015; Gabardi et al., Reference Gabardi, Solazzi, Leonardis and Frisoli2018). On the contrary, there are relatively few wearable JS-KHDs for the wrist and, to the best of the author’s knowledge, almost all of them are designed for application in rehabilitation (Hope and McDaid Reference Hope and McDaid2017; Lambelet et al. Reference Lambelet, Lyu, Woolley, Gassert and Wenderoth2017; Buongiorno et al. Reference Buongiorno, Sotgiu, Leonardis, Marcheschi, Solazzi and Frisoli2018). Note that in both wearable and grounded JS categories, there are several examples of solutions in which particular attention has been put in designing structures that aims to reduce or even remove the macromisalignment issues, as Schiele and Van Der Helm (Reference Schiele and Van Der Helm2006), Sergi et al. (Reference Sergi, Accoto, Tagliamonte, Carpino, Galzerano and Guglielmelli2012), and Jarrassé and Morel (Reference Jarrassé and Morel2011). In Esmaeili et al. (Reference Esmaeili, Guy, Dailey, Burdet and Campolo2013), for example, a wrist exoskeleton with customizable joint parameters has been proposed for such purpose.

An alternative to building an exoskeleton device is that of building a system with one main contact interface with the operator, exchanging forces with them not anymore at the level of joint torques, but at the level of the operational space (OS) devices. Differently from JS, OS interfaces bypass the joint alignment issue, acting directly at the end effector, therefore removing all the intermediate contact points and the associated forces ![]() $ {f}_C $. Furthermore, by avoiding to replicate the human kinematics, this class of devices has the potential to obtain a subspace of actuatable contact forces of full rank and to render an exact and complete wrench at the end effector, without intervening at the joint level. Grounded, operational space (GOS) devices are probably the most popular, and some of them are also available in the market. In this case,

$ {f}_C $. Furthermore, by avoiding to replicate the human kinematics, this class of devices has the potential to obtain a subspace of actuatable contact forces of full rank and to render an exact and complete wrench at the end effector, without intervening at the joint level. Grounded, operational space (GOS) devices are probably the most popular, and some of them are also available in the market. In this case, ![]() $ {f}_B $ is absent (and so the only contact force between human and device is

$ {f}_B $ is absent (and so the only contact force between human and device is ![]() $ {f}_E $ in Figure 1). Examples of small-workspace GOSs are the ones commercialized by Force DimensionFootnote 1 and 3D Systems,Footnote 2 or other platforms developed in research labs, as Frisoli et al. (Reference Frisoli, Sotgiu, Avizzano, Checcacci and Bergamasco2004) and Okamura et al. (Reference Okamura, Richard and Cutkosky2002), as well as the haptic interface of the DaVinci surgical robot from Intuitive.Footnote 3 An example of larger workspace can be found in Hulin et al. (Reference Hulin, Hertkorn, Kremer, Schätzle, Artigas, Sagardia, Zacharias and Preusche2011), where seven DoF robotic arms are used as haptic interfaces. An interesting solution can be found in Oblak et al. (Reference Oblak, Cikajlo and Matjacic2010), which proposes a system that can be configured to work for arm or wrist GOS rehabilitation.

$ {f}_E $ in Figure 1). Examples of small-workspace GOSs are the ones commercialized by Force DimensionFootnote 1 and 3D Systems,Footnote 2 or other platforms developed in research labs, as Frisoli et al. (Reference Frisoli, Sotgiu, Avizzano, Checcacci and Bergamasco2004) and Okamura et al. (Reference Okamura, Richard and Cutkosky2002), as well as the haptic interface of the DaVinci surgical robot from Intuitive.Footnote 3 An example of larger workspace can be found in Hulin et al. (Reference Hulin, Hertkorn, Kremer, Schätzle, Artigas, Sagardia, Zacharias and Preusche2011), where seven DoF robotic arms are used as haptic interfaces. An interesting solution can be found in Oblak et al. (Reference Oblak, Cikajlo and Matjacic2010), which proposes a system that can be configured to work for arm or wrist GOS rehabilitation.

Finally, there is the case of wearable OS devices (WOS-KHD), which try to combine the advantages of GOS-KHD with that of being portable. They present some contact forces at the base ![]() $ {f}_B $, while there are no

$ {f}_B $, while there are no ![]() $ {f}_{GI} $. Consequently, the interface weight compensation is demanded to the user, as for WJS. Furthermore, when rendering a given

$ {f}_{GI} $. Consequently, the interface weight compensation is demanded to the user, as for WJS. Furthermore, when rendering a given ![]() $ {f}_E $, also a

$ {f}_E $, also a ![]() $ {f}_B $ is inevitably generated at the base attachment. Nonetheless, as already said, wearable devices offer the undisputed advantage of portability. In the knowledge of the authors, WOS-KHDs are very few, with only few applications for the hand (Frisoli et al., Reference Frisoli, Simoncini, Bergamasco and Salsedo2007; Fontana et al., Reference Fontana, Dettori, Salsedo and Bergamasco2009; Iqbal et al., Reference Iqbal, Tsagarakis and Caldwell2015; Choi et al., Reference Choi, Hawkes, Christensen, Ploch and Follmer2016; Sarakoglou et al., Reference Sarakoglou, Brygo, Mazzanti, Hernandez, Caldwell and Tsagarakis2016), and none for arm and wrist. Table 1 reports the devices just listed, divided in the categories they belong to.

$ {f}_B $ is inevitably generated at the base attachment. Nonetheless, as already said, wearable devices offer the undisputed advantage of portability. In the knowledge of the authors, WOS-KHDs are very few, with only few applications for the hand (Frisoli et al., Reference Frisoli, Simoncini, Bergamasco and Salsedo2007; Fontana et al., Reference Fontana, Dettori, Salsedo and Bergamasco2009; Iqbal et al., Reference Iqbal, Tsagarakis and Caldwell2015; Choi et al., Reference Choi, Hawkes, Christensen, Ploch and Follmer2016; Sarakoglou et al., Reference Sarakoglou, Brygo, Mazzanti, Hernandez, Caldwell and Tsagarakis2016), and none for arm and wrist. Table 1 reports the devices just listed, divided in the categories they belong to.

Table 1. Classification of existing kinesthetic haptic displays and relative examples.

WOS solutions are less explored due to the difficulties in their design (in particular regarding the stability of their anchors to the user). Nonetheless, they are possibly the most interesting among all systems, because they combine several advantages. Indeed, wearabilty increases portability and facilitates the usage, since WOS-KHDs do not need a particular installation site or support.

Inspired by the advantages just described, this paper explores the possibility to design a new WOS for the wrist to be used in bilateral teleoperation. The idea is to design a light device that embraces the forearm and hand; they can measure the user’s wrist movements without obstructing them, and can render a force at the user palm coherent with the interaction sensed at the remote side. The result is a stand-alone WOS wrist KHD named “Wearable Delta” (W![]() $ \Delta $), shown in Figure 2. The device is anchored onto the forearm and uses a hybrid parallel–serial kinematic structure to render forces at the user’s hand, avoiding the problem of wrist axis joint misalignment. It also integrates a sensorized elbow brace and an inertial measurement unit (IMU) that, combined with the position sensors of the mechanism, can be used to calculate the user’s arm pose and their hand trajectory, which can in turn be used as input to the remote platform.

$ \Delta $), shown in Figure 2. The device is anchored onto the forearm and uses a hybrid parallel–serial kinematic structure to render forces at the user’s hand, avoiding the problem of wrist axis joint misalignment. It also integrates a sensorized elbow brace and an inertial measurement unit (IMU) that, combined with the position sensors of the mechanism, can be used to calculate the user’s arm pose and their hand trajectory, which can in turn be used as input to the remote platform.

Figure 2. Picture of the W![]() $ \Delta $ worn, complete with sensorized elbow brace and Myo armband for the arm trajectory tracking: (a) front and (b) back views.

$ \Delta $ worn, complete with sensorized elbow brace and Myo armband for the arm trajectory tracking: (a) front and (b) back views.

The paper is structured as follows: Section “Concept” introduced the concept of the W![]() $ \Delta $ and briefly summarizes its forward kinematics, exhaustively analyzed in Appendix A. The design specifications and implementation follow in Section “Design.” Section “Characterization” reports the mechanical characterization of the W

$ \Delta $ and briefly summarizes its forward kinematics, exhaustively analyzed in Appendix A. The design specifications and implementation follow in Section “Design.” Section “Characterization” reports the mechanical characterization of the W![]() $ \Delta $, and Section “Psychophysical Assessment” describes a performed psychometric assessment. Section “Teleoperation Framework” quickly summarizes the implemented bilateral teleoperation scheme (its complete analysis is reported in Appendix B), divided in the delivery of haptic feedback and the control of a remote robotic arm. Section “Experimental Validation” reports two example tasks to show general functionality, whereas Section “Usability Assessment” reports a preliminary usability assessment of the device and Section “Discussion, Limitations, and Future Developments” discusses the results and possible future improvements. Finally, in Section “Conclusion,” we conclude this manuscript with a critical summary of results and a description of future work.

$ \Delta $, and Section “Psychophysical Assessment” describes a performed psychometric assessment. Section “Teleoperation Framework” quickly summarizes the implemented bilateral teleoperation scheme (its complete analysis is reported in Appendix B), divided in the delivery of haptic feedback and the control of a remote robotic arm. Section “Experimental Validation” reports two example tasks to show general functionality, whereas Section “Usability Assessment” reports a preliminary usability assessment of the device and Section “Discussion, Limitations, and Future Developments” discusses the results and possible future improvements. Finally, in Section “Conclusion,” we conclude this manuscript with a critical summary of results and a description of future work.

Concept

The idea proposed in this work is to design a WOS-KHD attached to the forearm that acts directly on the palm for bilateral teleoperation applications. The wearable design is chosen to improve its portability, and the involvement of the final portion of the user arm only limits the device total weight and size. The choice of the OS option, instead, is motivated to improve the rendering precision of the desired wrench directly to its application point, in order to augment the haptic sensation and to make it as close as possible to the remote interaction. To avoid any possible kinematic mismatch issues, the device has six DoFs, since a frame fixed in the palm center performs both rotations and translations with respect to the forearm. The choice of the kinematic structure considers also user’s comfort. In particular, the chosen kinematics influence the weight distribution on the arm, and consequently the effort required for its compensation. A structure with a good weight distribution is preferable, for example, minimizing the distance of its center of mass with respect to the forearm longitudinal axis. Symmetric parallel kinematic chains can help matching this requirement. Some of the wrist devices listed in Section “Introduction” already implement parallel structures, from which take inspiration, as Andrikopoulos et al. (Reference Andrikopoulos, Nikolakopoulos and Manesis2015) and Lee et al. (Reference Lee, Song and Yang2018). The most interesting, and the one from which our device takes partial inspiration, is the RiceWrist. Presented in Gupta et al. (Reference Gupta, O’Malley, Patoglu and Burgar2008) and Gupta and O’Malley (Reference Gupta and O’Malley2006), it is a GJS rehabilitation device with four DoFs which uses a specific parallel mechanism, introduced in Lee and Shah (Reference Lee and Shah1988), with two rotational DOFs and one translational DoF. The design specifications of the RiceWrist, which is intended for rehabilitation, are such that the DoF arrangement and kinematics are thought to precisely guide the patient movements during the rehabilitation process. Nonetheless, a solution that foresees the explicit application of forces in function of trajectory errors and assistance-needed parameters has been proposed in Pehlivan et al. (Reference Pehlivan, Sergi and O’Malley2014). This indicates that haptics and rehabilitation devices can converge to similar control solutions, and mainly differ in the intended application and consequent design specifications. On this aspect, our wrist KHD is not conceived and designed to perform movement guidance, but rather to exert desired forces (coherent with a remote interaction) while allowing unconstrained user wrist motion and offering complete wearability.

The solution we propose is a structure resulting from the combination of both parallel and serial chains. It consists in the serial assembly of two quite common structures (see Figure 3a): a Delta robot structure (Clavel, Reference Clavel and Burckhardt1988) and a three-DoF gimbal. As shown in Figure 3a, the base of the Delta is conceived as a ring to fit the upper part of the forearm, with the actuators distributed around it. Ideally, when the hand is aligned with the forearm, the moving plate center coincides with the hand palm center. The Delta structure has three DoFs, all linear. Consequently, without additional joints, the palm’s rotations would be blocked, and so any wrist movement. The addition of a gimbal structure on the Delta’s plate (brown in Figure 3a) provides for the three missing rotational DoFs. The moving plate is reduced to just a ring used to connect each of the three legs universal joints to the external arc of the gimbal. The gimbal, then, uses the ring as a base, with its axes passing through the palm’s center. Its last link is fixed on the user’s backhand. Providing actuated joints also for the gimbal would mean adding more weight at the user’s arm tip, and a less compact solution, due to the space required by the actuators. Therefore, the idea is to leave the gimbal passive and to rely only on the Delta actuation, which will be controlled in torques for the haptic feedback. It follows that the device is able to provide linear forces only at the backhand anchor point. Please note that, with this kinematics, the device will automatically adapt to the user’s arm lengths. Indeed, while the gimbal enables the wrist rotation, the Delta structure automatically adapts to the user arm (especially along the forearm axis), as it opposes resistance to hand movements only when a force actuation is commanded. Furthermore, since the W![]() $ \Delta $ totally envelopes the user’s forearm and hand, its kinematics can be used to reconstruct the pose and velocities of the user’s arm. The study of the device kinematics and its integration with the humans is explained in detail in Appendix A. For the sake of brevity, we report here the final results. The forward kinematics of the user arm which exploits the W

$ \Delta $ totally envelopes the user’s forearm and hand, its kinematics can be used to reconstruct the pose and velocities of the user’s arm. The study of the device kinematics and its integration with the humans is explained in detail in Appendix A. For the sake of brevity, we report here the final results. The forward kinematics of the user arm which exploits the W![]() $ \Delta $ kinematics can be written as follows:

$ \Delta $ kinematics can be written as follows:

with ![]() $ {H}_{pm}^0 $ being the homogeneous transformation matrix of the palm frame

$ {H}_{pm}^0 $ being the homogeneous transformation matrix of the palm frame ![]() $ {\Psi}_{pm} $ with respect to word fixed frame

$ {\Psi}_{pm} $ with respect to word fixed frame ![]() $ {\Psi}_0 $.

$ {\Psi}_0 $.

Figure 3. Technical drawings and information of the W![]() $ \Delta $: (a) real device aspect with its different functional components highlighted; (b) tech drawings of the three main parts with highlighted lengths defined in the device; and (c) table summarizing the chosen values of the different dimensions interested in the design.

$ \Delta $: (a) real device aspect with its different functional components highlighted; (b) tech drawings of the three main parts with highlighted lengths defined in the device; and (c) table summarizing the chosen values of the different dimensions interested in the design.

Similarly, the system Jacobian, which allows to express the user palm twist as function of the arm and device joint velocities, is

$$ {T}_{pm}^{pm,0}={J_{\overline{H}}^{pm}}_{\left(6\times 10\right)}{\dot{q}}_{\overline{H}}=\left[{J_{H_{el}^0}^{pm}}_{\left(6\times 4\right)}\hskip0.5em {J_{W\Delta}^{pm}}_{\left(6\times 6\right)}\right]\left[\begin{array}{c}{\dot{q}}_{sh}\\ {}{\dot{q}}_{el}\\ {}{\dot{q}}_{W\Delta}\end{array}\right]. $$

$$ {T}_{pm}^{pm,0}={J_{\overline{H}}^{pm}}_{\left(6\times 10\right)}{\dot{q}}_{\overline{H}}=\left[{J_{H_{el}^0}^{pm}}_{\left(6\times 4\right)}\hskip0.5em {J_{W\Delta}^{pm}}_{\left(6\times 6\right)}\right]\left[\begin{array}{c}{\dot{q}}_{sh}\\ {}{\dot{q}}_{el}\\ {}{\dot{q}}_{W\Delta}\end{array}\right]. $$ For a detailed explanation of these formulas, please refer to Appendix A. In the next section, the design of the W![]() $ \Delta $ is reported.

$ \Delta $ is reported.

Design

This section presents the hardware design of the W![]() $ \Delta $. First, the description of the mechanical requirements and their accomplishment will be explained, followed by the description of the electronics, sensors, and actuators.

$ \Delta $. First, the description of the mechanical requirements and their accomplishment will be explained, followed by the description of the electronics, sensors, and actuators.

Mechanical Design

The technical drawing of the realized device are depicted in Figure 3. Since the W![]() $ \Delta $ has to be worn and attached to the forearm, the base of the Delta structure is designed as a ring (see Figure 3a,b). Referring to Figure 3a, the Delta base holds the actuators (cases in red) and the electronics (cases in dark gray). The forearm anchor is created linking the Delta base to an elbow brace (see Figures 2 and 3a for the elbow brace flange, depicted in dark green). The reason of this is to overcome to the stretch and slip of the skin. Embracing both arm and forearm and providing a rigid plate, the brace helps the W

$ \Delta $ has to be worn and attached to the forearm, the base of the Delta structure is designed as a ring (see Figure 3a,b). Referring to Figure 3a, the Delta base holds the actuators (cases in red) and the electronics (cases in dark gray). The forearm anchor is created linking the Delta base to an elbow brace (see Figures 2 and 3a for the elbow brace flange, depicted in dark green). The reason of this is to overcome to the stretch and slip of the skin. Embracing both arm and forearm and providing a rigid plate, the brace helps the W![]() $ \Delta $ to maintain a stable position despite the arm movements. The elbow encoder support (light green in Figure 3a) is attached to the brace flange. All these components are 3D printed in acrylonitrile butadiene styrene (ABS).

$ \Delta $ to maintain a stable position despite the arm movements. The elbow encoder support (light green in Figure 3a) is attached to the brace flange. All these components are 3D printed in acrylonitrile butadiene styrene (ABS).

The kinematics of each leg of the Delta is R–U–U. It has been realized with the rotational joint centered at the output shaft of each actuators, while an equivalent solution to the two universal joint has been created combining two rotational joints parallel to the actuator one and a four-bar mechanism with its joint axes normal to the previous (Figure 3). All the parts of the legs, in yellow in Figure 3a, are realized in stainless steel, whereas the joins (light blue) are in aluminum.

The moving plate of the Delta, that also works as base for the gimbal, is designed as a ring as well. It is supported by the last joints of the Delta legs, and in turn it houses the first joints of the gimbal, which is simply realized as a layering of rotating arcs. The most internal arc is designed to match with the hand support made for the commercial GoProFootnote 4 action camera called The Strap, Footnote 5 to which the user’s backhand is anchored. In this way, the user does not have to grasp any handle, as the interface is fixed at the back of its hand through straps (see the video linked in the footnote to easily understand the Strap functioning). The moving plate and the gimbal arcs (brown in Figure 3a) are 3D printed in ABS, while the gimbal passive joints (light blue) are realized in aluminum and house the gimbal encoders.

Actuators and Electronics

The motors used to actuate the three base joints of the Delta structures are Maxon Motor DCX 22 S + GPX22 12 Volt (83:1). This combination allows a maximum output continue torque of 1.2118 Nm at 1.65 A, and a peak torque of 8.964 Nm at 11.8 A. The chosen motor and gearbox have the efficiency of 85.2 and 74%, respectively, which is traduced in a very good backdrivability. This aspect is very important in a teleoperation scenarios, as the device should be as transparent as possible. To measure the rotation of the different joint axes, we use Austrian Microsystems 5054 position sensors, with a 16-bit resolution, corresponding to a resolution of ![]() $ \sim 0.011{}^{\circ} $ (

$ \sim 0.011{}^{\circ} $ (![]() $ =\sim 2\times {10}^{-4} $ rad). A total of seven encoders is present: three placed coaxially to the output motor shafts, three in the gimbals, and one aligned with the rotational axis of the elbow brace (see Figures 2 and 3a). As a consequence, the measurement resolution of the gimbal axis position (wrist rotation) is the same of the used encoders. The Delta plate position measurement resolution, instead, is not constant, as it depends on the Delta Jacobian (see (17)), and therefore on its dimensioning (explained hereafter) as well as its instantaneous joint position. Moreover, it also varies depending on the movement direction. Just to give an idea, considering the link length resulting from the following dimensioning, a standard user 1.8-m tall, and a straight wrist position (

$ =\sim 2\times {10}^{-4} $ rad). A total of seven encoders is present: three placed coaxially to the output motor shafts, three in the gimbals, and one aligned with the rotational axis of the elbow brace (see Figures 2 and 3a). As a consequence, the measurement resolution of the gimbal axis position (wrist rotation) is the same of the used encoders. The Delta plate position measurement resolution, instead, is not constant, as it depends on the Delta Jacobian (see (17)), and therefore on its dimensioning (explained hereafter) as well as its instantaneous joint position. Moreover, it also varies depending on the movement direction. Just to give an idea, considering the link length resulting from the following dimensioning, a standard user 1.8-m tall, and a straight wrist position (![]() $ {R}_{pm}^{b_{\Delta}}=I $ and

$ {R}_{pm}^{b_{\Delta}}=I $ and ![]() $ {p}_{p_{\Delta}}^{b_{\Delta}}=\left[\mathrm{0,0,0.2508}\right] $ m), we have a movement resolution of

$ {p}_{p_{\Delta}}^{b_{\Delta}}=\left[\mathrm{0,0,0.2508}\right] $ m), we have a movement resolution of ![]() $ \sim 0.3 $ mm along

$ \sim 0.3 $ mm along ![]() $ x $,

$ x $, ![]() $ \sim 0.12 $ mm along

$ \sim 0.12 $ mm along ![]() $ y $, and

$ y $, and ![]() $ \sim 0.05 $ mm along

$ \sim 0.05 $ mm along ![]() $ z $. Given the upper-arm length

$ z $. Given the upper-arm length ![]() $ {l}_u $ (Figure 17b), the elbow encoder is used to calculate the matrix

$ {l}_u $ (Figure 17b), the elbow encoder is used to calculate the matrix ![]() $ {H}_{el}^{sh} $ (see (21) in Section “Human Arm Kinematics” in Appendix A). The electronic boards used to read the encoders and control the motors are the ones presented in Della Santina et al. (Reference Della Santina, Piazza, Gasparri, Bonilla, Catalano, Grioli, Garabini and Bicchi2017).

$ {H}_{el}^{sh} $ (see (21) in Section “Human Arm Kinematics” in Appendix A). The electronic boards used to read the encoders and control the motors are the ones presented in Della Santina et al. (Reference Della Santina, Piazza, Gasparri, Bonilla, Catalano, Grioli, Garabini and Bicchi2017).

At the upper arm, a Myo armband is worn (see Figure 2). In the Myo armband, an IMU is used to extrapolate the rotation matrix of the homogeneous transformation matrix ![]() $ {H}_{sh}^0 $ (see Section “Human Arm Kinematics” in Appendix A). Moreover, the user holds a small trigger, embedding an eighth encoder, which can be used to control the end effector of the slave, for example, opening and closing a gripper.

$ {H}_{sh}^0 $ (see Section “Human Arm Kinematics” in Appendix A). Moreover, the user holds a small trigger, embedding an eighth encoder, which can be used to control the end effector of the slave, for example, opening and closing a gripper.

Device Dimensioning and Anthropomorphic Matching

The first general requirement for the W![]() $ \Delta $ is to be able to fit different arm sizes. From Winter (Reference Winter2009), the forearm length (from elbow to wrist) of an adult is the 14.5% of its height, while the hand length (from wrist to fingertips) is the 10.8%. These estimates are valid for both males and females. Then, covering users with height ranging

$ \Delta $ is to be able to fit different arm sizes. From Winter (Reference Winter2009), the forearm length (from elbow to wrist) of an adult is the 14.5% of its height, while the hand length (from wrist to fingertips) is the 10.8%. These estimates are valid for both males and females. Then, covering users with height ranging ![]() $ h=\left[\mathrm{1.6,2}\right] $ m, and adjusting the rounding up so to match also outliers, the forearm length ranges can be set to

$ h=\left[\mathrm{1.6,2}\right] $ m, and adjusting the rounding up so to match also outliers, the forearm length ranges can be set to ![]() $ {l}_f=\left[\mathrm{0.23,0.32}\right] $ m. The range distance between the wrist’s and the palm’s center (calculated as a third of wrist–fingertips length) can be set to

$ {l}_f=\left[\mathrm{0.23,0.32}\right] $ m. The range distance between the wrist’s and the palm’s center (calculated as a third of wrist–fingertips length) can be set to ![]() $ {l}_h=\left[\mathrm{0.06,0.08}\right] $ m. The workspace the device has to cover can be defined by combining the lengths

$ {l}_h=\left[\mathrm{0.06,0.08}\right] $ m. The workspace the device has to cover can be defined by combining the lengths ![]() $ {l}_f $ and

$ {l}_f $ and ![]() $ {l}_h $ and the range of motion shown in Table 2. It has to be considered also that the Delta base will be anchored on the forearm at a distance of

$ {l}_h $ and the range of motion shown in Table 2. It has to be considered also that the Delta base will be anchored on the forearm at a distance of ![]() $ \sim 0.05 $ m from the elbow. Finally, the desired workspace can be rounded up joining all the upper half sphere centered in

$ \sim 0.05 $ m from the elbow. Finally, the desired workspace can be rounded up joining all the upper half sphere centered in ![]() $ z={l}_f-0.05 $ m with a radius

$ z={l}_f-0.05 $ m with a radius ![]() $ \rho ={l}_h $, with

$ \rho ={l}_h $, with ![]() $ {l}_f=0.145h $ and

$ {l}_f=0.145h $ and ![]() $ {l}_h=\frac{0.108}{3}h $.

$ {l}_h=\frac{0.108}{3}h $.

Table 2. Range of motion (ROM) of human (a) forearm supination/pronation, (b) wrist abduction/adduction, and (c) wrist flexion/extension and length ranges of (d) forearm and (e) hand (wrist–palm’s center) human segments

All the lengths chosen in the design analysis that will follow are summarized in Figure 3c. The Delta structure parameters are basically four (see Figure 17a): (i) the radius of the base ![]() $ {r}_{b_{\Delta}} $; (ii) the radius of the moving plate

$ {r}_{b_{\Delta}} $; (ii) the radius of the moving plate ![]() $ {r}_{p_{\Delta}} $; (iii) the length

$ {r}_{p_{\Delta}} $; (iii) the length ![]() $ {L}_{\Delta} $ of the driver leg; and (iv) the length

$ {L}_{\Delta} $ of the driver leg; and (iv) the length ![]() $ {l}_{\Delta} $ of the driven leg.

$ {l}_{\Delta} $ of the driven leg.

The two radii are chosen in order to fit all the arm sizes. In particular, ![]() $ {r}_{b_{\Delta}} $ is influenced by the internal radius of the base circle

$ {r}_{b_{\Delta}} $ is influenced by the internal radius of the base circle ![]() $ {r}_{b_{\Delta},\mathit{\operatorname{int}}} $ (see the third drawing of Figure 3b), that should be large enough to fit any forearm. It has been set

$ {r}_{b_{\Delta},\mathit{\operatorname{int}}} $ (see the third drawing of Figure 3b), that should be large enough to fit any forearm. It has been set ![]() $ {r}_{b,\mathit{\operatorname{int}}}=0.07 $ m and, as consequence,

$ {r}_{b,\mathit{\operatorname{int}}}=0.07 $ m and, as consequence, ![]() $ {r}_{b_{\Delta}}=0.0975 $ m.

$ {r}_{b_{\Delta}}=0.0975 $ m.

On the other side, the gimbal has to be large enough to not interfere with the user’s wrist in all its movement. Considering this, the various radii of the gimbal have been set as (see top drawing of Figure 3b): ![]() $ {r}_{g,\mathit{\operatorname{ext}}}=0.1105 $ m,

$ {r}_{g,\mathit{\operatorname{ext}}}=0.1105 $ m, ![]() $ {r}_{g, mid}=0.09 $ m, and

$ {r}_{g, mid}=0.09 $ m, and ![]() $ {r}_{g,\mathit{\operatorname{int}}}=0.075 $ m. In this way, the hand should never touch the structure.

$ {r}_{g,\mathit{\operatorname{int}}}=0.075 $ m. In this way, the hand should never touch the structure.

Desiring a compact and easily foldable solution, we would like to have ![]() $ {r}_{p_{\Delta}}+{l}_{\Delta}={r}_{b_{\Delta}}+{L}_{\Delta} $, and in particular

$ {r}_{p_{\Delta}}+{l}_{\Delta}={r}_{b_{\Delta}}+{L}_{\Delta} $, and in particular ![]() $ {r}_{p_{\Delta}}={r}_{b_{\Delta}} $ and

$ {r}_{p_{\Delta}}={r}_{b_{\Delta}} $ and ![]() $ {l}_{\Delta}={L}_{\Delta} $. The first condition (

$ {l}_{\Delta}={L}_{\Delta} $. The first condition (![]() $ {r}_{p_{\Delta}}={r}_{b_{\Delta}} $) is achieved by shifting the plane in which the plate joint legs lie below the gimbal structure (an area never occupied by the user’s limb), with an offset of

$ {r}_{p_{\Delta}}={r}_{b_{\Delta}} $) is achieved by shifting the plane in which the plate joint legs lie below the gimbal structure (an area never occupied by the user’s limb), with an offset of ![]() $ {z}_{p, off}=0.025 $ m (see the gimbal drawing of Figure 3b).

$ {z}_{p, off}=0.025 $ m (see the gimbal drawing of Figure 3b).

Once ![]() $ {r}_{b_{\Delta}} $ and

$ {r}_{b_{\Delta}} $ and ![]() $ {r}_{p_{\Delta}} $ have been defined, we would like to define the lengths

$ {r}_{p_{\Delta}} $ have been defined, we would like to define the lengths ![]() $ {L}_{\Delta} $ and

$ {L}_{\Delta} $ and ![]() $ {l}_{\Delta} $ that (i) cover the desired workspace (the one spanned by the user palm center) in the one of W

$ {l}_{\Delta} $ that (i) cover the desired workspace (the one spanned by the user palm center) in the one of W![]() $ \Delta $ and (ii) assure the rendering of a continuous force of at least 5 N in any direction in any point of the desired workspace, considering a maximum continue current of 1.5 A (slightly lower than the one provided by data sheet in order to be sure to prevent motors’ damage). The possible combinations of

$ \Delta $ and (ii) assure the rendering of a continuous force of at least 5 N in any direction in any point of the desired workspace, considering a maximum continue current of 1.5 A (slightly lower than the one provided by data sheet in order to be sure to prevent motors’ damage). The possible combinations of ![]() $ {l}_{\Delta} $ and

$ {l}_{\Delta} $ and ![]() $ {L}_{\Delta} $ are explored through a recursive algorithm, which uses the inverse kinematic algorithm proposed in Williams (Reference Williams2016), considers also the offset

$ {L}_{\Delta} $ are explored through a recursive algorithm, which uses the inverse kinematic algorithm proposed in Williams (Reference Williams2016), considers also the offset ![]() $ {z}_{p, off} $, and varies the lengths

$ {z}_{p, off} $, and varies the lengths ![]() $ {L}_{\Delta} $ and

$ {L}_{\Delta} $ and ![]() $ {l}_{\Delta} $ with steps of 0.01 m. Finally, we choose a combination of

$ {l}_{\Delta} $ with steps of 0.01 m. Finally, we choose a combination of ![]() $ {L}_{\Delta} $ and

$ {L}_{\Delta} $ and ![]() $ {l}_{\Delta} $ that respect the second condition

$ {l}_{\Delta} $ that respect the second condition ![]() $ {l}_{\Delta}={L}_{\Delta} $, minimizing these two lengths:

$ {l}_{\Delta}={L}_{\Delta} $, minimizing these two lengths: ![]() $ {L}_{\Delta}={l}_{\Delta}=0.16 $ m. This choice reduces the envelope of the device as much as possible and, together with

$ {L}_{\Delta}={l}_{\Delta}=0.16 $ m. This choice reduces the envelope of the device as much as possible and, together with ![]() $ {r}_{p_{\Delta}}={r}_{b_{\Delta}} $, also the complete fold and compactness of the interface when not used. The width of the four-bar is set as

$ {r}_{p_{\Delta}}={r}_{b_{\Delta}} $, also the complete fold and compactness of the interface when not used. The width of the four-bar is set as ![]() $ {l}_{fb}=4.5 cm $. Table 3c summarizes all the values chosen for the different length of the W

$ {l}_{fb}=4.5 cm $. Table 3c summarizes all the values chosen for the different length of the W![]() $ \Delta $, whereas Table 4 summarizes the currents’ and motors’ torques from data sheet, as well as the corresponding assured force at

$ \Delta $, whereas Table 4 summarizes the currents’ and motors’ torques from data sheet, as well as the corresponding assured force at ![]() $ {\Psi}_{p_{\Delta}} $ and the torque at the user wrist in the nominal case

$ {\Psi}_{p_{\Delta}} $ and the torque at the user wrist in the nominal case ![]() $ {l}_h=0.7m $. Last column, instead, show the various data considering as maximum current the used value of 1.5 A, as explained just above.

$ {l}_h=0.7m $. Last column, instead, show the various data considering as maximum current the used value of 1.5 A, as explained just above.

Table 3. Device torques and forces summary. Columns divided in: (a) maximum continuous and (b) peak values (both from data sheet), and (c) used ones (through software saturation)

a This is the maximum force assured in all the interested workspace given the current saturation at 1.5 A, as specified in Section “Device Dimensioning and Anthropomorphic Matching.” This means that, depending on the device Jacobian (and thus on its joint position), it is also possible to reach greater values.

Table 4. The custom 7-point Likert scale questionnaire for the comparison of the two leader interfaces

The W![]() $ \Delta $ itself has a weight of 1.775 Kg, which grows to 2.224 Kg when considering the elbow brace (0.356 Kg) and the Myo armband (93 g). Figure 2 shows the actual final result mounted on a user’s arm.

$ \Delta $ itself has a weight of 1.775 Kg, which grows to 2.224 Kg when considering the elbow brace (0.356 Kg) and the Myo armband (93 g). Figure 2 shows the actual final result mounted on a user’s arm.

Characterization

A characterization of the device was performed, in order to match the actual force applied at the end effector with the desired one. The setup used for the W![]() $ \Delta $ characterization is depicted in Figure 4. The passive gimbal is unmounted from the W

$ \Delta $ characterization is depicted in Figure 4. The passive gimbal is unmounted from the W![]() $ \Delta $, consequently leaving only the Delta part, and replaced with a structure that functions as a flange between the Delta and the tool side of an ATI mini45-e F/T sensor.Footnote 6 The sensor is fixed to the end effector of a Panda robotic arm (Franka EmikaFootnote 7). The orientation of the Panda end effector is fixed so to be normal to the Delta base for the whole characterization. Its position is instead regulated so to match the desired position of the Delta moving plate center.

$ \Delta $, consequently leaving only the Delta part, and replaced with a structure that functions as a flange between the Delta and the tool side of an ATI mini45-e F/T sensor.Footnote 6 The sensor is fixed to the end effector of a Panda robotic arm (Franka EmikaFootnote 7). The orientation of the Panda end effector is fixed so to be normal to the Delta base for the whole characterization. Its position is instead regulated so to match the desired position of the Delta moving plate center.

Figure 4. Setup used for the characterization: the Delta has the base anchored to the table, and the plate attached to the Franka robot end effector through the ATI mini45-e F/T sensor. The Franka end-effector rotation is blocked so to be always look perpendicular to the table plane, while it is moved to pose the Delta plate in the interested position.

The characterization is performed as follows: 38 points lying on the edge and inside the expected users’ workspace are chosen. In each point, 144 directions on a unitary sphere are defined. All these directions define the versors ![]() $ {\hat{f}}_d\in {\mathrm{\mathbb{R}}}^3 $ of the desired forces. For each direction, a force is applied with intensity

$ {\hat{f}}_d\in {\mathrm{\mathbb{R}}}^3 $ of the desired forces. For each direction, a force is applied with intensity ![]() $ \left\Vert {f}_d\right\Vert $ going from 0 to 5 N and then back to 0 again, with steps of 1 N applied for 1.5 s. The resulting force is then

$ \left\Vert {f}_d\right\Vert $ going from 0 to 5 N and then back to 0 again, with steps of 1 N applied for 1.5 s. The resulting force is then

Through the Delta Jacobian ![]() $ {J}_{\Delta}\left({\theta}_{\Delta}\right) $ of (17), the desired torques

$ {J}_{\Delta}\left({\theta}_{\Delta}\right) $ of (17), the desired torques ![]() $ {\tau}_{\Delta, d} $ are calculated as

$ {\tau}_{\Delta, d} $ are calculated as

and the commanded currents to the motors ![]() $ {I}_c $ are calculated as

$ {I}_c $ are calculated as

being ![]() $ {C}_{T_m, ds} $ the current–torque actuator constant provided by the data sheet. For all the 38 chosen points, the commanded currents

$ {C}_{T_m, ds} $ the current–torque actuator constant provided by the data sheet. For all the 38 chosen points, the commanded currents ![]() $ {I}_{\Delta, c} $ to the motors, the motors’ positions

$ {I}_{\Delta, c} $ to the motors, the motors’ positions ![]() $ {\theta}_{\Delta} $, and the force measured by the F/T sensor

$ {\theta}_{\Delta} $, and the force measured by the F/T sensor ![]() $ {f}_m $ are registered and averaged in the time window of the application of all the desired forces. The average measured force

$ {f}_m $ are registered and averaged in the time window of the application of all the desired forces. The average measured force ![]() $ {\overline{f}}_m $ is then converted in measured torques

$ {\overline{f}}_m $ is then converted in measured torques ![]() $ {\tau}_{\Delta, m} $ through the Delta Jacobian:

$ {\tau}_{\Delta, m} $ through the Delta Jacobian:

Figure 5a–c shows the 3D plots of ![]() $ {\theta}_{\Delta}-{\tau}_{\Delta}-{I}_{\Delta} $. Projected on the

$ {\theta}_{\Delta}-{\tau}_{\Delta}-{I}_{\Delta} $. Projected on the ![]() $ {\tau}_{\Delta}-{I}_{\Delta} $ plane, the three characteristics can be well approximated by a straight line. The resulting

$ {\tau}_{\Delta}-{I}_{\Delta} $ plane, the three characteristics can be well approximated by a straight line. The resulting ![]() $ {\tau}_{\Delta}-{I}_{\Delta} $ relations for each motor are then approximated as

$ {\tau}_{\Delta}-{I}_{\Delta} $ relations for each motor are then approximated as

Furthermore, we performed a step response analysis. Figure 6 shows the results of the actuators response to a torque step ![]() $ {\tau}_s=1 $ N, with a control loop frequency of 400 Hz (cycle time

$ {\tau}_s=1 $ N, with a control loop frequency of 400 Hz (cycle time ![]() $ 2.5 $ ms).

$ 2.5 $ ms). ![]() $ {T}_n $ indicates the time required by the actuators to reach the

$ {T}_n $ indicates the time required by the actuators to reach the ![]() $ n\% $ of the step. The times reported in the figure are the slowest between all the motors. The Rise Time

$ n\% $ of the step. The times reported in the figure are the slowest between all the motors. The Rise Time ![]() $ {T}_r $, defined as the time required by the response to rise from 10 to 90% of its final value (

$ {T}_r $, defined as the time required by the response to rise from 10 to 90% of its final value (![]() $ {T}_r={T}_{90}-{T}_{10} $), is

$ {T}_r={T}_{90}-{T}_{10} $), is ![]() $ {T}_r=0.0614 $ s. Furthermore,

$ {T}_r=0.0614 $ s. Furthermore, ![]() $ {T}_s $ is the Settling Time and corresponds to

$ {T}_s $ is the Settling Time and corresponds to ![]() $ {T}_{95} $ and results

$ {T}_{95} $ and results ![]() $ {T}_s=0.0728 $ s. Considering the system of first order, we can then find the control loop bandwidth

$ {T}_s=0.0728 $ s. Considering the system of first order, we can then find the control loop bandwidth ![]() $ {\omega}_H $ as

$ {\omega}_H $ as

Figure 5. Results of the three motors’ characterization ([a] first, [b] second, and [c] third motors): position (rad)–torque (Nm)–current (A) fitting (brown points and colored surfaces), relative torque (Nm)–current (A) projection (gray points), and resulting first-order polynomial fitting (blue line) with relative equation.

Figure 6. Step response of the W![]() $ \Delta $ with reference torque

$ \Delta $ with reference torque ![]() $ {\tau}_s=1 $ N.

$ {\tau}_s=1 $ N. ![]() $ {T}_n $ indicates the time required by the actuators to reach the

$ {T}_n $ indicates the time required by the actuators to reach the ![]() $ n\% $ of the step. The times reported are the slowest between all the motors.

$ n\% $ of the step. The times reported are the slowest between all the motors. ![]() $ {T}_s $ is the Settling Time and corresponds to

$ {T}_s $ is the Settling Time and corresponds to ![]() $ {T}_{95} $.

$ {T}_{95} $. ![]() $ {T}_r $ is the Rise Time, defined as

$ {T}_r $ is the Rise Time, defined as ![]() $ {T}_r={T}_{90}-{T}_{10} $.

$ {T}_r={T}_{90}-{T}_{10} $.

Psychophysical Assessment

By means of psychophysical experiments, we evaluate the capacity of human participants in discriminating the different force intensity rendered by the device in different direction.

Materials

The setup used for this experiments is shown in Figure 7. The W![]() $ \Delta $ is anchored to a structure that holds it and is fixed to a table. The subjects wear the W

$ \Delta $ is anchored to a structure that holds it and is fixed to a table. The subjects wear the W![]() $ \Delta $, while sitting in a comfortable position, and try to maintain the straight position of Figure 7 for the whole experiment duration. Furthermore, the subjects are blindfolded and provided with an external white noise by noise-canceling over-ear headphones. The pool of subjects is composed of six participants, three males, and three females, between 25 and 35 years old.

$ \Delta $, while sitting in a comfortable position, and try to maintain the straight position of Figure 7 for the whole experiment duration. Furthermore, the subjects are blindfolded and provided with an external white noise by noise-canceling over-ear headphones. The pool of subjects is composed of six participants, three males, and three females, between 25 and 35 years old.

Figure 7. Setup used for the W![]() $ \Delta $ psychophysical test: the subject, seated, leans its elbow on a comfort foam and wears the W

$ \Delta $ psychophysical test: the subject, seated, leans its elbow on a comfort foam and wears the W![]() $ \Delta $, and witch is supported by a custom frame. The drawn reference frame orientation corresponds to the one of the base of the W

$ \Delta $, and witch is supported by a custom frame. The drawn reference frame orientation corresponds to the one of the base of the W![]() $ \Delta $ (see Figure 17a) in order to facilitate the read of plots reporting the assessment results in Figure 8.

$ \Delta $ (see Figure 17a) in order to facilitate the read of plots reporting the assessment results in Figure 8.

Methods

The assessment method is divided in three subexperiments, each of them concerning one direction, according to the frame of Figure 7. We used the method of constant stimuli (Gescheider, Reference Gescheider1976): in a forced-choice task, we presented participants with two stimuli of different intensity and asked them to report which of the two was perceived as stronger. After preliminary tests, the range of the stimuli has been set ![]() $ \left[2,4\right] $ N. Then, the Compared Stimuli (CS) are 2, 2.33, 2.67, 3, 3.33, 3.67, and 4 N, while the Reference Stimulus (RS) is 3 N, with a step of 0.33 N. The corresponding torques at the wrist for these CS are in the range

$ \left[2,4\right] $ N. Then, the Compared Stimuli (CS) are 2, 2.33, 2.67, 3, 3.33, 3.67, and 4 N, while the Reference Stimulus (RS) is 3 N, with a step of 0.33 N. The corresponding torques at the wrist for these CS are in the range ![]() $ \left[\mathrm{0.12,0.24}\right] $ Nm in case of minimum

$ \left[\mathrm{0.12,0.24}\right] $ Nm in case of minimum ![]() $ {l}_h $ (0.06 m), and in the range

$ {l}_h $ (0.06 m), and in the range ![]() $ \left[\mathrm{0.16,0.32}\right] $ Nm in case of maximum

$ \left[\mathrm{0.16,0.32}\right] $ Nm in case of maximum ![]() $ {l}_h $ (0.08 m, see Table 2). Twenty repetitions of each RS–CS couple are rendered to each subject, half with the RS as first stimulus and the other half with RS as second stimulus, all in a randomized order. Each stimulus is rendered as follows: a ramp of 0.5 s increases the applied force from 0 N to the desired stimulus to avoid discontinuities, then the force is kept constantly equal to the desired stimulus for 1.5 s and finally decreased back to 0 N with another ramp of 0.5 s. Between the first and second stimuli of each pair, a pause of 1 s is used. For each direction, then, the total number of trials is 140, presented in a pseudorandom order. The seed for the pseudorandom algorithm is changed for each new subexperiment. The order of the three subexperiments (three different directions of the applied forces) is shuffled with the same method. Once the desired force is given, the corresponding motor torques are calculated through (4), and the commanded currents through (7). Participants’ answers were recorded and saved for analysis.

$ {l}_h $ (0.08 m, see Table 2). Twenty repetitions of each RS–CS couple are rendered to each subject, half with the RS as first stimulus and the other half with RS as second stimulus, all in a randomized order. Each stimulus is rendered as follows: a ramp of 0.5 s increases the applied force from 0 N to the desired stimulus to avoid discontinuities, then the force is kept constantly equal to the desired stimulus for 1.5 s and finally decreased back to 0 N with another ramp of 0.5 s. Between the first and second stimuli of each pair, a pause of 1 s is used. For each direction, then, the total number of trials is 140, presented in a pseudorandom order. The seed for the pseudorandom algorithm is changed for each new subexperiment. The order of the three subexperiments (three different directions of the applied forces) is shuffled with the same method. Once the desired force is given, the corresponding motor torques are calculated through (4), and the commanded currents through (7). Participants’ answers were recorded and saved for analysis.

Data Analysis

The data resulting from the experiment of each subject, as well as the total pool, are reported in Figure 8. Abscissa axes’ values correspond to the CS used in the experiment, whereas ordinate axes’ values correspond to the portion of answers in which the subject felt the CS greater than the RS. Colored dots indicate the result for each CS in the three directions. It follows that, in the ideal case, these dots should correspond to 0 if the CS is lower than RS, 0.5 if the CS corresponds to the RS, and 1 if the CS is greater than the RS.

Figure 8. Results of the force discrimination in the different directions for each subject (first 12 boxes) and for the total data pool (bottom big box). Abscissa axes are centered at the RS (RS = 3 N), with range corresponding to the one of the CS (CS![]() $ \in \left[2,4\right] $ N). Grid vertical lines—plots left and right borders included—indicate the seven used CS (see Section “Methods”). On the ordinate axes, “Portion of greater” for each CS is reported, which is the portion of trials for that specific CS in which the subject declared it greater than the RS. Each box shows results for each CS (dots) and binomial fit (curve; see Section “Data Analysis”) in each direction (red for

$ \in \left[2,4\right] $ N). Grid vertical lines—plots left and right borders included—indicate the seven used CS (see Section “Methods”). On the ordinate axes, “Portion of greater” for each CS is reported, which is the portion of trials for that specific CS in which the subject declared it greater than the RS. Each box shows results for each CS (dots) and binomial fit (curve; see Section “Data Analysis”) in each direction (red for ![]() $ x $, yellow for

$ x $, yellow for ![]() $ y $, and blue for

$ y $, and blue for ![]() $ z $; see Figures 7 and 17a). The total plot also reports point of subjective equality (PSE) and just noticeable difference (JND) for each direction.

$ z $; see Figures 7 and 17a). The total plot also reports point of subjective equality (PSE) and just noticeable difference (JND) for each direction.

By means of a generalized linear model, the human testers’ sensitivity is tested in all the principal directions. The fitting is performed assuming a binomial distribution. After the fitting, the PSE and the JND are calculated for each direction and subject, as well as for the whole pool of recorded data. The resulting fitting curves, PSE and JND values for each subject and for the total pool, are reported in Figure 8.

The Weber constant resulting from the characterization (JND/RS ![]() $ =\sim 10\% $) is quite close to the intervals found in Pang et al. (Reference Pang, Tan and Durlach1991) and Jones (Reference Jones1989) (c.a.

$ =\sim 10\% $) is quite close to the intervals found in Pang et al. (Reference Pang, Tan and Durlach1991) and Jones (Reference Jones1989) (c.a. ![]() $ \left[5-10\right]\% $), confirming that the W

$ \left[5-10\right]\% $), confirming that the W![]() $ \Delta $ does not alter the capacity of the user to discriminate forces. Furthermore, the average JND along the different direction is 0.338 N and exactly corresponds to the wrist average force control resolution calculated in Tan et al. (Reference Tan, Srinivasan, Eberman and Cheng1994). This means that the device potentially allows the user to control a remote/virtual force through the device with the same accuracy they would have during a real physical interaction.

$ \Delta $ does not alter the capacity of the user to discriminate forces. Furthermore, the average JND along the different direction is 0.338 N and exactly corresponds to the wrist average force control resolution calculated in Tan et al. (Reference Tan, Srinivasan, Eberman and Cheng1994). This means that the device potentially allows the user to control a remote/virtual force through the device with the same accuracy they would have during a real physical interaction.

Teleoperation Framework

In this work, we implemented a classic position-force architecture (Hannaford and Ryu, Reference Hannaford and Ryu2002). The follower robot is moved through an impedance control, that takes as reference the user’s hand position/twist. The interaction wrench sensed at the remote side is fed back to the user through the interface. A representation of the whole scheme is shown in Figure 9. Its details are expansively explained in Appendix B, together with the study and characterization of the haptic feedback (Section “Haptic Feedback” in Appendix B). For the sake of brevity, we here report only the final and essential results. At the leader side, the wrench applied by the W![]() $ \Delta $ to users palm

$ \Delta $ to users palm ![]() $ {W}_a^{pm} $ corresponds to

$ {W}_a^{pm} $ corresponds to

where ![]() $ {W}_d^{pm} $ is the desired wrench at the palm, corresponding to the environment wrench sensed at the follower end effector

$ {W}_d^{pm} $ is the desired wrench at the palm, corresponding to the environment wrench sensed at the follower end effector ![]() $ {W}_e^{ee} $.

$ {W}_e^{ee} $. ![]() $ {C}_{W\Delta} $ is the map from the desired to the applied Wrench, which is the function of the device actuation and kinematics. Please refer to Section “Haptic Feedback” in Appendix B for its complete derivation. The follower, instead, is controlled in impedance, as said before. The total commanded Wrench

$ {C}_{W\Delta} $ is the map from the desired to the applied Wrench, which is the function of the device actuation and kinematics. Please refer to Section “Haptic Feedback” in Appendix B for its complete derivation. The follower, instead, is controlled in impedance, as said before. The total commanded Wrench ![]() $ {W}_{f, tot}^{ee} $ expressed in the end-effector frame

$ {W}_{f, tot}^{ee} $ expressed in the end-effector frame ![]() $ {\Psi}_{ee} $ is

$ {\Psi}_{ee} $ is

which is the sum of the impedance control Wrench ![]() $ {W}_{f, cmd}^{ee} $ and the equivalent gravity compensation Wrench

$ {W}_{f, cmd}^{ee} $ and the equivalent gravity compensation Wrench ![]() $ {W}_{f, cmp}^{ee} $.

$ {W}_{f, cmp}^{ee} $. ![]() $ {T}_i^{k,j} $ indicates the twist of the frame

$ {T}_i^{k,j} $ indicates the twist of the frame ![]() $ {\Psi}_i $ with respect to

$ {\Psi}_i $ with respect to ![]() $ {\Psi}_j $ expressed in the frame

$ {\Psi}_j $ expressed in the frame ![]() $ {\Psi}_k $.

$ {\Psi}_k $.

Figure 9. Teleoperation control loop block representation. Apices indicating the reference frame in which the entities are expressed and not reported for the sake of readability.

At the left side, the user/leader-side scheme is depicted. ![]() $ {Z}_{\ast } $ are impedances in the JS. Block

$ {Z}_{\ast } $ are impedances in the JS. Block ![]() $ {C}_{W\Delta} $ corresponds to (9), while

$ {C}_{W\Delta} $ corresponds to (9), while ![]() $ {J}_{wr} $ is the wrist Jacobian, which is associated to

$ {J}_{wr} $ is the wrist Jacobian, which is associated to ![]() $ {H}_{pm}^{wr} $ of (21) and is used to map the torques at the wrist joint

$ {H}_{pm}^{wr} $ of (21) and is used to map the torques at the wrist joint ![]() $ {\tau}_{wr} $ in the wrench

$ {\tau}_{wr} $ in the wrench ![]() $ {W}_{wr} $ in the frame

$ {W}_{wr} $ in the frame ![]() $ {\Psi}_{pm}\equiv {\Psi}_{p_{\Delta}} $.

$ {\Psi}_{pm}\equiv {\Psi}_{p_{\Delta}} $.

At the right side, the remote/follower-side block representation is shown. ![]() $ {\Sigma}_{\ast } $ are impedances in the Cartesian. The sum of contributions from blocks

$ {\Sigma}_{\ast } $ are impedances in the Cartesian. The sum of contributions from blocks ![]() $ {\Sigma}_c $ (impedance controller) and

$ {\Sigma}_c $ (impedance controller) and ![]() $ {\hat{\Sigma}}_f $ (dynamic compensation) correspond to the total commanded wrench

$ {\hat{\Sigma}}_f $ (dynamic compensation) correspond to the total commanded wrench ![]() $ {W}_{f, tot} $ of (10). This and the environment interaction force

$ {W}_{f, tot} $ of (10). This and the environment interaction force ![]() $ {W}_e $ influence the follower dynamics

$ {W}_e $ influence the follower dynamics ![]() $ {\Sigma}_f $, here indicated with its inverse due to causality consistency.

$ {\Sigma}_f $, here indicated with its inverse due to causality consistency.

Experimental Validation

This section reports some simple experiments to validate the device used in the teleoperation framework described in the previous section. First, the experimental setup is introduced, both for the leader side and the follower side (Section “Validation Setup”). Section “Examples of Use” reports the examples of usage of the W![]() $ \Delta $ in free-space position and simple interaction and analyzes the results.

$ \Delta $ in free-space position and simple interaction and analyzes the results.

Validation Setup

The leader–follower framework used for the experimental campaign is shown in Figure 10. The follower is a Panda robotic arm by Franka Emika,Footnote 8 the same used for the W![]() $ \Delta $ characterization (Section “Characterization”). The used follower end effector is the anthropomorphic Pisa/IIT SoftHand (Catalano et al., Reference Catalano, Grioli, Farnioli, Serio, Piazza and Bicchi2014).

$ \Delta $ characterization (Section “Characterization”). The used follower end effector is the anthropomorphic Pisa/IIT SoftHand (Catalano et al., Reference Catalano, Grioli, Farnioli, Serio, Piazza and Bicchi2014).

Figure 10. Setup used for the W![]() $ \Delta $ experimental validation.

$ \Delta $ experimental validation.

The follower end-effector transformation matrix ![]() $ {H}_{ee}^0 $ and twist

$ {H}_{ee}^0 $ and twist ![]() $ {T}_{ee}^{ee,0} $ are provided by the software library interface of the robot (Franka Control Interface), as well as its Jacobian

$ {T}_{ee}^{ee,0} $ are provided by the software library interface of the robot (Franka Control Interface), as well as its Jacobian ![]() $ {J}_s^{ee} $ and external interaction wrench

$ {J}_s^{ee} $ and external interaction wrench ![]() $ {W}_{ext}^{ee} $, used to provide the feedback to the user and to evaluate the subjects performances, as it will be explained hereafter. Since the measured force is quite noisy, a dead zone of

$ {W}_{ext}^{ee} $, used to provide the feedback to the user and to evaluate the subjects performances, as it will be explained hereafter. Since the measured force is quite noisy, a dead zone of ![]() $ \pm 2.5 $ N is applied along all the three directions, followed by a classic first order discrete exponential filter with

$ \pm 2.5 $ N is applied along all the three directions, followed by a classic first order discrete exponential filter with ![]() $ {\alpha}_f=0.8 $, resulting in

$ {\alpha}_f=0.8 $, resulting in ![]() $ {f}_{ext}^{ee} $. The desired torques at the Delta motors

$ {f}_{ext}^{ee} $. The desired torques at the Delta motors ![]() $ {\tau}_{\Delta, d} $ are then calculated through (4). The stiffness values used in the follower impedance control (39) are set to 300 N/m for the linear components and 15 Nm/rad for the angular components. The used motors are not powerful enough to cover all the range of force that can be sensed during the robot–environment interactions, and indeed the device prototype is designed to assure a maximum force of 5 N along any direction for each point of the interested workspace. As shown in (4), the desired forces are directly related to the motor torques through the device Jacobian. If a motor saturates due to its current limit, the torque applied by that motor is saturated as well, and consequently the rendered force could misalign with respect to the desired one. To prevent this undesired behavior, a saturation is done dynamically on the vector of the desired currents

$ {\tau}_{\Delta, d} $ are then calculated through (4). The stiffness values used in the follower impedance control (39) are set to 300 N/m for the linear components and 15 Nm/rad for the angular components. The used motors are not powerful enough to cover all the range of force that can be sensed during the robot–environment interactions, and indeed the device prototype is designed to assure a maximum force of 5 N along any direction for each point of the interested workspace. As shown in (4), the desired forces are directly related to the motor torques through the device Jacobian. If a motor saturates due to its current limit, the torque applied by that motor is saturated as well, and consequently the rendered force could misalign with respect to the desired one. To prevent this undesired behavior, a saturation is done dynamically on the vector of the desired currents ![]() $ {I}_{\Delta, c} $. Given a current limit

$ {I}_{\Delta, c} $. Given a current limit ![]() $ {I}_{lim}=1.5 $ A, we perform a saturation as

$ {I}_{lim}=1.5 $ A, we perform a saturation as

where ![]() $ \parallel \cdot {\parallel}_1 $ is the one norm of the vector, that is, the absolute value of the largest component;

$ \parallel \cdot {\parallel}_1 $ is the one norm of the vector, that is, the absolute value of the largest component; ![]() $ {\overline{I}}_{\Delta, c} $ is the vector of the direction consistent saturated currents;

$ {\overline{I}}_{\Delta, c} $ is the vector of the direction consistent saturated currents; ![]() $ {r}_{sat} $ is the scaling factor due to saturation. The actuated torques

$ {r}_{sat} $ is the scaling factor due to saturation. The actuated torques ![]() $ {\overline{\tau}}_{\Delta, c} $ are the one corresponding to the saturated current, calculated then through the inverse of the relations of (7). With this saturation, the force actually rendered to the user

$ {\overline{\tau}}_{\Delta, c} $ are the one corresponding to the saturated current, calculated then through the inverse of the relations of (7). With this saturation, the force actually rendered to the user ![]() $ {\overline{f}}_a^{pm} $ (see (35)) maintains the same direction of

$ {\overline{f}}_a^{pm} $ (see (35)) maintains the same direction of ![]() $ {f}_{ext}^{ee} $ but is scaled of factor

$ {f}_{ext}^{ee} $ but is scaled of factor ![]() $ {r}_{sat} $ due to the saturation. Indeed,

$ {r}_{sat} $ due to the saturation. Indeed,

The whole framework is implemented in ROS,Footnote 9 with the Franka node running at 1 kHz, and the W![]() $ \Delta $ node at 400 Hz.

$ \Delta $ node at 400 Hz.

Examples of Use

Here, two simple usage examples of the device are reported, to show its basic functionalities. The first one is a free-space motion example, in which the user executes random movements in the environment without interacting with any object. Figure 11 reports the leader and follower end-effectors’ trajectories, the follower position error, the force applied by its impedance controller, and the environmental forces sensed and rendered to the user after the saturation (indicated as ![]() $ f $ and

$ f $ and ![]() $ \overline{f} $, respectively, and so avoiding the apex and the subscript used before for the sake of simplicity).

$ \overline{f} $, respectively, and so avoiding the apex and the subscript used before for the sake of simplicity).

Figure 11. Free-space motion: trajectories and forces. For the sake of simplicity, only the linear components are reported. First row: desired follower positions (dashed) and actual ones (continuous). Second row: follower position errors. Third row: linear forces commanded by the follower impedance controller, expressed in the end-effector frame ![]() $ {\Psi}_{ee} $. Fourth row: environment forces received by the W

$ {\Psi}_{ee} $. Fourth row: environment forces received by the W![]() $ \Delta $ (dashed) and the ones rendered to the user after the current saturation (continuous), expressed in the palm frame

$ \Delta $ (dashed) and the ones rendered to the user after the current saturation (continuous), expressed in the palm frame ![]() $ {\Psi}_{pm} $.

$ {\Psi}_{pm} $.

In the second example, the user executes random movements in the environment and eventually hit an object. Figure 12 depicts the data of three consecutive contacts as well as a frame extrapolated from the video of an instant in which the contact occurs. The time intervals relative to the contacts are highlighted with light blue strips. In the picture at the bottom of Figure 12, the ![]() $ y $- and

$ y $- and ![]() $ z $-axes of

$ z $-axes of ![]() $ {\Psi}_{ee} $ are reported, oriented in the same way of

$ {\Psi}_{ee} $ are reported, oriented in the same way of ![]() $ {\Psi}_{pm} $, to help the reader understand the direction of the forces in the scene.

$ {\Psi}_{pm} $, to help the reader understand the direction of the forces in the scene.

Figure 12. Contact with a surface experiment: trajectories and forces. The plot and data distribution follow the same convention of Figure 11. The light blue strips indicate the time intervals in which the contacts occur. In this case, the effect of motor current saturation on the exerted force is clearly appreciable in the fourth plot, where the force rendered to the user after the current saturation (continuous line) is way lower than the one received by the remote side (dashed line).

Figure 12 shows the results of a contact example. In the last plot, it is possible to see that the force rendered to the user (continuous lines) are lower than the ones sensed at the follower side (dashed lines), due to the saturation described before (Section “Validation Setup”). Note that the three components of the force are scaled by the same factor, so to maintain the same direction of the real remote interaction force. Forces are mainly distributed along ![]() $ y $, because it is expressed in the palm frame

$ y $, because it is expressed in the palm frame ![]() $ {\Psi}_{pm} $ (see Figure 17).

$ {\Psi}_{pm} $ (see Figure 17).

The free-space motion example results (Figure 11) show the general trajectory tracking performance of the built framework. As it is possible to see, the position error (the second plot of Figure 11) is always relative low, almost null in steady state and above 0.1 m only during fast movements. The force commanded by the impedance controller (third row) follows the same pattern. In the bottom plot, forces sensed at the follower side are not null, due to imperfect force estimation in the robot arm.

Usability Assessment

Experiment Description