1. Introduction

Liquid flowing down a fibre may destabilise into a train of beads, commonly called a bead-on-fibre pattern. Bead formation may result from inertia-driven Kaptiza-like instability (Kapitza Reference Kapitza1948) or capillary-driven Plateau–Rayleigh-like instability (Plateau Reference Plateau1873; Rayleigh Reference Rayleigh1878), depending on the liquid properties, flow rate and fibre properties. When the dominant instability is capillary driven, the liquid beads have highly curved interfaces and time-invariant bead properties. In addition, viscosity slows the beads making them ideal for direct-contact heat and mass transfer applications where large retention times ![]() $\tau _r$ increase efficiency (Hattori, Ishikawa & Mori Reference Hattori, Ishikawa and Mori1994; Chinju, Uchiyama & Mori Reference Chinju, Uchiyama and Mori2000). In such applications, it is desirable to control the interfacial area

$\tau _r$ increase efficiency (Hattori, Ishikawa & Mori Reference Hattori, Ishikawa and Mori1994; Chinju, Uchiyama & Mori Reference Chinju, Uchiyama and Mori2000). In such applications, it is desirable to control the interfacial area ![]() $A$ available for heat and mass transfer along the length

$A$ available for heat and mass transfer along the length ![]() $L$ of the fibre. The interfacial area is

$L$ of the fibre. The interfacial area is ![]() $A \approx \tau _{r} f A_{b}$, where

$A \approx \tau _{r} f A_{b}$, where ![]() $f$ is the bead frequency and

$f$ is the bead frequency and ![]() $A_{b}$ is the interfacial area of a bead. Thus,

$A_{b}$ is the interfacial area of a bead. Thus, ![]() $f$ is a key parameter for optimising bead-on-fibre flows for applications. Here, we derive a scaling law for

$f$ is a key parameter for optimising bead-on-fibre flows for applications. Here, we derive a scaling law for ![]() $f$ of an Ostwaldian fluid with power-law rheology, of which a Newtonian fluid is a limiting case, and validate it with new experiments coupled with experimental data from prior works, including symmetric and asymmetric bead profiles.

$f$ of an Ostwaldian fluid with power-law rheology, of which a Newtonian fluid is a limiting case, and validate it with new experiments coupled with experimental data from prior works, including symmetric and asymmetric bead profiles.

A thin liquid film coating on a horizontal fibre naturally destabilises into beads, similar to morning dew on a spider's web (Goren Reference Goren1962), as shown in figure 1(a). On a vertically oriented fibre, this gravity-driven flow becomes unstable above a critical thickness (Quéré Reference Quéré1990; Kalliadasis & Chang Reference Kalliadasis and Chang1994; Chang & Demekhin Reference Chang and Demekhin1999). Early studies, motivated by fibre withdrawal from liquid baths (Lin & Liu Reference Lin and Liu1975), examined the nonlinear evolution equations governing these wavy flows (Frenkel Reference Frenkel1992; Trifonov Reference Trifonov1992). For continuous flow down a fibre, Hattori et al. (Reference Hattori, Ishikawa and Mori1994) and Kliakhandler, Davis & Bankoff (Reference Kliakhandler, Davis and Bankoff2001) observed bead-on-fibre patterns characterised by three dynamic regimes, (i) convective (C), (ii) Plateau–Rayleigh (PR) and (iii) isolated (I), as shown in figure 1(b). Isolated patterns appear at low flow rates and have equally spaced beads moving at a constant velocity connected by an undulating film that also results from capillary instability. As flow rate increases, bead spacing decreases, leading to the Plateau–Rayleigh regime, where the film between beads lacks sufficient time to destabilise. At higher flow rates, inertia dominates, resulting in the convective regime characterised by interactive dynamics and irregular bead properties. Transitions between regimes provide insight into the instability type and dominant mechanism. For example, the shift from a single bead frequency (I and PR regime) to a broad frequency distribution (C regime) reflects the transition from an absolute instability to a convective instability (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007). However, bound state formation may result in multiple preferred wavelengths in the C regime when dispersive and dissipative effects are strong (Duprat et al. Reference Duprat, Giorgiutti-Dauphiné, Tseluiko, Saprykin and Kalliadasis2009a). Furthermore, drop-like beads in the I and PR regimes arise from capillary-driven instability at low flow rates, while wave-like beads emerge at higher flow rates due to inertial instability (Duprat, Ruyer-Quil & Giorgiutti-Dauphiné Reference Duprat, Ruyer-Quil and Giorgiutti-Dauphiné2009b). These features were examined by Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012) for the two-equation model derived by Ruyer-Quil et al. (Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008) and single evolution equation derived by Craster & Matar (Reference Craster and Matar2006). Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012) adopt scalings where the radial length scale is the flat-film thickness ![]() $L \;\widehat {=}\; h$ determined by neglecting destabilising terms, the axial length scale is

$L \;\widehat {=}\; h$ determined by neglecting destabilising terms, the axial length scale is ![]() $L \;\widehat {=}\; \kappa h$ where

$L \;\widehat {=}\; \kappa h$ where ![]() $\kappa \;\widehat {=}\; ( \sigma / \rho g h^{2} )^{1/3}$ reflects the balance between capillary pressure and hydrostatic pressure, and the time scale is defined based on

$\kappa \;\widehat {=}\; ( \sigma / \rho g h^{2} )^{1/3}$ reflects the balance between capillary pressure and hydrostatic pressure, and the time scale is defined based on ![]() $h$. These scalings hold in the long-wavelength limit but break down when the instability is absolute and the film evolves into highly curved drop-like beads at high bead frequency

$h$. These scalings hold in the long-wavelength limit but break down when the instability is absolute and the film evolves into highly curved drop-like beads at high bead frequency ![]() $f$. In this case, Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012) noted an alternative scaling

$f$. In this case, Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012) noted an alternative scaling

which compares gravity acceleration with momentum diffusion.

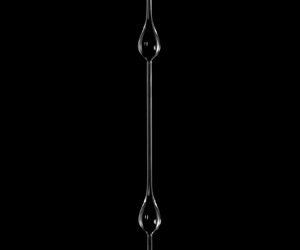

Figure 1. Bead-on-fibre patterns. (a) Beads on a horizontal fibre. (b) Three primary dynamical regimes observed in flow down a vertically-hung fibre as flow rate ![]() $Q$ is decreased: (i) convective, (ii) Plateau–Rayleigh and (iii) isolated (reproduced from Kliakhandler et al. Reference Kliakhandler, Davis and Bankoff2001). Beads can exhibit either (c) symmetric or (d) asymmetric morphology (reproduced from Gabbard & Bostwick Reference Gabbard and Bostwick2021a).

$Q$ is decreased: (i) convective, (ii) Plateau–Rayleigh and (iii) isolated (reproduced from Kliakhandler et al. Reference Kliakhandler, Davis and Bankoff2001). Beads can exhibit either (c) symmetric or (d) asymmetric morphology (reproduced from Gabbard & Bostwick Reference Gabbard and Bostwick2021a).

The bead morphology, describing the eccentricity of the beads relative to the fibre, can be either symmetric or asymmetric, as shown in figures 1(c) and 1(d). Hattori et al. (Reference Hattori, Ishikawa and Mori1994) first observed the transition from symmetric to asymmetric beads in high-surface-energy liquids. Gabbard & Bostwick (Reference Gabbard and Bostwick2021a) later showed that increasing surface tension ![]() $\sigma$ and fibre radius

$\sigma$ and fibre radius ![]() $r$ leads to asymmetric flow, characterised by faster-moving beads and larger bead spacing. Drops of low-surface-energy oils have also been observed flowing in a metastable asymmetric configuration (Gilet, Terwagne & Vandewalle Reference Gilet, Terwagne and Vandewalle2010), and Eghbali et al. (Reference Eghbali, Keiser, Boujo and Gallaire2022) showed that quasi-inertialess flow down eccentric fibres can destabilise into a train of asymmetric beads. In addition, shear-thinning behaviour promotes asymmetry in polymer solutions (Gabbard & Bostwick Reference Gabbard and Bostwick2023). In the case of shear-thinning liquids, the rheological behaviour is often modelled using the Ostwald power-law model

$r$ leads to asymmetric flow, characterised by faster-moving beads and larger bead spacing. Drops of low-surface-energy oils have also been observed flowing in a metastable asymmetric configuration (Gilet, Terwagne & Vandewalle Reference Gilet, Terwagne and Vandewalle2010), and Eghbali et al. (Reference Eghbali, Keiser, Boujo and Gallaire2022) showed that quasi-inertialess flow down eccentric fibres can destabilise into a train of asymmetric beads. In addition, shear-thinning behaviour promotes asymmetry in polymer solutions (Gabbard & Bostwick Reference Gabbard and Bostwick2023). In the case of shear-thinning liquids, the rheological behaviour is often modelled using the Ostwald power-law model

where ![]() $\mu$ is dynamic viscosity,

$\mu$ is dynamic viscosity, ![]() $\beta$ is the fluid consistency index,

$\beta$ is the fluid consistency index, ![]() $\dot {\gamma }$ is shear rate and

$\dot {\gamma }$ is shear rate and ![]() $n$ is the power law index. For Newtonian fluids

$n$ is the power law index. For Newtonian fluids ![]() $n=1$ and

$n=1$ and ![]() $\beta = \mu$, whereas

$\beta = \mu$, whereas ![]() $n<1$ for shear-thinning fluids. This model has been used to explore shear-thinning and shear-thickening effects in drops flowing down vertical fibres (Yu & Hinch Reference Yu and Hinch2014). Boulogne, Pauchard & Giorgiutti-Dauphiné (Reference Boulogne, Pauchard and Giorgiutti-Dauphiné2012) explored the flow of polymer solutions on a fibre, finding that decreasing

$n<1$ for shear-thinning fluids. This model has been used to explore shear-thinning and shear-thickening effects in drops flowing down vertical fibres (Yu & Hinch Reference Yu and Hinch2014). Boulogne, Pauchard & Giorgiutti-Dauphiné (Reference Boulogne, Pauchard and Giorgiutti-Dauphiné2012) explored the flow of polymer solutions on a fibre, finding that decreasing ![]() $n$ leads to thinner pre-instability films and a transition in the velocity profile from parabolic to plug-like. While these effects modify the growth rate of capillary instability, they maintain the same underlying time scale for drop-like beads, as discussed by Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012), with adjustments for shear-thinning:

$n$ leads to thinner pre-instability films and a transition in the velocity profile from parabolic to plug-like. While these effects modify the growth rate of capillary instability, they maintain the same underlying time scale for drop-like beads, as discussed by Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012), with adjustments for shear-thinning: ![]() $\tau \;\widehat {=}\; (\beta / \rho gr)^{1/n}$. These studies illustrate the wide range of bead-on-fibre patterns. Despite this, a comprehensive understanding of the bead dynamics is lacking.

$\tau \;\widehat {=}\; (\beta / \rho gr)^{1/n}$. These studies illustrate the wide range of bead-on-fibre patterns. Despite this, a comprehensive understanding of the bead dynamics is lacking.

Specifically, a unifying scaling for the frequency of beads is critical for designing and optimising heat and mass transfer applications such as ![]() $\textrm {CO}_2$ separation (Chinju et al. Reference Chinju, Uchiyama and Mori2000; Uchiyama et al. Reference Uchiyama, Migita, Ohmura and Mori2003; Migita, Soga & Mori Reference Migita, Soga and Mori2005; Wagstaff et al. Reference Wagstaff, Al-Juaied, Prabhudharwadkar and Roberts2024), gas-side mass transfer (Grünig et al. Reference Grünig, Lyagin, Horn, Skale and Kraume2012), direct-contact heat exchange (Hattori et al. Reference Hattori, Ishikawa and Mori1994; Zeng et al. Reference Zeng, Sadeghpour, Warrier and Ju2017; Zeng, Sadeghpour & Ju Reference Zeng, Sadeghpour and Ju2018), desalination (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019; Zeng, Sadeghpour & Ju Reference Zeng, Sadeghpour and Ju2019), fine and ultrafine particle collection (Sadeghpour et al. Reference Sadeghpour, Oroumiyeh, Zhu, Ko, Ji, Bertozzi and Ju2021) and liquid–liquid extraction (Zhang, Liu & Chen Reference Zhang, Liu and Chen2023; Chang et al. Reference Chang, Zheng, Xu, Wang, Su and Kuang2024). Bead-on-fibre flow has also been proposed as an ideal low-energy alternative for vacuum distillation applications (Grünig, Skale & Kraume Reference Grünig, Skale and Kraume2010) and observed in fibre-based fog harvesting applications (Shi et al. Reference Shi, Anderson, Tulkoff, Kennedy and Boreyko2018; Labbé & Duprat Reference Labbé and Duprat2019; Moncuquet et al. Reference Moncuquet, Mitranescu, Marchand, Ramananarivo and Duprat2022). Bead-on-fibre flow gained popularity as an effective alternative to traditional direct-contact systems after being introduced by Hattori et al. (Reference Hattori, Ishikawa and Mori1994) for heat exchange, and later for mass transfer (Chinju et al. Reference Chinju, Uchiyama and Mori2000). These early studies showed that viscous shear increased the bead retention time compared with free-falling drops in commercial spray towers and exhibited enhanced mixing due to a velocity mismatch between the beads and their connecting films. These systems also help regularise the bead density and show that film waviness enhances mass transfer compared to planar films (Grünig et al. Reference Grünig, Lyagin, Horn, Skale and Kraume2012), a feature which has been attributed to the ability of the high-curvature beads to serve as sinks for mass transfer (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019). In addition, the smooth liquid–gas interface results in up to two orders of magnitude lower pressure drop across the system compared with a conventional packed-bed column (Migita et al. Reference Migita, Soga and Mori2005) and an order of magnitude lower than comparable corrugated sheet structured packings (Grünig et al. Reference Grünig, Skale and Kraume2010). The bead frequency

$\textrm {CO}_2$ separation (Chinju et al. Reference Chinju, Uchiyama and Mori2000; Uchiyama et al. Reference Uchiyama, Migita, Ohmura and Mori2003; Migita, Soga & Mori Reference Migita, Soga and Mori2005; Wagstaff et al. Reference Wagstaff, Al-Juaied, Prabhudharwadkar and Roberts2024), gas-side mass transfer (Grünig et al. Reference Grünig, Lyagin, Horn, Skale and Kraume2012), direct-contact heat exchange (Hattori et al. Reference Hattori, Ishikawa and Mori1994; Zeng et al. Reference Zeng, Sadeghpour, Warrier and Ju2017; Zeng, Sadeghpour & Ju Reference Zeng, Sadeghpour and Ju2018), desalination (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019; Zeng, Sadeghpour & Ju Reference Zeng, Sadeghpour and Ju2019), fine and ultrafine particle collection (Sadeghpour et al. Reference Sadeghpour, Oroumiyeh, Zhu, Ko, Ji, Bertozzi and Ju2021) and liquid–liquid extraction (Zhang, Liu & Chen Reference Zhang, Liu and Chen2023; Chang et al. Reference Chang, Zheng, Xu, Wang, Su and Kuang2024). Bead-on-fibre flow has also been proposed as an ideal low-energy alternative for vacuum distillation applications (Grünig, Skale & Kraume Reference Grünig, Skale and Kraume2010) and observed in fibre-based fog harvesting applications (Shi et al. Reference Shi, Anderson, Tulkoff, Kennedy and Boreyko2018; Labbé & Duprat Reference Labbé and Duprat2019; Moncuquet et al. Reference Moncuquet, Mitranescu, Marchand, Ramananarivo and Duprat2022). Bead-on-fibre flow gained popularity as an effective alternative to traditional direct-contact systems after being introduced by Hattori et al. (Reference Hattori, Ishikawa and Mori1994) for heat exchange, and later for mass transfer (Chinju et al. Reference Chinju, Uchiyama and Mori2000). These early studies showed that viscous shear increased the bead retention time compared with free-falling drops in commercial spray towers and exhibited enhanced mixing due to a velocity mismatch between the beads and their connecting films. These systems also help regularise the bead density and show that film waviness enhances mass transfer compared to planar films (Grünig et al. Reference Grünig, Lyagin, Horn, Skale and Kraume2012), a feature which has been attributed to the ability of the high-curvature beads to serve as sinks for mass transfer (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019). In addition, the smooth liquid–gas interface results in up to two orders of magnitude lower pressure drop across the system compared with a conventional packed-bed column (Migita et al. Reference Migita, Soga and Mori2005) and an order of magnitude lower than comparable corrugated sheet structured packings (Grünig et al. Reference Grünig, Skale and Kraume2010). The bead frequency ![]() $f$ characterises the flow pattern and has an application-specific effect on system efficiency. For instance, Sadeghpour et al. (Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019) found that mass transfer conductance in a humidification–dehumidification desalination system increases with decreasing bead spacing up to the transition between absolute and convective flow. Thus, a high

$f$ characterises the flow pattern and has an application-specific effect on system efficiency. For instance, Sadeghpour et al. (Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019) found that mass transfer conductance in a humidification–dehumidification desalination system increases with decreasing bead spacing up to the transition between absolute and convective flow. Thus, a high ![]() $f$ in the absolute regime is desirable for efficiency. Alternatively, Zeng et al. (Reference Zeng, Sadeghpour and Ju2018) found that closely spaced beads associated with high

$f$ in the absolute regime is desirable for efficiency. Alternatively, Zeng et al. (Reference Zeng, Sadeghpour and Ju2018) found that closely spaced beads associated with high ![]() $f$ reduced the heat transfer coefficient. Thus, optimising system performance requires a detailed understanding of bead-on-fibre flow physics in order to tailor bead frequency for specific system requirements.

$f$ reduced the heat transfer coefficient. Thus, optimising system performance requires a detailed understanding of bead-on-fibre flow physics in order to tailor bead frequency for specific system requirements.

In this work, we address the timely need for predicting bead frequency across liquid rheology and bead morphology by deriving a scaling law for the bead frequency ![]() $f$, as it depends on the flow rate

$f$, as it depends on the flow rate ![]() $Q$ through dimensional analysis in § 2. Next, we describe our experimental protocol and image processing technique for extracting experimental data in § 3. In § 4, we test our scaling law a against an extensive experimental data set. We provide a brief discussion of our results with relevance to practical applications in § 5. We end by offering some concluding remarks in § 6.

$Q$ through dimensional analysis in § 2. Next, we describe our experimental protocol and image processing technique for extracting experimental data in § 3. In § 4, we test our scaling law a against an extensive experimental data set. We provide a brief discussion of our results with relevance to practical applications in § 5. We end by offering some concluding remarks in § 6.

2. Scaling analysis

Consider a fluid with surface tension ![]() $\sigma$, viscosity

$\sigma$, viscosity ![]() $\mu$ and density

$\mu$ and density ![]() $\rho$ flowing down a thin vertical fibre of radius

$\rho$ flowing down a thin vertical fibre of radius ![]() $r$. The liquid film is uniform if the volume flow rate

$r$. The liquid film is uniform if the volume flow rate ![]() $Q$ is low (Quéré Reference Quéré1990). If the flow rate increases, liquid beads appear on the film, as illustrated in figure 2(a). Our objective is to determine the steady-state frequency of the beads in terms of

$Q$ is low (Quéré Reference Quéré1990). If the flow rate increases, liquid beads appear on the film, as illustrated in figure 2(a). Our objective is to determine the steady-state frequency of the beads in terms of ![]() $Q$ for an Ostwaldian fluid. In our analysis, we assume beads are drop-like and result from an absolutely unstable base flow such that the steady-state bead frequency

$Q$ for an Ostwaldian fluid. In our analysis, we assume beads are drop-like and result from an absolutely unstable base flow such that the steady-state bead frequency ![]() $f$ is single-valued and time-invariant. For such flows, we assume the primary factors influencing the frequency are the liquid properties, fibre size and flow rate.

$f$ is single-valued and time-invariant. For such flows, we assume the primary factors influencing the frequency are the liquid properties, fibre size and flow rate.

Figure 2. Experiment. (a) Schematic of the experimental apparatus with the inset showing the experimental variables. (b) Viscosity ![]() $\mu$ against shear rate

$\mu$ against shear rate ![]() $\dot {\gamma }$ for a Newtonian (gray circles) and Ostwaldian (red diamonds) liquid with dashed lines showing their best fit to a constant viscosity (

$\dot {\gamma }$ for a Newtonian (gray circles) and Ostwaldian (red diamonds) liquid with dashed lines showing their best fit to a constant viscosity (![]() $\mu = 36.6 \times 10^{-3}$ Pa s) and power-law model (

$\mu = 36.6 \times 10^{-3}$ Pa s) and power-law model (![]() $\beta = 51.9 \times 10^{-3}$ Pa

$\beta = 51.9 \times 10^{-3}$ Pa ![]() $\textrm {s}^{n}$,

$\textrm {s}^{n}$, ![]() $n=0.95$), respectively. (c) Spatiotemporal diagram showing the global evolution of beads (white) for a bead-on-fibre pattern with constant bead velocity

$n=0.95$), respectively. (c) Spatiotemporal diagram showing the global evolution of beads (white) for a bead-on-fibre pattern with constant bead velocity ![]() $v$ and bead frequency

$v$ and bead frequency ![]() $f=1/\tau$.

$f=1/\tau$.

2.1. The scaling for Ostwaldian fluids

The Ostwald–de Waele model (1.2) is a surrogate for the constitutive law of shear-thinning (i.e. pseudoplastic) or dilatant fluids. It expresses the shear stress ![]() $\tau _{ss}$ as a power law of the shear rate

$\tau _{ss}$ as a power law of the shear rate ![]() $\dot {\gamma }$, i.e. the velocity gradient perpendicular to the plane of shear:

$\dot {\gamma }$, i.e. the velocity gradient perpendicular to the plane of shear: ![]() $\tau _{ss} = \beta \dot {\gamma }^n$. The power-law index

$\tau _{ss} = \beta \dot {\gamma }^n$. The power-law index ![]() $n$ is less than 1 for a shear-thinning (pseudoplastic) fluid and greater than 1 for a dilatant one. When

$n$ is less than 1 for a shear-thinning (pseudoplastic) fluid and greater than 1 for a dilatant one. When ![]() $n=1$, the liquid is Newtonian and the shear stress

$n=1$, the liquid is Newtonian and the shear stress ![]() $\tau _{ss}$ is a linear function of shear rate

$\tau _{ss}$ is a linear function of shear rate ![]() $\dot {\gamma }$. As in SI units, the shear stress

$\dot {\gamma }$. As in SI units, the shear stress ![]() $\tau _{ss}$ is in Pa, the shear rate

$\tau _{ss}$ is in Pa, the shear rate ![]() $\dot {\gamma }$ in s

$\dot {\gamma }$ in s![]() $^{-1}$ and the fluid consistency index

$^{-1}$ and the fluid consistency index ![]() $\beta$ is in Pa s

$\beta$ is in Pa s![]() $^n$. We must emphasise that the values of

$^n$. We must emphasise that the values of ![]() $\beta$ and

$\beta$ and ![]() $n$ are experimentally determined for a certain domain of validity, as shown in figure 2(b).

$n$ are experimentally determined for a certain domain of validity, as shown in figure 2(b).

The motion of the film is impelled by gravity and impeded by the Ostwaldian consistency index ![]() $\beta$, which yields a characteristic time

$\beta$, which yields a characteristic time ![]() $\tau \;\widehat {=}\; (\beta / \rho gr)^{1/n}$, also used by Boulogne et al. (Reference Boulogne, Pauchard and Giorgiutti-Dauphiné2012) for polymer solutions. This definition entails the two quantities

$\tau \;\widehat {=}\; (\beta / \rho gr)^{1/n}$, also used by Boulogne et al. (Reference Boulogne, Pauchard and Giorgiutti-Dauphiné2012) for polymer solutions. This definition entails the two quantities ![]() $\beta$ and

$\beta$ and ![]() $n$ that characterise an Ostwaldian fluid. Defining a gravity time

$n$ that characterise an Ostwaldian fluid. Defining a gravity time ![]() $\tau _{g} \;\widehat {=}\; (r / g )^{1/2}$ and a momentum diffusion time

$\tau _{g} \;\widehat {=}\; (r / g )^{1/2}$ and a momentum diffusion time ![]() $\tau _{d} \;\widehat {=}\; (\rho r^2 / \beta )^{1/(2-n)}$ we obtain a physical significance of the Ostwaldian characteristic time

$\tau _{d} \;\widehat {=}\; (\rho r^2 / \beta )^{1/(2-n)}$ we obtain a physical significance of the Ostwaldian characteristic time ![]() $\tau \equiv (\tau _{g}^2 / \tau _{d}^{2-n})^{1/n}$.

$\tau \equiv (\tau _{g}^2 / \tau _{d}^{2-n})^{1/n}$.

We now apply a physically-based dimensional analysis. First, we posit that the bead frequency ![]() $f$ depends on the following quantities of interest: the characteristic time

$f$ depends on the following quantities of interest: the characteristic time ![]() $\tau$ of the Ostwaldian fluid, the fibre radius

$\tau$ of the Ostwaldian fluid, the fibre radius ![]() $r$, the weight per unit volume

$r$, the weight per unit volume ![]() $\rho g$ of the fluid, the surface tension

$\rho g$ of the fluid, the surface tension ![]() $\sigma$ and the volume flow rate

$\sigma$ and the volume flow rate ![]() $Q$ of the fluid. Second, we note that two length dimensions exist: one

$Q$ of the fluid. Second, we note that two length dimensions exist: one ![]() $L_r$ in the radial direction and the other

$L_r$ in the radial direction and the other ![]() $L_z$ in the vertical direction. Adding base dimensions is a method introduced by Huntley (Reference Huntley1952) and is known as vectorial or directional dimensional analysis. Expressing the dimensions of all the quantities of interest in terms of the minimum number of base dimensions required, we get

$L_z$ in the vertical direction. Adding base dimensions is a method introduced by Huntley (Reference Huntley1952) and is known as vectorial or directional dimensional analysis. Expressing the dimensions of all the quantities of interest in terms of the minimum number of base dimensions required, we get

\begin{equation} \left.\begin{gathered} \mbox{dim}[f] = {T}^{{-}1}, \quad \mbox{dim}[\tau] = {T}, \quad \mbox{dim}[Q] = {L}_r^2{L}_z {T}^{{-}1}, \\ \mbox{dim}[r] = {L}_r, \quad \mbox{dim}[\rho g] = {M}{L}_r^{{-}2}{T}^{{-}2} ,\quad \mbox{dim}[\sigma] = {M}{L}_r^{{-}1}{L}_z {T}^{{-}2}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \mbox{dim}[f] = {T}^{{-}1}, \quad \mbox{dim}[\tau] = {T}, \quad \mbox{dim}[Q] = {L}_r^2{L}_z {T}^{{-}1}, \\ \mbox{dim}[r] = {L}_r, \quad \mbox{dim}[\rho g] = {M}{L}_r^{{-}2}{T}^{{-}2} ,\quad \mbox{dim}[\sigma] = {M}{L}_r^{{-}1}{L}_z {T}^{{-}2}. \end{gathered}\right\} \end{equation}As we have six quantities of interest and four base dimensions, the Pi-theorem yields two dimensionless groups for describing the problem. Making all the quantities of interest dimensionless, we obtain

\begin{equation}

\left.\begin{array}{cccccc@{}} \dfrac{f}{{T}^{{-}1}} &

\dfrac{\tau}{{T}} & \dfrac{Q}{{L}_r^2{L}_z {T}^{{-}1}} &

\dfrac{r}{{L}_r} & \dfrac{\rho

g}{{M}{L}_r^{{-}2}{T}^{{-}2}} &

\dfrac{\sigma}{{M}{L}_r^{{-}1}{L}_z {T}^{{-}2}} \\ (1) &

(2) & (3) & (4) & (5) & (6) \end{array}.\right\}

\end{equation}

\begin{equation}

\left.\begin{array}{cccccc@{}} \dfrac{f}{{T}^{{-}1}} &

\dfrac{\tau}{{T}} & \dfrac{Q}{{L}_r^2{L}_z {T}^{{-}1}} &

\dfrac{r}{{L}_r} & \dfrac{\rho

g}{{M}{L}_r^{{-}2}{T}^{{-}2}} &

\dfrac{\sigma}{{M}{L}_r^{{-}1}{L}_z {T}^{{-}2}} \\ (1) &

(2) & (3) & (4) & (5) & (6) \end{array}.\right\}

\end{equation}

Choosing a yardstick for each base dimension, starting with the simplest:

\begin{equation} \left.\begin{gathered} (2) \Rightarrow {T} = \tau \quad (4) \Rightarrow {L}_r =r ,\\ (3) \Rightarrow {L}_z = \frac{Q \tau}{r^2} \quad (6) \Rightarrow {M} = \frac{\sigma r^3\tau}{Q}, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} (2) \Rightarrow {T} = \tau \quad (4) \Rightarrow {L}_r =r ,\\ (3) \Rightarrow {L}_z = \frac{Q \tau}{r^2} \quad (6) \Rightarrow {M} = \frac{\sigma r^3\tau}{Q}, \end{gathered}\right\} \end{equation}the two Pi-terms immediately appear,

Let us now look for the physical interpretations of the two Pi-terms. By analogy with a Newtonian fluid for which ![]() $\beta \equiv \mu$ and

$\beta \equiv \mu$ and ![]() $n=1$, the dimensionless frequency

$n=1$, the dimensionless frequency ![]() $\varPi _1$ is the ratio of the bead frequency

$\varPi _1$ is the ratio of the bead frequency ![]() $f$ to the scale

$f$ to the scale ![]() $gr/\nu$ of the kinematic wave frequency that may propagate on the surface of the liquid film, where

$gr/\nu$ of the kinematic wave frequency that may propagate on the surface of the liquid film, where ![]() $\nu = \mu /\rho$ is the kinematic viscosity. As the speed of a kinematic wave is three times the average velocity of the film,

$\nu = \mu /\rho$ is the kinematic viscosity. As the speed of a kinematic wave is three times the average velocity of the film, ![]() $\varPi _1$ can be considered the product of the measured frequency by the film advective time scale. Consequently,

$\varPi _1$ can be considered the product of the measured frequency by the film advective time scale. Consequently, ![]() $\varPi _1$ can be thought of as a Strouhal number

$\varPi _1$ can be thought of as a Strouhal number ![]() $St \;\widehat {=}\; f\tau$.

$St \;\widehat {=}\; f\tau$.

By using the same analogy, and to parallel the Newtonian case ![]() $(\beta \equiv \mu, n = 1)$, the dimensionless volume flow rate

$(\beta \equiv \mu, n = 1)$, the dimensionless volume flow rate ![]() $\varPi _2$ can be interpreted as a capillary number

$\varPi _2$ can be interpreted as a capillary number ![]() $Ca \;\widehat {=}\; (\rho g Q \tau )/(\sigma r)$.

$Ca \;\widehat {=}\; (\rho g Q \tau )/(\sigma r)$.

2.2. The Newtonian limit  $n \rightarrow 1$

$n \rightarrow 1$

In the limit ![]() $n \rightarrow 1$,

$n \rightarrow 1$, ![]() $\beta \equiv \mu$ and Newtonian flow is recovered. Here, the viscogravitational time scale

$\beta \equiv \mu$ and Newtonian flow is recovered. Here, the viscogravitational time scale ![]() $\tau \equiv (\tau _{g}^2 / \tau _{d}^{2-n})^{1/n}$ reduces to (1.1). The Pi-terms in (2.4) simplify to

$\tau \equiv (\tau _{g}^2 / \tau _{d}^{2-n})^{1/n}$ reduces to (1.1). The Pi-terms in (2.4) simplify to

where ![]() $\varPi _1$ is the Strouhal number

$\varPi _1$ is the Strouhal number ![]() $St \;\widehat {=}\; ( f \mu ) / ( \rho g r )$ and

$St \;\widehat {=}\; ( f \mu ) / ( \rho g r )$ and ![]() $\varPi _2$ is the capillary number

$\varPi _2$ is the capillary number ![]() $Ca \;\widehat {=}\; ( \mu Q ) / ( \sigma r^{2} )$.

$Ca \;\widehat {=}\; ( \mu Q ) / ( \sigma r^{2} )$.

3. Experiment

We performed experiments using an apparatus composed of an aluminium frame, a 3D-printed liquid reservoir, and a custom nozzle housing that ensured the liquid was applied concentric to the fibre, as shown in figure 2(a). The apparatus was mounted on a pneumatic optical table to minimise external vibrations and preserve spatial calibrations. The fibres used were nylon monofilament with radius ranging from ![]() $0.9\,\textrm {mm} \leq r \leq 1.5\,\textrm {mm}$, and the nozzle was stainless steel with radius

$0.9\,\textrm {mm} \leq r \leq 1.5\,\textrm {mm}$, and the nozzle was stainless steel with radius ![]() $r_{n}=1.15$ mm. Before each experiment, a clean fibre was pinned at the top and bottom of the apparatus and manually tensioned. A precision syringe pump (NE-1000) applied the working fluid to the fibre at a flow rate

$r_{n}=1.15$ mm. Before each experiment, a clean fibre was pinned at the top and bottom of the apparatus and manually tensioned. A precision syringe pump (NE-1000) applied the working fluid to the fibre at a flow rate ![]() $Q$ and the resulting bead-on-fibre patterns were characterised by the bead velocity

$Q$ and the resulting bead-on-fibre patterns were characterised by the bead velocity ![]() $v$ and wavelength

$v$ and wavelength ![]() $\lambda$, shown in the inset of figure 2(a).

$\lambda$, shown in the inset of figure 2(a).

The working fluids were solutions of xanthan gum (XG), a rod-like polymer with shear-thinning behaviour and negligible elasticity, dissolved in mixtures of distilled water and glycerol. Solutions were prepared by mixing the water and glycerol until the solution appeared homogenous, adding a prescribed concentration ![]() $0\,\textrm {ppm} \leq \varPhi \leq 3000$ ppm of XG to the solution, and stirring the solution with a magnetic stirrer for at least 24 hours. All solutions were tested shortly after synthesis to avoid phase separation. The surface tension

$0\,\textrm {ppm} \leq \varPhi \leq 3000$ ppm of XG to the solution, and stirring the solution with a magnetic stirrer for at least 24 hours. All solutions were tested shortly after synthesis to avoid phase separation. The surface tension ![]() $\sigma = 0.051 - 0.065$ N m

$\sigma = 0.051 - 0.065$ N m![]() $^{-1}$ and density

$^{-1}$ and density ![]() $\rho = 1204\unicode{x2013} 1224$ kg

$\rho = 1204\unicode{x2013} 1224$ kg ![]() $\textrm {m}^{-3}$ of each solution were measured with an Attension Sigma 702 tensiometer with a Whilhelmy plate and density probe, respectively. In our experiments the capillary length

$\textrm {m}^{-3}$ of each solution were measured with an Attension Sigma 702 tensiometer with a Whilhelmy plate and density probe, respectively. In our experiments the capillary length ![]() $\ell _c \;\widehat {=}\; ( \sigma / \rho g)^{1/2}$ ranged from 2.1 to 2.3 mm. Up to now, most bead frequency data were collected using thin fibres with radius

$\ell _c \;\widehat {=}\; ( \sigma / \rho g)^{1/2}$ ranged from 2.1 to 2.3 mm. Up to now, most bead frequency data were collected using thin fibres with radius ![]() $r \leq 0.5$ mm despite bead-on-fibre flows emerging on fibres up to

$r \leq 0.5$ mm despite bead-on-fibre flows emerging on fibres up to ![]() $r \approx 0.8$ mm, above which the film remains uniform (Hattori et al. Reference Hattori, Ishikawa and Mori1994). Here, we fill in this missing data by testing thick fibres

$r \approx 0.8$ mm, above which the film remains uniform (Hattori et al. Reference Hattori, Ishikawa and Mori1994). Here, we fill in this missing data by testing thick fibres ![]() $0.5\,\textrm {mm} \leq r \leq 0.75$ mm such that the axial and azimuthal interfacial curvature are comparable, as described by the Goucher number

$0.5\,\textrm {mm} \leq r \leq 0.75$ mm such that the axial and azimuthal interfacial curvature are comparable, as described by the Goucher number ![]() $Go \;\widehat {=}\; r / \ell _{c} = 0.22\unicode{x2013} 0.36$. The viscosity

$Go \;\widehat {=}\; r / \ell _{c} = 0.22\unicode{x2013} 0.36$. The viscosity ![]() $\mu$ was measured against shear rate

$\mu$ was measured against shear rate ![]() $\dot {\gamma }$ using a standard shear rate sweep from 0.1 to

$\dot {\gamma }$ using a standard shear rate sweep from 0.1 to ![]() $1000\,\textrm {s}^{-1}$ performed on an Anton-Paar 302 shear rheometer with a cone and plate configuration, as shown in figure 2(b) for a 0 ppm (Newtonian) and 50 ppm (Ostwaldian) XG solution. The rheology was characterised by an Ostwald power-law model with a consistency index

$1000\,\textrm {s}^{-1}$ performed on an Anton-Paar 302 shear rheometer with a cone and plate configuration, as shown in figure 2(b) for a 0 ppm (Newtonian) and 50 ppm (Ostwaldian) XG solution. The rheology was characterised by an Ostwald power-law model with a consistency index ![]() $\beta$ from

$\beta$ from ![]() $37 \times 10^{-3}$ to

$37 \times 10^{-3}$ to ![]() $1538 \times 10^{-3}$ Pa

$1538 \times 10^{-3}$ Pa ![]() $\textrm {s}^{n}$ and power law index

$\textrm {s}^{n}$ and power law index ![]() $n$ from 0.53 to 1 for all solutions tested. For the limiting case of a Newtonian fluid,

$n$ from 0.53 to 1 for all solutions tested. For the limiting case of a Newtonian fluid, ![]() $n=1$ and

$n=1$ and ![]() $\beta = \mu$.

$\beta = \mu$.

We began each set of experiments by flushing the system with IPA and inserting a new fibre. The liquid was then applied to the fibre, readily destabilising into a bead-on-fibre pattern that could be symmetric or asymmetric, depending on the solution and fibre radius. A Chronos 2.1-HD high-speed camera (Kron Technologies) or a Nikon D3500 DSLR camera was used to record the pattern, which was illuminated from the side by a Godox SL200III studio light and an LED panel. Videos were recorded approximately 500 mm beneath the nozzle and the liquid was continuously applied for up to 20 minutes before recording to ensure steady-state dynamics. The videos were analysed by tracking a column of pixels intersecting the widest part of the flowing beads giving rise to the spatiotemporal diagram shown in figure 2(c). The slope of the white lines measures the bead velocity ![]() $v$, which is constant and consistent across all beads when the lines are straight and parallel. The horizontal spacing between lines measures the time

$v$, which is constant and consistent across all beads when the lines are straight and parallel. The horizontal spacing between lines measures the time ![]() $\tau$ between two beads passing the same point giving a frequency

$\tau$ between two beads passing the same point giving a frequency ![]() $f=1/\tau$. Herein, we restrict our study to patterns with constant frequency and regular dynamics. The random error for each experiment was calculated by recording a large number of beads and using the built-in standard deviation MATLAB function.

$f=1/\tau$. Herein, we restrict our study to patterns with constant frequency and regular dynamics. The random error for each experiment was calculated by recording a large number of beads and using the built-in standard deviation MATLAB function.

4. Results

To test the scaling law derived in § 2, we combined frequency data from seven prior studies (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007; Sadeghpour, Zeng & Ju Reference Sadeghpour, Zeng and Ju2017; Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019; Gabbard & Bostwick Reference Gabbard and Bostwick2021a,Reference Gabbard and Bostwickb, Reference Gabbard and Bostwick2023; Xie et al. Reference Xie, Liu, Wang and Chen2021) with our new experimental results. This extensive data set contains 1061 experiments, including symmetric and asymmetric patterns, Ostwaldian and Newtonian working liquids, fibre radii ranging from 0.1 to 1.5 mm and flow rates ranging from 0.01 to 180.56 ![]() $\textrm {mm}^{3}$ s

$\textrm {mm}^{3}$ s![]() $^{-1}$. Table 1 provides the morphology, power-law index

$^{-1}$. Table 1 provides the morphology, power-law index ![]() $n$, Goucher number

$n$, Goucher number ![]() $Go$ and capillary number

$Go$ and capillary number ![]() $Ca$ for each data source. Our new data for large fibres and shear-thinning solutions extend the range of

$Ca$ for each data source. Our new data for large fibres and shear-thinning solutions extend the range of ![]() $Ca$ by two decades, giving a total range

$Ca$ by two decades, giving a total range ![]() $10^{-4} \leq Ca \leq 10^{3}$.

$10^{-4} \leq Ca \leq 10^{3}$.

A variety of patterns are observed across the data, such that even data with similar ![]() $Ca$ may exhibit stark differences in bead profiles and spacing

$Ca$ may exhibit stark differences in bead profiles and spacing ![]() $\lambda$, as demonstrated in figure 3(a) for patterns with

$\lambda$, as demonstrated in figure 3(a) for patterns with ![]() $Ca \approx 10^{-1}$ and

$Ca \approx 10^{-1}$ and ![]() $n$ decreasing from 1 to 0.53 (left to right). In this example, shear thinning promotes asymmetry, leading to a comparable increase in speed and spacing of beads. Figure 3(b) plots the Strouhal number

$n$ decreasing from 1 to 0.53 (left to right). In this example, shear thinning promotes asymmetry, leading to a comparable increase in speed and spacing of beads. Figure 3(b) plots the Strouhal number ![]() $St$ against capillary number

$St$ against capillary number ![]() $Ca$ for the symmetric (hollow markers) and asymmetric (solid markers) bead-on-fibre data represented in table 1. The plot marker shape denotes the source and the marker shading indicates the value of the power-law index

$Ca$ for the symmetric (hollow markers) and asymmetric (solid markers) bead-on-fibre data represented in table 1. The plot marker shape denotes the source and the marker shading indicates the value of the power-law index ![]() $n$. The data collapses along a single power-law trend, shown as a red dashed line. Here the best-fit trend is

$n$. The data collapses along a single power-law trend, shown as a red dashed line. Here the best-fit trend is ![]() $St=0.06\,Ca^{0.68}$ with goodness-of-fit

$St=0.06\,Ca^{0.68}$ with goodness-of-fit ![]() ${R}^{2}=0.92$. Thus, we find strong evidence for the proposed scaling law across an extensive range of

${R}^{2}=0.92$. Thus, we find strong evidence for the proposed scaling law across an extensive range of ![]() $Ca$.

$Ca$.

Figure 3. (a) Bead-on-fibre patterns for ![]() $Ca \approx 10^{-1}$. (b) Strouhal number

$Ca \approx 10^{-1}$. (b) Strouhal number ![]() $St \;\widehat {=}\; f \tau = f (\beta / \rho gr)^{1/n}$ plotted against capillary number

$St \;\widehat {=}\; f \tau = f (\beta / \rho gr)^{1/n}$ plotted against capillary number ![]() $Ca \;\widehat {=}\; (\rho g Q \tau )/(\sigma r)$ for symmetric (hollow markers) and asymmetric (solid markers) bead-on-fibre patterns. Marker shape indicates the data source and marker shading corresponds to the shear-thinning index

$Ca \;\widehat {=}\; (\rho g Q \tau )/(\sigma r)$ for symmetric (hollow markers) and asymmetric (solid markers) bead-on-fibre patterns. Marker shape indicates the data source and marker shading corresponds to the shear-thinning index ![]() $n$ following the shading scale bar. The dashed red lines shows a best-fit power-law trend

$n$ following the shading scale bar. The dashed red lines shows a best-fit power-law trend ![]() $St=0.06\,Ca^{0.68}$ with goodness-of-fit

$St=0.06\,Ca^{0.68}$ with goodness-of-fit ![]() ${R}^{2}=0.92$.

${R}^{2}=0.92$.

Table 1. Data source with reported flow morphology, shear-thinning index ![]() $n$, Goucher number

$n$, Goucher number ![]() $Go$ and capillary number

$Go$ and capillary number ![]() $Ca$.

$Ca$.

Interestingly, Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012) observed that the velocity of drop-like beads is strongly influenced by the thickness of the residual film, which is controlled by the capillary number ![]() $Ca = \mu v / \sigma$. They found that the film thickness exhibits a dependency on

$Ca = \mu v / \sigma$. They found that the film thickness exhibits a dependency on ![]() $Ca^{2/3}$, drawing a direct analogy to the classic Landau–Levich–Derjaguin law. In this process, the bead velocity governs the film thickness, which then affects the motion of subsequent beads, establishing a dynamic equilibrium. We propose that this same mechanism, where the flow dynamics depend on the film thickness, underlies the

$Ca^{2/3}$, drawing a direct analogy to the classic Landau–Levich–Derjaguin law. In this process, the bead velocity governs the film thickness, which then affects the motion of subsequent beads, establishing a dynamic equilibrium. We propose that this same mechanism, where the flow dynamics depend on the film thickness, underlies the ![]() $Ca^{2/3}$ dependency we observe.

$Ca^{2/3}$ dependency we observe.

5. Discussion

We have validated a scaling law for ![]() $St$ across seven decades of

$St$ across seven decades of ![]() $Ca$. Our extensive data set includes changes in experimental variables that are assumed negligible in the dimensional analysis. These features include the nozzle radius

$Ca$. Our extensive data set includes changes in experimental variables that are assumed negligible in the dimensional analysis. These features include the nozzle radius ![]() $r_n$, which ranged from 0.5 to 3.2 mm in Sadeghpour et al. (Reference Sadeghpour, Zeng and Ju2017) and 0.4 to 3.3 mm in Gabbard & Bostwick (Reference Gabbard and Bostwick2021b), whose role in altering the dynamical regime was first noted by Chinju et al. (Reference Chinju, Uchiyama and Mori2000) and later modelled by Ji et al. (Reference Ji, Sadeghpour, Ju and Bertozzi2020). The orientation of the nozzle relative to the fibre is also varied within our data set, where three studies orient the nozzle perpendicular to the fibre while the others, including the current experiments, use a concentric nozzle–fibre orientation. Notably, the same qualitative regimes emerge for both orientations but with slight quantitative differences, specifically in the transition flow rate between regimes (Gabbard & Bostwick Reference Gabbard and Bostwick2021a). Despite this, our proposed scaling law accurately captures the frequency behaviour over several orders of

$r_n$, which ranged from 0.5 to 3.2 mm in Sadeghpour et al. (Reference Sadeghpour, Zeng and Ju2017) and 0.4 to 3.3 mm in Gabbard & Bostwick (Reference Gabbard and Bostwick2021b), whose role in altering the dynamical regime was first noted by Chinju et al. (Reference Chinju, Uchiyama and Mori2000) and later modelled by Ji et al. (Reference Ji, Sadeghpour, Ju and Bertozzi2020). The orientation of the nozzle relative to the fibre is also varied within our data set, where three studies orient the nozzle perpendicular to the fibre while the others, including the current experiments, use a concentric nozzle–fibre orientation. Notably, the same qualitative regimes emerge for both orientations but with slight quantitative differences, specifically in the transition flow rate between regimes (Gabbard & Bostwick Reference Gabbard and Bostwick2021a). Despite this, our proposed scaling law accurately captures the frequency behaviour over several orders of ![]() $Ca$ and is insensitive to boundary conditions at the nozzle. Different fibre types were used in the studies we examined, including nylon monofilament, nylon multifilament and cotton threads. Similar to nozzle orientation, fibre properties play a minor role in augmenting general variable dependencies but can affect patterns quantitatively. In these cases, a slip coefficient

$Ca$ and is insensitive to boundary conditions at the nozzle. Different fibre types were used in the studies we examined, including nylon monofilament, nylon multifilament and cotton threads. Similar to nozzle orientation, fibre properties play a minor role in augmenting general variable dependencies but can affect patterns quantitatively. In these cases, a slip coefficient ![]() $\lambda$ has been introduced to improve model predictions (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019). We demonstrate that our proposed scaling law is robust to fibre properties by including the results of Xie et al. (Reference Xie, Liu, Wang and Chen2021), who used fibres with different cross-sectional shapes. We expect our results to become invalid for more exotic fibre shapes or multiple fibre arrangements, which are capable of suppressing capillary instability (Wang et al. Reference Wang, Zhou, Xu, Lu, Meng and Liu2020; Gabbard, Rhoads & Bostwick Reference Gabbard, Rhoads and Bostwick2024; Xu et al. Reference Xu, Shi, Lu, Hu, Cheng, Zhu, Jiang and Liu2024).

$\lambda$ has been introduced to improve model predictions (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019). We demonstrate that our proposed scaling law is robust to fibre properties by including the results of Xie et al. (Reference Xie, Liu, Wang and Chen2021), who used fibres with different cross-sectional shapes. We expect our results to become invalid for more exotic fibre shapes or multiple fibre arrangements, which are capable of suppressing capillary instability (Wang et al. Reference Wang, Zhou, Xu, Lu, Meng and Liu2020; Gabbard, Rhoads & Bostwick Reference Gabbard, Rhoads and Bostwick2024; Xu et al. Reference Xu, Shi, Lu, Hu, Cheng, Zhu, Jiang and Liu2024).

The empirical agreement between our dataset and the scaling law derived in § 2 highlights the dominant factors governing bead frequency. Despite this, several assumptions and unexplored physics limit its applicability outside this range. The scaling is derived for unstable flow down a fibre in the absolute regime, requiring a capillary number ![]() $Ca$ large enough to avoid nonlinear saturation inhibiting bead growth (Quéré Reference Quéré1990) but low enough to remain below the absolute/convective threshold (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007). Beyond this threshold, bead-like drops become wave-like, necessitating a different axial length scale (Ruyer-Quil & Kalliadasis Reference Ruyer-Quil and Kalliadasis2012), and statistical approaches may better capture frequency behaviour. Newtonian and shear-thinning fluids modelled by (1.2) align with the derived scaling. This rheological model is valid for the moderate shear rates typical for flow down a fibre but may be less accurate in the high- and low-shear rate limits. We have not currently explored these limits in the studies discussed herein. Using thicker, thinner fibres and a more complex rheological description of the liquid behaviour could quantitatively specify these limits. In addition, while some experiments in our dataset used surfactant to promote flow symmetry (Boulogne et al. Reference Boulogne, Pauchard and Giorgiutti-Dauphiné2012; Gabbard & Bostwick Reference Gabbard and Bostwick2021a, Reference Gabbard and Bostwick2023), surfactant kinetics were not fully explored. Prior studies on fibre coatings show a complex relationship between surfactant concentration and coating thickness (Shen et al. Reference Shen, Gleason, McKinley and Stone2002), with high surfactant concentrations shown to suppress instability (Boulogne et al. Reference Boulogne, Fardin, Lerouge, Pauchard and Giorgiutti-Dauphiné2013). Similar thickening effects have been observed in polymer solutions due to normal stresses (De Ryck & Quéré Reference De Ryck and Quéré1998). The role of elasticity on bead frequency is not fully understood and may limit the applicability of our results, necessitating further experimental investigation. In summary, while the proposed scaling law captures key physics for most practical liquids, its applicability is limited and highly elastic fluids or those with high surfactant concentrations may present dynamics that deviate from our prediction.

$Ca$ large enough to avoid nonlinear saturation inhibiting bead growth (Quéré Reference Quéré1990) but low enough to remain below the absolute/convective threshold (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007). Beyond this threshold, bead-like drops become wave-like, necessitating a different axial length scale (Ruyer-Quil & Kalliadasis Reference Ruyer-Quil and Kalliadasis2012), and statistical approaches may better capture frequency behaviour. Newtonian and shear-thinning fluids modelled by (1.2) align with the derived scaling. This rheological model is valid for the moderate shear rates typical for flow down a fibre but may be less accurate in the high- and low-shear rate limits. We have not currently explored these limits in the studies discussed herein. Using thicker, thinner fibres and a more complex rheological description of the liquid behaviour could quantitatively specify these limits. In addition, while some experiments in our dataset used surfactant to promote flow symmetry (Boulogne et al. Reference Boulogne, Pauchard and Giorgiutti-Dauphiné2012; Gabbard & Bostwick Reference Gabbard and Bostwick2021a, Reference Gabbard and Bostwick2023), surfactant kinetics were not fully explored. Prior studies on fibre coatings show a complex relationship between surfactant concentration and coating thickness (Shen et al. Reference Shen, Gleason, McKinley and Stone2002), with high surfactant concentrations shown to suppress instability (Boulogne et al. Reference Boulogne, Fardin, Lerouge, Pauchard and Giorgiutti-Dauphiné2013). Similar thickening effects have been observed in polymer solutions due to normal stresses (De Ryck & Quéré Reference De Ryck and Quéré1998). The role of elasticity on bead frequency is not fully understood and may limit the applicability of our results, necessitating further experimental investigation. In summary, while the proposed scaling law captures key physics for most practical liquids, its applicability is limited and highly elastic fluids or those with high surfactant concentrations may present dynamics that deviate from our prediction.

5.1. Optimising bead-on-fibre flows

As discussed in § 1, bead-on-fibre flows have emerged as a promising solution for direct-contact heat exchangers and mass transfer applications. The effect of bead frequency on performance, whether enhancing (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019) or degrading (Zeng et al. Reference Zeng, Sadeghpour and Ju2018), depends on the specific application. In either case, our scaling law provides a design tool for optimising bead-on-fibre patterns, complementing theoretical thresholds for absolute instability (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007) and empirical guidelines for flow morphology (Gabbard & Bostwick Reference Gabbard and Bostwick2021a, Reference Gabbard and Bostwick2023) to form a comprehensive framework for efficient design. For example, consider the application of bead-on-fibre flow as a direct-contact condenser in a humidification–dehumidification desalination system (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019). In this case, high bead curvature and long retention times are desired, favouring a symmetric flow morphology, which offers higher bead density and retention. Guidelines for producing symmetric flows can be applied first. As bead frequency increases with flow rate ![]() $Q$, mass transfer conductance improves, up to the transition from absolutely to convectively unstable flow. Beyond this transition, further increases in water demand reduce system efficiency, as higher flow rates no longer boost mass transfer. Thus, the absolute/convective transition threshold (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007) serves as the next design constraint. Once the symmetric absolutely unstable flow regime is defined, our scaling law can approximate the maximum bead frequency within this parameter space. This design approach is broadly applicable but may require further refinement for specific cases, such as enhancing fibre composites with curable liquids (Ghosh, Greenfeld & Wagner Reference Ghosh, Greenfeld and Wagner2023), liquid-liquid extraction systems, such as those proposed for lithium recovery from salt lake brines (Chang et al. Reference Chang, Zheng, Xu, Wang, Su and Kuang2024), or counterflow systems with high counterflow velocities, which reduce bead frequency significantly and alter bead shape (Grünig et al. Reference Grünig, Skale and Kraume2010).

$Q$, mass transfer conductance improves, up to the transition from absolutely to convectively unstable flow. Beyond this transition, further increases in water demand reduce system efficiency, as higher flow rates no longer boost mass transfer. Thus, the absolute/convective transition threshold (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007) serves as the next design constraint. Once the symmetric absolutely unstable flow regime is defined, our scaling law can approximate the maximum bead frequency within this parameter space. This design approach is broadly applicable but may require further refinement for specific cases, such as enhancing fibre composites with curable liquids (Ghosh, Greenfeld & Wagner Reference Ghosh, Greenfeld and Wagner2023), liquid-liquid extraction systems, such as those proposed for lithium recovery from salt lake brines (Chang et al. Reference Chang, Zheng, Xu, Wang, Su and Kuang2024), or counterflow systems with high counterflow velocities, which reduce bead frequency significantly and alter bead shape (Grünig et al. Reference Grünig, Skale and Kraume2010).

6. Concluding remarks

We have derived a robust and comprehensive scaling law for the steady-state bead frequency ![]() $f$ of an absolutely unstable thin film flowing down a fibre, which relates a generalised Strouhal number

$f$ of an absolutely unstable thin film flowing down a fibre, which relates a generalised Strouhal number ![]() $St$ to the capillary number

$St$ to the capillary number ![]() $Ca$ for an Ostwaldian fluid with a Newtonian fluid as a limiting case. We verified our scaling analysis using experimental data from seven prior works (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007; Sadeghpour et al. Reference Sadeghpour, Zeng and Ju2017, Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019; Gabbard & Bostwick Reference Gabbard and Bostwick2021a,Reference Gabbard and Bostwickb, Reference Gabbard and Bostwick2023; Xie et al. Reference Xie, Liu, Wang and Chen2021) and new experiments performed with XG polymer solutions on large fibres, specifically selected to expand the range of

$Ca$ for an Ostwaldian fluid with a Newtonian fluid as a limiting case. We verified our scaling analysis using experimental data from seven prior works (Duprat et al. Reference Duprat, Ruyer-Quil, Kalliadasis and Giorgiutti-Dauphiné2007; Sadeghpour et al. Reference Sadeghpour, Zeng and Ju2017, Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019; Gabbard & Bostwick Reference Gabbard and Bostwick2021a,Reference Gabbard and Bostwickb, Reference Gabbard and Bostwick2023; Xie et al. Reference Xie, Liu, Wang and Chen2021) and new experiments performed with XG polymer solutions on large fibres, specifically selected to expand the range of ![]() $Ca$. The data spans seven orders of magnitude in

$Ca$. The data spans seven orders of magnitude in ![]() $Ca$ and fits a power-law trend of the form

$Ca$ and fits a power-law trend of the form ![]() $St \sim Ca^{2/3}$. Furthermore, the data include a diverse set of bead-on-fibre patterns including axially symmetric and asymmetric patterns, which have previously been shown to exhibit significantly different dynamics (Gabbard & Bostwick Reference Gabbard and Bostwick2021a, Reference Gabbard and Bostwick2023). Thus, our results provide valuable insight into the underlying physics that govern bead-on-fibre flows, irrespective of fibre radius

$St \sim Ca^{2/3}$. Furthermore, the data include a diverse set of bead-on-fibre patterns including axially symmetric and asymmetric patterns, which have previously been shown to exhibit significantly different dynamics (Gabbard & Bostwick Reference Gabbard and Bostwick2021a, Reference Gabbard and Bostwick2023). Thus, our results provide valuable insight into the underlying physics that govern bead-on-fibre flows, irrespective of fibre radius ![]() $r$, flow rate

$r$, flow rate ![]() $Q$, bead morphology, nozzle radius

$Q$, bead morphology, nozzle radius ![]() $r_n$ and nozzle orientation.

$r_n$ and nozzle orientation.

The agreement between empirical data and our proposed scaling law supports the use of the viscogravitational time scale first introduced by Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012) for drop-like beads and later adapted for shear-thinning flow by Boulogne et al. (Reference Boulogne, Pauchard and Giorgiutti-Dauphiné2012). Recent research has further explored flow down fibres, revealing insights that mimic natural processes and enable advanced control in practical applications. These studies provide numerous opportunities to expand and test our findings for bead-on-fibre flow, including the use of other complex fluids such as shear-thickening and viscoelastic solutions, and systems involving soft (Chao et al. Reference Chao, Zhu, Ding, Kong, Chang and Wang2024), grooved (Leonard et al. Reference Leonard, Van Hulle, Weyer, Terwagne and Vandewalle2023), twisted (Kern & Carlson Reference Kern and Carlson2024; Van Hulle et al. Reference Van Hulle, Delforge, Léonard, Follet and Vandewalle2024) or spaced fibres (Gabbard & Bostwick Reference Gabbard and Bostwick2024; Gabbard et al. Reference Gabbard, Rhoads and Bostwick2024). Moreover, our work draws inspiration from real-world applications, offering a valuable basis for future comparisons in more complex settings, such as in cross-flow (Cazaubiel & Carlson Reference Cazaubiel and Carlson2023), counterflow (Grünig et al. Reference Grünig, Skale and Kraume2010) or configurations involving closely spaced fibres (Wagstaff et al. Reference Wagstaff, Gubba, Truscott, Algashgari and Roberts2023). Evaluating the performance of our scaling in these diverse settings will be critical for optimising bead-on-fibre systems for industrial applications.

Funding

J.B.B. acknowledges support from the NSF (grant number CMMI-1935590). This project is partially supported by the Clemson University Creative Inquiry program.

Declaration of interests

The authors report no conflict of interest.

Appendix. Solution properties

The liquid properties used for the low-![]() $Ca$ experiments reported here are listed in table 2.

$Ca$ experiments reported here are listed in table 2.

Table 2. Composition and properties of solutions used for low-![]() $Ca$ data.

$Ca$ data.