1. Introduction

Gravity flow of elongated drops in circular vertical pipes is frequent in both industrial processes and natural systems. The early contribution by Beirute & Flumerfelt (Reference Beirute and Flumerfelt1977) analysed the laminar displacement of drilling muds in a pipe due to the pumping of cement slurry, modelling both fluids as non-Newtonian with yield stress. The analytical approach focused on the most favourable conditions for effective mud displacement during cementing, and a detailed analysis of the role of several important variables was performed in achieving the objective. Subsequent analyses were devoted to the buoyancy driven exchange flows of two Bingham fluids in a cylindrical inclined duct, where viscoplastic and buoyancy forces almost balance one another (Frigaard & Scherzer Reference Frigaard and Scherzer1998, Reference Frigaard and Scherzer2000; Bittleston, Ferguson & Frigaard Reference Bittleston, Ferguson and Frigaard2002; Pelipenko & Frigaard Reference Pelipenko and Frigaard2004a), in most cases in the presence of an annulus gap unwrapped in a Hele-Shaw cell of varying gap. It is noteworthy that Frigaard & Scherzer (Reference Frigaard and Scherzer1998) presented, alongside a discussion of an engineering problem, a detailed analysis of the deviatoric stress in the unyielded region. In this same flow field geometry, interface instabilities and travelling wave solutions were also analysed; see Pelipenko & Frigaard (Reference Pelipenko and Frigaard2004b), who derived the stability/instability conditions of the front during displacement on the basis of rigorous Navier–Stokes equations and well-defined scaling arguments. In addition to the theoretical studies, numerous experiments have been carried out to measure the distribution of velocity and concentration in gravity currents of Newtonian fluids flowing in inclined tubes (see e.g. Seon et al. Reference Seon, Hulin, Salin, Perrin and Hinch2006).

In natural systems, gravity flow of elongated drops in circular vertical pipes mimics magma flows in volcanoes, where degassing and temperature effects induce vertical exchange between fluids of different density and viscosity (Kazahaya, Shinohara & Saito Reference Kazahaya, Shinohara and Saito1994; Stevenson & Blake Reference Stevenson and Blake1998; Llewellin & Manga Reference Llewellin and Manga2005). Other than magma ascension during eruptions, the phenomenon is typically associated with lock-exchange flows, and is controlled by the density difference between the ascending and the descending fluids, and by their viscosity. We note that we mean fluid ascending on average, since, depending on the characteristics of the flow field, part of the lighter fluid may be dragged downwards by the denser fluid, producing a backflow. In a typical configuration, gas Taylor bubbles (Taylor Reference Taylor1961), symmetric and bullet shaped, ascend near the axis of the pipe, while the heavier fluid descends, remaining in contact with the walls. This well-defined process has received attention from numerous researchers, who developed analytical models and performed experimental measurements, in particular for elongated gas bubbles in circular pipes (Viana et al. Reference Viana, Pardo, Yánez, Trallero and Joseph2003). In terms of dominant forces, the balance can be between buoyancy and (i) inertia, (ii) viscosity or (iii) surface tension. The ascent speed scales with different variables and parameters, and the flow stability is affected by the numerical value of relevant dimensionless parameters. In the buoyancy–inertia regime, the ascent speed is proportional to ![]() $\sqrt {gR}$, where g is gravity and

$\sqrt {gR}$, where g is gravity and ![]() $R$ is the radius of curvature in the region of the vertex (Davies & Taylor Reference Davies and Taylor1950). In the buoyancy–viscosity regime, the ascent speed is

$R$ is the radius of curvature in the region of the vertex (Davies & Taylor Reference Davies and Taylor1950). In the buoyancy–viscosity regime, the ascent speed is ![]() ${\propto }{\rm \Delta} \rho gD^2/\mu$ where

${\propto }{\rm \Delta} \rho gD^2/\mu$ where ![]() $\rho$ and

$\rho$ and ![]() $\mu$ are the fluid density and dynamic viscosity and

$\mu$ are the fluid density and dynamic viscosity and ![]() $D$ is the equivalent diameter of the bubble. In some cases, inertial, capillary and viscous forces are of the same order of magnitude, and the ascent speed expression varies according to the flow regime (see Peebles Reference Peebles1953; Wallis Reference Wallis1969).

$D$ is the equivalent diameter of the bubble. In some cases, inertial, capillary and viscous forces are of the same order of magnitude, and the ascent speed expression varies according to the flow regime (see Peebles Reference Peebles1953; Wallis Reference Wallis1969).

A key element in the rise of Taylor bubbles in vertical circular pipes is the thickness of the descending liquid film, experimentally analysed by Llewellin et al. (Reference Llewellin, Del Bello, Taddeucci, Scarlato and Lane2012) for Newtonian fluids as a function of a buoyancy Reynolds number ![]() $D\sqrt {gD}/\nu$, where

$D\sqrt {gD}/\nu$, where ![]() $D$ is the pipe diameter and

$D$ is the pipe diameter and ![]() $\nu$ is the fluid kinematic viscosity. A reduction in film thickness causes an increase in the skin friction drag on the bubble, with a rate depending on

$\nu$ is the fluid kinematic viscosity. A reduction in film thickness causes an increase in the skin friction drag on the bubble, with a rate depending on ![]() $\nu$ in the viscous regime; conversely, buoyancy also increases. As a result, the film thickness is inversely proportional to the buoyancy Reynolds number. If surface tension is considered, the film thickness also undergoes a decrease with increasing Eötvös number, defined as the ratio of gravitational to capillary forces, even to the point of blocking bubble rise when surface tension is dominant.

$\nu$ in the viscous regime; conversely, buoyancy also increases. As a result, the film thickness is inversely proportional to the buoyancy Reynolds number. If surface tension is considered, the film thickness also undergoes a decrease with increasing Eötvös number, defined as the ratio of gravitational to capillary forces, even to the point of blocking bubble rise when surface tension is dominant.

Similar analyses have been conducted for bubbles rising in the presence of non-Newtonian fluids (Shosho & Ryan Reference Shosho and Ryan2001). However, the results appear to be unconvincing also because the fluid rheology is largely disregarded; some indications may be inferred from the nature of the non-Newtonian fluid (e.g. carboxymethyl cellulose mixtures are generally shear thinning), but the characterization is poor and, in defining dimensionless groups, reference is generically made to the average viscosity measured at low shear-rate values. No significant influence on the bubble rise is attributed by Shosho & Ryan (Reference Shosho and Ryan2001) to the fluid rheology.

There exist a number of recent studies on bubbles displaced by flows of non-Newtonian ambient fluids in different contexts. Jalaal & Balmforth (Reference Jalaal and Balmforth2016) conducted a lubrication analysis of the thin films buffering a long bubble that is displaced down a slit or tube by ambient viscoplastic fluid flow. Laborie et al. (Reference Laborie, Rouyer, Angelescu and Lorenceau2017) revisited the classical Taylor and Bretherton film deposition problem in a circular channel adopting a yield-stress shear-thinning fluid rather than a Newtonian one. Zare, Daneshi & Frigaard (Reference Zare, Daneshi and Frigaard2021) observed experimentally and studied theoretically that bubbles rising in a yield-stress fluid create pathways that are preferentially followed by subsequent bubbles. Shemilt et al. (Reference Shemilt, Horsley, Jensen, Thompson and Whitfield2022) performed a stability analysis of an axisymmetric layer of a viscoplastic Bingham liquid coating the interior of a rigid tube, modelling an airway in the presence of mucus.

A behaviour akin to Taylor bubbles is observed in Taylor drops, which consist of a liquid rather than a gas. In this case, the dynamics of the ascending liquid becomes as important as that of the descending liquid, and requires further investigation in order to evaluate, for example, the speed of ascent or the thickness of the descending liquid film. Taylor drops form naturally, e.g. in volcanic chimneys as a result of degassing, which generates a magma of lower density than the ambient liquid and substantially affects viscosity (Francis, Oppenheimer & Stevenson Reference Francis, Oppenheimer and Stevenson1993) by causing crystallization of a mass fraction. In this regard, the conveyor-belt scheme proposed by Huppert & Hallworth (Reference Huppert and Hallworth2007) is of particular interest: the magma, relatively rich in gas (sulphur dioxide is mainly considered, due to the easy measurements with respect to other gases) rises in the volcanic chimney and, once at the surface, releases the gas into the atmosphere. Near the surface, the process is amplified by the pressure drop, as the gas bubbles increase their size and more bubbles develop according to Henry's law. Gas liberation, with the growth of crystals, in turn produces an increase in the average density of magma, and the process is also accentuated by cooling that results in a viscosity increase: thus denser and more viscous magma is available, which sinks into the chimney with a movement of a convective nature that leads to a much lower average erupted flow rate than is actually recirculated. This is why the evaluation of the magma flow rate based on the measured amount of sulphur dioxide overestimates the actual flow rate by several orders of magnitude.

In describing the convective motion of magma, we have assumed so far that the less dense magma rises near the conduit axis, while the denser magma descends at its periphery. Actually, this configuration is only one among the several possible forms of the process, since numerous experimental tests have shown different flow regimes as a function of the viscosity ratio (also defined viscosity contrast) between the descending and ascending fluids, ![]() $\mathcal {M}=\mu _d/\mu _a$: according to Kazahaya et al. (Reference Kazahaya, Shinohara and Saito1994), the ascending fluid is near the axis only if

$\mathcal {M}=\mu _d/\mu _a$: according to Kazahaya et al. (Reference Kazahaya, Shinohara and Saito1994), the ascending fluid is near the axis only if ![]() $\mathcal {M}>300$; it occupies the periphery of the conduit, remaining adherent to the walls, for

$\mathcal {M}>300$; it occupies the periphery of the conduit, remaining adherent to the walls, for ![]() $\mathcal {M}<10$; for

$\mathcal {M}<10$; for ![]() $10<\mathcal {M}<300$ the descending fluid splits into blobs. In fact, the classification of the field geometry appears vague, since the counter-flux of two fluids in vertical pipes is largely unstable (Joseph et al. Reference Joseph, Bai, Chen and Renardy1997). Indeed, several authors have been interested in the stability of core-annular flow in the various possible configurations, performing linear (Hickox Reference Hickox1971) or nonlinear (Chen & Joseph Reference Chen and Joseph1991) analyses. A common conclusion is that for a high viscosity contrast and due to the effect of surface tension, a core-annular flow that is inherently unstable appears stable or possibly metastable, with the presence of standing waves (bamboo and corkscrew) (see e.g. Bai, Chen & Joseph Reference Bai, Chen and Joseph1992). Stability has been analysed in depth by Suckale et al. (Reference Suckale, Qin, Picchi, Keller and Battiato2018): they conclude that bistability is inherent to core-annular flows, and it is not possible to predict which of the two possible equilibrium configurations (thin- and thick-core solutions) actually takes place on the basis of pipe geometry and fluid rheology alone. Instead, it is necessary to consider the boundary conditions.

$10<\mathcal {M}<300$ the descending fluid splits into blobs. In fact, the classification of the field geometry appears vague, since the counter-flux of two fluids in vertical pipes is largely unstable (Joseph et al. Reference Joseph, Bai, Chen and Renardy1997). Indeed, several authors have been interested in the stability of core-annular flow in the various possible configurations, performing linear (Hickox Reference Hickox1971) or nonlinear (Chen & Joseph Reference Chen and Joseph1991) analyses. A common conclusion is that for a high viscosity contrast and due to the effect of surface tension, a core-annular flow that is inherently unstable appears stable or possibly metastable, with the presence of standing waves (bamboo and corkscrew) (see e.g. Bai, Chen & Joseph Reference Bai, Chen and Joseph1992). Stability has been analysed in depth by Suckale et al. (Reference Suckale, Qin, Picchi, Keller and Battiato2018): they conclude that bistability is inherent to core-annular flows, and it is not possible to predict which of the two possible equilibrium configurations (thin- and thick-core solutions) actually takes place on the basis of pipe geometry and fluid rheology alone. Instead, it is necessary to consider the boundary conditions.

In general, we expect the mechanics of Taylor drops and of slug flows or elongated drops generated by a lock exchange to be different, but as long as the viscosity difference between the two fluids is at least one order of magnitude, the speed of rise is the same (Stevenson & Blake Reference Stevenson and Blake1998). This enables collapse of the results of experiments despite the differences in the geometry of the flow field.

The buoyancy-driven flow of Taylor drops in the buoyancy–viscous regime has been analysed in detail by Picchi, Suckale & Battiato (Reference Picchi, Suckale and Battiato2020), using mechanical energy budgets including dissipation to correctly scale the radius and the speed of rise of the drops. In the non-dissipative regime, the dimensionless radius of the drops during steady-state ascent does not depend on fluid characteristics, and is equal to ![]() $\sqrt {2}/2$; when dissipation is considered, it is equal to

$\sqrt {2}/2$; when dissipation is considered, it is equal to ![]() $\sqrt {2\mathcal {R}}/2$, where

$\sqrt {2\mathcal {R}}/2$, where ![]() $\mathcal {R}=\rho _a/\rho _d<1$ is the density ratio, indicating that dissipation decreases the radius of the internal ascending current and increases the thickness of the descending current.

$\mathcal {R}=\rho _a/\rho _d<1$ is the density ratio, indicating that dissipation decreases the radius of the internal ascending current and increases the thickness of the descending current.

The present work extends the study of Taylor drops to a nonlinear rheology. Specifically, the ascending fluid is taken to be non-Newtonian and shear thinning, while the descending fluid is Newtonian. The shear-thinning behaviour is represented in general via the three-parameter Herschel–Bulkley (HB) model, able to capture the presence of a non-zero yield stress, which is fundamental in many applications; when the yield stress is negligible, the HB model reduces to the Ostwald–de Waele (OdW) model. As the latter model has the known drawback of an unrealistically large apparent viscosity for low shear stress values, we also present novel developments for the three-parameter Ellis model. The adoption of a non-Newtonian rheology in the context of buoyancy-driven vertical flows is mainly motivated by geophysical applications, and is in particular largely documented for magma flow (Manga et al. Reference Manga, Castro, Cashman and Loewenberg1998; Sonder, Zimanowski & Büttner Reference Sonder, Zimanowski and Büttner2006; Jones, Llewellin & Mader Reference Jones, Llewellin and Mader2020); a nonlinear rheology is also associated with the presence of gas bubbles and crystals, so the scheme adopted appears realistic and representative of field cases of interest. In all of the aforementioned works, the non-Newtonian behaviour is associated with an OdW shear-thinning or Cross model without yield stress, but a non-zero yield stress characterizes materials such as subliquidus basalt (Hoover, Cashman & Manga Reference Hoover, Cashman and Manga2001) in volcanic applications and edible crystal-melt suspensions (Mishra, Dufour & Windhab Reference Mishra, Dufour and Windhab2020) in the food industry.

We develop a theoretical model and experimentally validate it in an integral manner by measuring the ascent front speed and the radius of the inner current, generated with a lock-exchange set-up. Further, detailed measurements pertain to the velocity profiles.

The paper is organized as follows. Section 2 describes the theoretical model under the hypothesis of long drops, with the ascending fluid modelled according to the HB constitutive equation or its simpler subcase, the OdW equation. Section 3 describes a modification of the model using the Ellis rheology for the ascending non-Newtonian fluid. Section 4 derives and analyses the energy budget of the current to understand the dependence of the drop thickness on problem parameters, while § 5 reports the asymptotic values of the transport parameters. Section 6 describes the experiments and the measurement techniques. A discussion on observed bistability effects is included in § 7. Section 8 contains the conclusions and perspectives for future work. Mathematical details on the mechanics of the ascending and descending currents are reported in Appendix A, while dynamic similarity criteria are explained in Appendix B. Appendix C depicts the flow curves for the HB fluids used in the experiments.

2. Theoretical model with ascending HB fluid

We consider two immiscible and incompressible fluids moving in opposite directions in a circular pipe, with a rheology described by the following general constitutive equation:

where ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\boldsymbol{\mathsf{I}}$ is the unit tensor,

$\boldsymbol{\mathsf{I}}$ is the unit tensor, ![]() $\boldsymbol{\mathsf{D}}=(1/2)(\boldsymbol {\nabla } \boldsymbol {v}+\boldsymbol {\nabla } \boldsymbol {v}^T)$ is the strain-rate tensor,

$\boldsymbol{\mathsf{D}}=(1/2)(\boldsymbol {\nabla } \boldsymbol {v}+\boldsymbol {\nabla } \boldsymbol {v}^T)$ is the strain-rate tensor, ![]() $\boldsymbol {{\tau }}= 2 \eta \boldsymbol{\mathsf{D}}$ is the deviatoric tensor and

$\boldsymbol {{\tau }}= 2 \eta \boldsymbol{\mathsf{D}}$ is the deviatoric tensor and ![]() $\eta$ is the apparent viscosity. In particular, in the present section, the first fluid is taken to be described by the HB model (Herschel & Bulkley Reference Herschel and Bulkley1926), given by

$\eta$ is the apparent viscosity. In particular, in the present section, the first fluid is taken to be described by the HB model (Herschel & Bulkley Reference Herschel and Bulkley1926), given by

\begin{equation} \left. \begin{array}{ll@{}} |\boldsymbol{{\tau}}|\le \tau_y & \textrm{if}\ | \dot{\boldsymbol{\gamma}}|=0, \\ \boldsymbol{{\tau}} = \left(\mu_0|\dot{\boldsymbol{\gamma}}|^{n-1}+ \dfrac{\tau_y}{|{{\dot{\boldsymbol{\gamma}}}}|}\right) \dot{\boldsymbol{\gamma}} & \textrm{if}\ | \dot{\boldsymbol{\gamma}}|\ne 0, \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{ll@{}} |\boldsymbol{{\tau}}|\le \tau_y & \textrm{if}\ | \dot{\boldsymbol{\gamma}}|=0, \\ \boldsymbol{{\tau}} = \left(\mu_0|\dot{\boldsymbol{\gamma}}|^{n-1}+ \dfrac{\tau_y}{|{{\dot{\boldsymbol{\gamma}}}}|}\right) \dot{\boldsymbol{\gamma}} & \textrm{if}\ | \dot{\boldsymbol{\gamma}}|\ne 0, \end{array}\right\} \end{equation}

where ![]() $\mu _0$ is the consistency index,

$\mu _0$ is the consistency index, ![]() $n$ is the fluid behaviour index,

$n$ is the fluid behaviour index, ![]() $\tau _y$ is the yield stress (positive),

$\tau _y$ is the yield stress (positive), ![]() $|\dot {\boldsymbol {\gamma }}| = \sqrt {(\dot {\boldsymbol {\gamma }}:\dot {\boldsymbol {\gamma }})/2}$ and

$|\dot {\boldsymbol {\gamma }}| = \sqrt {(\dot {\boldsymbol {\gamma }}:\dot {\boldsymbol {\gamma }})/2}$ and ![]() $|\boldsymbol {{\tau }}|=\sqrt {({{\boldsymbol {\tau :\tau }}})/2}$ are a (positive) measure of the shear rate and of the stress, respectively, with

$|\boldsymbol {{\tau }}|=\sqrt {({{\boldsymbol {\tau :\tau }}})/2}$ are a (positive) measure of the shear rate and of the stress, respectively, with ![]() $\dot {\boldsymbol{\gamma}}:\dot {\boldsymbol{\gamma}}=\dot {{\gamma }}_{ij} \dot {{\gamma }}^{ij}$ and

$\dot {\boldsymbol{\gamma}}:\dot {\boldsymbol{\gamma}}=\dot {{\gamma }}_{ij} \dot {{\gamma }}^{ij}$ and ![]() ${{\boldsymbol {\tau :\tau }}}=\tau _{ij}\tau ^{ij}$; in the latter expressions, the Einstein notation applies. If

${{\boldsymbol {\tau :\tau }}}=\tau _{ij}\tau ^{ij}$; in the latter expressions, the Einstein notation applies. If ![]() $\tau _y=0$, the HB model describes an OdW fluid (Morrell & de Waele Reference Morrell and de Waele1920; Ostwald Reference Ostwald1929), if

$\tau _y=0$, the HB model describes an OdW fluid (Morrell & de Waele Reference Morrell and de Waele1920; Ostwald Reference Ostwald1929), if ![]() $n=1$, (2.2) represents a Bingham fluid (Bingham Reference Bingham1922) and, if

$n=1$, (2.2) represents a Bingham fluid (Bingham Reference Bingham1922) and, if ![]() $\tau _y=0$ and

$\tau _y=0$ and ![]() $n=1$, (2.2) models a Newtonian fluid. The assumption of an ascending HB fluid holds for the entire § 2 and is relaxed in § 3.

$n=1$, (2.2) models a Newtonian fluid. The assumption of an ascending HB fluid holds for the entire § 2 and is relaxed in § 3.

The second fluid is always taken to be Newtonian, hence ![]() $\eta =\mu _d$, where

$\eta =\mu _d$, where ![]() $\mu _d$ is the viscosity independent of the shear rate.

$\mu _d$ is the viscosity independent of the shear rate.

The flow problem is fully described by the continuity equation under the incompressibility constraint

and by the linear momentum balance equation

where ![]() $\boldsymbol {v}$ is the velocity field and

$\boldsymbol {v}$ is the velocity field and ![]() $\boldsymbol {b}$ is the body force per unit mass, reducing to gravity only in many applications.

$\boldsymbol {b}$ is the body force per unit mass, reducing to gravity only in many applications.

Let us consider a vertical pipe where the inner ascending current, of lower density, has the said HB rheology and the heavier descending current, in contact with the pipe walls, is Newtonian; see figure 1. Both currents fall under the buoyancy–viscosity regime. We further assume that the ascending current, or long drop, has a length scale parallel to the ![]() $z$ axis equal to

$z$ axis equal to ![]() $\mathcal {L}$ and a radial scale equal to the pipe radius

$\mathcal {L}$ and a radial scale equal to the pipe radius ![]() $R$, with an aspect ratio

$R$, with an aspect ratio ![]() $\varepsilon =R/\mathcal {L}\ll 1$. To derive the vertical velocity scale

$\varepsilon =R/\mathcal {L}\ll 1$. To derive the vertical velocity scale ![]() $U$, we equate, under steady-state conditions, the buoyancy

$U$, we equate, under steady-state conditions, the buoyancy ![]() ${\rm \Delta} \rho gR$ to the viscous forces at the pipe wall,

${\rm \Delta} \rho gR$ to the viscous forces at the pipe wall, ![]() $\mu _dU/R$, yielding

$\mu _dU/R$, yielding

where ![]() ${\rm \Delta} \rho =\rho _d-\rho _a$, and

${\rm \Delta} \rho =\rho _d-\rho _a$, and ![]() $\rho _a$ and

$\rho _a$ and ![]() $\rho _d$ are the density of the lighter HB ascending fluid and of the denser Newtonian descending fluid, respectively. By continuity, the radial velocity scale is

$\rho _d$ are the density of the lighter HB ascending fluid and of the denser Newtonian descending fluid, respectively. By continuity, the radial velocity scale is ![]() $UR/\mathcal {L}\equiv \varepsilon U$, the time scale is

$UR/\mathcal {L}\equiv \varepsilon U$, the time scale is ![]() $\mathcal {L}/U\equiv (R/U)/\varepsilon$ and the pressure scale is

$\mathcal {L}/U\equiv (R/U)/\varepsilon$ and the pressure scale is ![]() $\mu _dU\mathcal {L}/R^2\equiv \mu _dU/(\varepsilon R)$.

$\mu _dU\mathcal {L}/R^2\equiv \mu _dU/(\varepsilon R)$.

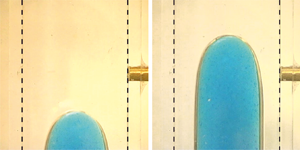

Figure 1. Schematic of a long drop in a circular pipe. The descending fluid (red) moves near the walls with an annular cross-section, the ascending fluid moves near the pipe axis. Here, ![]() $z_d$ and

$z_d$ and ![]() $z_a$ are the coordinates of the descending and ascending fronts,

$z_a$ are the coordinates of the descending and ascending fronts, ![]() $\mathcal {L}=z_a-z_d$ is the length of the drop,

$\mathcal {L}=z_a-z_d$ is the length of the drop, ![]() $U_d$ and

$U_d$ and ![]() $U_a$ are the front speeds of the two fluids.

$U_a$ are the front speeds of the two fluids.

Dimensionless relevant parameters are the density ratio ![]() $\mathcal {R}\equiv \rho _a/\rho _d<1$, the Archimedes number

$\mathcal {R}\equiv \rho _a/\rho _d<1$, the Archimedes number ![]() ${Ar}=\rho _d{\rm \Delta} \rho g R^3/\mu _d^2$, equal to the ratio between buoyancy and viscous forces, the Reynolds number

${Ar}=\rho _d{\rm \Delta} \rho g R^3/\mu _d^2$, equal to the ratio between buoyancy and viscous forces, the Reynolds number ![]() ${Re}=(\rho _dR\sqrt {g R {\rm \Delta} \rho /\rho _d})/\mu _d$, the viscosity contrast

${Re}=(\rho _dR\sqrt {g R {\rm \Delta} \rho /\rho _d})/\mu _d$, the viscosity contrast

i.e. the ratio between the scales of the viscous Newtonian and power-law stresses, and the modified Bingham number for HB fluids

the ratio between the yield stress and the scale of the shear component of the tangential stress. Large values of ![]() $\mathcal {M}$ indicate a dominant viscosity in the descending Newtonian fluid, while large values of

$\mathcal {M}$ indicate a dominant viscosity in the descending Newtonian fluid, while large values of ![]() $Bm$ indicate a dominant contribution of the yield stress to the dynamics of the ascending HB fluid.

$Bm$ indicate a dominant contribution of the yield stress to the dynamics of the ascending HB fluid.

The mass balance and momentum equations in a cylindrical geometry for the two fluids can be derived in dimensionless form as reported in Appendix A. In particular, if ![]() $\mathcal {M}\gg \varepsilon$, (A11)–(A14) reduce at

$\mathcal {M}\gg \varepsilon$, (A11)–(A14) reduce at ![]() $O (1)$ to

$O (1)$ to

\begin{align} \left.\begin{array}{@{}ll@{}} \displaystyle \dfrac{1}{\tilde{r}}\dfrac{\partial {}}{\partial {\tilde{r}}}\left(\tilde{r} \dfrac{\partial {\tilde{u}_d}}{\partial {\tilde{r}}}\right) = \dfrac{\partial {\tilde{p}_d}}{\partial {\tilde{z}}} +\dfrac{1}{1-\mathcal{R}}, & \tilde{r}\in[\tilde{\delta},1],\\ \begin{aligned} &\displaystyle\dfrac{1}{\mathcal{M}}\dfrac{1}{\tilde{r}}\dfrac{\partial {}}{\partial {\tilde{r}}} \left(\tilde{r}\left|\dfrac{\partial {\tilde{u}_a}}{\partial {\tilde{r}}}\right|^{n-1} \dfrac{\partial {\tilde{u}_a}}{\partial {\tilde{r}}}\right)\\ &\quad +\,{sgn}\left(\dfrac{\partial {\tilde{u}_a}}{\partial {\tilde{r}}}\right) \dfrac{{Bm}}{\mathcal{M}}\dfrac{1}{\tilde{r}} = \dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{z}}} + \dfrac{\mathcal{R}}{1-\mathcal{R}},\end{aligned} & \textrm{if}\ |{\tau_{rz}}| > \tau_y,\ \tilde{r}\in[0,\tilde{\delta}],\\ \tilde{u}_a=\textrm{const.}, & \textrm{if}\ |{\tau_{rz}}|\le \tau_y,\ \tilde{r}\in[0,\tilde{\delta}],\\ \displaystyle \dfrac{\partial {\tilde{p}_d}}{\partial {\tilde{r}}}=\dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{r}}}=0, \end{array}\right\} \end{align}

\begin{align} \left.\begin{array}{@{}ll@{}} \displaystyle \dfrac{1}{\tilde{r}}\dfrac{\partial {}}{\partial {\tilde{r}}}\left(\tilde{r} \dfrac{\partial {\tilde{u}_d}}{\partial {\tilde{r}}}\right) = \dfrac{\partial {\tilde{p}_d}}{\partial {\tilde{z}}} +\dfrac{1}{1-\mathcal{R}}, & \tilde{r}\in[\tilde{\delta},1],\\ \begin{aligned} &\displaystyle\dfrac{1}{\mathcal{M}}\dfrac{1}{\tilde{r}}\dfrac{\partial {}}{\partial {\tilde{r}}} \left(\tilde{r}\left|\dfrac{\partial {\tilde{u}_a}}{\partial {\tilde{r}}}\right|^{n-1} \dfrac{\partial {\tilde{u}_a}}{\partial {\tilde{r}}}\right)\\ &\quad +\,{sgn}\left(\dfrac{\partial {\tilde{u}_a}}{\partial {\tilde{r}}}\right) \dfrac{{Bm}}{\mathcal{M}}\dfrac{1}{\tilde{r}} = \dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{z}}} + \dfrac{\mathcal{R}}{1-\mathcal{R}},\end{aligned} & \textrm{if}\ |{\tau_{rz}}| > \tau_y,\ \tilde{r}\in[0,\tilde{\delta}],\\ \tilde{u}_a=\textrm{const.}, & \textrm{if}\ |{\tau_{rz}}|\le \tau_y,\ \tilde{r}\in[0,\tilde{\delta}],\\ \displaystyle \dfrac{\partial {\tilde{p}_d}}{\partial {\tilde{r}}}=\dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{r}}}=0, \end{array}\right\} \end{align}

for the descending and the ascending fluid, respectively. The symbol ![]() $\widetilde {\cdots }$ indicates a dimensionless variable and

$\widetilde {\cdots }$ indicates a dimensionless variable and ![]() $\delta$ is the radius of the internal current.

$\delta$ is the radius of the internal current.

Neglecting the interface tension, the pressure assumes a unique value in the horizontal cross-section for the descending and ascending fluids, ![]() $p_d=p_a=p(z)$, and (2.8) can be written as

$p_d=p_a=p(z)$, and (2.8) can be written as

\begin{equation} \left.\begin{array}{@{}ll@{}} \displaystyle \dfrac{1}{{r}}\dfrac{\textrm{d}}{\textrm{d}r} \left({r}\dfrac{\textrm{d}{u}_d} {\textrm{d}{r}}\right) =\underbrace{\dfrac{\textrm{d}p}{\textrm{d}z} +\dfrac{1}{1-\mathcal{R}}}_{\mathcal{P}}, & {r}\in[{\delta},1],\\ \begin{aligned}&\displaystyle\dfrac{1}{\mathcal{M}}\dfrac{1}{r}\dfrac{\textrm{d}}{\textrm{d}{r}} \left({r}\left|\dfrac{\textrm{d}{u}_a}{\textrm{d}{r}}\right|^{n-1} \dfrac{\textrm{d}{u}_a}{\textrm{d}{r}}\right)\\ &\quad +\,{sgn}\left(\dfrac{\textrm{d}{u}_a}{\textrm{d}{r}}\right) \dfrac{{Bm}}{\mathcal{M}}\dfrac{1}{r} = \underbrace{\dfrac{\textrm{d} p}{\textrm{d}z} +\dfrac{\mathcal{R}}{1-\mathcal{R}}}_{\mathcal{P}-1},\end{aligned} & \textrm{if}\ |{\tau_{rz}}| > \tau_y,\ {r}\in[0,{\delta}],\\ u_a=\textrm{const.}, & \textrm{if}\ |{\tau_{rz}}| \le \tau_y,\ {r}\in [0,{\delta}], \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{@{}ll@{}} \displaystyle \dfrac{1}{{r}}\dfrac{\textrm{d}}{\textrm{d}r} \left({r}\dfrac{\textrm{d}{u}_d} {\textrm{d}{r}}\right) =\underbrace{\dfrac{\textrm{d}p}{\textrm{d}z} +\dfrac{1}{1-\mathcal{R}}}_{\mathcal{P}}, & {r}\in[{\delta},1],\\ \begin{aligned}&\displaystyle\dfrac{1}{\mathcal{M}}\dfrac{1}{r}\dfrac{\textrm{d}}{\textrm{d}{r}} \left({r}\left|\dfrac{\textrm{d}{u}_a}{\textrm{d}{r}}\right|^{n-1} \dfrac{\textrm{d}{u}_a}{\textrm{d}{r}}\right)\\ &\quad +\,{sgn}\left(\dfrac{\textrm{d}{u}_a}{\textrm{d}{r}}\right) \dfrac{{Bm}}{\mathcal{M}}\dfrac{1}{r} = \underbrace{\dfrac{\textrm{d} p}{\textrm{d}z} +\dfrac{\mathcal{R}}{1-\mathcal{R}}}_{\mathcal{P}-1},\end{aligned} & \textrm{if}\ |{\tau_{rz}}| > \tau_y,\ {r}\in[0,{\delta}],\\ u_a=\textrm{const.}, & \textrm{if}\ |{\tau_{rz}}| \le \tau_y,\ {r}\in [0,{\delta}], \end{array}\right\} \end{equation}where the tilde has been dropped for simplicity. The boundary conditions are

\begin{equation} \left.\begin{array}{c@{}} u_d(1)=0,\\ u_a(0)\ \textrm{is finite},\\ u_d(\delta)=u_a(\delta),\\ \displaystyle\left.\dfrac{\textrm{d}u_d}{\textrm{d} r}\right|_{r=\delta}= \dfrac{1}{\mathcal{M}}\left|\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|^{n-1}_{r=\delta} \left.\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|_{r=\delta}+ \dfrac{{Bm}}{\mathcal{M}}{sgn}\left(\left.\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|_{r=\delta}\right), \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{c@{}} u_d(1)=0,\\ u_a(0)\ \textrm{is finite},\\ u_d(\delta)=u_a(\delta),\\ \displaystyle\left.\dfrac{\textrm{d}u_d}{\textrm{d} r}\right|_{r=\delta}= \dfrac{1}{\mathcal{M}}\left|\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|^{n-1}_{r=\delta} \left.\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|_{r=\delta}+ \dfrac{{Bm}}{\mathcal{M}}{sgn}\left(\left.\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|_{r=\delta}\right), \end{array}\right\} \end{equation}

representing (i) the no-slip condition at the wall, (ii) the finiteness of velocity at the axis and the continuity of (iii) velocity and (iv) shear stress ![]() $\tau _{rz}$ at the interface between the two fluids.

$\tau _{rz}$ at the interface between the two fluids.

Solving the differential problem yields the following velocity profile:

\begin{align} \left.\begin{array}{ll@{}} u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r}, & {r}\in[{\delta},1],\\ \begin{aligned} u_a(r) & =\dfrac{n}{n+1}\dfrac{[ \mathcal{M} (1-\mathcal{P})\delta-2 Bm ]^{{(n+1)}/{n}}-[\mathcal{M} (1-\mathcal{P}) r-2 Bm ]^{{(n+1)}/{n}}}{ \mathcal{M} (1-\mathcal{P})2^{1/n}}\\ & \quad +\dfrac{\mathcal{P}}{4}(\delta^2-1)-\dfrac{\delta^2}{2}\ln \delta, \end{aligned} & {r}\in[r_y,{\delta}],\\ u_{a({plug})}\equiv u_a(r_y), & {r}\in[0,r_y], \end{array}\right\} \end{align}

\begin{align} \left.\begin{array}{ll@{}} u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r}, & {r}\in[{\delta},1],\\ \begin{aligned} u_a(r) & =\dfrac{n}{n+1}\dfrac{[ \mathcal{M} (1-\mathcal{P})\delta-2 Bm ]^{{(n+1)}/{n}}-[\mathcal{M} (1-\mathcal{P}) r-2 Bm ]^{{(n+1)}/{n}}}{ \mathcal{M} (1-\mathcal{P})2^{1/n}}\\ & \quad +\dfrac{\mathcal{P}}{4}(\delta^2-1)-\dfrac{\delta^2}{2}\ln \delta, \end{aligned} & {r}\in[r_y,{\delta}],\\ u_{a({plug})}\equiv u_a(r_y), & {r}\in[0,r_y], \end{array}\right\} \end{align}

where ![]() $\mathcal {P}=\textrm {d}p/\textrm {d}z+1/(1-\mathcal {R})$ is the driving force of the ascending fluid and

$\mathcal {P}=\textrm {d}p/\textrm {d}z+1/(1-\mathcal {R})$ is the driving force of the ascending fluid and ![]() $r_y=2{Bm}/[\mathcal {M}(1-\mathcal {P})]$ is the radius of the axial plug. Imposing a zero net flux at the generic cross-section of the pipe by setting

$r_y=2{Bm}/[\mathcal {M}(1-\mathcal {P})]$ is the radius of the axial plug. Imposing a zero net flux at the generic cross-section of the pipe by setting

we obtain an equation involving ![]() $\mathcal {M}, Bm, \mathcal {P}, \delta$ and

$\mathcal {M}, Bm, \mathcal {P}, \delta$ and ![]() $n$, to be solved numerically in order to evaluate

$n$, to be solved numerically in order to evaluate ![]() $\mathcal {P}$.

$\mathcal {P}$.

For the case of a OdW fluid (a HB fluid with null yield stress, ![]() ${Bm}=0$) the ascending and descending velocities reduce to

${Bm}=0$) the ascending and descending velocities reduce to

\begin{equation} \left. \begin{array}{ll} \displaystyle u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r}, & {r}\in[{\delta},1],\\ \begin{aligned} \displaystyle u_a(r) & =\dfrac{n}{n+1}\left[\dfrac{\mathcal{M} (1-\mathcal{P})}{2}\right]^{{1}/{n}}(\delta^{{(n+1)}/{n}} -r^{{(n+1)}/{n}}) \\ & \quad +\displaystyle\dfrac{\mathcal{P}}{4}(\delta^2-1)- \dfrac{\delta^2}{2}\ln \delta, \end{aligned} & {r}\in[0,{\delta}], \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{ll} \displaystyle u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r}, & {r}\in[{\delta},1],\\ \begin{aligned} \displaystyle u_a(r) & =\dfrac{n}{n+1}\left[\dfrac{\mathcal{M} (1-\mathcal{P})}{2}\right]^{{1}/{n}}(\delta^{{(n+1)}/{n}} -r^{{(n+1)}/{n}}) \\ & \quad +\displaystyle\dfrac{\mathcal{P}}{4}(\delta^2-1)- \dfrac{\delta^2}{2}\ln \delta, \end{aligned} & {r}\in[0,{\delta}], \end{array}\right\} \end{equation}and the zero net flux condition in the generic cross-section, (2.12), becomes

\begin{equation} \frac{(1-\delta ^4) \mathcal{P}}{8}- \dfrac{n \delta ^{(3n+1)/n}}{(3 n+1) }\left[ \dfrac{\mathcal{M} (1-\mathcal{P})}{2}\right]^{{1}/{n}}- \frac{ \delta ^2 (1-\delta ^2)}{4}=0.\end{equation}

\begin{equation} \frac{(1-\delta ^4) \mathcal{P}}{8}- \dfrac{n \delta ^{(3n+1)/n}}{(3 n+1) }\left[ \dfrac{\mathcal{M} (1-\mathcal{P})}{2}\right]^{{1}/{n}}- \frac{ \delta ^2 (1-\delta ^2)}{4}=0.\end{equation}

Equation (2.14) admits an analytical solution for ![]() $n=1, 1/2, 1/3, 1/4$ (and for

$n=1, 1/2, 1/3, 1/4$ (and for ![]() $n=2, 3, 4$, a shear-thickening fluid). For

$n=2, 3, 4$, a shear-thickening fluid). For ![]() $n=1$ it results in

$n=1$ it results in

coincident with the solution derived by Picchi et al. (Reference Picchi, Suckale and Battiato2020). For ![]() $n=1/2$ the closed-form solution is

$n=1/2$ the closed-form solution is

The analytical solutions for ![]() $n=1/3, 1/4$ are cumbersome and are not shown; a numerical solution to (2.14) can be derived for any value of the fluid behaviour index.

$n=1/3, 1/4$ are cumbersome and are not shown; a numerical solution to (2.14) can be derived for any value of the fluid behaviour index.

Figure 2(a) shows the overall driving term ![]() $\mathcal {P}$ as a function of the long drop radius

$\mathcal {P}$ as a function of the long drop radius ![]() $\delta$ and figure 2(b) does the same for the pressure gradient; different values of the viscosity ratio

$\delta$ and figure 2(b) does the same for the pressure gradient; different values of the viscosity ratio ![]() $\mathcal {M}$, density ratio

$\mathcal {M}$, density ratio ![]() $\mathcal {R}$ and flow behaviour index

$\mathcal {R}$ and flow behaviour index ![]() $n$ are considered. On the one hand, the driving term increases with the drop radius, more rapidly for lower

$n$ are considered. On the one hand, the driving term increases with the drop radius, more rapidly for lower ![]() $\delta$ values and larger viscosity ratios

$\delta$ values and larger viscosity ratios ![]() $\mathcal {M}$, until a quasi-linear increase is reached for unit

$\mathcal {M}$, until a quasi-linear increase is reached for unit ![]() $\mathcal {M}$; more shear-thinning fluids determine a more rapid increase of

$\mathcal {M}$; more shear-thinning fluids determine a more rapid increase of ![]() $\mathcal {P}$ for larger viscosity ratios, while the influence of rheology is modest for lower viscosity ratios. On the other hand, the pressure gradient increases with the drop radius and also, significantly so, with the density ratio

$\mathcal {P}$ for larger viscosity ratios, while the influence of rheology is modest for lower viscosity ratios. On the other hand, the pressure gradient increases with the drop radius and also, significantly so, with the density ratio ![]() $\mathcal {R}$, while it remains largely unaffected by the fluid rheology. Figure 3(a) shows the velocity profiles computed for a Newtonian and a shear-thinning OdW fluid, for different values of

$\mathcal {R}$, while it remains largely unaffected by the fluid rheology. Figure 3(a) shows the velocity profiles computed for a Newtonian and a shear-thinning OdW fluid, for different values of ![]() $\mathcal {M}$ and for

$\mathcal {M}$ and for ![]() $\delta =0.6$. Figure 3(b) does the same for the case of an ascending HB fluid, with the presence of a modest plug as a consequence of the non-zero value of

$\delta =0.6$. Figure 3(b) does the same for the case of an ascending HB fluid, with the presence of a modest plug as a consequence of the non-zero value of ![]() ${Bm}$ selected; the velocity profile is almost unaffected by the presence of the plug. A backflow of the inner current is observed in both cases as a consequence of the drag of the descending outer current. An increasing viscosity contrast

${Bm}$ selected; the velocity profile is almost unaffected by the presence of the plug. A backflow of the inner current is observed in both cases as a consequence of the drag of the descending outer current. An increasing viscosity contrast ![]() $\mathcal {M}$ between the internal and the external fluid determines an increasing backflow in the ascending fluid; shear-thinning fluids show a flattened velocity distribution near the axis, more so for low values of

$\mathcal {M}$ between the internal and the external fluid determines an increasing backflow in the ascending fluid; shear-thinning fluids show a flattened velocity distribution near the axis, more so for low values of ![]() $\mathcal {M}$.

$\mathcal {M}$.

Figure 2. An OdW ascending fluid (![]() $Bm = 0$) and Newtonian descending fluid. (a) Dimensionless

$Bm = 0$) and Newtonian descending fluid. (a) Dimensionless ![]() $\mathcal {P}$ as a function of the long drop radius

$\mathcal {P}$ as a function of the long drop radius ![]() $\delta$ and of the viscosity ratio

$\delta$ and of the viscosity ratio ![]() $\mathcal {M}$ for a fluid behaviour index of the ascending fluid

$\mathcal {M}$ for a fluid behaviour index of the ascending fluid ![]() $n=1,1/2,1/3$; (b) dimensionless pressure gradient as a function of

$n=1,1/2,1/3$; (b) dimensionless pressure gradient as a function of ![]() $\delta$ and of the density ratio

$\delta$ and of the density ratio ![]() $\mathcal {R}$ for

$\mathcal {R}$ for ![]() $\mathcal {M}=10$. The inset shows the domain

$\mathcal {M}=10$. The inset shows the domain ![]() $\delta -\mathcal {M}$ where the

$\delta -\mathcal {M}$ where the ![]() $\mathcal {P}$ for Newtonian fluid exceeds

$\mathcal {P}$ for Newtonian fluid exceeds ![]() $\mathcal {P}$ for a shear-thinning fluid with

$\mathcal {P}$ for a shear-thinning fluid with ![]() $n=1/2$ or

$n=1/2$ or ![]() $1/3$: the two curves cannot be distinguished.

$1/3$: the two curves cannot be distinguished.

Figure 3. Velocity profiles for a generic configuration with ![]() $\delta =0.6$ for different values of the viscosity ratio

$\delta =0.6$ for different values of the viscosity ratio ![]() $\mathcal {M}$, and for flow behaviour indexes

$\mathcal {M}$, and for flow behaviour indexes ![]() $n=1,0.7$, (a) for OdW fluids (

$n=1,0.7$, (a) for OdW fluids (![]() ${Bm}=0$) and (b) for HB fluids with

${Bm}=0$) and (b) for HB fluids with ![]() ${Bm}=0.05$. The thicker part of the curves near the axis indicates the plug.

${Bm}=0.05$. The thicker part of the curves near the axis indicates the plug.

Figure 4 shows the radius of the plug for different properties of the HB fluids constituting the internal ascending current. The dashed grey area represents the fluid domain subject to shear for a fixed ![]() $Bm$ value: the domain becomes larger for small values of

$Bm$ value: the domain becomes larger for small values of ![]() $Bm$. The plug radius decreases for increasing

$Bm$. The plug radius decreases for increasing ![]() $Bm$ and for more shear-thinning fluids.

$Bm$ and for more shear-thinning fluids.

Figure 4. Radius of the plug ![]() $r_y$ as a function of the radius

$r_y$ as a function of the radius ![]() $\delta$ of the inner ascending current for different values of its properties

$\delta$ of the inner ascending current for different values of its properties ![]() $n$ and

$n$ and ![]() $Bm$ and for

$Bm$ and for ![]() $\mathcal {M}=10$. The grey area represents the shearing zone for a HB fluid with

$\mathcal {M}=10$. The grey area represents the shearing zone for a HB fluid with ![]() $Bm=1$.

$Bm=1$.

The shear stress at the interface is shown in figure 5 as a function of the interface position ![]() $\delta$ for different values of

$\delta$ for different values of ![]() $Bm$ and

$Bm$ and ![]() $n$ of the ascending inner fluid and a fixed viscosity ratio. The (negative) shear stress decreases with increasing

$n$ of the ascending inner fluid and a fixed viscosity ratio. The (negative) shear stress decreases with increasing ![]() $\delta$, reaches a minimum and then increases to zero for

$\delta$, reaches a minimum and then increases to zero for ![]() $\delta =1$. Conversely, for a given

$\delta =1$. Conversely, for a given ![]() $\delta$ the magnitude of the tangential stress increases with

$\delta$ the magnitude of the tangential stress increases with ![]() $Bm$ and is greater for shear-thinning than for Newtonian fluids.

$Bm$ and is greater for shear-thinning than for Newtonian fluids.

Figure 5. Tangential stress at ![]() $r=\delta$, the interface between the inner and the outer current, as a function of the fluid behaviour index

$r=\delta$, the interface between the inner and the outer current, as a function of the fluid behaviour index ![]() $n$ and of the Bingham number

$n$ and of the Bingham number ![]() $Bm$ of the inner ascending fluid, for

$Bm$ of the inner ascending fluid, for ![]() $\mathcal {M}=10$.

$\mathcal {M}=10$.

Figures 6(a) and 6(b) show the velocity and the tangential stress profiles for an ascending non-Newtonian fluid with zero (OdW) and non-zero (HB) yield stress, respectively. A backflow occurs in both cases, with the non-Newtonian fluid dragged down by the Newtonian one at their interface, while a plug is evident for the HB fluid. The velocity profiles associated with the HB fluid are flatter due to the presence of the plug. The tangential stress shows a linear behaviour, attaining the minimum value at the drop radius, the maximum value at the outer wall and a null value where the downward Newtonian velocity is larger in absolute value.

Figure 6. Velocity profiles (blue hatched) and tangential stress (green hatched) radial distributions for a Newtonian descending fluid and (a) an OdW ascending shear-thinning fluid (![]() ${Bm}=0$) and (b) a HB ascending fluid (

${Bm}=0$) and (b) a HB ascending fluid (![]() ${Bm}=0.2$). The parameter values are

${Bm}=0.2$). The parameter values are ![]() $n=0.5, \mathcal {M}=10, \delta =0.6$.

$n=0.5, \mathcal {M}=10, \delta =0.6$.

The average ascending and descending speed of the long drop is obtained by averaging the velocity profiles (2.11) along the cross-section

Since the zero net flux condition, (2.12), can be written as ![]() $U_aA_a+U_dA_d=0$, this gives

$U_aA_a+U_dA_d=0$, this gives

Figure 7 shows the speed of the ascending and descending fronts as a function of the long drop radius ![]() $\delta$ and of the viscosity contrast

$\delta$ and of the viscosity contrast ![]() $\mathcal {M}$ for an ascending fluid that is Newtonian (

$\mathcal {M}$ for an ascending fluid that is Newtonian (![]() $n=1$) and shear-thinning OdW fluid (

$n=1$) and shear-thinning OdW fluid (![]() ${Bm}=0$) with

${Bm}=0$) with ![]() $n=1/2, 1/3$. It is seen that the speed of the ascending fluid depends on the long drop radius in a non-monotonic fashion, first increasing from zero, reaching a maximum and then decreasing towards zero as

$n=1/2, 1/3$. It is seen that the speed of the ascending fluid depends on the long drop radius in a non-monotonic fashion, first increasing from zero, reaching a maximum and then decreasing towards zero as ![]() $\delta$ goes from zero to unity. The ascent speed strongly increases for a large viscosity contrast

$\delta$ goes from zero to unity. The ascent speed strongly increases for a large viscosity contrast ![]() $\mathcal {M}$ until

$\mathcal {M}$ until ![]() $\delta <0.8$, while it is modestly affected by the fluid rheology. The downward speed of the descending Newtonian fluid shows a similar behaviour, except the influence of the rheology of the ascending fluid is relatively more impactful. Further, the

$\delta <0.8$, while it is modestly affected by the fluid rheology. The downward speed of the descending Newtonian fluid shows a similar behaviour, except the influence of the rheology of the ascending fluid is relatively more impactful. Further, the ![]() $n$-index modulates the speed, and it can happen that a current with

$n$-index modulates the speed, and it can happen that a current with ![]() $n<1$ shows a higher ascent speed than one with

$n<1$ shows a higher ascent speed than one with ![]() $n=1$. To exemplify this case, figure 8 shows the

$n=1$. To exemplify this case, figure 8 shows the ![]() $\delta -\mathcal {M}$ shaded domain where an OdW ascending fluid with

$\delta -\mathcal {M}$ shaded domain where an OdW ascending fluid with ![]() $n=1/2$ or

$n=1/2$ or ![]() $1/3$ generates a long drop faster than a HB ascending fluid with

$1/3$ generates a long drop faster than a HB ascending fluid with ![]() $n=1$ and

$n=1$ and ![]() $Bm = 0.0, 0.1, 1.0$. The domain is almost rectangular with

$Bm = 0.0, 0.1, 1.0$. The domain is almost rectangular with ![]() $\delta$ ranging from

$\delta$ ranging from ![]() $0.05$ to

$0.05$ to ![]() $0.55$ for

$0.55$ for ![]() $\mathcal {M}>80$, while its width narrows for

$\mathcal {M}>80$, while its width narrows for ![]() $\mathcal {M}<80$, until at

$\mathcal {M}<80$, until at ![]() $\mathcal {M}\approx 10.4$ for both

$\mathcal {M}\approx 10.4$ for both ![]() $n=1/2$ and

$n=1/2$ and ![]() $1/3$, the required condition is satisfied only for a single value,

$1/3$, the required condition is satisfied only for a single value, ![]() $\delta =0.32$. Increasing

$\delta =0.32$. Increasing ![]() $Bm$ results in a shrinking of the domain.

$Bm$ results in a shrinking of the domain.

Figure 7. Long drop average speed for an OdW ascending fluid (![]() ${Bm}=0$). (a) Ascent speed and (b) descent speed as a function of the long drop radius

${Bm}=0$). (a) Ascent speed and (b) descent speed as a function of the long drop radius ![]() $\delta$ and the viscosity ratio

$\delta$ and the viscosity ratio ![]() $\mathcal {M}$ for

$\mathcal {M}$ for ![]() $n=1,1/2,1/3$.

$n=1,1/2,1/3$.

Figure 8. Ranges ![]() $\delta$–

$\delta$–![]() $\mathcal {M}$ where the ascent speed for an OdW fluid with

$\mathcal {M}$ where the ascent speed for an OdW fluid with ![]() $n=1/2$ and

$n=1/2$ and ![]() $n=1/3$ is larger than the ascent speed for a HB fluid with

$n=1/3$ is larger than the ascent speed for a HB fluid with ![]() $n=1$ and

$n=1$ and ![]() ${Bm}=0, 0.1, 1$.

${Bm}=0, 0.1, 1$.

The limit condition ![]() $\mathcal {M}\rightarrow \infty$ is equivalent to a descending Newtonian fluid having a viscosity much larger than the viscosity (for a Newtonian ascending fluid) or the apparent viscosity (for a HB ascending fluid) of the inner current. The asymptotic speeds are

$\mathcal {M}\rightarrow \infty$ is equivalent to a descending Newtonian fluid having a viscosity much larger than the viscosity (for a Newtonian ascending fluid) or the apparent viscosity (for a HB ascending fluid) of the inner current. The asymptotic speeds are

\begin{equation} \left. \begin{array}{l@{}} U_d(\delta,\mathcal{M}\rightarrow\infty,{Bm},n)={-} \dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8(1-\delta^2)},\\ U_a(\delta,\mathcal{M}\rightarrow\infty,{Bm},n)= \dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8\delta^2}, \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{l@{}} U_d(\delta,\mathcal{M}\rightarrow\infty,{Bm},n)={-} \dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8(1-\delta^2)},\\ U_a(\delta,\mathcal{M}\rightarrow\infty,{Bm},n)= \dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8\delta^2}, \end{array}\right\} \end{equation}

and do not depend on ![]() ${Bm}$ or the fluid behaviour index

${Bm}$ or the fluid behaviour index ![]() $n$. This result was expected, since in (2.9), the limit

$n$. This result was expected, since in (2.9), the limit ![]() $\mathcal {M}\to \infty$, with finite

$\mathcal {M}\to \infty$, with finite ![]() $Bm$, leads to the condition

$Bm$, leads to the condition ![]() $\mathcal {P}=1$ with the homogeneous boundary condition

$\mathcal {P}=1$ with the homogeneous boundary condition ![]() $\textrm {d}u_d/\textrm {d}r=0$ at

$\textrm {d}u_d/\textrm {d}r=0$ at ![]() $r=\delta$, which allows integration of the velocity profile of the Newtonian descending current without involving any rheological parameter of the ascending fluid. When

$r=\delta$, which allows integration of the velocity profile of the Newtonian descending current without involving any rheological parameter of the ascending fluid. When ![]() $\mathcal {M}\to \infty$ and

$\mathcal {M}\to \infty$ and ![]() $Bm$ is of the same order as

$Bm$ is of the same order as ![]() $\mathcal {M}$, the boundary conditions for the descending fluid reduces to

$\mathcal {M}$, the boundary conditions for the descending fluid reduces to ![]() $\textrm {d}u_d/\textrm {d}r=- Bm /\mathcal {M}$ at

$\textrm {d}u_d/\textrm {d}r=- Bm /\mathcal {M}$ at ![]() $r=\delta$, and the asymptotic speeds are

$r=\delta$, and the asymptotic speeds are

\begin{align} \left. \begin{array}{l@{}} U_d(\delta,\mathcal{M}\rightarrow\infty,{Bm}=O(\mathcal{M}),n) ={-}\dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8(1-\delta^2)}+ \dfrac{Bm}{\mathcal{M}}\dfrac{1-\delta^2}{8\delta},\\ U_a(\delta,\mathcal{M}\rightarrow\infty,{Bm}=O(\mathcal{M}),n) =\dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8\delta^2}- \dfrac{Bm}{\mathcal{M}}\dfrac{(1-\delta^2)^2}{8\delta^3}, \end{array}\right\} \end{align}

\begin{align} \left. \begin{array}{l@{}} U_d(\delta,\mathcal{M}\rightarrow\infty,{Bm}=O(\mathcal{M}),n) ={-}\dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8(1-\delta^2)}+ \dfrac{Bm}{\mathcal{M}}\dfrac{1-\delta^2}{8\delta},\\ U_a(\delta,\mathcal{M}\rightarrow\infty,{Bm}=O(\mathcal{M}),n) =\dfrac{\delta^4(3-4\ln\delta)+1-4\delta^2}{8\delta^2}- \dfrac{Bm}{\mathcal{M}}\dfrac{(1-\delta^2)^2}{8\delta^3}, \end{array}\right\} \end{align}

with the descending current slowed by the tangential stress at the interface of the ascending internal plug. Equations (2.20) are valid only for the ![]() $\delta$ values that make the average speed for the descending and ascending current negative and positive, respectively.

$\delta$ values that make the average speed for the descending and ascending current negative and positive, respectively.

The other limit of interest ![]() $\mathcal {M}\rightarrow 0$ corresponds to a rigid plug, and the speeds are

$\mathcal {M}\rightarrow 0$ corresponds to a rigid plug, and the speeds are

\begin{align} \left. \begin{array}{l@{}} U_d(\delta,\mathcal{M}\rightarrow 0,{Bm}=0,n)={-} \dfrac{\delta^4(\delta^2-1-\ln\delta-\delta^2\ln\delta)}{2(1-\delta^4)},\\ U_a(\delta,\mathcal{M}\rightarrow 0,{Bm}=0,n)= \dfrac{\delta^2(\delta^2-1-\ln\delta-\delta^2\ln\delta)}{2(\delta^2+1)}, \end{array}\right\} \end{align}

\begin{align} \left. \begin{array}{l@{}} U_d(\delta,\mathcal{M}\rightarrow 0,{Bm}=0,n)={-} \dfrac{\delta^4(\delta^2-1-\ln\delta-\delta^2\ln\delta)}{2(1-\delta^4)},\\ U_a(\delta,\mathcal{M}\rightarrow 0,{Bm}=0,n)= \dfrac{\delta^2(\delta^2-1-\ln\delta-\delta^2\ln\delta)}{2(\delta^2+1)}, \end{array}\right\} \end{align}

again independent on the fluid behaviour index ![]() $n$. Note that, for

$n$. Note that, for ![]() $\mathcal {M} \to 0$, the limiting radius of the plug tends to infinity unless

$\mathcal {M} \to 0$, the limiting radius of the plug tends to infinity unless ![]() $Bm = 0$ since

$Bm = 0$ since ![]() $r_y=2 Bm /(\mathcal {M}(1-\mathcal {P}))$ with

$r_y=2 Bm /(\mathcal {M}(1-\mathcal {P}))$ with ![]() $\mathcal {P}< 1$, so the latter limit condition is only valid for an OdW fluid with

$\mathcal {P}< 1$, so the latter limit condition is only valid for an OdW fluid with ![]() $Bm=0$.

$Bm=0$.

For ![]() $\mathcal {M}=O(1)$ and

$\mathcal {M}=O(1)$ and ![]() $Bm$ sufficiently large, the ascending current is all plug, with

$Bm$ sufficiently large, the ascending current is all plug, with ![]() $\mathcal {P}\to 2\delta ^2/(1+\delta ^2)$. The condition

$\mathcal {P}\to 2\delta ^2/(1+\delta ^2)$. The condition ![]() $r_y=\delta$ is reached for

$r_y=\delta$ is reached for ![]() ${Bm}=\mathcal {M}\delta (1-\delta ^2)/(2+2\delta ^2)$, with a maximum value

${Bm}=\mathcal {M}\delta (1-\delta ^2)/(2+2\delta ^2)$, with a maximum value ![]() ${Bm}\approx 0.15\mathcal {M}$, so for

${Bm}\approx 0.15\mathcal {M}$, so for ![]() $Bm$ not particularly large. The asymptotic speeds are again those in (2.21).

$Bm$ not particularly large. The asymptotic speeds are again those in (2.21).

A more in-depth analysis of the asymptotic ascending speed for ![]() $\mathcal {M} \to 0$ and

$\mathcal {M} \to 0$ and ![]() $\mathcal {M} \to \infty$, and of the corresponding flow rate, is reported in § 5.

$\mathcal {M} \to \infty$, and of the corresponding flow rate, is reported in § 5.

3. The Ellis model for the inner ascending current

In the previous section, the HB model adopted for the ascending fluid reduces to the OdW model for ![]() $Bm=0$. Now the OdW model typically shows an inconsistency: the apparent viscosity tends to infinity for shear rates tending to zero (see e.g. Myers Reference Myers2005). In order to eliminate this inconsistency and to adapt the rheological model to the effective experimental behaviour of shear-thinning fluids, we adopt the three-parameter Ellis model, which has been extensively and successfully applied to describe the flow in complex geometries (Al-Behadili et al. Reference Al-Behadili, Sellier, Hewett, Nokes and Moyers-Gonzalez2019; Ali et al. Reference Ali, Hussain, Ullah and Bég2019; Celli, Barletta & Brandão Reference Celli, Barletta and Brandão2021; Ciriello et al. Reference Ciriello, Lenci, Longo and Di Federico2021; Picchi et al. Reference Picchi, Ullmann, Brauner and Poesio2021). The Ellis model relates the apparent viscosity to the stress tensor as

$Bm=0$. Now the OdW model typically shows an inconsistency: the apparent viscosity tends to infinity for shear rates tending to zero (see e.g. Myers Reference Myers2005). In order to eliminate this inconsistency and to adapt the rheological model to the effective experimental behaviour of shear-thinning fluids, we adopt the three-parameter Ellis model, which has been extensively and successfully applied to describe the flow in complex geometries (Al-Behadili et al. Reference Al-Behadili, Sellier, Hewett, Nokes and Moyers-Gonzalez2019; Ali et al. Reference Ali, Hussain, Ullah and Bég2019; Celli, Barletta & Brandão Reference Celli, Barletta and Brandão2021; Ciriello et al. Reference Ciriello, Lenci, Longo and Di Federico2021; Picchi et al. Reference Picchi, Ullmann, Brauner and Poesio2021). The Ellis model relates the apparent viscosity to the stress tensor as

\begin{equation} \eta=\dfrac{\eta_0}{1+\left(\dfrac{{{{\boldsymbol{\tau: \tau}}}}}{2\tau_0^2}\right)^{(\alpha-1)/2}}, \end{equation}

\begin{equation} \eta=\dfrac{\eta_0}{1+\left(\dfrac{{{{\boldsymbol{\tau: \tau}}}}}{2\tau_0^2}\right)^{(\alpha-1)/2}}, \end{equation}

where ![]() $\tau _0$ is the shear stress corresponding to an apparent viscosity

$\tau _0$ is the shear stress corresponding to an apparent viscosity ![]() $\eta _0/2$ and

$\eta _0/2$ and ![]() $\alpha \ge 1$ for a shear-thinning fluid is an indicial parameter. The apparent viscosity tends to 0 for

$\alpha \ge 1$ for a shear-thinning fluid is an indicial parameter. The apparent viscosity tends to 0 for ![]() $\tau _0\to 0$ and

$\tau _0\to 0$ and ![]() $\alpha >1$ and tends to

$\alpha >1$ and tends to ![]() $\eta _0/2$ for

$\eta _0/2$ for ![]() $\alpha \to 1$. For intense shear stress

$\alpha \to 1$. For intense shear stress ![]() $\tau \gg \tau _0$ the apparent viscosity reduces to

$\tau \gg \tau _0$ the apparent viscosity reduces to

and the fluid behaves as an OdW power law with ![]() $\alpha =1/n$ and a consistency factor

$\alpha =1/n$ and a consistency factor ![]() $\mu _0=\eta _0^n\tau _0^{1-n}$. For

$\mu _0=\eta _0^n\tau _0^{1-n}$. For ![]() $\alpha =1$ the fluid is Newtonian with

$\alpha =1$ the fluid is Newtonian with ![]() $\eta =\eta _0/2$.

$\eta =\eta _0/2$.

With the same approximations adopted for an ascending HB fluid, the balance of linear momentum in the vertical direction reads

\begin{equation} \dfrac{1}{\mathcal{M'}}\dfrac{\partial \tilde{u}_a}{\partial \tilde{r}}=\left(\underbrace{\dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{z}}} + \dfrac{\mathcal{R}}{1-\mathcal{R}}}_{\mathcal{P}-1}\right) \left[1+\beta\left|\underbrace{\dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{z}}} +\dfrac{\mathcal{R}}{1-\mathcal{R}}}_{\mathcal{P}-1}\right|^{\alpha-1} \left(\dfrac{\tilde{r}}{2}\right)^{\alpha-1}\right] \dfrac{\tilde{r}}{2},\quad \tilde{r}\in[0,\tilde{\delta}], \end{equation}

\begin{equation} \dfrac{1}{\mathcal{M'}}\dfrac{\partial \tilde{u}_a}{\partial \tilde{r}}=\left(\underbrace{\dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{z}}} + \dfrac{\mathcal{R}}{1-\mathcal{R}}}_{\mathcal{P}-1}\right) \left[1+\beta\left|\underbrace{\dfrac{\partial {\tilde{p}_a}}{\partial {\tilde{z}}} +\dfrac{\mathcal{R}}{1-\mathcal{R}}}_{\mathcal{P}-1}\right|^{\alpha-1} \left(\dfrac{\tilde{r}}{2}\right)^{\alpha-1}\right] \dfrac{\tilde{r}}{2},\quad \tilde{r}\in[0,\tilde{\delta}], \end{equation}where a second viscosity ratio

was introduced, and the parameter

measures the relative importance of buoyancy and the typical shear stress of an Ellis fluid. The boundary conditions are

\begin{equation} \left. \begin{array}{c@{}} u_d(1)=0,\\ u_a(0)\ \textrm{is finite},\\ u_d(\delta)=u_a(\delta),\\ \left.\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|_{r=\delta} =\mathcal{M}'\left[1+\beta\left|\left.\dfrac{\textrm{d}u_d}{\textrm{d} r}\right|_{r=\delta}\right|^{\alpha-1}\right] \left.\dfrac{\textrm{d}u_d}{\textrm{d} r}\right|_{r=\delta}, \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{c@{}} u_d(1)=0,\\ u_a(0)\ \textrm{is finite},\\ u_d(\delta)=u_a(\delta),\\ \left.\dfrac{\textrm{d}u_a}{\textrm{d} r}\right|_{r=\delta} =\mathcal{M}'\left[1+\beta\left|\left.\dfrac{\textrm{d}u_d}{\textrm{d} r}\right|_{r=\delta}\right|^{\alpha-1}\right] \left.\dfrac{\textrm{d}u_d}{\textrm{d} r}\right|_{r=\delta}, \end{array}\right\} \end{equation}with the same meaning as (2.10) and where the tilde has been dropped.

Solving the differential problem, we calculate the following velocity profiles:

\begin{equation} \left. \begin{array}{ll@{}} u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r} , & {r}\in[{\delta},1],\\ \begin{aligned} u_a(r) & =\mathcal{M}'(1-\mathcal{P})\dfrac{\delta^2-r^2}{4}+\mathcal{M}' \beta(1-\mathcal{P})^\alpha\dfrac{\delta^{\alpha+1}-r^{\alpha+1}}{2^\alpha (\alpha+1)} \\ & \quad+\dfrac{\mathcal{P}}{4}(\delta^2-1)- \dfrac{\delta^2}{2}\ln \delta,\end{aligned} & {r}\in[0,{\delta}],\\ \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{ll@{}} u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r} , & {r}\in[{\delta},1],\\ \begin{aligned} u_a(r) & =\mathcal{M}'(1-\mathcal{P})\dfrac{\delta^2-r^2}{4}+\mathcal{M}' \beta(1-\mathcal{P})^\alpha\dfrac{\delta^{\alpha+1}-r^{\alpha+1}}{2^\alpha (\alpha+1)} \\ & \quad+\dfrac{\mathcal{P}}{4}(\delta^2-1)- \dfrac{\delta^2}{2}\ln \delta,\end{aligned} & {r}\in[0,{\delta}],\\ \end{array}\right\} \end{equation}

where we have assumed ![]() $\mathcal {P}<1$ for physical consistency. For

$\mathcal {P}<1$ for physical consistency. For ![]() $\tau _{rz}\gg \tau _0$ (3.7) simplify as follows:

$\tau _{rz}\gg \tau _0$ (3.7) simplify as follows:

\begin{equation} \left. \begin{array}{ll@{}} u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r} , & {r}\in[{\delta},1],\\ \begin{aligned} u_a(r) & \approx\mathcal{M}'\beta(1-\mathcal{P})^\alpha \dfrac{\delta^{\alpha+1}-r^{\alpha+1}}{2^\alpha(\alpha+1)} \\ & \quad+\dfrac{\mathcal{P}}{4}(\delta^2-1)- \dfrac{\delta^2}{2}\ln \delta, \end{aligned} & {r}\in[0,{\delta}], \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{ll@{}} u_d(r)=\dfrac{\mathcal{P}}{4}(r^2-1)-\dfrac{\delta ^2}{2}\ln{r} , & {r}\in[{\delta},1],\\ \begin{aligned} u_a(r) & \approx\mathcal{M}'\beta(1-\mathcal{P})^\alpha \dfrac{\delta^{\alpha+1}-r^{\alpha+1}}{2^\alpha(\alpha+1)} \\ & \quad+\dfrac{\mathcal{P}}{4}(\delta^2-1)- \dfrac{\delta^2}{2}\ln \delta, \end{aligned} & {r}\in[0,{\delta}], \end{array}\right\} \end{equation}

which upon substituting ![]() $\alpha =1/n$ and

$\alpha =1/n$ and ![]() $\mu _0=\eta _0^n\tau _0^{1-n}$ collapse to (2.13) valid for an OdW fluid.

$\mu _0=\eta _0^n\tau _0^{1-n}$ collapse to (2.13) valid for an OdW fluid.

Figure 9 shows the velocity profiles computed for an ascending Ellis fluid, for different values of ![]() $\mathcal {M}',\beta,\alpha$ and for

$\mathcal {M}',\beta,\alpha$ and for ![]() $\delta =0.6$. The profiles are qualitatively similar to those for an OdW fluid, with a backflow of the inner current due to the drag of the outer current; the backflow is accentuated as the buoyancy dominates over the typical shear stress of an Ellis fluid (larger

$\delta =0.6$. The profiles are qualitatively similar to those for an OdW fluid, with a backflow of the inner current due to the drag of the outer current; the backflow is accentuated as the buoyancy dominates over the typical shear stress of an Ellis fluid (larger ![]() $\beta$). More shear-thinning fluids (larger

$\beta$). More shear-thinning fluids (larger ![]() $\alpha$) exhibit flatter velocity profiles and hence less backflow. An increasing viscosity contrast

$\alpha$) exhibit flatter velocity profiles and hence less backflow. An increasing viscosity contrast ![]() $\mathcal {M}'$ reduces the differences between velocity profiles for different values of

$\mathcal {M}'$ reduces the differences between velocity profiles for different values of ![]() $\beta$ and

$\beta$ and ![]() $\alpha$.

$\alpha$.

Figure 9. Ellis ascending fluid and Newtonian descending fluid. Velocity profiles for a generic configuration with ![]() $\delta =0.6$, different values of the ratio

$\delta =0.6$, different values of the ratio ![]() $\beta, \alpha =2,3$ and (a)

$\beta, \alpha =2,3$ and (a) ![]() $\mathcal {M}'=1$ and (b)

$\mathcal {M}'=1$ and (b) ![]() $\mathcal {M}'=10$.

$\mathcal {M}'=10$.

The average speeds of the descending outer current and of the ascending inner current are

\begin{equation} \left. \begin{array}{c@{}} U_d=\dfrac{1}{8(1-\delta^2)}[2\delta^2(1-\delta^2+2\delta^2\ln\delta)- (1-\delta^2)^2\mathcal{P}],\\ U_a=\dfrac{ \mathcal{M}' \beta\delta ^{\alpha +1} (1- \mathcal{P})^{\alpha }}{2^{\alpha }(\alpha +3)}+\dfrac{1}{8} \mathcal{M}'\delta ^2 (1-\mathcal{P})-\dfrac{1}{4} [2 \delta ^2 \ln\delta+ \mathcal{P}(1-\delta^2)], \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{c@{}} U_d=\dfrac{1}{8(1-\delta^2)}[2\delta^2(1-\delta^2+2\delta^2\ln\delta)- (1-\delta^2)^2\mathcal{P}],\\ U_a=\dfrac{ \mathcal{M}' \beta\delta ^{\alpha +1} (1- \mathcal{P})^{\alpha }}{2^{\alpha }(\alpha +3)}+\dfrac{1}{8} \mathcal{M}'\delta ^2 (1-\mathcal{P})-\dfrac{1}{4} [2 \delta ^2 \ln\delta+ \mathcal{P}(1-\delta^2)], \end{array}\right\} \end{equation}

and the corresponding flow rates are ![]() $Q_d={\rm \pi} (1-\delta ^2)U_d, Q_a={\rm \pi} \delta ^2U_a$.

$Q_d={\rm \pi} (1-\delta ^2)U_d, Q_a={\rm \pi} \delta ^2U_a$.

Figure 10 shows the average speed as a function of the long drop radius ![]() $\delta$, of the ratio of scale stresses

$\delta$, of the ratio of scale stresses ![]() $\beta$, of the viscosity ratio

$\beta$, of the viscosity ratio ![]() $\mathcal {M}'$ for Ellis shear-thinning fluids with

$\mathcal {M}'$ for Ellis shear-thinning fluids with ![]() $\alpha =2, 3$ and

$\alpha =2, 3$ and ![]() $\beta =10,100,1000,10\,000$. As for OdW and HB fluids, the ascent speed peaks at an intermediate value of the long drop radius; further, it is strongly impacted by the

$\beta =10,100,1000,10\,000$. As for OdW and HB fluids, the ascent speed peaks at an intermediate value of the long drop radius; further, it is strongly impacted by the ![]() $\beta$ value, and significantly decreases with increasing shear-thinning behaviour, especially in the low range of

$\beta$ value, and significantly decreases with increasing shear-thinning behaviour, especially in the low range of ![]() $\delta$. A similar behaviour is shared by the Newtonian descent speed, except the absolute values of the speed are lower.

$\delta$. A similar behaviour is shared by the Newtonian descent speed, except the absolute values of the speed are lower.

Figure 10. Long drop speeds for an Ellis ascending fluid and a Newtonian descending fluid. (a) Ascent speed and (b) descent speed as a function of the long drop radius ![]() $\delta$ and the ratio

$\delta$ and the ratio ![]() $\beta$ for

$\beta$ for ![]() $\alpha =2,3, \mathcal {M}'=10$.

$\alpha =2,3, \mathcal {M}'=10$.

By imposing ![]() $Q_a+Q_d=0$, an equation in

$Q_a+Q_d=0$, an equation in ![]() $\mathcal {P},\mathcal {M}',\beta,\alpha,\delta$ is obtained, which may be used to calculate the driving term

$\mathcal {P},\mathcal {M}',\beta,\alpha,\delta$ is obtained, which may be used to calculate the driving term ![]() $\mathcal {P}$ for given values of the other parameters. The equation admits analytical solutions for

$\mathcal {P}$ for given values of the other parameters. The equation admits analytical solutions for ![]() $\alpha =1,2,3,4$, and requires a numerical solution for other values of

$\alpha =1,2,3,4$, and requires a numerical solution for other values of ![]() $\alpha$.

$\alpha$.

The asymptotic velocities for ![]() $\mathcal {M}'\to \infty$ and for

$\mathcal {M}'\to \infty$ and for ![]() $\mathcal {M}'\to 0$ collapse to (2.19) and to (2.21), respectively, and are independent of

$\mathcal {M}'\to 0$ collapse to (2.19) and to (2.21), respectively, and are independent of ![]() $\beta$.

$\beta$.

A more in-depth analysis of the asymptotic ascending speed for ![]() $\mathcal {M}' \to 0$ and

$\mathcal {M}' \to 0$ and ![]() $\mathcal {M}' \to \infty$, and of the corresponding flow rate, is reported in § 5.

$\mathcal {M}' \to \infty$, and of the corresponding flow rate, is reported in § 5.

4. The energy balance for a Newtonian descending fluid and a HB or Ellis ascending fluid

The present section formulates the energy balance for the non-Newtonian ascending Taylor drop; the balance is valid after enough time has elapsed from its formation, allowing the drop to elongate so that the validity of the lubrication approximation previously employed is ensured. The ascending drop gains energy in potential form, loses energy due to viscous dissipation and stores some energy as kinetic energy of the two counter-current fluids. Neglecting the work performed by the forces at the interfaces, the balance is between kinetic energy ![]() $\mathcal {E}_k$, potential energy

$\mathcal {E}_k$, potential energy ![]() $\mathcal {E}_p$ and viscous dissipation

$\mathcal {E}_p$ and viscous dissipation ![]() $\varPhi$ according to (Picchi et al. Reference Picchi, Suckale and Battiato2020)

$\varPhi$ according to (Picchi et al. Reference Picchi, Suckale and Battiato2020)

written in dimensional form. The corresponding scales are ![]() $\mathcal {E}_k \sim \rho _d U^2 \mathcal {L}R^2, \mathcal {E}_p\sim (\rho _d-\rho _a) g\mathcal {L}^2R^2$ and

$\mathcal {E}_k \sim \rho _d U^2 \mathcal {L}R^2, \mathcal {E}_p\sim (\rho _d-\rho _a) g\mathcal {L}^2R^2$ and ![]() $\varPhi \sim \mu _dU^2\mathcal {L}$, hence (4.1) can be written in dimensionless variables as

$\varPhi \sim \mu _dU^2\mathcal {L}$, hence (4.1) can be written in dimensionless variables as

where ![]() ${Ri}$ is the Richardson number expressing the ratio between potential and kinetic energy. For the special case

${Ri}$ is the Richardson number expressing the ratio between potential and kinetic energy. For the special case ![]() ${Ri}\to \infty$ considered hereinafter the kinetic energy variation is negligible and (4.2) reduces to

${Ri}\to \infty$ considered hereinafter the kinetic energy variation is negligible and (4.2) reduces to

The potential energy in (4.1) is computed by integration over the drop region and is equal to

\begin{align} \mathcal{E}_p&=\rho_dg{\rm \pi}\left[(R^2-\delta^2)\int_{z_d}^{z_a}z\,\textrm{d} z+R^2\int_{z_a}^{L}z\,\textrm{d} z\right]\nonumber\\ &\quad +\rho_ag{\rm \pi}\left[\delta^2\int_{z_d}^{z_a}z\,\textrm{d} z+R^2\int^{z_d}_{{-}L}z\,\textrm{d} z\right]. \end{align}

\begin{align} \mathcal{E}_p&=\rho_dg{\rm \pi}\left[(R^2-\delta^2)\int_{z_d}^{z_a}z\,\textrm{d} z+R^2\int_{z_a}^{L}z\,\textrm{d} z\right]\nonumber\\ &\quad +\rho_ag{\rm \pi}\left[\delta^2\int_{z_d}^{z_a}z\,\textrm{d} z+R^2\int^{z_d}_{{-}L}z\,\textrm{d} z\right]. \end{align}In dimensionless form the potential energy results in

or equivalently

where ![]() $Q_a$ is the flow rate of the ascending current, also defined as the transport number

$Q_a$ is the flow rate of the ascending current, also defined as the transport number ![]() $Te$ (see Huppert & Hallworth Reference Huppert and Hallworth2007), and the tilde symbol is omitted for simplicity.

$Te$ (see Huppert & Hallworth Reference Huppert and Hallworth2007), and the tilde symbol is omitted for simplicity.

The dissipation rate is computed as

where ![]() $\mathcal {V}_{a,d}$ refers to the volume of ascending lighter/descending denser fluid.

$\mathcal {V}_{a,d}$ refers to the volume of ascending lighter/descending denser fluid.

In a cylindrical geometry and under a HB rheology for the internal current one has

\begin{equation} \varPhi\equiv\varPhi_d+\varPhi_a=2{\rm \pi}\mathcal{L}(t)\left\{\mu_d \int_{\delta}^R \left(\dfrac{\textrm{d}u_d}{\textrm{d} r}\right)^2 \,\textrm{d}r +\int_{0}^\delta \left[\mu_0\left|\dfrac{\textrm{d} u_a}{\textrm{d} r}\right|^{n+1}+\tau_y\left|\dfrac{\textrm{d} u_a}{\textrm{d} r}\right|\right]\,\textrm{d}r\right\}, \end{equation}

\begin{equation} \varPhi\equiv\varPhi_d+\varPhi_a=2{\rm \pi}\mathcal{L}(t)\left\{\mu_d \int_{\delta}^R \left(\dfrac{\textrm{d}u_d}{\textrm{d} r}\right)^2 \,\textrm{d}r +\int_{0}^\delta \left[\mu_0\left|\dfrac{\textrm{d} u_a}{\textrm{d} r}\right|^{n+1}+\tau_y\left|\dfrac{\textrm{d} u_a}{\textrm{d} r}\right|\right]\,\textrm{d}r\right\}, \end{equation}or in dimensionless form

\begin{equation} \tilde{\varPhi}\equiv\tilde{\varPhi}_d+\tilde{\varPhi}_a= 2{\rm \pi}\tilde{\mathcal{L}}(\tilde{t})\left\{\int_{\tilde{\delta}}^1 \left(\dfrac{\textrm{d}\tilde{u}_d}{\textrm{d} \tilde{r}} \right)^2\textrm{d}\tilde{r} +\dfrac{1}{\mathcal{M}} \int_{0}^{\tilde{\delta}} \left[\left|\dfrac{\textrm{d} \tilde{u}_a}{\textrm{d} \tilde{r}}\right|^{n+1}+{Bm} \left|\dfrac{\textrm{d}\tilde{u}_a}{\textrm{d} \tilde{r}} \right|\right]\,\textrm{d}\tilde{r}\right\}.\end{equation}

\begin{equation} \tilde{\varPhi}\equiv\tilde{\varPhi}_d+\tilde{\varPhi}_a= 2{\rm \pi}\tilde{\mathcal{L}}(\tilde{t})\left\{\int_{\tilde{\delta}}^1 \left(\dfrac{\textrm{d}\tilde{u}_d}{\textrm{d} \tilde{r}} \right)^2\textrm{d}\tilde{r} +\dfrac{1}{\mathcal{M}} \int_{0}^{\tilde{\delta}} \left[\left|\dfrac{\textrm{d} \tilde{u}_a}{\textrm{d} \tilde{r}}\right|^{n+1}+{Bm} \left|\dfrac{\textrm{d}\tilde{u}_a}{\textrm{d} \tilde{r}} \right|\right]\,\textrm{d}\tilde{r}\right\}.\end{equation}Upon integration using (2.11), (4.9) transforms into

\begin{equation} \left. \begin{array}{c} \varPhi_d = 2{\rm \pi}(U_a-U_d)\left\{ \dfrac{\rm \pi}{8}\mathcal{P} [(1-\delta^4)\mathcal{P}-4\delta^2(1-\delta^2)]- \dfrac{\rm \pi}{2}\delta^4\ln\delta\right\}t, \\ \begin{aligned} \varPhi_a & = 2{\rm \pi}(U_a-U_d)\left\{\dfrac{{\rm \pi} n[\delta \mathcal{M}(1- \mathcal{P})-2 Bm ]^{(2n+1)/n} [2n Bm +\delta \mathcal{M} (2 n+1)(1-\mathcal{P})]}{ 2^{1/n}\mathcal{M}^3 (6 n^2+5 n+1) (1-\mathcal{P})^2}\right.\\ & \quad+\left.\dfrac{ {\rm \pi} Bm [ Bm +\delta \mathcal{M}(1-\mathcal{P})] [2 Bm -\delta \mathcal{M}(1-\mathcal{P})]^2}{3 \mathcal{M}^3 (1-\mathcal{P})^2}\right\}t, \end{aligned} \end{array}\right\} \end{equation}

\begin{equation} \left. \begin{array}{c} \varPhi_d = 2{\rm \pi}(U_a-U_d)\left\{ \dfrac{\rm \pi}{8}\mathcal{P} [(1-\delta^4)\mathcal{P}-4\delta^2(1-\delta^2)]- \dfrac{\rm \pi}{2}\delta^4\ln\delta\right\}t, \\ \begin{aligned} \varPhi_a & = 2{\rm \pi}(U_a-U_d)\left\{\dfrac{{\rm \pi} n[\delta \mathcal{M}(1- \mathcal{P})-2 Bm ]^{(2n+1)/n} [2n Bm +\delta \mathcal{M} (2 n+1)(1-\mathcal{P})]}{ 2^{1/n}\mathcal{M}^3 (6 n^2+5 n+1) (1-\mathcal{P})^2}\right.\\ & \quad+\left.\dfrac{ {\rm \pi} Bm [ Bm +\delta \mathcal{M}(1-\mathcal{P})] [2 Bm -\delta \mathcal{M}(1-\mathcal{P})]^2}{3 \mathcal{M}^3 (1-\mathcal{P})^2}\right\}t, \end{aligned} \end{array}\right\} \end{equation}

where the symbol ![]() $\widetilde {\cdots }$ is omitted for simplicity, and where

$\widetilde {\cdots }$ is omitted for simplicity, and where ![]() $\mathcal {L}(t)=(U_a-U_d)t$ is the time varying length of the drop. This suggests an alternative formulation of (4.9) as

$\mathcal {L}(t)=(U_a-U_d)t$ is the time varying length of the drop. This suggests an alternative formulation of (4.9) as

clarifying that, in dimensionless form, the dissipation rate per unit length is equal to the flow rate. Figure 11 depicts the dissipation rate per unit length ![]() $\varPhi /\mathcal {L}$ for two different viscosity ratios and several combinations of ascending fluids. The dissipation rate is zero at

$\varPhi /\mathcal {L}$ for two different viscosity ratios and several combinations of ascending fluids. The dissipation rate is zero at ![]() $\delta =0,1$ and peaks at an intermediate value of

$\delta =0,1$ and peaks at an intermediate value of ![]() $\delta$ in all cases. A higher total dissipation rate is attained for a larger viscosity ratio, while shear-thinning effects decrease or increase the total dissipation rate with respect to the Newtonian case

$\delta$ in all cases. A higher total dissipation rate is attained for a larger viscosity ratio, while shear-thinning effects decrease or increase the total dissipation rate with respect to the Newtonian case ![]() $n=1$ depending on the value of the viscosity ratio. The appearance of a non-zero yield stress induces a lower total dissipation rate for many combinations of viscosity ratio and fluid behaviour index, while for other combinations the total dissipation rate is practically unchanged. There exists a complex interplay between shear rate and shear stress, so it cannot be immediately established which of the two terms is more affected by the presence of yield stress (non-zero