1. Introduction

In the vicinity of a solid boundary, cavitation bubbles in stagnant liquids collapse non-spherically. They result in jetting and shockwave emissions and expose the boundary to significant wall shear stresses and pressures. The dynamics of the simple case of a bubble collapsing near a rigid planar surface has been the subject of many studies in the last decades; see, for example, (Plesset & Chapman Reference Plesset and Chapman1971; Lauterborn & Bolle Reference Lauterborn and Bolle1975; Zhang, Duncan & Chahine Reference Zhang, Duncan and Chahine1993; Supponen et al. Reference Supponen, Obreschkow, Tinguely, Kobel, Dorsaz and Farhat2016). Jets pierce the bubble and are typically directed toward the rigid boundary. They can reach velocities of 50–100 m s![]() $^{-1}$ (Benjamin & Ellis Reference Benjamin and Ellis1966; Blake & Gibson Reference Blake and Gibson1987; Lauterborn & Kurz Reference Lauterborn and Kurz2010) for millimetre-sized bubbles at atmospheric pressure, known as regular jetting. The most important parameter that determines the bubble dynamics in a stagnant liquid and in the absence of gravity is the non-dimensional stand-off distance

$^{-1}$ (Benjamin & Ellis Reference Benjamin and Ellis1966; Blake & Gibson Reference Blake and Gibson1987; Lauterborn & Kurz Reference Lauterborn and Kurz2010) for millimetre-sized bubbles at atmospheric pressure, known as regular jetting. The most important parameter that determines the bubble dynamics in a stagnant liquid and in the absence of gravity is the non-dimensional stand-off distance ![]() $\gamma =d/R_{max}$, where

$\gamma =d/R_{max}$, where ![]() $d$ is the initial distance of bubble nucleation from the wall and

$d$ is the initial distance of bubble nucleation from the wall and ![]() $R_{max}$ is the radius of the bubble at its maximum expansion. For the smallest bubble-to-wall stand-off distances, even velocities of more than one order of magnitude larger are possible, known as needle jetting (Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2019; Reuter & Ohl Reference Reuter and Ohl2021; Bußmann et al. Reference Bußmann, Riahi, Gökce, Adami, Barcikowski and Adams2023). Most violent collapses, i.e. erosive cavitation, occur when a bubble during its collapse focuses the self-emitted shockwaves onto itself to produce a shockwave self-intensified collapse. This was observed for bubbles of very small stand-off distances, i.e.

$R_{max}$ is the radius of the bubble at its maximum expansion. For the smallest bubble-to-wall stand-off distances, even velocities of more than one order of magnitude larger are possible, known as needle jetting (Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2019; Reuter & Ohl Reference Reuter and Ohl2021; Bußmann et al. Reference Bußmann, Riahi, Gökce, Adami, Barcikowski and Adams2023). Most violent collapses, i.e. erosive cavitation, occur when a bubble during its collapse focuses the self-emitted shockwaves onto itself to produce a shockwave self-intensified collapse. This was observed for bubbles of very small stand-off distances, i.e. ![]() $\gamma \lesssim 0.2$ by Reuter, Deiter & Ohl (Reference Reuter, Deiter and Ohl2022a).

$\gamma \lesssim 0.2$ by Reuter, Deiter & Ohl (Reference Reuter, Deiter and Ohl2022a).

A particularly interesting case is when the bubble takes the shape of a slender spherical cap during maximum expansion, which leads to a liquid jet that is directed away from the boundary. This kind of jet has been predicted for mildly ellipsoidal capped bubbles by Lauer et al. (Reference Lauer, Hu, Hickel and Adams2012) and Aganin, Kosolapova & Malakhov (Reference Aganin, Kosolapova and Malakhov2019), and was later shown to occur for axisymmetric cap-shaped bubbles in simulations and experiments by Saini et al. (Reference Saini, Tanne, Arrigoni, Zaleski and Fuster2022). Here, a high-pressure region below the bubble forms that accelerates a liquid jet flow away from the surface. Other configurations involving elastic boundaries (Gibson & Blake Reference Gibson and Blake1982; Brujan et al. Reference Brujan, Nahen, Schmidt and Vogel2001) or a narrow gap (Chahine Reference Chahine1982; Gonzalez-Avila et al. Reference Gonzalez-Avila, Klaseboer, Khoo and Ohl2011b; Zeng, Gonzalez-Avila & Ohl Reference Zeng, Gonzalez-Avila and Ohl2020) result in hourglass-shaped bubbles that pinch-off and give rise to two fast and rather thin jets in opposite directions.

The broad range of bubble dynamics allows for a wide field of useful applications, such as surface cleaning (Ohl et al. Reference Ohl, Arora, Dijkink, Janve and Lohse2006a; Kim et al. Reference Kim, Kim, Choi and Kim2009; Gonzalez-Avila et al. Reference Gonzalez-Avila, Huang, Quinto-Su, Wu and Ohl2011a; Reuter & Mettin Reference Reuter and Mettin2016; Reuter et al. Reference Reuter, Lauterborn, Mettin and Lauterborn2017; Ando et al. Reference Ando, Sugawara, Sakota, Ishibashi, Matsuo and Watanabe2021, Reference Ando, Sakota, Usui, Ishibashi, Matsuo and Watanabe2023) or drug delivery via sonoporation (Prentice et al. Reference Prentice, Cuschieri, Dholakia, Prausnitz and Campbell2005; Ohl et al. Reference Ohl, Arora, Ikink, De Jong, Versluis, Delius and Lohse2006b; Gac et al. Reference Gac, Zwaan, Berg and Ohl2007). For these applications, large wall shear stresses are beneficial, especially if they can be generated without exposing the wall to an excessively large pressure that may cause damage to even the hardest materials (Tomita & Shima Reference Tomita and Shima1986; Philipp & Lauterborn Reference Philipp and Lauterborn1998; Reuter et al. Reference Reuter, Deiter and Ohl2022a). Wall shear stresses from a single bubble collapse have been measured (Dijkink & Ohl Reference Dijkink and Ohl2008; Reuter & Mettin Reference Reuter and Mettin2018) and simulated (Koukouvinis et al. Reference Koukouvinis, Strotos, Zeng, Gonzalez-Avila, Theodorakakos, Gavaises and Ohl2018; Zeng, An & Ohl Reference Zeng, An and Ohl2022) to reach peak values of 100 kPa. Experimental data yield peak values that are one order of magnitude smaller, which is still compatible, as sampling periods were one order of magnitude larger than the shear spike durations.

While these observations are valid for bubbles in an initially stagnant liquid, the presence of a flow can change the bubble dynamics and, thus, the wall shear stress and pressure generated at the wall drastically. One interesting case is hydrodynamic cavitation in a stagnation flow, as it was shown by Knapp (Reference Knapp1955) that the strongest erosion for a model in a water tunnel can be found in the area around stagnation points. So far, research on the effect of a flow on the dynamics of a single bubble was conducted through simulations by Blake, Taib & Doherty (Reference Blake, Taib and Doherty1986), Robinson & Blake (Reference Robinson and Blake1994) and Blake, Leppinen & Wang (Reference Blake, Leppinen and Wang2015).

They utilised a boundary element method to study the influence of an ideal stagnation point flow on the gross bubble dynamics and, in particular, on the bubble's jetting behaviour. They found hourglass-shaped bubbles that pinch-off, resulting in much faster and thinner jets. Experimental research on the dynamics of bubbles in flows near a stagnation point is rather scarce. Starrett (Reference Starrett1982) reported in his thesis of a striking contrast between the bubble dynamics in a quiescent liquid and in a stagnation flow. He observed that during expansion the bubble deforms into an ellipsoid with the major axis aligned parallel to the wall, then the bubble forms a waist at its equator that divides the bubble into two parts just prior to collapse. Starret studied the dynamics of rather large bubbles created with an electric discharge in stagnation flows with free-stream velocities between about 6–18 m s![]() $^{-1}$ and concentrated on larger distances rather than on small stand-offs, which are more relevant for the bubble–wall interaction.

$^{-1}$ and concentrated on larger distances rather than on small stand-offs, which are more relevant for the bubble–wall interaction.

In the present work we study the dynamics of a single cavitation bubble in a wall jet in particular at rather low flow velocities and small stand-off distances, i.e. where viscosity plays an important role. This regime is relevant for many applications. In experiments, we record the bubble dynamics with a suitable high-speed camera to resolve the details of the collapse, whereas the simulations, which include the effects of compressibility and viscosity, allow for determining the wall shear stresses and pressure acting on the wall as a consequence of the bubble collapse. The results reveal that a bubble collapse with beneficial high wall shear stresses can be realised while avoiding potentially damaging behaviour.

2. Methods

2.1. Experimental methods

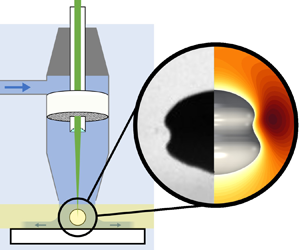

A single, laser-induced cavitation bubble is produced in a wall jet flow at a well-controlled distance to a wall. The submerged wall jet (Glauert Reference Glauert1956) is issued from a conical nozzle and provides a laminar water stream perpendicular to the wall that spreads radially outwards, see figure 1, i.e. providing a stagnation point flow. The cavitation bubble is laser seeded on the central axis of the wall jet at a variable distance from the wall.

Figure 1. (a) Sketch of the experimental set-up. The cavitation bubble is generated by focusing the laser pulse through a lens into the wall jet. The wall jet flow is submerged to ease optical access using a high-speed camera. The liquid flow is driven with a pump and controlled with a flow rate sensor feedback loop. A honeycomb filter straightens the flow, resulting in a laminar wall jet flow. The distance of the bubble to the wall is adjusted by moving the glass plate, while the nozzle assembly remains fixed. (b) Schematic illustration of the bubble in the wall jet and the axisymmetric simulation set-up (not to scale).

For convenience, the water is collected in a transparent water tank and recirculated. About 1.2 litres of water are used and pumped with a rotary vane pump (aquastream XT, Aqua Computer GmbH, Germany) through the nozzle. The nozzle is fully submerged in the water of the tank to ease observation of the bubble dynamics within the wall jet. The back part of the nozzle assembly is open to air; see figure 1(a). Inside the nozzle, the water passes through a honeycomb filter (stacked cylinders with 2 mm diameter and 30 mm length) to straighten the flow. The volumetric flow rate ![]() $Q$ is measured with a turbine flow meter (FCH-midi-POM, B.I.O-TECH e.K.) located between the pump and the nozzle inlet. The average wall jet velocity is given by

$Q$ is measured with a turbine flow meter (FCH-midi-POM, B.I.O-TECH e.K.) located between the pump and the nozzle inlet. The average wall jet velocity is given by ![]() $v_{{jet}}=Q/A_{{nozzle}}$, where

$v_{{jet}}=Q/A_{{nozzle}}$, where ![]() $A_{{nozzle}}={\rm \pi} r_{{nozzle}}^2$ is the cross-sectional area of the circular nozzle with an inner radius of

$A_{{nozzle}}={\rm \pi} r_{{nozzle}}^2$ is the cross-sectional area of the circular nozzle with an inner radius of ![]() $r_{{nozzle}}=1.5$ mm. In our set-up,

$r_{{nozzle}}=1.5$ mm. In our set-up, ![]() $v_{{jet}}$ can be controlled between

$v_{{jet}}$ can be controlled between ![]() $0$ and

$0$ and ![]() $5$ m s

$5$ m s![]() $^{-1}$ using the software provided with the pump.

$^{-1}$ using the software provided with the pump.

To generate single cavitation bubbles, one pulse from a frequency-doubled Nd:YAG laser (wavelength of 532 nm) is first collimated and guided through a hollow tube from the back end of the nozzle assembly. Then the laser is focused, and a bubble explosively grows as a result of the optic breakdown. Focusing is achieved using a planoconvex lens of focal length ![]() $f=10$ mm (in air) with a diameter of 6 mm (Thorlabs, LA1116). The lens is bonded into the wall-facing end of a tube. The planar side of the lens is in contact with water, while the curved side is in contact with air on the hollow tube side. The distance of the lens to the nozzle exit is 11 mm. When the laser is fired, a cavitation bubble is created at a distance of 4.4 mm from the nozzle exit. Due to the strong deformation of the bubbles, in experiments and simulations, the volume-equivalent bubble radius was measured. The geometry of the three-dimensionally printed nozzle (PLA plastic) went through a number of iterations to achieve a smooth water flow along the lens such that no air gets entrapped at the lens output aperture. A linear convergent nozzle together with a honeycomb flow rectifier accomplishes this requirement. In addition, there is no significant recirculation or disturbance of the stagnation flow since the bubble size is much smaller than the outer nozzle diameter (7 mm) and the solid sample. To confirm the laminar flow profile, we have used micrometre-sized particles as flow tracers together with high-speed imaging; see Appendix A.

$f=10$ mm (in air) with a diameter of 6 mm (Thorlabs, LA1116). The lens is bonded into the wall-facing end of a tube. The planar side of the lens is in contact with water, while the curved side is in contact with air on the hollow tube side. The distance of the lens to the nozzle exit is 11 mm. When the laser is fired, a cavitation bubble is created at a distance of 4.4 mm from the nozzle exit. Due to the strong deformation of the bubbles, in experiments and simulations, the volume-equivalent bubble radius was measured. The geometry of the three-dimensionally printed nozzle (PLA plastic) went through a number of iterations to achieve a smooth water flow along the lens such that no air gets entrapped at the lens output aperture. A linear convergent nozzle together with a honeycomb flow rectifier accomplishes this requirement. In addition, there is no significant recirculation or disturbance of the stagnation flow since the bubble size is much smaller than the outer nozzle diameter (7 mm) and the solid sample. To confirm the laminar flow profile, we have used micrometre-sized particles as flow tracers together with high-speed imaging; see Appendix A.

The wall is provided by a square-shaped coverslip with side length 24 mm and a thickness of 0.16 mm. It is mounted onto a plastic frame such that a central ‘window’ of ![]() $14\,{\rm mm}\times 14\,{\rm mm}$ remains for observation through the wall. The size of the glass sample is much larger than the nozzle diameter such that edge effects of the sample do not influence the flow in the gap between nozzle and sample surface. The distance between the laser plasma, i.e. bubble generation, and the glass wall is adjusted with a translation stage. The bubble dynamics is recorded with a high-speed camera (Shimadzu HPV-X2) imaging through the water-filled tank and the discharged wall jet flow from the nozzle. As a light source, we used an intense, pulsed light emitting diode (LED-P40, SMETec).

$14\,{\rm mm}\times 14\,{\rm mm}$ remains for observation through the wall. The size of the glass sample is much larger than the nozzle diameter such that edge effects of the sample do not influence the flow in the gap between nozzle and sample surface. The distance between the laser plasma, i.e. bubble generation, and the glass wall is adjusted with a translation stage. The bubble dynamics is recorded with a high-speed camera (Shimadzu HPV-X2) imaging through the water-filled tank and the discharged wall jet flow from the nozzle. As a light source, we used an intense, pulsed light emitting diode (LED-P40, SMETec).

2.2. Simulation methods

Numerical simulations complement the experimental recordings. The primary aim of these simulations is to investigate the differences in wall shear stress and pressure generated by a collapsing bubble in a wall jet flow, as compared with in an initially stagnant body of liquid. Experimentally, these quantities are inaccessible due to the required temporal and spatial resolutions.

The considered compressible two-phase flow is governed by the continuity equation

and the momentum equation

where ![]() $t$ represents time,

$t$ represents time, ![]() $\rho$ is the mass density of the fluid,

$\rho$ is the mass density of the fluid, ![]() $\mu$ is the dynamic viscosity of the fluid,

$\mu$ is the dynamic viscosity of the fluid, ![]() $\boldsymbol {u}$ is the velocity of the flow,

$\boldsymbol {u}$ is the velocity of the flow, ![]() $p$ is the pressure and

$p$ is the pressure and ![]() $\boldsymbol {I}$ is the identity tensor. An algebraic volume-of-fluid method (Denner, Xiao & van Wachem Reference Denner, Xiao and van Wachem2018) is adopted to model the gas–liquid interface and distinguish the gas and the liquid. The governing conservation laws are closed using the Noble–Abel stiffened gas (NASG) equation of state (Le Métayer & Saurel Reference Le Métayer and Saurel2016) in polytropic form, with the density and speed of sound defined as

$\boldsymbol {I}$ is the identity tensor. An algebraic volume-of-fluid method (Denner, Xiao & van Wachem Reference Denner, Xiao and van Wachem2018) is adopted to model the gas–liquid interface and distinguish the gas and the liquid. The governing conservation laws are closed using the Noble–Abel stiffened gas (NASG) equation of state (Le Métayer & Saurel Reference Le Métayer and Saurel2016) in polytropic form, with the density and speed of sound defined as

$$\begin{gather}c = \sqrt{\kappa \frac{p+\varPi}{\rho (1-b \rho)}}, \end{gather}$$

$$\begin{gather}c = \sqrt{\kappa \frac{p+\varPi}{\rho (1-b \rho)}}, \end{gather}$$

respectively, where ![]() $\kappa$ is the polytropic exponent,

$\kappa$ is the polytropic exponent, ![]() $\varPi$ is a pressure constant and

$\varPi$ is a pressure constant and ![]() ${K=\rho _0 / [(p_0 + \varPi )^{1/\kappa } (1-b\rho _0)]}$ defines a constant reference state based on a reference pressure

${K=\rho _0 / [(p_0 + \varPi )^{1/\kappa } (1-b\rho _0)]}$ defines a constant reference state based on a reference pressure ![]() $p_0$ and density

$p_0$ and density ![]() $\rho _0$.

$\rho _0$.

We are choosing the polytropic form of the NASG equation of state because we are not focusing on the details of the decay of the emitted pressure pulses that may (or may not) form shock fronts as they propagate away from the bubble, and since the Péclet number associated with the liquid jet that pierces the bubble during collapse is high, ![]() ${Re} > 10^3$, we do not consider heat transfer to be an important factor for our simulations. Using such a polytropic fluid model has been demonstrated to be suitable even for the prediction of complex bubble behaviour, such as wall-bounded cavitation (Koch et al. Reference Koch, Lechner, Reuter, Köhler, Mettin and Lauterborn2016; Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018). Following previous work we are neglecting surface tension and justify this simplification by (i) the relatively large bubble size with a volume-equivalent diameter

${Re} > 10^3$, we do not consider heat transfer to be an important factor for our simulations. Using such a polytropic fluid model has been demonstrated to be suitable even for the prediction of complex bubble behaviour, such as wall-bounded cavitation (Koch et al. Reference Koch, Lechner, Reuter, Köhler, Mettin and Lauterborn2016; Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018). Following previous work we are neglecting surface tension and justify this simplification by (i) the relatively large bubble size with a volume-equivalent diameter ![]() ${>}1\,\mathrm {mm}$ at maximum expansion, and (ii) the high Weber number,

${>}1\,\mathrm {mm}$ at maximum expansion, and (ii) the high Weber number, ![]() ${We} > 10^3$, of the liquid jet that pierces the bubble during collapse.

${We} > 10^3$, of the liquid jet that pierces the bubble during collapse.

The liquid is assumed to be water, with ![]() $\kappa _l = 1.186$,

$\kappa _l = 1.186$, ![]() $\varPi _l = 7.028 \times 10^8\,\mathrm {Pa}$,

$\varPi _l = 7.028 \times 10^8\,\mathrm {Pa}$, ![]() $b_l = 6.61 \times 10^{-4}\,\mathrm {m}^3\,\mathrm {kg}^{-1}$,

$b_l = 6.61 \times 10^{-4}\,\mathrm {m}^3\,\mathrm {kg}^{-1}$, ![]() $\rho _{0,l} = 957.74\,\mathrm {kg}\,{\rm m}^{-3}$,

$\rho _{0,l} = 957.74\,\mathrm {kg}\,{\rm m}^{-3}$, ![]() $c_{0,l} = 1540.2\,\mathrm {m}\,\mathrm {s}^{-1}$ and

$c_{0,l} = 1540.2\,\mathrm {m}\,\mathrm {s}^{-1}$ and ![]() $p_{0,l} = 10^5 \,\mathrm {Pa}$, as previously proposed by Le Métayer & Saurel (Reference Le Métayer and Saurel2016), and

$p_{0,l} = 10^5 \,\mathrm {Pa}$, as previously proposed by Le Métayer & Saurel (Reference Le Métayer and Saurel2016), and ![]() $\mu _l = 10^{-3} \, \mathrm {Pa}\,\mathrm {s}$. The bubble content is taken to be non-condensable air, modelled as an ideal gas (

$\mu _l = 10^{-3} \, \mathrm {Pa}\,\mathrm {s}$. The bubble content is taken to be non-condensable air, modelled as an ideal gas (![]() $\varPi _g = 0$,

$\varPi _g = 0$, ![]() $b_g=0$), with

$b_g=0$), with ![]() $\kappa _g = 1.4$,

$\kappa _g = 1.4$, ![]() $\rho _{0,g} = 1.2 \, \mathrm {kg}\,\mathrm {m}^{-3}$,

$\rho _{0,g} = 1.2 \, \mathrm {kg}\,\mathrm {m}^{-3}$, ![]() $p_{0,g} = 10^5 \, \mathrm {Pa}$ and

$p_{0,g} = 10^5 \, \mathrm {Pa}$ and ![]() $\mu _g = 1.82 \times 10^{-5} \, \mathrm {Pa}\,\mathrm {s}$. The governing equations are discretised using a second-order finite-volume method and solved using a fully coupled implicit pressure-based algorithm (Denner et al. Reference Denner, Xiao and van Wachem2018; Denner, Evrard & van Wachem Reference Denner, Evrard and van Wachem2020a).

$\mu _g = 1.82 \times 10^{-5} \, \mathrm {Pa}\,\mathrm {s}$. The governing equations are discretised using a second-order finite-volume method and solved using a fully coupled implicit pressure-based algorithm (Denner et al. Reference Denner, Xiao and van Wachem2018; Denner, Evrard & van Wachem Reference Denner, Evrard and van Wachem2020a).

The computational set-up is illustrated schematically in figure 1(b). The axisymmetric simulations are carried out in a ![]() $0.25 \, \mathrm {m} \times 0.25 \, \mathrm {m}$ computational domain, which is sufficiently large such that the boundary conditions do not influence the bubble dynamics or the flow field in the vicinity of the bubble in the considered time frame. The bubble is initialised at a distance

$0.25 \, \mathrm {m} \times 0.25 \, \mathrm {m}$ computational domain, which is sufficiently large such that the boundary conditions do not influence the bubble dynamics or the flow field in the vicinity of the bubble in the considered time frame. The bubble is initialised at a distance ![]() $d$ from the wall with initial gas pressure

$d$ from the wall with initial gas pressure ![]() $p_{g,0}=54.5 \, \mathrm {MPa}$ and initial radius

$p_{g,0}=54.5 \, \mathrm {MPa}$ and initial radius ![]() $R_0=84 \, \mathrm {\mu }\mathrm {m}$, tuned to achieve a desired maximum radius

$R_0=84 \, \mathrm {\mu }\mathrm {m}$, tuned to achieve a desired maximum radius ![]() $R_{max}$. Based on the experimental set-up, the wall jet flow is represented by a uniform flow with velocity magnitude

$R_{max}$. Based on the experimental set-up, the wall jet flow is represented by a uniform flow with velocity magnitude ![]() $v_{jet}$ and radius

$v_{jet}$ and radius ![]() $r_{jet} = 1500 \, \mathrm {\mu } \mathrm {m}$.

$r_{jet} = 1500 \, \mathrm {\mu } \mathrm {m}$.

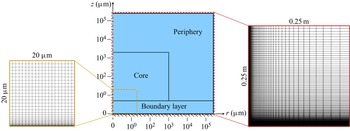

The mesh resolution required to resolve the considered cases adequately is primarily governed by the diameter of the liquid jet penetrating the bubble, ![]() $\gtrsim 10 \, \mathrm {\mu } \mathrm {m}$, and the velocity gradient normal to the wall,

$\gtrsim 10 \, \mathrm {\mu } \mathrm {m}$, and the velocity gradient normal to the wall, ![]() ${O}(10^7)\unicode{x2013}{O}(10^9) \, \mathrm {s}^{-1}$, associated with the generated wall shear stresses. The computational mesh is static (i.e. does not adapt) and separated into three primary regions, as illustrated in figure 2: the boundary layer close to the rigid wall, the core region with the bubble and stagnation flow, and the periphery that mainly exists to avoid pressure waves reaching the domain boundaries. Note that, due to the large range of length scales, the computational domain is sketched on a logarithmic scale in figure 2. In line with previous studies on wall-bounded bubble collapse (Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018; Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2020; Gonzalez-Avila, Denner & Ohl Reference Gonzalez-Avila, Denner and Ohl2021; Mifsud et al. Reference Mifsud, Lockerby, Chung and Jones2021), the core region of the domain (

${O}(10^7)\unicode{x2013}{O}(10^9) \, \mathrm {s}^{-1}$, associated with the generated wall shear stresses. The computational mesh is static (i.e. does not adapt) and separated into three primary regions, as illustrated in figure 2: the boundary layer close to the rigid wall, the core region with the bubble and stagnation flow, and the periphery that mainly exists to avoid pressure waves reaching the domain boundaries. Note that, due to the large range of length scales, the computational domain is sketched on a logarithmic scale in figure 2. In line with previous studies on wall-bounded bubble collapse (Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018; Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2020; Gonzalez-Avila, Denner & Ohl Reference Gonzalez-Avila, Denner and Ohl2021; Mifsud et al. Reference Mifsud, Lockerby, Chung and Jones2021), the core region of the domain (![]() $r \leq 1000$ and

$r \leq 1000$ and ![]() $z \leq 2000 \,\mathrm {\mu } \mathrm {m}$) is resolved with a mesh spacing of

$z \leq 2000 \,\mathrm {\mu } \mathrm {m}$) is resolved with a mesh spacing of ![]() ${\rm \Delta} x_0 = 1 \, \mathrm {\mu } \mathrm {m}$ and the mesh near the wall (

${\rm \Delta} x_0 = 1 \, \mathrm {\mu } \mathrm {m}$ and the mesh near the wall (![]() $z < 5 \, \mathrm {\mu } \mathrm {m}$) is gradually refined, such that the centres of the layer of cells closest to the wall are located at a distance of only

$z < 5 \, \mathrm {\mu } \mathrm {m}$) is gradually refined, such that the centres of the layer of cells closest to the wall are located at a distance of only ![]() $12.5 \, \mathrm {nm}$ from the wall. In the periphery region of the domain (

$12.5 \, \mathrm {nm}$ from the wall. In the periphery region of the domain (![]() $r > 1000$ and

$r > 1000$ and ![]() $z > 2000\, \mathrm {\mu } \mathrm {m}$), the mesh is gradually coarsened. Similar to our previous work (Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021), the adaptively chosen time step is

$z > 2000\, \mathrm {\mu } \mathrm {m}$), the mesh is gradually coarsened. Similar to our previous work (Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021), the adaptively chosen time step is ![]() ${\rm \Delta} t = {Co} \, {\rm \Delta} x / |\boldsymbol {u}|$, where

${\rm \Delta} t = {Co} \, {\rm \Delta} x / |\boldsymbol {u}|$, where ![]() ${Co} = 0.7$ is the applied convective Courant number.

${Co} = 0.7$ is the applied convective Courant number.

Figure 2. Schematic illustration of the computational domain with the three primary mesh regions (sketched on a logarithmic scale), with a close up of the computational mesh near the wall on the left and the complete computational mesh on the right.

The employed numerical methods and case set-up were validated successfully against experiments of laser-induced bubble expansion and collapse near walls in our previous work, regarding the bubble evolution and shape as well as the acoustic emissions of the bubble collapse (Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021), and regarding the minimum thickness of the thin liquid film remaining between bubble and wall (Reuter & Kaiser Reference Reuter and Kaiser2019; Denner, Evrard & van Wachem Reference Denner, Evrard and van Wachem2020b). Furthermore, the numerical methods have been compared favourably to experimental measurements and numerical predictions of shock-driven bubble collapse (Denner et al. Reference Denner, Xiao and van Wachem2018) and to the Gilmore model for a Rayleigh collapse (Denner & Schenke Reference Denner and Schenke2023). The specific resolution requirements of the simulated bubble dynamics are discussed alongside the simulation results in § 3 and representative results obtained with different mesh resolutions are reviewed in § 4.

2.3. Scaling with bubble size

Here, we consider bubbles with maximum radii ranging between ![]() $R_{max}=480$ and

$R_{max}=480$ and ![]() $716\,\mathrm {\mu }$m. To ease the discussion, we show that for a bubble in the considered wall jet, the same scaling as for a Rayleigh bubble holds.

$716\,\mathrm {\mu }$m. To ease the discussion, we show that for a bubble in the considered wall jet, the same scaling as for a Rayleigh bubble holds.

The potential energy of a laser-induced cavitation bubble with negligible vapour pressure (![]() $p_{vap} \ll p_\infty$) is customarily approximated as (Liang et al. Reference Liang, Linz, Freidank, Paltauf and Vogel2022)

$p_{vap} \ll p_\infty$) is customarily approximated as (Liang et al. Reference Liang, Linz, Freidank, Paltauf and Vogel2022)

We estimate the kinetic energy imparted on the bubble by the wall jet as the product of the dynamic pressure of the wall jet and a suitably defined reference volume,

We further assume that the wall jet acts on the upper hemisphere of the bubble, with a projected area of ![]() $A = {\rm \pi}R^2_{max}$. Since the distance over which the bubble is advected by the wall jet during the bubble lifetime is negligible (

$A = {\rm \pi}R^2_{max}$. Since the distance over which the bubble is advected by the wall jet during the bubble lifetime is negligible (![]() $R_{max} \gg v_{jet} T_C$),

$R_{max} \gg v_{jet} T_C$), ![]() $R_{max}$ is the reference length scale of the problem. Thus, the reference volume is then defined as

$R_{max}$ is the reference length scale of the problem. Thus, the reference volume is then defined as

such that ![]() $E_{jet} \propto \rho _{0,l} v_{jet}^2 R_{max}^3$. For simplicity, we do not take surface tension and viscosity into account, since a collapsing cavitation bubble is an inertia-driven process; see, for example, Reuter, Zeng & Ohl (Reference Reuter, Zeng and Ohl2022b). Taking the ratio of

$E_{jet} \propto \rho _{0,l} v_{jet}^2 R_{max}^3$. For simplicity, we do not take surface tension and viscosity into account, since a collapsing cavitation bubble is an inertia-driven process; see, for example, Reuter, Zeng & Ohl (Reference Reuter, Zeng and Ohl2022b). Taking the ratio of ![]() $E_{jet}$ and

$E_{jet}$ and ![]() $E_{pot}$ yields

$E_{pot}$ yields

Consequently, neglecting surface tension and viscous dissipation, the influence of the wall jet can be assumed to be independent of the bubble size. Therefore, the presented results are, in first approximation, independent of the bubble size.

This allows us to normalize the times on the bubble lifetime ![]() $T_{L}$, i.e. the time between bubble nucleation and first collapse (minimum volume) as

$T_{L}$, i.e. the time between bubble nucleation and first collapse (minimum volume) as ![]() $T_{{L}}\propto R_{{max}}$, to facilitate the comparison of similarly sized bubbles.

$T_{{L}}\propto R_{{max}}$, to facilitate the comparison of similarly sized bubbles.

3. Results

The results are organised by reporting the effect of the flow velocity of the wall jet, ![]() $v_{jet}$, on the bubble dynamics for three different stand-off distances

$v_{jet}$, on the bubble dynamics for three different stand-off distances ![]() $\gamma$. (1) The first stand-off is far from the wall at a large distance of

$\gamma$. (1) The first stand-off is far from the wall at a large distance of ![]() $\gamma \approx 1.7$. Here, the bubble shows a pinch-off, as shown in previous studies for cavitation bubbles in a stagnation flow (Starrett Reference Starrett1982; Blake et al. Reference Blake, Taib and Doherty1986; Robinson & Blake Reference Robinson and Blake1994; Blake et al. Reference Blake, Leppinen and Wang2015). (2) The second stand-off is at an intermediate distance of

$\gamma \approx 1.7$. Here, the bubble shows a pinch-off, as shown in previous studies for cavitation bubbles in a stagnation flow (Starrett Reference Starrett1982; Blake et al. Reference Blake, Taib and Doherty1986; Robinson & Blake Reference Robinson and Blake1994; Blake et al. Reference Blake, Leppinen and Wang2015). (2) The second stand-off is at an intermediate distance of ![]() $\gamma \approx 0.7$, which shows a needle-like high-speed jet, as observed in stagnant liquid for smaller stand-off distances,

$\gamma \approx 0.7$, which shows a needle-like high-speed jet, as observed in stagnant liquid for smaller stand-off distances, ![]() $\gamma \lessapprox 0.2$ (Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2019; Reuter & Ohl Reference Reuter and Ohl2021; Bußmann et al. Reference Bußmann, Riahi, Gökce, Adami, Barcikowski and Adams2023). (3) Last, a cavitation bubble representing the small stand-off distance dynamics (

$\gamma \lessapprox 0.2$ (Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2019; Reuter & Ohl Reference Reuter and Ohl2021; Bußmann et al. Reference Bußmann, Riahi, Gökce, Adami, Barcikowski and Adams2023). (3) Last, a cavitation bubble representing the small stand-off distance dynamics (![]() $\gamma \approx 0.4$) is presented. Here, the bubble pinches off directly above the wall, resulting in a lift-off of the bubble before it collapses. This is probably the most interesting case regarding the bubble–wall interaction, since a potentially harmful collapse in direct contact with the wall can be avoided. For each stand-off distance, high-speed imaging and numerical results of the bubble dynamics are shown and analysed, and the spatio-temporal wall shear stress and wall pressure distributions are discussed. Note that the given values may be considered as lower bounds of these quantities, which is discussed in more detail in § 4.

$\gamma \approx 0.4$) is presented. Here, the bubble pinches off directly above the wall, resulting in a lift-off of the bubble before it collapses. This is probably the most interesting case regarding the bubble–wall interaction, since a potentially harmful collapse in direct contact with the wall can be avoided. For each stand-off distance, high-speed imaging and numerical results of the bubble dynamics are shown and analysed, and the spatio-temporal wall shear stress and wall pressure distributions are discussed. Note that the given values may be considered as lower bounds of these quantities, which is discussed in more detail in § 4.

3.1. Large stand-off distance

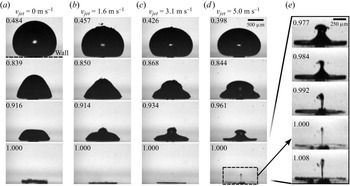

Figure 3 depicts the typical bubble dynamics for large stand-off distances. In the selected series, ![]() $\gamma$ is between

$\gamma$ is between ![]() $1.56$ and

$1.56$ and ![]() $1.88$ and the glass wall is located at the bottom of each frame. Each column shows five snapshots from one experiment, showing the bubble at maximum expansion, the bubble just before and just after the collapse (from top to bottom), as well as the instance when the bubble makes contact with the wall and the second collapse. Each column in figure 3 shows one experiment with a specific wall jet velocity

$1.88$ and the glass wall is located at the bottom of each frame. Each column shows five snapshots from one experiment, showing the bubble at maximum expansion, the bubble just before and just after the collapse (from top to bottom), as well as the instance when the bubble makes contact with the wall and the second collapse. Each column in figure 3 shows one experiment with a specific wall jet velocity ![]() $v_{{jet}}$. Four wall jet velocities are shown, increasing from left to right.

$v_{{jet}}$. Four wall jet velocities are shown, increasing from left to right.

Figure 3. High-speed imaging of bubble dynamics for four different wall jet velocities ![]() $v_{jet}$ at large stand-off distances (

$v_{jet}$ at large stand-off distances (![]() $\gamma =1.73,1.78,1.56,1.88$, from left to right). For sufficiently large wall jet velocities, the bubble pinches off and two axial jets develop in opposite directions. Times indicated in each tile are normalized to the bubble lifetime. The respective lifetimes are

$\gamma =1.73,1.78,1.56,1.88$, from left to right). For sufficiently large wall jet velocities, the bubble pinches off and two axial jets develop in opposite directions. Times indicated in each tile are normalized to the bubble lifetime. The respective lifetimes are ![]() $T_{L}=135,124,127,118\,\mathrm {\mu }$s. The bottom of each frame coincides with the wall, as sketched in the first tile. The rightmost column shows the bubble splitting and collapse for the last case in more detail. A video of the dynamics at

$T_{L}=135,124,127,118\,\mathrm {\mu }$s. The bottom of each frame coincides with the wall, as sketched in the first tile. The rightmost column shows the bubble splitting and collapse for the last case in more detail. A video of the dynamics at ![]() $v_{jet}=5$ m s

$v_{jet}=5$ m s![]() $^{-1}$ can be found in the supplementary material as movie 1 available at https://doi.org/10.1017/jfm.2023.1048.

$^{-1}$ can be found in the supplementary material as movie 1 available at https://doi.org/10.1017/jfm.2023.1048.

The first column without jet flow (![]() $v_{jet}=0$ m s

$v_{jet}=0$ m s![]() $^{-1}$) depicts the well-known jetting behaviour of a bubble nucleated at a large stand-off distance (here

$^{-1}$) depicts the well-known jetting behaviour of a bubble nucleated at a large stand-off distance (here ![]() $\gamma = 1.73$) from the wall, as previously reported, for instance, by Philipp & Lauterborn (Reference Philipp and Lauterborn1998). At maximum expansion,

$\gamma = 1.73$) from the wall, as previously reported, for instance, by Philipp & Lauterborn (Reference Philipp and Lauterborn1998). At maximum expansion, ![]() $t=0.467\,T_{L}$, the bubble is rather spherical but with some small bubbles at the wall-near pole. Here, the usage of a small lens with a rather small opening angle to focus the laser results in some aberration and multiple breakdowns. During collapse, the presence of the wall impedes the radial inflow from below, and a pressure gradient forms, with a higher pressure at the top. As a result, the bubble's centroid moves towards the wall (Benjamin & Ellis Reference Benjamin and Ellis1966) and the bubble develops a jet that passes through the bubble interior toward the wall. The specific illumination applied in the experiments does not reveal this jet flow, but it is visible by the small axial indentation of the upper pole just before the collapse. At time

$t=0.467\,T_{L}$, the bubble is rather spherical but with some small bubbles at the wall-near pole. Here, the usage of a small lens with a rather small opening angle to focus the laser results in some aberration and multiple breakdowns. During collapse, the presence of the wall impedes the radial inflow from below, and a pressure gradient forms, with a higher pressure at the top. As a result, the bubble's centroid moves towards the wall (Benjamin & Ellis Reference Benjamin and Ellis1966) and the bubble develops a jet that passes through the bubble interior toward the wall. The specific illumination applied in the experiments does not reveal this jet flow, but it is visible by the small axial indentation of the upper pole just before the collapse. At time ![]() $t=1.193\,T_{L}$ the main bubble reaches the wall while re-expanding. Later, it collapses a second time, now in proximity to the wall at

$t=1.193\,T_{L}$ the main bubble reaches the wall while re-expanding. Later, it collapses a second time, now in proximity to the wall at ![]() $t=1.741\,T_{L}$.

$t=1.741\,T_{L}$.

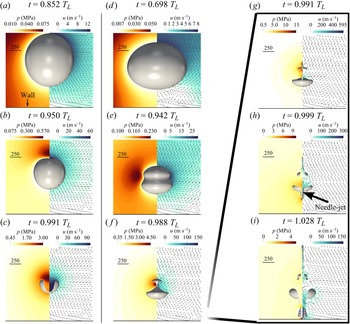

The simulated dynamics of the corresponding bubble is shown in figure 4(a–c). Here the jet formation is clear and jet velocities reach up to ![]() $100\,\mathrm {m}\,\mathrm {s}^{-1}$, which is in close agreement with previous studies (Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018; Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021). Stresses on the wall are given in figure 5(a). The peak wall pressure is reached at

$100\,\mathrm {m}\,\mathrm {s}^{-1}$, which is in close agreement with previous studies (Zeng et al. Reference Zeng, Gonzalez-Avila, Dijkink, Koukouvinis, Gavaises and Ohl2018; Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021). Stresses on the wall are given in figure 5(a). The peak wall pressure is reached at ![]() $t = 1.003 \, T_{L}$ and associated with the bubble collapse, rather than the jet impact pressure at

$t = 1.003 \, T_{L}$ and associated with the bubble collapse, rather than the jet impact pressure at ![]() $t = 1.101 \, T_{L}$, in agreement with our previous work (Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021). However, as the jet impacts the wall, it generates significant wall shear stresses, with a maximum of

$t = 1.101 \, T_{L}$, in agreement with our previous work (Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021). However, as the jet impacts the wall, it generates significant wall shear stresses, with a maximum of ![]() $94 \, \mathrm {kPa}$.

$94 \, \mathrm {kPa}$.

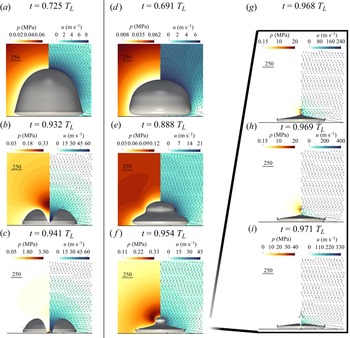

Figure 4. Bubble shape, pressure (left half) and velocity field (right half) at different time instances during the collapse of the bubble initially located at ![]() $d = 1200\, \mathrm {\mu } \mathrm {m}$ (

$d = 1200\, \mathrm {\mu } \mathrm {m}$ (![]() $\gamma = 1.53$ and

$\gamma = 1.53$ and ![]() $1.75$, respectively). The arrows in the right half of each figure indicate the direction of the flow. (a–c) In quiescent water (

$1.75$, respectively). The arrows in the right half of each figure indicate the direction of the flow. (a–c) In quiescent water (![]() $v_{jet} = 0 \, \mathrm {m}\,\mathrm {s}^{-1}$). The lifetime of this bubble is

$v_{jet} = 0 \, \mathrm {m}\,\mathrm {s}^{-1}$). The lifetime of this bubble is ![]() $T_{L} = 164.4 \,\mathrm {\mu } \mathrm {s}$. (d–i) Subject to a wall jet with

$T_{L} = 164.4 \,\mathrm {\mu } \mathrm {s}$. (d–i) Subject to a wall jet with ![]() $v_{jet} = 5 \, \mathrm {m}\,\mathrm {s}^{-1}$. The lifetime of this bubble is

$v_{jet} = 5 \, \mathrm {m}\,\mathrm {s}^{-1}$. The lifetime of this bubble is ![]() $T_{L} = 143.4 \, \mathrm {\mu } \mathrm {s}$. The scale bar corresponds to

$T_{L} = 143.4 \, \mathrm {\mu } \mathrm {s}$. The scale bar corresponds to ![]() $250 \, \mathrm {\mu } \mathrm {m}$.

$250 \, \mathrm {\mu } \mathrm {m}$.

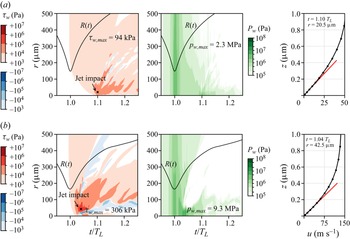

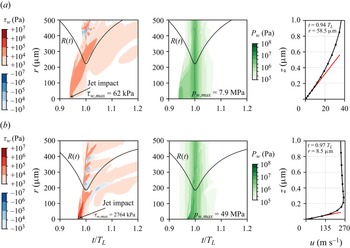

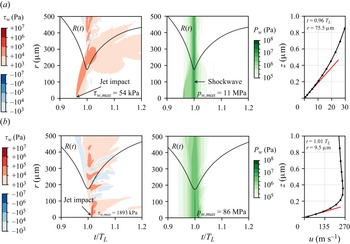

Figure 5. Space–time plots of the wall shear stress ![]() $\tau _{w}$ and the wall pressure

$\tau _{w}$ and the wall pressure ![]() $p_{w}$, and profile of the radial velocity

$p_{w}$, and profile of the radial velocity ![]() $u$ of the liquid at the location of the highest wall shear rate, of the bubble initially located at

$u$ of the liquid at the location of the highest wall shear rate, of the bubble initially located at ![]() ${d = 1200 \,\mathrm {\mu } \mathrm {m}}$. In the space–time plots, the black line shows the volume-equivalent bubble radius

${d = 1200 \,\mathrm {\mu } \mathrm {m}}$. In the space–time plots, the black line shows the volume-equivalent bubble radius ![]() $R(t)$ and, with respect to

$R(t)$ and, with respect to ![]() $\tau _{w}$, red (blue) areas indicate a radially outward (inward) going flow. The location of maximum wall shear stress is indicated with a bold cross in the space–time plots. In the plots of the velocity profiles, the red line represents the velocity gradient associated with

$\tau _{w}$, red (blue) areas indicate a radially outward (inward) going flow. The location of maximum wall shear stress is indicated with a bold cross in the space–time plots. In the plots of the velocity profiles, the red line represents the velocity gradient associated with ![]() $\tau _{w,max}$, and the black dots show the locations of the cell centres of the applied computational mesh. Results are shown for (a)

$\tau _{w,max}$, and the black dots show the locations of the cell centres of the applied computational mesh. Results are shown for (a) ![]() $v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$,

$v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$, ![]() $\gamma = 1.53$;(b)

$\gamma = 1.53$;(b) ![]() $v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$,

$v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$, ![]() $\gamma = 1.75$.

$\gamma = 1.75$.

Let us now look at how the wall jet flow modifies the bubble dynamics, considering the case of the largest wall jet flow velocity ![]() $v_{{jet}}=5$ m s

$v_{{jet}}=5$ m s![]() $^{-1}$ first. In comparison to the stagnant case, the bubble takes an ellipsoidal shape with the major axis aligned parallel to the wall, i.e. it is flattened at the bottom, see the first row. A video of the corresponding bubble is available as movie 1 of the supplementary material. As the bubble collapses, instead of an indentation in the axial direction from the regular axial jet flow, a planar convergent jet indents the bubble from the sides and results in the horizontal kink in the second row. As this flow converges towards the axis of symmetry, two oppositely directed jets are ejected axially, see third row. More insights into this process are gained from the flow and pressure fields of figure 4(d–f) and the snapshot series at smaller time intervals showing the jet formation and piercing process in figure 4(g–i) as well as the rightmost column of figure 3. The convergent planar flow results in an axial needle-like jet with a radius of the order of

$^{-1}$ first. In comparison to the stagnant case, the bubble takes an ellipsoidal shape with the major axis aligned parallel to the wall, i.e. it is flattened at the bottom, see the first row. A video of the corresponding bubble is available as movie 1 of the supplementary material. As the bubble collapses, instead of an indentation in the axial direction from the regular axial jet flow, a planar convergent jet indents the bubble from the sides and results in the horizontal kink in the second row. As this flow converges towards the axis of symmetry, two oppositely directed jets are ejected axially, see third row. More insights into this process are gained from the flow and pressure fields of figure 4(d–f) and the snapshot series at smaller time intervals showing the jet formation and piercing process in figure 4(g–i) as well as the rightmost column of figure 3. The convergent planar flow results in an axial needle-like jet with a radius of the order of ![]() $6 \,\mathrm {\mu } \mathrm {m}$, indicated by an arrow in figure 4(h). The jet directed toward the wall reaches a maximum velocity of

$6 \,\mathrm {\mu } \mathrm {m}$, indicated by an arrow in figure 4(h). The jet directed toward the wall reaches a maximum velocity of ![]() ${\approx }300 \,\mathrm {m}\,\mathrm {s}^{-1}$, a threefold increase compared with the liquid jet generated in the corresponding case with no wall jet flow (

${\approx }300 \,\mathrm {m}\,\mathrm {s}^{-1}$, a threefold increase compared with the liquid jet generated in the corresponding case with no wall jet flow (![]() $v_{jet}=0$ m s

$v_{jet}=0$ m s![]() $^{-1}$). Upon impact on the wall, the jet generates a maximum wall shear stress of

$^{-1}$). Upon impact on the wall, the jet generates a maximum wall shear stress of ![]() $306 \, \mathrm {kPa}$, see figure 5(b), which is roughly three times higher than in the stationary case. Due to the formation of a stagnation point around the region where the axis of symmetry intersects the wall, the shear stresses are smaller there Reuter & Mettin (Reference Reuter and Mettin2018). Also, some negative shear rates are seen from splashing and recirculations of the complex flow after the jet impacts on the wall. The maximum pressures at the wall reach about

$306 \, \mathrm {kPa}$, see figure 5(b), which is roughly three times higher than in the stationary case. Due to the formation of a stagnation point around the region where the axis of symmetry intersects the wall, the shear stresses are smaller there Reuter & Mettin (Reference Reuter and Mettin2018). Also, some negative shear rates are seen from splashing and recirculations of the complex flow after the jet impacts on the wall. The maximum pressures at the wall reach about ![]() $p_{{max}}=9.3 \, \mathrm {MPa}$ (a fourfold increase compared with

$p_{{max}}=9.3 \, \mathrm {MPa}$ (a fourfold increase compared with ![]() $v_{jet}=0$ m s

$v_{jet}=0$ m s![]() $^{-1}$) and coincide with the jet impact. They are not generated from the shockwaves emitted during the collapse. The impact velocity of the jet can be approximated as

$^{-1}$) and coincide with the jet impact. They are not generated from the shockwaves emitted during the collapse. The impact velocity of the jet can be approximated as ![]() $u=135 \,\mathrm {m}\,\mathrm {s}^{-1}$ as the maximum pressure on the wall corresponds to the stagnation pressure of the jet,

$u=135 \,\mathrm {m}\,\mathrm {s}^{-1}$ as the maximum pressure on the wall corresponds to the stagnation pressure of the jet, ![]() $p_{{max}}=0.5\rho _{0,l}u^2$ (Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021).

$p_{{max}}=0.5\rho _{0,l}u^2$ (Gonzalez-Avila et al. Reference Gonzalez-Avila, Denner and Ohl2021).

The pressure distribution in figure 4(e) reveals a larger pressure at the wall distal side around the bubble, which explains why, after pinch-off, the upper bubble collapses before the lower bubble. For increasing wall jet velocity, the bubble becomes more ellipsoidal; see figure 3 first row. Furthermore, while at ![]() $v_{jet}=5$ m s

$v_{jet}=5$ m s![]() $^{-1}$ the pinch-off occurs about the equatorial, which results in the bubble splitting into two about equally sized volumes, for lower wall jet velocities the pinch-off occurs closer to the upper bubble pole, which, in turn, results in an uneven splitting of the bubble. A smaller bubble is produced above and a larger bubble below the pinch-off region, as observed by comparing the second and fourth row in figure 3.

$^{-1}$ the pinch-off occurs about the equatorial, which results in the bubble splitting into two about equally sized volumes, for lower wall jet velocities the pinch-off occurs closer to the upper bubble pole, which, in turn, results in an uneven splitting of the bubble. A smaller bubble is produced above and a larger bubble below the pinch-off region, as observed by comparing the second and fourth row in figure 3.

3.2. Intermediate stand-off distance

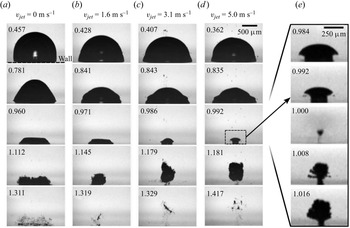

Figure 6 shows the evolution of the bubble dynamics for increasing wall jet flow velocities at intermediate stand-off distances of ![]() $\gamma \approx 0.75$. For each velocity the bubble is shown in four phases: (1) the moment of maximum expansion, (2) in the collapse phase when being increasingly deformed by the inflow, (3) the shape before, and (4) after the bubble collapse.

$\gamma \approx 0.75$. For each velocity the bubble is shown in four phases: (1) the moment of maximum expansion, (2) in the collapse phase when being increasingly deformed by the inflow, (3) the shape before, and (4) after the bubble collapse.

Figure 6. Bubble dynamics with increasing wall jet velocity at intermediate stand-offs (![]() ${\gamma =0.74},0.72,0.78,0.78$, from left to right). The wall extends along the bottom of the frames. For the fastest wall jet flow, a high-speed needle-like jet occurs. Times indicated in each tile are normalized to the bubble lifetime. The respective lifetimes are

${\gamma =0.74},0.72,0.78,0.78$, from left to right). The wall extends along the bottom of the frames. For the fastest wall jet flow, a high-speed needle-like jet occurs. Times indicated in each tile are normalized to the bubble lifetime. The respective lifetimes are ![]() $T_{L}=155, 140, 136, 128 \,\mathrm {\mu } \mathrm {s}$ (from left to right). The collapse for the case

$T_{L}=155, 140, 136, 128 \,\mathrm {\mu } \mathrm {s}$ (from left to right). The collapse for the case ![]() $v_{jet}={max}$ is studied in further detail in the rightmost column. The corresponding video of the bubble at

$v_{jet}={max}$ is studied in further detail in the rightmost column. The corresponding video of the bubble at ![]() $v_{jet}=5$ m s

$v_{jet}=5$ m s![]() $^{-1}$ can be found in the supplementary material as movie 2.

$^{-1}$ can be found in the supplementary material as movie 2.

Again, in the first column, a collapsing bubble in quiescent liquid is shown. At ![]() ${t=0.484\,T_{L}}$, the bubble has reached approximately its maximum expansion. At

${t=0.484\,T_{L}}$, the bubble has reached approximately its maximum expansion. At ![]() $t=0.916\,T_{L}$ the bubble is pierced by a rather wide jet, which is easily visible in the simulation result shown in figure 7(b). The velocity of this jet is

$t=0.916\,T_{L}$ the bubble is pierced by a rather wide jet, which is easily visible in the simulation result shown in figure 7(b). The velocity of this jet is ![]() ${\approx }65 \,\mathrm {m}\,\mathrm {s}^{-1}$ and results in a toroidal collapse of the bubble in figure 6 at

${\approx }65 \,\mathrm {m}\,\mathrm {s}^{-1}$ and results in a toroidal collapse of the bubble in figure 6 at ![]() $t = 1.000 \, T_{L}$. Upon impact at

$t = 1.000 \, T_{L}$. Upon impact at ![]() $t \approx 0.938 \, T_{L}$ on the wall, the jet generates a wall shear stress of up to

$t \approx 0.938 \, T_{L}$ on the wall, the jet generates a wall shear stress of up to ![]() $62 \, \mathrm {kPa}$; see figure 8(a). The torus collapse close to the wall generates even larger shear stresses of up to

$62 \, \mathrm {kPa}$; see figure 8(a). The torus collapse close to the wall generates even larger shear stresses of up to ![]() $157 \, \mathrm {kPa}$ at

$157 \, \mathrm {kPa}$ at ![]() $r \approx 450 \,\mathrm {\mu } \mathrm {m}$, further away from the location of the jet impact. Again, recirculations result in negative shear stresses. The shockwaves emitted at the collapse result in the vertically extended green region at

$r \approx 450 \,\mathrm {\mu } \mathrm {m}$, further away from the location of the jet impact. Again, recirculations result in negative shear stresses. The shockwaves emitted at the collapse result in the vertically extended green region at ![]() $t = 1.000 \, T_{L}$ in figure 8(a).

$t = 1.000 \, T_{L}$ in figure 8(a).

Figure 7. Bubble shape, pressure and velocity field at different time instances during the collapse of the bubble initially located at ![]() $d = 490\,\mathrm {\mu } \mathrm {m}$ (

$d = 490\,\mathrm {\mu } \mathrm {m}$ (![]() $\gamma = 0.63$ and

$\gamma = 0.63$ and ![]() $0.73$, respectively). (a–c) In quiescent water (

$0.73$, respectively). (a–c) In quiescent water (![]() $v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$). The lifetime of this bubble is

$v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$). The lifetime of this bubble is ![]() $T_{L} = 179.3 \,\mathrm {\mu } \mathrm {s}$. (d–i) Subject to a wall jet with

$T_{L} = 179.3 \,\mathrm {\mu } \mathrm {s}$. (d–i) Subject to a wall jet with ![]() $v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$. The lifetime of this bubble is

$v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$. The lifetime of this bubble is ![]() $T_{L} = 152.0 \,\mathrm {\mu } \mathrm {s}$. The scale bar corresponds to

$T_{L} = 152.0 \,\mathrm {\mu } \mathrm {s}$. The scale bar corresponds to ![]() $250 \,\mathrm {\mu } \mathrm {m}$.

$250 \,\mathrm {\mu } \mathrm {m}$.

Figure 8. Space–time plots of the wall shear stress ![]() $\tau _{w}$ and the wall pressure

$\tau _{w}$ and the wall pressure ![]() $p_{w}$, and profile of the radial velocity

$p_{w}$, and profile of the radial velocity ![]() $u$ of the liquid at the location of the highest wall shear rate, of the bubble initially located at

$u$ of the liquid at the location of the highest wall shear rate, of the bubble initially located at ![]() $d = 490 \,\mathrm {\mu } \mathrm {m}$. In the space–time plots, the black line shows the volume-equivalent bubble radius

$d = 490 \,\mathrm {\mu } \mathrm {m}$. In the space–time plots, the black line shows the volume-equivalent bubble radius ![]() $R(t)$ and, with respect to

$R(t)$ and, with respect to ![]() $\tau _{w}$, red (blue) areas indicate a radially outward (inward) going flow. In the plots of the velocity profiles, the red line represents the velocity gradient associated with

$\tau _{w}$, red (blue) areas indicate a radially outward (inward) going flow. In the plots of the velocity profiles, the red line represents the velocity gradient associated with ![]() $\tau _{w,max}$, and the black dots show the locations of the cell centres of the applied computational mesh. Results are shown for (a)

$\tau _{w,max}$, and the black dots show the locations of the cell centres of the applied computational mesh. Results are shown for (a) ![]() $v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$,

$v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$, ![]() $\gamma = 0.63$; (b)

$\gamma = 0.63$; (b) ![]() $v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$,

$v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$, ![]() $\gamma = 0.73$.

$\gamma = 0.73$.

When adding a wall jet flow of ![]() $v_{{jet}}=5\,{\rm m}\,{\rm s}^{-1}$ (fourth column), similarly to the large

$v_{{jet}}=5\,{\rm m}\,{\rm s}^{-1}$ (fourth column), similarly to the large ![]() $\gamma$ case, the bubble assumes an ellipsoidal shape. The maximum extension in the axial direction is already reached at

$\gamma$ case, the bubble assumes an ellipsoidal shape. The maximum extension in the axial direction is already reached at ![]() $t=0.398\,T_{L}$ and the bubble is visibly pushed downward by the wall jet. As a result, the wall-near bottom of the bubble still extends along the wall, while the more distal parts already collapse (see movie 2 of the supplementary material). Again, a planar inflow shapes a kink into the bubble, which can be observed clearly in the simulations in figure 7(d–f). This bubble shape is very similar to a bubble in the stagnant liquid case without a wall jet flow but at a much smaller stand-off when forming a needle-like high-speed jet (Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2019; Reuter & Ohl Reference Reuter and Ohl2021; Bußmann et al. Reference Bußmann, Riahi, Gökce, Adami, Barcikowski and Adams2023). Figure 7(d–i) confirms the formation of a thin needle-like jet, with peak velocities of

$t=0.398\,T_{L}$ and the bubble is visibly pushed downward by the wall jet. As a result, the wall-near bottom of the bubble still extends along the wall, while the more distal parts already collapse (see movie 2 of the supplementary material). Again, a planar inflow shapes a kink into the bubble, which can be observed clearly in the simulations in figure 7(d–f). This bubble shape is very similar to a bubble in the stagnant liquid case without a wall jet flow but at a much smaller stand-off when forming a needle-like high-speed jet (Lechner et al. Reference Lechner, Lauterborn, Koch and Mettin2019; Reuter & Ohl Reference Reuter and Ohl2021; Bußmann et al. Reference Bußmann, Riahi, Gökce, Adami, Barcikowski and Adams2023). Figure 7(d–i) confirms the formation of a thin needle-like jet, with peak velocities of ![]() $300\unicode{x2013}400 \,\mathrm {m}\,\mathrm {s}^{-1}$. This needle jet yields a maximum wall shear stress of

$300\unicode{x2013}400 \,\mathrm {m}\,\mathrm {s}^{-1}$. This needle jet yields a maximum wall shear stress of ![]() $2764 \, \mathrm {kPa}$ as shown in figure 8(b) at

$2764 \, \mathrm {kPa}$ as shown in figure 8(b) at ![]() $t\approx 0.97 \, T_{L}$, which is

$t\approx 0.97 \, T_{L}$, which is ![]() $44$ times higher compared with the conventional jetting case (

$44$ times higher compared with the conventional jetting case (![]() $v_{{jet}}=0 \,\mathrm {m}\,\mathrm {s}^{-1}$). Despite this very large wall shear stress, the associated velocity gradients are resolved adequately by the employed computational mesh, as evident by the velocity profile that coincides with the maximum wall shear stress on the right-hand side of figure 8(b). The maximum wall pressure of

$v_{{jet}}=0 \,\mathrm {m}\,\mathrm {s}^{-1}$). Despite this very large wall shear stress, the associated velocity gradients are resolved adequately by the employed computational mesh, as evident by the velocity profile that coincides with the maximum wall shear stress on the right-hand side of figure 8(b). The maximum wall pressure of ![]() $49 \, \mathrm {MPa}$ (a sixfold increase compared with the stationary case) is generated by the impact of this needle jet, see figure 8(b), from which the impact velocity of the needle jet on the wall can be estimated as

$49 \, \mathrm {MPa}$ (a sixfold increase compared with the stationary case) is generated by the impact of this needle jet, see figure 8(b), from which the impact velocity of the needle jet on the wall can be estimated as ![]() ${\approx }310 \,\mathrm {m}\,\mathrm {s}^{-1}$. In contrast to the large

${\approx }310 \,\mathrm {m}\,\mathrm {s}^{-1}$. In contrast to the large ![]() $\gamma$ case, now only an insignificant flow in the upward direction is generated.

$\gamma$ case, now only an insignificant flow in the upward direction is generated.

From the evolution of the bubble shape with decreasing wall jet flow velocities in figure 6, it can be seen how the bubble becomes less ellipsoidal and the kink less pronounced. At ![]() $v_{{jet}}=3.1$ and

$v_{{jet}}=3.1$ and ![]() $v_{{jet}}=5.0\,\mathrm {m}\,\mathrm {s}^{-1}$ in the last row, a string-like gas phase is visible along the axis of symmetry but not for

$v_{{jet}}=5.0\,\mathrm {m}\,\mathrm {s}^{-1}$ in the last row, a string-like gas phase is visible along the axis of symmetry but not for ![]() $v_{{jet}}=1.6$ and

$v_{{jet}}=1.6$ and ![]() $v_{{jet}}=1.6\,\mathrm {m}\,\mathrm {s}^{-1}$. Note that this string-like gas phase is an indicator that the planar jet has converged onto the axis of symmetry, as, for instance, visible along the axis of symmetry in figure 4(i). As the simulations suggest, this is a result of the pinch-off process, i.e. only in the two higher wall jet velocity cases does the planar jet converge on the axis of symmetry, while for the cases

$v_{{jet}}=1.6\,\mathrm {m}\,\mathrm {s}^{-1}$. Note that this string-like gas phase is an indicator that the planar jet has converged onto the axis of symmetry, as, for instance, visible along the axis of symmetry in figure 4(i). As the simulations suggest, this is a result of the pinch-off process, i.e. only in the two higher wall jet velocity cases does the planar jet converge on the axis of symmetry, while for the cases ![]() $v_{{jet}} \leq 1.6\,\mathrm {m}\,\mathrm {s}^{-1}$ the regular jet passes the axis already before the planar jet can reach the axis of symmetry.

$v_{{jet}} \leq 1.6\,\mathrm {m}\,\mathrm {s}^{-1}$ the regular jet passes the axis already before the planar jet can reach the axis of symmetry.

3.3. Small stand-off distance

The bubble dynamics for the smallest stand-offs presented here (![]() $\gamma \approx 0.45$) are depicted in figure 9 for increasing wall jet velocities. The first row shows the maximum expansion, the second row the shape during shrinkage, the third and fourth rows depict the bubble just before and after the collapse, respectively, and the last row shows the bubble at the second collapse.

$\gamma \approx 0.45$) are depicted in figure 9 for increasing wall jet velocities. The first row shows the maximum expansion, the second row the shape during shrinkage, the third and fourth rows depict the bubble just before and after the collapse, respectively, and the last row shows the bubble at the second collapse.

Figure 9. Bubble dynamics at small stand-off (![]() $\gamma =0.49,0.46,0.44,0.46$, from left to right). For the fastest wall jet, an upwards-directed jet flow evolves. The normalized time is indicated in each frame, the respective lifetimes are

$\gamma =0.49,0.46,0.44,0.46$, from left to right). For the fastest wall jet, an upwards-directed jet flow evolves. The normalized time is indicated in each frame, the respective lifetimes are ![]() $T_{L}=151,138,140,127\,\mathrm {\mu }$s. The rightmost column shows the collapse for

$T_{L}=151,138,140,127\,\mathrm {\mu }$s. The rightmost column shows the collapse for ![]() $v_{max}$ in detail. The wall is located at the bottom of each frame. A video of the bubble at

$v_{max}$ in detail. The wall is located at the bottom of each frame. A video of the bubble at ![]() $v_{jet}=5$ m s

$v_{jet}=5$ m s![]() $^{-1}$ is provided in the supplementary material as movie 3.

$^{-1}$ is provided in the supplementary material as movie 3.

The quiescent case (![]() $v_{{jet}}=0\,{\rm m}\,{\rm s}^{-1}$) is similar to the quiescent intermediate

$v_{{jet}}=0\,{\rm m}\,{\rm s}^{-1}$) is similar to the quiescent intermediate ![]() $\gamma$ case shown in figure 6. The simulation results are shown in figure 10(a–c). They reveal a jet velocity of

$\gamma$ case shown in figure 6. The simulation results are shown in figure 10(a–c). They reveal a jet velocity of ![]() ${\approx }45\,{\rm m}\,{\rm s}^{-1}$ and a maximum wall shear stress of

${\approx }45\,{\rm m}\,{\rm s}^{-1}$ and a maximum wall shear stress of ![]() $54 \, \mathrm {kPa}$ in the space–time plots in figure 11(a) at

$54 \, \mathrm {kPa}$ in the space–time plots in figure 11(a) at ![]() $t = 0.964 \, T_{L}$, due to the jet impact before the bubble reaches its minimum volume. The maximum pressure peak of

$t = 0.964 \, T_{L}$, due to the jet impact before the bubble reaches its minimum volume. The maximum pressure peak of ![]() $11\,\mathrm {MPa}$, however, is caused by the collapse of the bubble.

$11\,\mathrm {MPa}$, however, is caused by the collapse of the bubble.

Figure 10. Bubble shape, pressure and velocity field at different time instances during the collapse of the bubble initially located at ![]() $d = 290 \,\mathrm {\mu } \mathrm {m}$ (

$d = 290 \,\mathrm {\mu } \mathrm {m}$ (![]() $\gamma = 0.37$ and

$\gamma = 0.37$ and ![]() $0.43$, respectively). (a–c) In quiescent water (

$0.43$, respectively). (a–c) In quiescent water (![]() ${v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}}$). The lifetime of this bubble is

${v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}}$). The lifetime of this bubble is ![]() $T_{L} = 181.6 \,\mathrm {\mu } \mathrm {s}$. (d–i) Subject to a wall jet with

$T_{L} = 181.6 \,\mathrm {\mu } \mathrm {s}$. (d–i) Subject to a wall jet with ![]() $v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$. The lifetime of this bubble is

$v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$. The lifetime of this bubble is ![]() $T_{L} = 155.3 \,\mathrm {\mu } \mathrm {s}$. The scale bar corresponds to

$T_{L} = 155.3 \,\mathrm {\mu } \mathrm {s}$. The scale bar corresponds to ![]() $250 \,\mathrm {\mu } \mathrm {m}$.

$250 \,\mathrm {\mu } \mathrm {m}$.

Figure 11. Space–time plots of the wall shear stress ![]() $\tau _{w}$ and the wall pressure

$\tau _{w}$ and the wall pressure ![]() $p_{w}$, and profile of the radial velocity

$p_{w}$, and profile of the radial velocity ![]() $u$ of the liquid at the location of the highest wall shear rate, of the bubble initially located at

$u$ of the liquid at the location of the highest wall shear rate, of the bubble initially located at ![]() $d = 290 \,\mathrm {\mu } \mathrm {m}$. In the space–time plots, the black line shows the volume-equivalent bubble radius

$d = 290 \,\mathrm {\mu } \mathrm {m}$. In the space–time plots, the black line shows the volume-equivalent bubble radius ![]() $R(t)$ and, with respect to

$R(t)$ and, with respect to ![]() $\tau _{w}$, red (blue) areas indicate a radially outward (inward) going flow. In the plots of the velocity profiles, the red line represents the velocity gradient associated with

$\tau _{w}$, red (blue) areas indicate a radially outward (inward) going flow. In the plots of the velocity profiles, the red line represents the velocity gradient associated with ![]() $\tau _{w,max}$, and the black dots show the locations of the cell centres of the applied computational mesh. Results are shown for (a)

$\tau _{w,max}$, and the black dots show the locations of the cell centres of the applied computational mesh. Results are shown for (a) ![]() $v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$,

$v_{jet} = 0 \,\mathrm {m}\,\mathrm {s}^{-1}$, ![]() $\gamma = 0.37$; (b)

$\gamma = 0.37$; (b) ![]() $v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$,

$v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$, ![]() $\gamma = 0.43$.

$\gamma = 0.43$.

When introducing a wall jet flow with ![]() $v_{{jet}}=5\,{\rm m}\,{\rm s}^{-1}$, in the fourth column of figure 9, the bubble during its expansion already moves significantly towards the wall and then shows a quite different dynamics. A video of the corresponding bubble is available as movie 3 of the supplementary material. The bubble extends to a rather flat shape along the wall and a kink is formed during the collapse stage; see

$v_{{jet}}=5\,{\rm m}\,{\rm s}^{-1}$, in the fourth column of figure 9, the bubble during its expansion already moves significantly towards the wall and then shows a quite different dynamics. A video of the corresponding bubble is available as movie 3 of the supplementary material. The bubble extends to a rather flat shape along the wall and a kink is formed during the collapse stage; see ![]() $t = 0.835 \, T_{L}$ and figure 10(e). This kink again is related to the planar and converging jet flow that now develops directly at the wall. This planar jet now converges in very close distance to the wall and proceeds here even below the bubble, such that it gives the bubble a mushroom-like shape; see

$t = 0.835 \, T_{L}$ and figure 10(e). This kink again is related to the planar and converging jet flow that now develops directly at the wall. This planar jet now converges in very close distance to the wall and proceeds here even below the bubble, such that it gives the bubble a mushroom-like shape; see ![]() $t = 0.992 \, T_{L}$ in figure 9 and the magnification in figure 10(h). Upon convergence of the planar jet, the bubble is lifted off the wall and an axial jet is formed, similar as before in the case of a larger stand-off, but this time in the reverse direction, i.e. away from the wall with velocities of

$t = 0.992 \, T_{L}$ in figure 9 and the magnification in figure 10(h). Upon convergence of the planar jet, the bubble is lifted off the wall and an axial jet is formed, similar as before in the case of a larger stand-off, but this time in the reverse direction, i.e. away from the wall with velocities of ![]() ${\approx }160 \,\mathrm {m}\,\mathrm {s}^{-1}$; see figure 10(i). As a result, the final collapse occurs about

${\approx }160 \,\mathrm {m}\,\mathrm {s}^{-1}$; see figure 10(i). As a result, the final collapse occurs about ![]() $120\,\mathrm {\mu }$m away from the wall; see

$120\,\mathrm {\mu }$m away from the wall; see ![]() $t = 1.000 \, T_{L}$. Subsequently, the gas phase, now in the several bubbles arranged along a ring, translates further upward such that the second collapse occurs at a distance of

$t = 1.000 \, T_{L}$. Subsequently, the gas phase, now in the several bubbles arranged along a ring, translates further upward such that the second collapse occurs at a distance of ![]() $500\,\mathrm {\mu } \mathrm {m}$ from the wall (

$500\,\mathrm {\mu } \mathrm {m}$ from the wall (![]() $t = 1.409\, T_{L}$).

$t = 1.409\, T_{L}$).

However, even if it is not possible to see directly in the presented graphs, the space–time plot in figure 11(b) indicates that also a downwards-directed jet hits the wall shortly after the bubble reaches its minimum volume, visible through the wall shear stress peak at ![]() $t = 1.01 \, T_{L}$. Upon impact, the jet generates a wall shear stress of

$t = 1.01 \, T_{L}$. Upon impact, the jet generates a wall shear stress of ![]() $1893 \, \mathrm {kPa}$, which is

$1893 \, \mathrm {kPa}$, which is ![]() $35$ times larger compared with the stationary case. At the same time, the maximum wall pressure reaches

$35$ times larger compared with the stationary case. At the same time, the maximum wall pressure reaches ![]() $86 \, \mathrm {MPa}$, which is about

$86 \, \mathrm {MPa}$, which is about ![]() $8$ times larger compared with cavitation bubbles in a quiescent liquid and which corresponds to the stagnation pressure of a jet with a velocity of

$8$ times larger compared with cavitation bubbles in a quiescent liquid and which corresponds to the stagnation pressure of a jet with a velocity of ![]() ${\approx }410 \,\mathrm {m}\,\mathrm {s}^{-1}$.

${\approx }410 \,\mathrm {m}\,\mathrm {s}^{-1}$.

Comparing the bubble shapes of the two middle columns just prior and after the collapse in figure 9, suggests that in the case of ![]() $v_{{jet}}=1.6\,{\rm m}\,{\rm s}^{-1}$ the regular jet that forms axially pierces the bubble already before the planar boundary-parallel inflow can converge; see

$v_{{jet}}=1.6\,{\rm m}\,{\rm s}^{-1}$ the regular jet that forms axially pierces the bubble already before the planar boundary-parallel inflow can converge; see ![]() $t = 0.992 \, T_{L}$. After impact on the wall, the regular jet collides with and inhibits further planar inflow towards the axis of symmetry. In contrast, for

$t = 0.992 \, T_{L}$. After impact on the wall, the regular jet collides with and inhibits further planar inflow towards the axis of symmetry. In contrast, for ![]() $v_{{jet}}=3.1\,{\rm m}\,{\rm s}^{-1}$, the wall-parallel flow is sufficiently fast to meet on the axis of symmetry before the regular jet pierces the bubble, such that the wall-parallel flow can still lift the bubble off upon convergence. However, the collapse seems to occur closer to the wall than in the case with

$v_{{jet}}=3.1\,{\rm m}\,{\rm s}^{-1}$, the wall-parallel flow is sufficiently fast to meet on the axis of symmetry before the regular jet pierces the bubble, such that the wall-parallel flow can still lift the bubble off upon convergence. However, the collapse seems to occur closer to the wall than in the case with ![]() $v_{{jet}}=5.0\,{\rm m}\,{\rm s}^{-1}$.

$v_{{jet}}=5.0\,{\rm m}\,{\rm s}^{-1}$.

3.4. Parameter overview

While in the last section, the effect of the wall jet flow on the bubble shape dynamics is studied, in figure 12 we compare the stand-off dependence of the bubble shape for the maximum wall jet velocity of ![]() $v_{{jet}}=5$ m s

$v_{{jet}}=5$ m s![]() $^{-1}$. For large stand-offs (

$^{-1}$. For large stand-offs (![]() $\gamma =1.88$), kink and pinch-off occur rather symmetric, i.e. close to the bubble equator. As the bubble is generated closer to the wall, i.e. for decreasing

$\gamma =1.88$), kink and pinch-off occur rather symmetric, i.e. close to the bubble equator. As the bubble is generated closer to the wall, i.e. for decreasing ![]() $\gamma$, the bubble extends further along the wall. There, the bubble dynamics is slowed down and the wall distal part above the pinch-off region collapses faster, resulting in a small cap being shaped; see, for example,

$\gamma$, the bubble extends further along the wall. There, the bubble dynamics is slowed down and the wall distal part above the pinch-off region collapses faster, resulting in a small cap being shaped; see, for example, ![]() $\gamma =0.89$. Only at the smallest stand-off (

$\gamma =0.89$. Only at the smallest stand-off (![]() $\gamma =0.46$) shown does the planar jet evolve sufficiently fast and sufficiently close to the wall to result in a bubble lift-off.

$\gamma =0.46$) shown does the planar jet evolve sufficiently fast and sufficiently close to the wall to result in a bubble lift-off.

Figure 12. Bubble shape in the last instance before the collapse for different stand-off distances ![]() $\gamma$ (indicated above each frame) with the constant wall jet velocity of

$\gamma$ (indicated above each frame) with the constant wall jet velocity of ![]() $v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$. The wall coincides with the bottom in all frames. The scale differs in the frames.

$v_{jet} = 5 \,\mathrm {m}\,\mathrm {s}^{-1}$. The wall coincides with the bottom in all frames. The scale differs in the frames.

In figure 13 the jetting behaviour as a function of stand-off and wall jet velocity is presented. In this parameter map we divide the jetting behaviour into four regimes. First, the regular jet, i.e. the rather broad/thick/wide jet that is directed axially towards the wall, being a few hundred micrometres in diameter and reaching typical velocities of 50–150 m s![]() $^{-1}$ (green). Second, the splitting regime, in which the rather symmetric bubble splits upon the convergence of the planar jet (red) with the generation of two oppositely directed jets. Third, the needle-jet regime, i.e. the convergence of the planar jet that results in a much faster jet axially directed toward the wall (blue). And fourth, the detachment regime, where the planar convergent jet runs at the wall pushing between the bubble and wall, converging before the regular jet pierces the bubble, resulting in bubble lift-off (magenta).

$^{-1}$ (green). Second, the splitting regime, in which the rather symmetric bubble splits upon the convergence of the planar jet (red) with the generation of two oppositely directed jets. Third, the needle-jet regime, i.e. the convergence of the planar jet that results in a much faster jet axially directed toward the wall (blue). And fourth, the detachment regime, where the planar convergent jet runs at the wall pushing between the bubble and wall, converging before the regular jet pierces the bubble, resulting in bubble lift-off (magenta).