1. Introduction

A large proportion of the energy required in transportation and pipe systems is used to overcome fluid-dynamic drag. In particular, skin friction constitutes approximately ![]() $50\,\%$ of the total drag on aircraft and ships, up to

$50\,\%$ of the total drag on aircraft and ships, up to ![]() $90\,\%$ for very large crude carriers (Monty et al. Reference Monty, Dogan, Hanson, Scardino, Ganapathisubramani and Hutchins2016) and almost all the drag in pipelines. Hence, reduction in skin friction can bring a substantial energy saving. Riblets are streamwise-aligned micro-grooves that can reduce skin-friction drag by up to

$90\,\%$ for very large crude carriers (Monty et al. Reference Monty, Dogan, Hanson, Scardino, Ganapathisubramani and Hutchins2016) and almost all the drag in pipelines. Hence, reduction in skin friction can bring a substantial energy saving. Riblets are streamwise-aligned micro-grooves that can reduce skin-friction drag by up to ![]() $10\,\%$ in laboratory conditions (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997) and approximately

$10\,\%$ in laboratory conditions (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997) and approximately ![]() $5\,\%$ at full-scale conditions (Spalart & McLean Reference Spalart and McLean2011), and are therefore considered one of the most promising techniques of passive drag reduction. Indeed, the International Civil Aviation Organization in its 2019 environmental report (ICAO 2019) explicitly mentions riblets as a promising passive technique for reducing drag over aircraft. Pioneering studies on riblets can be traced back to the experiments of Kennedy, Hsu & Lin (Reference Kennedy, Hsu and Lin1973), who suggested that the mean wall-shear stress over a finned surface may be reduced, due to the reduction of wall-shear stress towards the riblet trough. After this seminal work a considerable amount of experimental (Walsh Reference Walsh1980, Reference Walsh1982; Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989; Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997) and numerical (Choi, Moin & Kim Reference Choi, Moin and Kim1993; Chu & Karniadakis Reference Chu and Karniadakis1993; Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1995; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011; Bannier, Garnier & Sagaut Reference Bannier, Garnier and Sagaut2015) studies appeared in the literature, but despite this effort, riblets are not widely used in engineering applications, for different reasons. Flight tests carried out on an aircraft with

$5\,\%$ at full-scale conditions (Spalart & McLean Reference Spalart and McLean2011), and are therefore considered one of the most promising techniques of passive drag reduction. Indeed, the International Civil Aviation Organization in its 2019 environmental report (ICAO 2019) explicitly mentions riblets as a promising passive technique for reducing drag over aircraft. Pioneering studies on riblets can be traced back to the experiments of Kennedy, Hsu & Lin (Reference Kennedy, Hsu and Lin1973), who suggested that the mean wall-shear stress over a finned surface may be reduced, due to the reduction of wall-shear stress towards the riblet trough. After this seminal work a considerable amount of experimental (Walsh Reference Walsh1980, Reference Walsh1982; Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989; Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997) and numerical (Choi, Moin & Kim Reference Choi, Moin and Kim1993; Chu & Karniadakis Reference Chu and Karniadakis1993; Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1995; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011; Bannier, Garnier & Sagaut Reference Bannier, Garnier and Sagaut2015) studies appeared in the literature, but despite this effort, riblets are not widely used in engineering applications, for different reasons. Flight tests carried out on an aircraft with ![]() $70\,\%$ of its surface covered with riblets have shown a drag reduction of approximately

$70\,\%$ of its surface covered with riblets have shown a drag reduction of approximately ![]() $2\,\%$ (Szodruch Reference Szodruch1991), consistent with the aforementioned

$2\,\%$ (Szodruch Reference Szodruch1991), consistent with the aforementioned ![]() $5\,\%$ of

$5\,\%$ of ![]() $50\,\%$, but this reduction in drag becomes only marginally convenient when the additional costs of manufacturing and maintenance are considered (Robert Reference Robert1992). Therefore, in order to have riblets that are more cost-efficient, groove geometries capable of larger drag reduction are desirable. At present, the maximum drag reduction achievable by classical riblets is limited by our understanding of their flow physics.

$50\,\%$, but this reduction in drag becomes only marginally convenient when the additional costs of manufacturing and maintenance are considered (Robert Reference Robert1992). Therefore, in order to have riblets that are more cost-efficient, groove geometries capable of larger drag reduction are desirable. At present, the maximum drag reduction achievable by classical riblets is limited by our understanding of their flow physics.

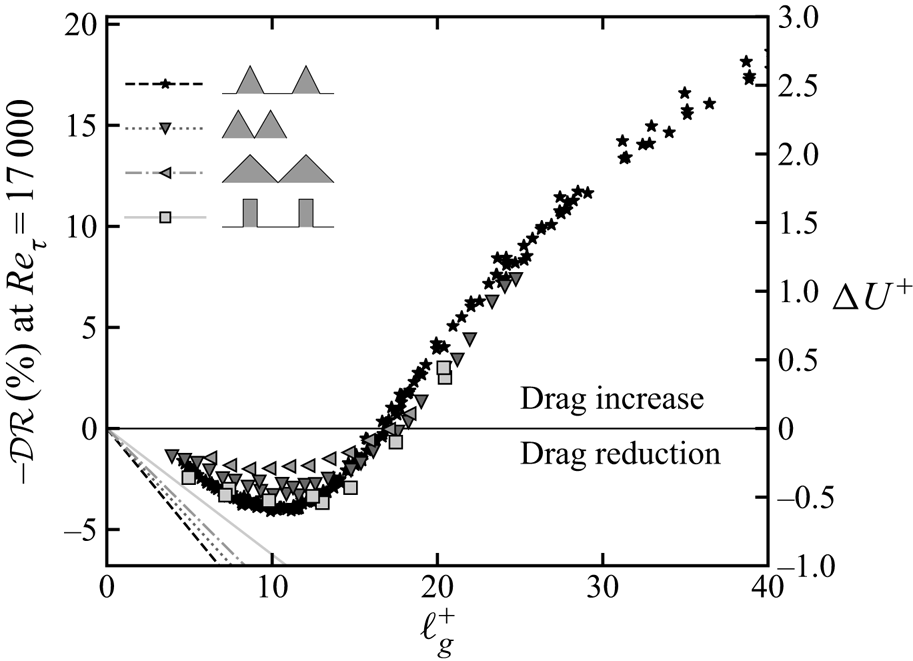

Figure 1 shows the velocity shift with respect to the smooth wall ![]() $\Delta U^+$ and the drag reduction

$\Delta U^+$ and the drag reduction ![]() $\mathcal {DR}\approx -\Delta U^+\sqrt {2C_{fs}}$ (Spalart & McLean Reference Spalart and McLean2011) as a function of the viscous-scaled square root of the groove area

$\mathcal {DR}\approx -\Delta U^+\sqrt {2C_{fs}}$ (Spalart & McLean Reference Spalart and McLean2011) as a function of the viscous-scaled square root of the groove area ![]() $\ell _g^+\equiv \ell _g/\delta _v$,

$\ell _g^+\equiv \ell _g/\delta _v$, ![]() $\ell _g\equiv \sqrt {A_g}$ (where

$\ell _g\equiv \sqrt {A_g}$ (where ![]() $A_g$ is the groove area,

$A_g$ is the groove area, ![]() $\delta _v\equiv \nu /u_\tau$ is the viscous length scale,

$\delta _v\equiv \nu /u_\tau$ is the viscous length scale, ![]() $\nu$ is the kinematic viscosity of the fluid,

$\nu$ is the kinematic viscosity of the fluid, ![]() $u_\tau \equiv \sqrt {\tau _w/\rho }$ is the friction velocity,

$u_\tau \equiv \sqrt {\tau _w/\rho }$ is the friction velocity, ![]() $\tau _w$ is the mean wall-shear stress, i.e. drag per unit wall-plane area, and

$\tau _w$ is the mean wall-shear stress, i.e. drag per unit wall-plane area, and ![]() $\rho$ is the fluid density). The regime in which riblets reduce drag is referred to as the viscous or linear regime as drag decreases linearly with the riblet size up to an optimum (

$\rho$ is the fluid density). The regime in which riblets reduce drag is referred to as the viscous or linear regime as drag decreases linearly with the riblet size up to an optimum (![]() $\ell _g^+\approx 11$). However, further increasing

$\ell _g^+\approx 11$). However, further increasing ![]() $\ell _g^+$ leads to degradation of the linear regime and riblets eventually increase drag. The drag reduction in the linear regime has been extensively studied, and different authors seem to agree on the flow physics of small riblets. Bechert, Hoppe & Reif (Reference Bechert, Hoppe and Reif1985); Bechert et al. (Reference Bechert, Bartenwerfer, Hoppe and Reif1986) attributed the drag reduction to the capability of riblets to inhibit the spanwise motion of streamwise vortices in the viscous sublayer,

$\ell _g^+$ leads to degradation of the linear regime and riblets eventually increase drag. The drag reduction in the linear regime has been extensively studied, and different authors seem to agree on the flow physics of small riblets. Bechert, Hoppe & Reif (Reference Bechert, Hoppe and Reif1985); Bechert et al. (Reference Bechert, Bartenwerfer, Hoppe and Reif1986) attributed the drag reduction to the capability of riblets to inhibit the spanwise motion of streamwise vortices in the viscous sublayer, ![]() $z^+\equiv z/\delta _v\lesssim 5\text {--}6$, where

$z^+\equiv z/\delta _v\lesssim 5\text {--}6$, where ![]() $z$ is the distance from the wall. A different interpretation of basically the same drag-reducing mechanism has been given by Choi et al. (Reference Choi, Moin and Kim1993), Suzuki & Kasagi (Reference Suzuki and Kasagi1994) and Goldstein et al. (Reference Goldstein, Handler and Sirovich1995), who showed that riblets lift these vortices farther from the wall, with subsequent relief of the turbulent stress. These vortices have a diameter of approximately

$z$ is the distance from the wall. A different interpretation of basically the same drag-reducing mechanism has been given by Choi et al. (Reference Choi, Moin and Kim1993), Suzuki & Kasagi (Reference Suzuki and Kasagi1994) and Goldstein et al. (Reference Goldstein, Handler and Sirovich1995), who showed that riblets lift these vortices farther from the wall, with subsequent relief of the turbulent stress. These vortices have a diameter of approximately ![]() $30\delta _v$ (Lee & Lee Reference Lee and Lee2001), in agreement with the observation that riblets with a smaller spacing reduce drag by preventing the lodgement of these vortices into the grooves. This interpretation progressed towards a more quantitative idea that riblets reduce drag by shifting the location at which the streamwise turbulent flow perceives the equivalent smooth wall, or virtual origin (Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989). Different definitions of virtual origin are available in the literature which involve, for instance, best fitting of the law-of-the-wall (Hooshmand, Youngs & Wallace Reference Hooshmand, Youngs and Wallace1983) or matching the location of the maximum in the streamwise velocity fluctuations (Choi et al. Reference Choi, Moin and Kim1993). Luchini et al. (Reference Luchini, Manzo and Pozzi1991) showed that the appropriate quantity that relates to the drag reduction, is the difference between the location of the virtual wall seen by the streamwise flow and that seen by the spanwise flow,

$30\delta _v$ (Lee & Lee Reference Lee and Lee2001), in agreement with the observation that riblets with a smaller spacing reduce drag by preventing the lodgement of these vortices into the grooves. This interpretation progressed towards a more quantitative idea that riblets reduce drag by shifting the location at which the streamwise turbulent flow perceives the equivalent smooth wall, or virtual origin (Bechert & Bartenwerfer Reference Bechert and Bartenwerfer1989). Different definitions of virtual origin are available in the literature which involve, for instance, best fitting of the law-of-the-wall (Hooshmand, Youngs & Wallace Reference Hooshmand, Youngs and Wallace1983) or matching the location of the maximum in the streamwise velocity fluctuations (Choi et al. Reference Choi, Moin and Kim1993). Luchini et al. (Reference Luchini, Manzo and Pozzi1991) showed that the appropriate quantity that relates to the drag reduction, is the difference between the location of the virtual wall seen by the streamwise flow and that seen by the spanwise flow, ![]() $\Delta h\equiv h_\parallel -h_\perp$. For small sizes (

$\Delta h\equiv h_\parallel -h_\perp$. For small sizes (![]() $s^+\lesssim 5$), these virtual locations

$s^+\lesssim 5$), these virtual locations ![]() $h_\parallel$ and

$h_\parallel$ and ![]() $h_\perp$, called protrusion heights, can be readily calculated using the Stokes approximation and their difference is proportional to the drag reduction

$h_\perp$, called protrusion heights, can be readily calculated using the Stokes approximation and their difference is proportional to the drag reduction ![]() $\mathcal {DR}\sim \Delta h^+$ (figure 1 and García-Mayoral, Gómez-de-Segura & Fairhall Reference García-Mayoral, Gómez-de-Segura and Fairhall2019). The difference in protrusion heights can be used to design and optimize riblets in the viscous regime, in which drag reduction increases indefinitely with riblet size, but fails to describe the drag increase relative to the optimum.

$\mathcal {DR}\sim \Delta h^+$ (figure 1 and García-Mayoral, Gómez-de-Segura & Fairhall Reference García-Mayoral, Gómez-de-Segura and Fairhall2019). The difference in protrusion heights can be used to design and optimize riblets in the viscous regime, in which drag reduction increases indefinitely with riblet size, but fails to describe the drag increase relative to the optimum.

Figure 1. Drag reduction curve at friction Reynolds number ![]() $Re_\tau=17\ 000$ typical of aircraft wing (left axis) and velocity shift with respect to the smooth wall

$Re_\tau=17\ 000$ typical of aircraft wing (left axis) and velocity shift with respect to the smooth wall ![]() $\Delta U^+$ (right axis) as a function of the viscous-scaled square root of groove area

$\Delta U^+$ (right axis) as a function of the viscous-scaled square root of groove area ![]() $\ell _g^+=\ell _g/\delta _v$. Here,

$\ell _g^+=\ell _g/\delta _v$. Here, ![]() $\Delta U^+$ values are reported for the riblets data of Gatti et al. (Reference Gatti, von Deyn, Forooghi and Frohnapfel2020, stars), Bechert et al. (Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997, triangles) and García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2012, (squares)). Straight lines indicate slopes for infinitely small riblets of the four shapes calculated in the Stokes-flow limit (Luchini, Manzo & Pozzi Reference Luchini, Manzo and Pozzi1991).

$\Delta U^+$ values are reported for the riblets data of Gatti et al. (Reference Gatti, von Deyn, Forooghi and Frohnapfel2020, stars), Bechert et al. (Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997, triangles) and García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2012, (squares)). Straight lines indicate slopes for infinitely small riblets of the four shapes calculated in the Stokes-flow limit (Luchini, Manzo & Pozzi Reference Luchini, Manzo and Pozzi1991).

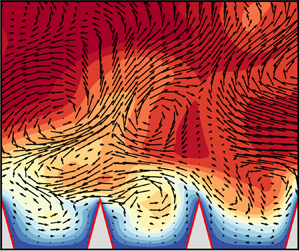

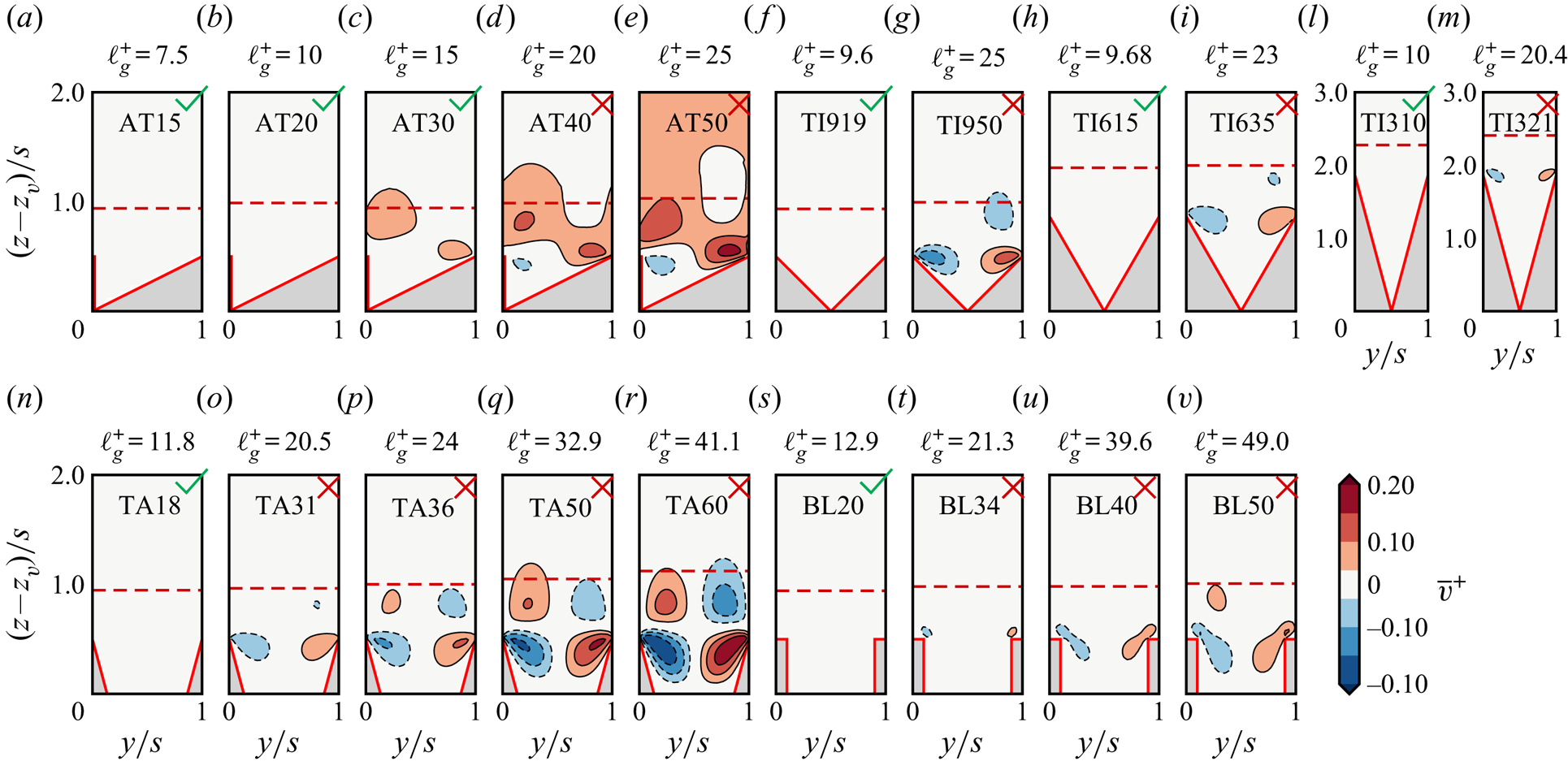

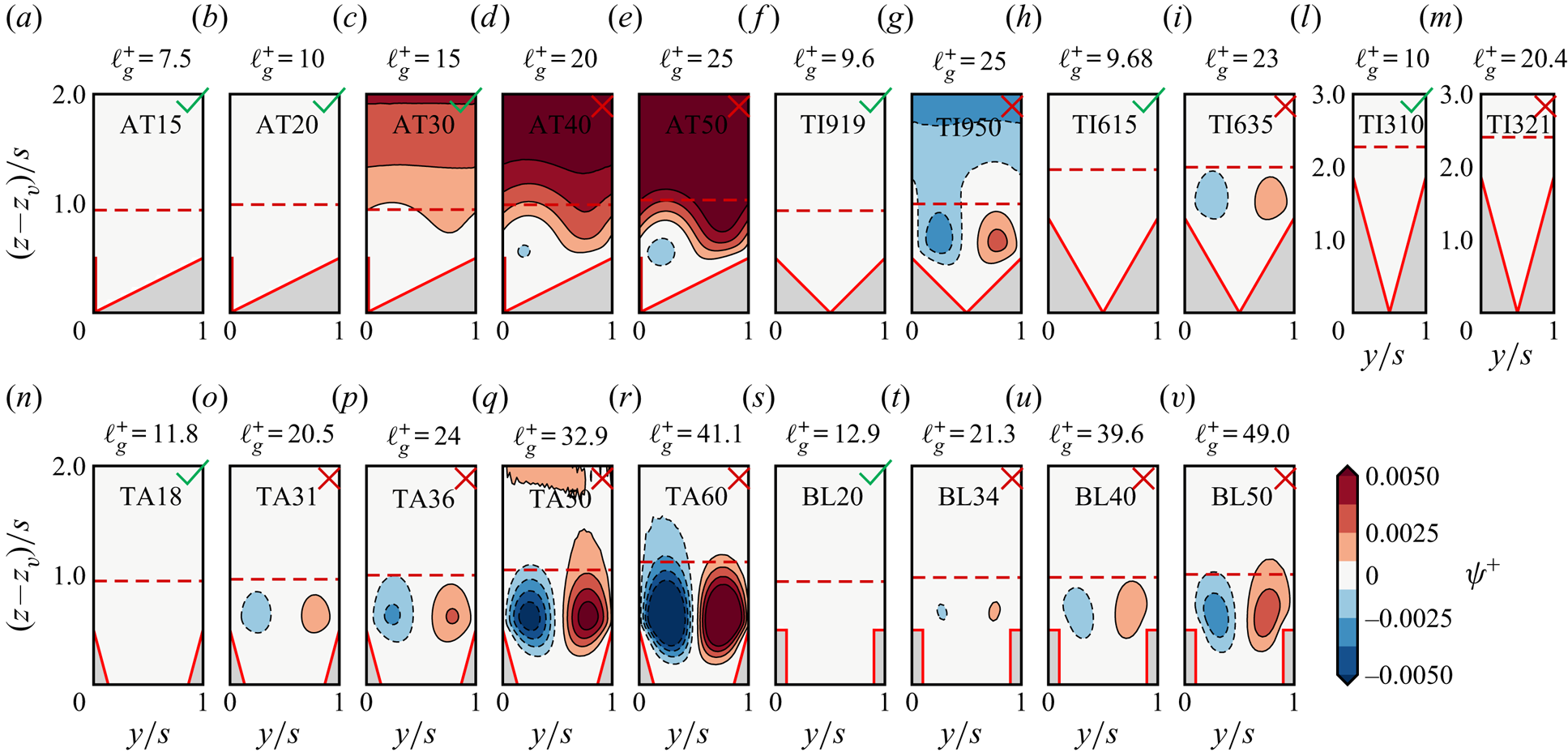

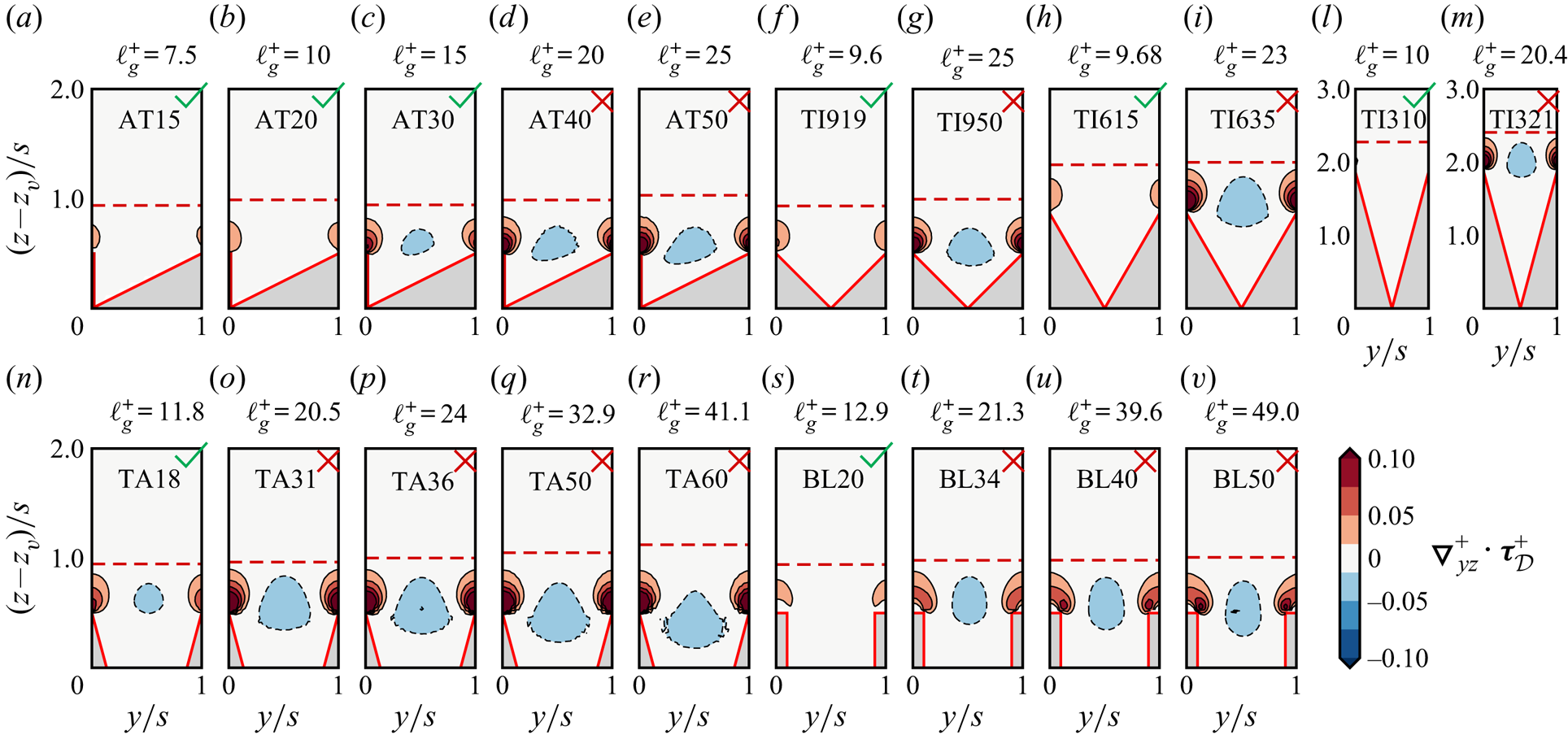

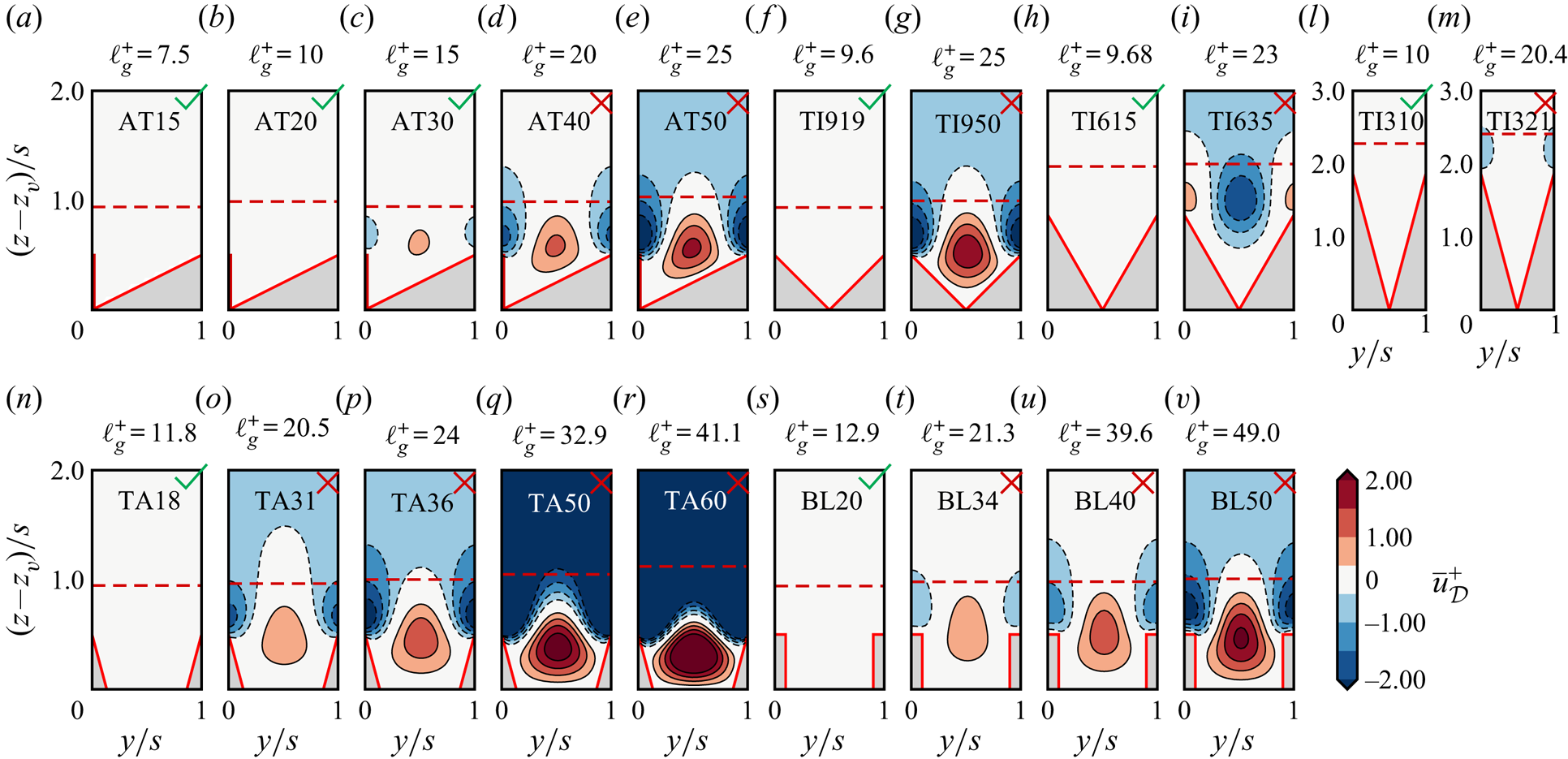

Several mechanisms have been proposed to explain the disruption of the viscous-flow regime, which in one way or another can all be traced back to turbulence, i.e. a non-negligible inertial flow near riblets. Choi et al. (Reference Choi, Moin and Kim1993) inspected instantaneous flow visualizations of the cross-stream plane and attributed the drag increase to the lodgement of the streamwise vortices inside the riblets grooves when these become larger than the vortices’ diameter (![]() $s^+\gtrsim 20$). They also observed the appearance of non-zero mean (time-averaged) cross-stream velocities in the riblet grooves, similar to the secondary motions found in non-circular ducts (Prandtl Reference Prandtl1926), with the main difference that the former only appear in the riblets vicinity, whereas the latter retain a large-scale contribution, occupying the whole cross-stream section (Pirozzoli et al. Reference Pirozzoli, Modesti, Orlandi and Grasso2018). Other authors addressed the correlation between secondary velocities, or dispersive velocities, and the drag increase over riblets. Suzuki & Kasagi (Reference Suzuki and Kasagi1994) carried out experiments using three-dimensional particle tracking velocimetry and observed the formation of mean cross-stream velocities over riblets operating beyond the drag optimum. They attributed the drag increase to the additional momentum transport caused by these secondary velocities, although they did not quantify their contribution to the drag variation. Goldstein & Tuan (Reference Goldstein and Tuan1998) used direct numerical simulation (DNS) to study the dispersive velocities, forming over large-spaced riblets and attributed them to the drag increase, arguing that the loss of performance occurring for large riblets could be tackled by disrupting these secondary velocities which also contribute to the total stress. The additional stress carried by the secondary, or dispersive, velocities is referred to as dispersive stress and is absent in smooth-wall turbulent flows. Both the dispersive and turbulent stress can be traced back to inertial momentum transfer, but the dispersive stresses represent spatial variations in the time-averaged mean about the riblets, and turbulent stresses represent fluctuations about this spatially varying mean.

$s^+\gtrsim 20$). They also observed the appearance of non-zero mean (time-averaged) cross-stream velocities in the riblet grooves, similar to the secondary motions found in non-circular ducts (Prandtl Reference Prandtl1926), with the main difference that the former only appear in the riblets vicinity, whereas the latter retain a large-scale contribution, occupying the whole cross-stream section (Pirozzoli et al. Reference Pirozzoli, Modesti, Orlandi and Grasso2018). Other authors addressed the correlation between secondary velocities, or dispersive velocities, and the drag increase over riblets. Suzuki & Kasagi (Reference Suzuki and Kasagi1994) carried out experiments using three-dimensional particle tracking velocimetry and observed the formation of mean cross-stream velocities over riblets operating beyond the drag optimum. They attributed the drag increase to the additional momentum transport caused by these secondary velocities, although they did not quantify their contribution to the drag variation. Goldstein & Tuan (Reference Goldstein and Tuan1998) used direct numerical simulation (DNS) to study the dispersive velocities, forming over large-spaced riblets and attributed them to the drag increase, arguing that the loss of performance occurring for large riblets could be tackled by disrupting these secondary velocities which also contribute to the total stress. The additional stress carried by the secondary, or dispersive, velocities is referred to as dispersive stress and is absent in smooth-wall turbulent flows. Both the dispersive and turbulent stress can be traced back to inertial momentum transfer, but the dispersive stresses represent spatial variations in the time-averaged mean about the riblets, and turbulent stresses represent fluctuations about this spatially varying mean.

Another mechanism has been proposed by García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011), who observed that large riblets also trigger the onset of spanwise-coherent vortical structures, which are visible in the two-dimensional pre-multiplied velocity spectrum right above the riblet crest, and are similar to Kelvin–Helmholtz rollers, which represent an additional contribution to the Reynolds stress. Their stability analysis over a modelled impedance boundary condition shows that the growth rate of these rollers is proportional to the square root of the groove area, which suggested the use of ![]() $\ell _g^+$ as a scaling parameter to compare drag reduction in riblets with different geometries (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011).

$\ell _g^+$ as a scaling parameter to compare drag reduction in riblets with different geometries (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011).

This literature survey shows that there is still little consensus on the physical mechanisms responsible for the degradation of the riblets drag-reducing performance. Given the more recent date of the study on Kelvin–Helmholtz-like rollers, this mechanism has been considered the only cause of the linear-regime breakdown in recent years. However, Endrikat et al. (Reference Endrikat, Modesti, MacDonald, García-Mayoral, Hutchins and Chung2020, Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021) recently used the present DNS dataset to study how the groove shape affects the Kelvin–Helmholtz-like rollers and found that they are only active for certain riblet geometries, namely sharp triangles and blades. Nevertheless, all riblet shapes exhibit the linear-regime breakdown eventually leading to a drag increase, thus pointing to a possible route to performance degradation that is unrelated to Kelvin–Helmholtz rollers.

Although most studies of riblets are mainly focused on two-dimensional straight symmetric geometries, flow cases over three-dimensional riblets have been performed. Bechert et al. (Reference Bechert, Bartenwerfer, Hoppe and Reif1986) argued that a staggered arrangement of short riblets may be able to increase the maximum attainable drag reduction, due to a larger streamwise protrusion height caused by a larger effective spanwise spacing. However, in a more recent experiment (Bechert, Bruse & Hage Reference Bechert, Bruse and Hage2000), they instead found lower drag reduction with respect to the two-dimensional riblets. Sasamori et al. (Reference Sasamori, Mamori, Iwamoto and Murata2014, Reference Sasamori, Iihama, Mamori, Iwamoto and Murata2017) carried out experiments and DNS of three-dimensional sinusoidal riblets and, despite the additional pressure drag contribution, found higher drag reduction with respect to two-dimensional riblets. Kevin et al. (Reference Kevin, Monty, Bai, Pathikonda, Nugroho, Barros, Christensen and Hutchins2017) performed stereoscopic particle image velocimetry of developed boundary layers over herringbone (large patches of converging–diverging yawed) riblets and observed large-scale mean secondary flows in the cross-stream plane. Drag reduction for this configuration has been quantified by Benschop & Breugem (Reference Benschop and Breugem2017), who carried out DNS of channel flow over herringbone riblets and found that they can both decrease or increase drag, depending on the wavelength of the spanwise texture, but the effect of the large-scale secondary flow is always detrimental for drag reduction. Boomsma & Sotiropoulos (Reference Boomsma and Sotiropoulos2016) performed DNS of three-dimensional riblets that closely resemble the denticles found on shark skin and found that three-dimensionality limits the drag reduction due to the large increase in pressure drag.

Despite the extensive work carried out on riblets, the following fundamental aspects of the flow physics are not yet fully understood: (i) the precise effect of the groove shape, (ii) whether the mechanism of drag increase is universal and (iii) the effect of spanwise asymmetry. On point (i), most parametric studies involving the effect of the geometry have been carried out through experiments (Walsh Reference Walsh1982; Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997), which do not provide access to the three-dimensional flow field, whereas DNS studies of two-dimensional riblets are limited to triangular and blade geometries (Choi et al. Reference Choi, Moin and Kim1993; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011). On point (ii), different mechanisms have been proposed for the breakdown in drag reduction, but often these are based on observations from particular distinct riblet geometries. For example the analysis of Goldstein & Tuan (Reference Goldstein and Tuan1998) of secondary flows was based on DNS of triangular riblets, while the observations of García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011) of the Kelvin–Helmholtz instability were based on DNS of blade riblets. In a recent study (Endrikat et al. Reference Endrikat, Modesti, García-Mayoral, Hutchins and Chung2021) we showed that not all riblet shapes trigger the onset of Kelvin–Helmholtz rollers, revealing that the effect of the groove geometry might be more important than previously thought. What is needed is a systematic study across a broad parameter space to assess the validity and generality of the various proposed mechanisms. To this end, we carry out DNS of minimal-channel flow over many symmetric riblet geometries, namely triangular, trapezoidal and blade riblets, to understand if a common mechanism leading to the drag increase exists. On point (iii), we study the flow over two-dimensional triangular riblets, asymmetric in the spanwise direction (Walsh Reference Walsh1982). These riblets could induce a non-zero mean cross-flow that will effectively behave similarly to yawed straight riblets, without pressure drag penalty.

2. Methodology

We solve the incompressible Navier–Stokes equations,

where ![]() $\varPi >0$ is the uniform and constant kinematic pressure gradient, driving the flow in the streamwise direction. The streamwise, spanwise and wall-normal directions are denoted as

$\varPi >0$ is the uniform and constant kinematic pressure gradient, driving the flow in the streamwise direction. The streamwise, spanwise and wall-normal directions are denoted as ![]() $x$,

$x$, ![]() $y$,

$y$, ![]() $z$, respectively and the velocity components in the corresponding directions are

$z$, respectively and the velocity components in the corresponding directions are ![]() $u$,

$u$, ![]() $v$,

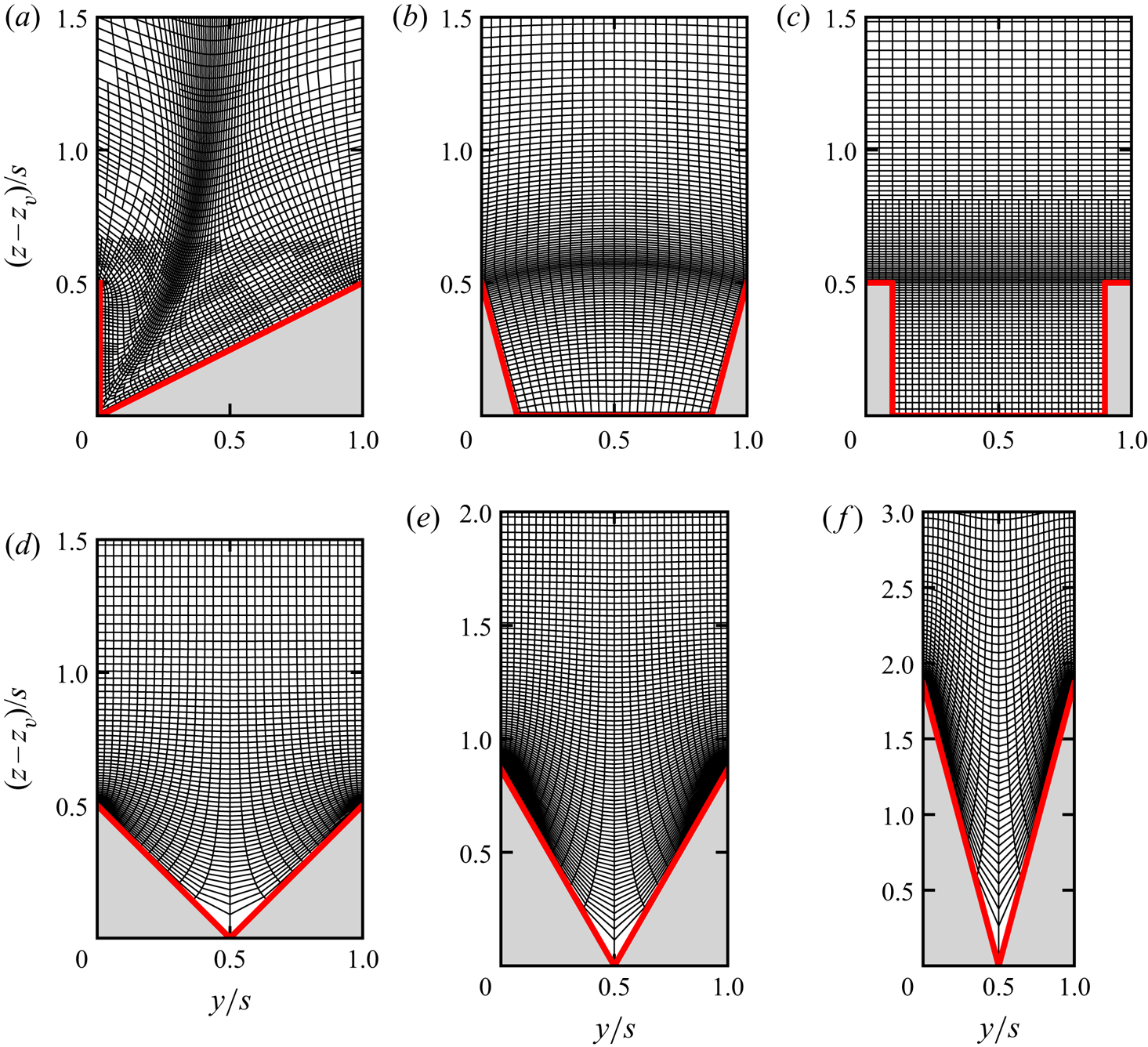

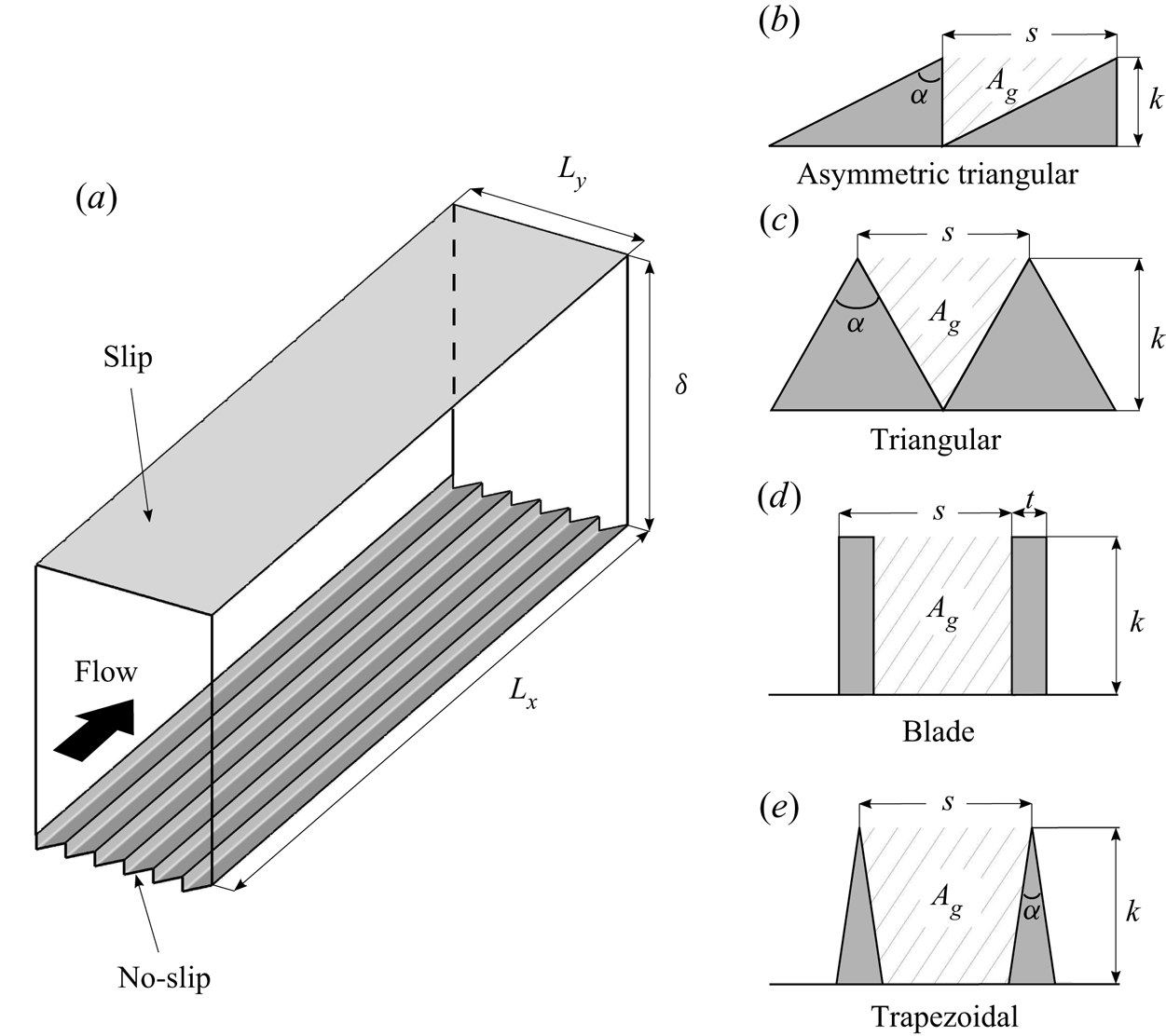

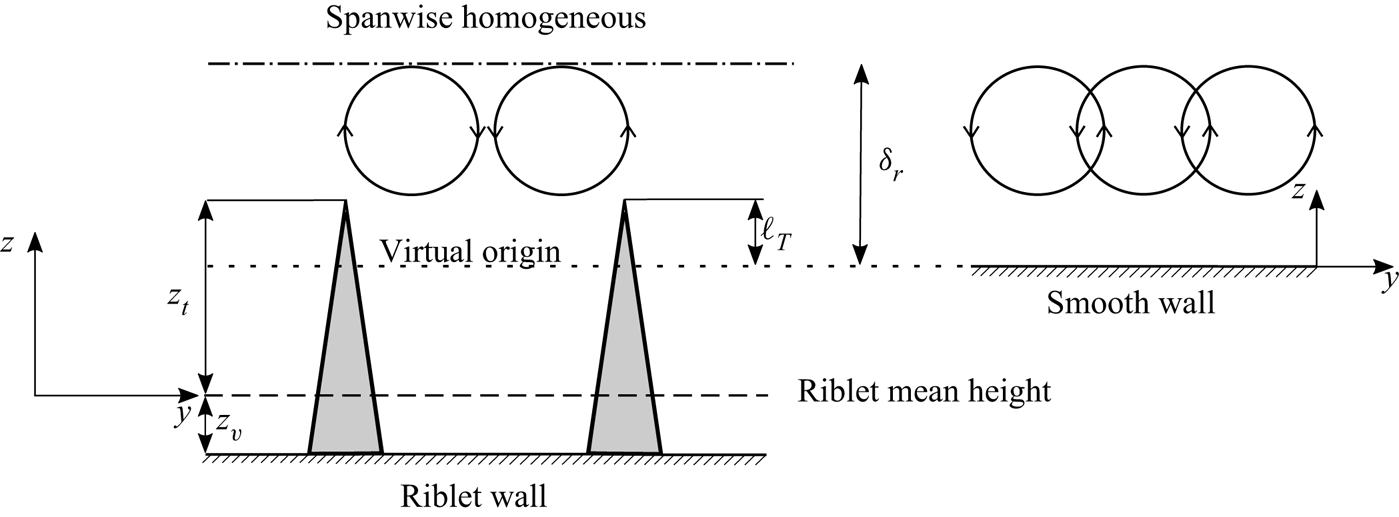

$v$, ![]() $w$. Figure 2 shows the computational body-fitted mesh used for different riblet geometries. All meshes are constituted by tetrahedral elements, in which adjacent cells do not necessarily share the same number of nodes at the interface (hanging nodes) (figure 2a,c).

$w$. Figure 2 shows the computational body-fitted mesh used for different riblet geometries. All meshes are constituted by tetrahedral elements, in which adjacent cells do not necessarily share the same number of nodes at the interface (hanging nodes) (figure 2a,c).

Figure 2. Computational mesh for different riblets: (a) asymmetric triangular AT50, (b) trapezoidal TA50, (c) blade BL50, (d) triangular TI950, (e) triangular TI635, ( f) triangular TI321. Here, ![]() $z_v$ indicates the riblet valley.

$z_v$ indicates the riblet valley.

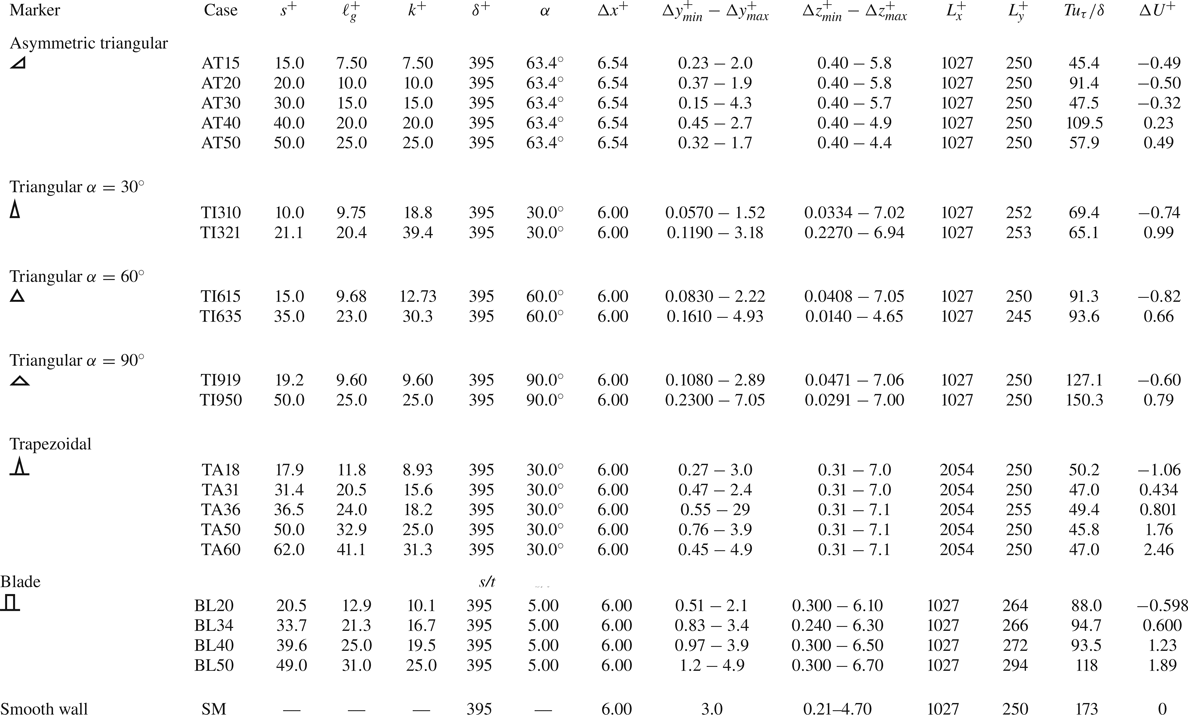

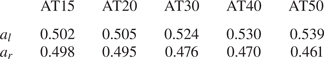

Flow cases are reported in table 1 and a representative case name is assigned to each riblet groove. For asymmetric triangular riblets we use the acronym AT, for symmetric triangular riblets TI, for trapezoidal riblets TA and for blades BL. Symmetric riblet cases contain the tip angle ![]() $\alpha$ and the spacing in viscous units

$\alpha$ and the spacing in viscous units ![]() $s^+$, whereas all other cases only contain

$s^+$, whereas all other cases only contain ![]() $s^+$. For instance, triangular riblets with tip angle

$s^+$. For instance, triangular riblets with tip angle ![]() $30^\circ$ and spacing

$30^\circ$ and spacing ![]() $s^+=10$ are denoted as TI310, whereas blades riblet with spacing

$s^+=10$ are denoted as TI310, whereas blades riblet with spacing ![]() $s^+=20$ are denoted as BL20. As for the choice of the riblet geometry, for asymmetric triangles, triangles with tip angle

$s^+=20$ are denoted as BL20. As for the choice of the riblet geometry, for asymmetric triangles, triangles with tip angle ![]() $\alpha =90^\circ$, blades and trapezoids we fixed the ratio

$\alpha =90^\circ$, blades and trapezoids we fixed the ratio ![]() $k/s=0.5$, and we also consider triangular riblets with tip angle

$k/s=0.5$, and we also consider triangular riblets with tip angle ![]() $\alpha =30^\circ$ and

$\alpha =30^\circ$ and ![]() $\alpha =60^\circ$. We consider five asymmetric triangular riblet sizes, and two triangular riblet sizes for each tip angle, as the former geometry has not been previously studied, whereas extensive literature is available for the latter (Choi et al. Reference Choi, Moin and Kim1993; Goldstein & Tuan Reference Goldstein and Tuan1998; Li & Liu Reference Li and Liu2018). Moreover, the dataset is skewed in favour of riblets with larger sizes than those typically considered optimal in terms of drag reduction

$\alpha =60^\circ$. We consider five asymmetric triangular riblet sizes, and two triangular riblet sizes for each tip angle, as the former geometry has not been previously studied, whereas extensive literature is available for the latter (Choi et al. Reference Choi, Moin and Kim1993; Goldstein & Tuan Reference Goldstein and Tuan1998; Li & Liu Reference Li and Liu2018). Moreover, the dataset is skewed in favour of riblets with larger sizes than those typically considered optimal in terms of drag reduction ![]() $\ell _g^+\approx 11$ (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011). This choice is motivated by our intention to study the flow mechanisms responsible for the drag increase, which is less understood than the viscous regime (which can be studied in terms of linear mechanism of Luchini et al. Reference Luchini, Manzo and Pozzi1991).

$\ell _g^+\approx 11$ (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011). This choice is motivated by our intention to study the flow mechanisms responsible for the drag increase, which is less understood than the viscous regime (which can be studied in terms of linear mechanism of Luchini et al. Reference Luchini, Manzo and Pozzi1991).

Table 1. DNS cases of minimal open-channel flow; ![]() $s^+=s/\delta _v$ and

$s^+=s/\delta _v$ and ![]() $\ell _g^+=\ell _g/\delta _v$, respectively, the viscous-scaled riblet spacing and square root of the groove area,

$\ell _g^+=\ell _g/\delta _v$, respectively, the viscous-scaled riblet spacing and square root of the groove area, ![]() $\ell _g\equiv \sqrt {A_g}$;

$\ell _g\equiv \sqrt {A_g}$; ![]() $\Delta x^+$ is the viscous-scaled mesh spacing in the streamwise direction and

$\Delta x^+$ is the viscous-scaled mesh spacing in the streamwise direction and ![]() $\Delta y_{min}^+-\Delta y_{max}^+$,

$\Delta y_{min}^+-\Delta y_{max}^+$, ![]() $\Delta z_{min}^+-\Delta z_{max}^+$ the minimum and maximum mesh spacing in the spanwise and wall-normal directions;

$\Delta z_{min}^+-\Delta z_{max}^+$ the minimum and maximum mesh spacing in the spanwise and wall-normal directions; ![]() $L_x^+$ and

$L_x^+$ and ![]() $L_y^+$ are the viscous-scaled dimensions of the computational domain in the streamwise and spanwise directions, respectively;

$L_y^+$ are the viscous-scaled dimensions of the computational domain in the streamwise and spanwise directions, respectively; ![]() $T$ is the time-averaging interval. Symbols in the first column indicate figure markers for different geometries.

$T$ is the time-averaging interval. Symbols in the first column indicate figure markers for different geometries.

The equations are discretized using the unstructured second-order finite-volume solver CTI Cliff (Ham, Mattsson & Iaccarino Reference Ham, Mattsson and Iaccarino2006; Ham et al. Reference Ham, Mattsson, Iaccarino and Moin2007). The use of hanging nodes allows a coarser mesh in the spanwise direction towards the channel centre, reducing the computational cost (spacings given in table 1). The mesh spacing in the streamwise and wall-normal directions are the ones typical of DNS, whereas in the spanwise direction we use at least 32 points for each riblet period, below the riblet crest. The equations are solved in a minimal-channel domain (Jiménez & Moin Reference Jiménez and Moin1991; Flores & Jiménez Reference Flores and Jiménez2010) with dimensions ![]() $L_x\times L_y\times \delta$ (figure 3). Flow cases share the same computational box, apart from trapezoidal riblets for which

$L_x\times L_y\times \delta$ (figure 3). Flow cases share the same computational box, apart from trapezoidal riblets for which ![]() $L_x$ is two times larger. This does not influence minimal-channel results, as shown by the extensive analysis of MacDonald et al. (Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017) on the box size. Small computational domains are known to produce unphysical results in the outer part of the flow, but the wall-normal extent of the unphysical region can be controlled by changing the spanwise length of the box. In particular, Flores & Jiménez (Reference Flores and Jiménez2010) showed that the turbulent flow statistics remain representative of the full channel flow up to a critical wall-normal location

$L_x$ is two times larger. This does not influence minimal-channel results, as shown by the extensive analysis of MacDonald et al. (Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017) on the box size. Small computational domains are known to produce unphysical results in the outer part of the flow, but the wall-normal extent of the unphysical region can be controlled by changing the spanwise length of the box. In particular, Flores & Jiménez (Reference Flores and Jiménez2010) showed that the turbulent flow statistics remain representative of the full channel flow up to a critical wall-normal location ![]() $z_c^+\approx 0.3L_y^+$, on a smooth wall. Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015) first used this methodology to study rough walls and MacDonald et al. (Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017) extended the methodology, e.g. to open-channel flow, and showed that the minimal-channel results match the ones of the smooth channel up to

$z_c^+\approx 0.3L_y^+$, on a smooth wall. Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015) first used this methodology to study rough walls and MacDonald et al. (Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017) extended the methodology, e.g. to open-channel flow, and showed that the minimal-channel results match the ones of the smooth channel up to ![]() $z_c^+\approx 0.4L_y^+$. The use of the minimal-channel domain is here justified by the fact that the effect of roughness elements only extends to the region in the immediate vicinity of the riblets, often referred to as roughness sublayer. In this region the flow physics can be accurately represented using a minimal box, as long as the spanwise size of the computational domain is chosen in such a way that the riblet sublayer is below

$z_c^+\approx 0.4L_y^+$. The use of the minimal-channel domain is here justified by the fact that the effect of roughness elements only extends to the region in the immediate vicinity of the riblets, often referred to as roughness sublayer. In this region the flow physics can be accurately represented using a minimal box, as long as the spanwise size of the computational domain is chosen in such a way that the riblet sublayer is below ![]() $z_c$ (Chung et al. Reference Chung, Chan, MacDonald, Hutchins and Ooi2015; MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016, Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017). The open-channel height

$z_c$ (Chung et al. Reference Chung, Chan, MacDonald, Hutchins and Ooi2015; MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016, Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017). The open-channel height ![]() $\delta$ is fixed, defined as the distance from the top smooth wall to the riblet mean height, thus the volume of the computational domain

$\delta$ is fixed, defined as the distance from the top smooth wall to the riblet mean height, thus the volume of the computational domain ![]() $L_xA_c$ (where

$L_xA_c$ (where ![]() $A_c$ is the fluid cross-sectional area) is fixed and so is the mean wall-shear stress,

$A_c$ is the fluid cross-sectional area) is fixed and so is the mean wall-shear stress,

As a consequence, the friction Reynolds number ![]() $Re_\tau =\delta /\delta _v$, for the same

$Re_\tau =\delta /\delta _v$, for the same ![]() $\varPi$,

$\varPi$, ![]() $\delta$ and

$\delta$ and ![]() $\nu$. Here,

$\nu$. Here, ![]() $Re_\tau =395$ for all cases. We consider four different riblet geometries, namely, triangles with opening angle

$Re_\tau =395$ for all cases. We consider four different riblet geometries, namely, triangles with opening angle ![]() $\alpha =30^\circ$,

$\alpha =30^\circ$, ![]() $\alpha =60^\circ$,

$\alpha =60^\circ$, ![]() $\alpha =90^\circ$, asymmetric triangles

$\alpha =90^\circ$, asymmetric triangles ![]() $\alpha =63.4^\circ$, trapezoid

$\alpha =63.4^\circ$, trapezoid ![]() $\alpha =30^\circ$ and blades with spacing-to-thickness ratio

$\alpha =30^\circ$ and blades with spacing-to-thickness ratio ![]() $s/t=5$ (table 1 and figure 3). No-slip boundary conditions are imposed at the bottom riblet wall, whereas a free-slip boundary condition is used at the top boundary and periodicity is imposed in the streamwise and spanwise directions. The flow over riblets is initialized by interpolating previous converged simulations of smooth channel flow, and simulations are continued to statistically stationary conditions. Three-dimensional flow fields are then stored each

$s/t=5$ (table 1 and figure 3). No-slip boundary conditions are imposed at the bottom riblet wall, whereas a free-slip boundary condition is used at the top boundary and periodicity is imposed in the streamwise and spanwise directions. The flow over riblets is initialized by interpolating previous converged simulations of smooth channel flow, and simulations are continued to statistically stationary conditions. Three-dimensional flow fields are then stored each ![]() $0.25\delta /u_\tau$ for dimensionless time intervals

$0.25\delta /u_\tau$ for dimensionless time intervals ![]() $Tu_\tau /\delta$ that are reported in table 1, and independence from the initial conditions is a posteriori checked by shifting the averaging time interval of

$Tu_\tau /\delta$ that are reported in table 1, and independence from the initial conditions is a posteriori checked by shifting the averaging time interval of ![]() $T/4$ and verifying that the variation of the mean wall-shear stress is below

$T/4$ and verifying that the variation of the mean wall-shear stress is below ![]() $1\,\%$. Ensemble averages (averages in time, streamwise direction and riblet period) are indicated by the overline symbol,

$1\,\%$. Ensemble averages (averages in time, streamwise direction and riblet period) are indicated by the overline symbol, ![]() $\bar {f}(y,z)$ with

$\bar {f}(y,z)$ with ![]() $y\times z$

$y\times z$ ![]() $\in [0,s]\times [z_v,\delta ]$ (

$\in [0,s]\times [z_v,\delta ]$ (![]() $z_v$ indicates the location of the riblet valley), whereas plane averages (averages in streamwise and spanwise directions and in time) are indicated as

$z_v$ indicates the location of the riblet valley), whereas plane averages (averages in streamwise and spanwise directions and in time) are indicated as ![]() $\langle \,f \rangle (z)$. Turbulent fluctuation is defined with respect to ensemble averages,

$\langle \,f \rangle (z)$. Turbulent fluctuation is defined with respect to ensemble averages, ![]() $f'=f-\bar {f}$. Variables normalized with respect to wall units (

$f'=f-\bar {f}$. Variables normalized with respect to wall units (![]() $\delta _v$,

$\delta _v$, ![]() $u_\tau$) are denoted with a

$u_\tau$) are denoted with a ![]() $+$ superscript. The ensemble-averaged cross-stream velocity components

$+$ superscript. The ensemble-averaged cross-stream velocity components ![]() $\bar {v}$ and

$\bar {v}$ and ![]() $\bar {w}$ are hereafter referred to as dispersive or secondary velocities and

$\bar {w}$ are hereafter referred to as dispersive or secondary velocities and ![]() $\bar {v}\,\bar {u}$,

$\bar {v}\,\bar {u}$, ![]() $\bar {w}\,\bar {u}$ are the associated dispersive stresses.

$\bar {w}\,\bar {u}$ are the associated dispersive stresses.

Figure 3. Sketch of the computational domain. Minimal open-channel configuration with box dimension ![]() $L_x\times L_y\times \delta$. Different groove geometries are considered, from (b) to (e): asymmetric triangular with opening angle

$L_x\times L_y\times \delta$. Different groove geometries are considered, from (b) to (e): asymmetric triangular with opening angle ![]() $\alpha =63.4^\circ$, triangular with opening angle

$\alpha =63.4^\circ$, triangular with opening angle ![]() $\alpha =30^\circ$,

$\alpha =30^\circ$, ![]() $\alpha =60^\circ$,

$\alpha =60^\circ$, ![]() $\alpha =90^\circ$, blade with spacing-to-thickness-ratio

$\alpha =90^\circ$, blade with spacing-to-thickness-ratio ![]() $s/t=5$ and trapezoidal with opening angle

$s/t=5$ and trapezoidal with opening angle ![]() $\alpha =30^\circ$.

$\alpha =30^\circ$.

3. Drag reduction and virtual origin

Drag reduction can be quantified as the difference of the friction coefficients between smooth and riblet walls,

where ![]() $C_{fsm}$ and

$C_{fsm}$ and ![]() $C_{f}$ are the friction coefficients over the smooth and riblet walls, respectively,

$C_{f}$ are the friction coefficients over the smooth and riblet walls, respectively, ![]() $C_f\equiv 2\tau _w/(\rho U_\delta ^2)=2/U_\delta ^{2+}$ and

$C_f\equiv 2\tau _w/(\rho U_\delta ^2)=2/U_\delta ^{2+}$ and ![]() $U_\delta ^+\equiv \langle u\rangle ^+(\delta )$, the mean velocity at the slip boundary. The use of the friction coefficients based on

$U_\delta ^+\equiv \langle u\rangle ^+(\delta )$, the mean velocity at the slip boundary. The use of the friction coefficients based on ![]() $U_\delta ^+$ allows us to directly relate the drag reduction (3.1) to the shift in the velocity profile with respect to the smooth wall. Further manipulation of (3.1) casts it as

$U_\delta ^+$ allows us to directly relate the drag reduction (3.1) to the shift in the velocity profile with respect to the smooth wall. Further manipulation of (3.1) casts it as

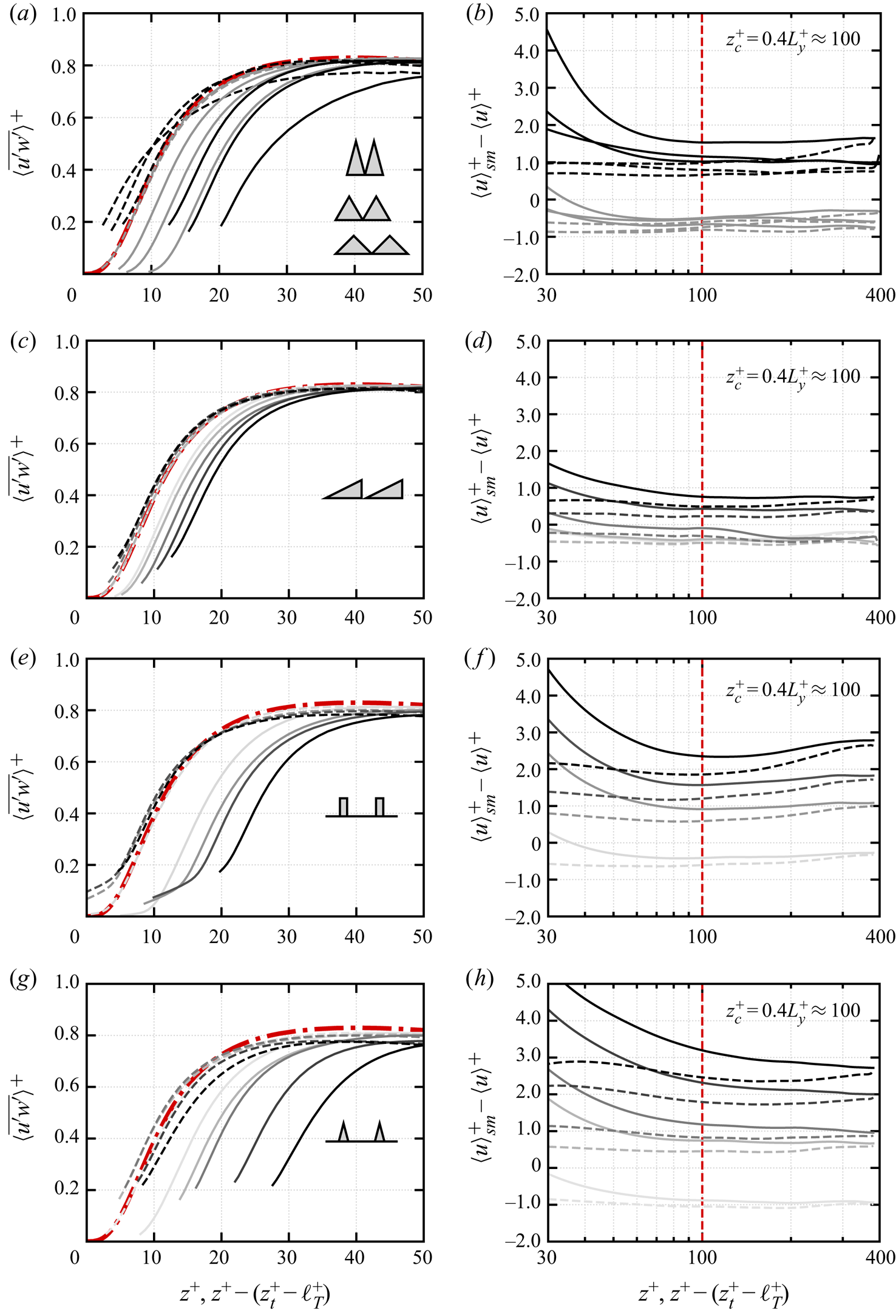

\begin{equation} \mathcal{DR} =1 - \frac{1}{\left(1-\dfrac{\Delta U^+}{U_{\delta sm}^+}\right)^2}, \end{equation}

\begin{equation} \mathcal{DR} =1 - \frac{1}{\left(1-\dfrac{\Delta U^+}{U_{\delta sm}^+}\right)^2}, \end{equation}

where ![]() $\Delta U^+=\langle u\rangle _{sm}^+(\delta ) - \langle u\rangle ^+(\delta )$ is the velocity shift with respect to the smooth wall, or the Hama roughness function, at

$\Delta U^+=\langle u\rangle _{sm}^+(\delta ) - \langle u\rangle ^+(\delta )$ is the velocity shift with respect to the smooth wall, or the Hama roughness function, at ![]() $z=\delta$. A positive

$z=\delta$. A positive ![]() $\Delta U^+$ therefore corresponds to a drag increase, whereas negative values indicate drag reduction. Note that (3.2) and evaluation of

$\Delta U^+$ therefore corresponds to a drag increase, whereas negative values indicate drag reduction. Note that (3.2) and evaluation of ![]() $\Delta U^+$ at

$\Delta U^+$ at ![]() $z=\delta$ is only valid for matched

$z=\delta$ is only valid for matched ![]() $Re_\tau$, whereas a different relation can be written for matched Reynolds numbers based on the bulk velocity (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011). Use of

$Re_\tau$, whereas a different relation can be written for matched Reynolds numbers based on the bulk velocity (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011). Use of ![]() $\Delta U^+$ has the advantage that unlike

$\Delta U^+$ has the advantage that unlike ![]() $\mathcal {DR}$, it does not depend on the outer Reynolds number. This is a direct consequence of the outer layer similarity hypothesis (Townsend Reference Townsend1976), which has been verified extensively for rough-wall boundary layers (Flack, Schultz & Connelly Reference Flack, Schultz and Connelly2007; Schultz & Flack Reference Schultz and Flack2007). Use of

$\mathcal {DR}$, it does not depend on the outer Reynolds number. This is a direct consequence of the outer layer similarity hypothesis (Townsend Reference Townsend1976), which has been verified extensively for rough-wall boundary layers (Flack, Schultz & Connelly Reference Flack, Schultz and Connelly2007; Schultz & Flack Reference Schultz and Flack2007). Use of ![]() $\Delta U^+$ allows easier comparison with other studies at different Reynolds number and drag reduction can always be recovered using (3.2). For instance, if we consider a wide-body long-range commercial aircraft with a mean aerodynamic wing chord of 7 m and a fuselage length of 60 m, flying at a cruise speed of

$\Delta U^+$ allows easier comparison with other studies at different Reynolds number and drag reduction can always be recovered using (3.2). For instance, if we consider a wide-body long-range commercial aircraft with a mean aerodynamic wing chord of 7 m and a fuselage length of 60 m, flying at a cruise speed of ![]() $250\ \textrm {m}\,\textrm {s}^{-1}$ with

$250\ \textrm {m}\,\textrm {s}^{-1}$ with ![]() $\nu =3.5\times 10^{-5}\ \textrm {m}^2\,\textrm {s}^{-1}$, we can estimate a Reynolds number of

$\nu =3.5\times 10^{-5}\ \textrm {m}^2\,\textrm {s}^{-1}$, we can estimate a Reynolds number of ![]() $Re_x\approx 5\times 10^7$ for the wing and

$Re_x\approx 5\times 10^7$ for the wing and ![]() $Re_x\approx 4\times 10^8$ for the fuselage corresponding to a friction Reynolds number of

$Re_x\approx 4\times 10^8$ for the fuselage corresponding to a friction Reynolds number of ![]() $Re_\tau \approx 17\,000$ and

$Re_\tau \approx 17\,000$ and ![]() $Re_\tau \approx 80\,000$ (Schlichting (Reference Schlichting1979), (21.16) footnote), respectively. Equation (3.2) shows that drag reduction depends on the Reynolds number through

$Re_\tau \approx 80\,000$ (Schlichting (Reference Schlichting1979), (21.16) footnote), respectively. Equation (3.2) shows that drag reduction depends on the Reynolds number through ![]() $C_{fsm}=2/U_{\delta sm}^+$ (Spalart & McLean Reference Spalart and McLean2011), thus

$C_{fsm}=2/U_{\delta sm}^+$ (Spalart & McLean Reference Spalart and McLean2011), thus ![]() $10\,\%$ of drag reduction at

$10\,\%$ of drag reduction at ![]() $Re_\tau \approx 400$, typical of DNS, is only

$Re_\tau \approx 400$, typical of DNS, is only ![]() $6\,\%$ at

$6\,\%$ at ![]() $Re_\tau \approx 17\,000$ (wing) and

$Re_\tau \approx 17\,000$ (wing) and ![]() $5\,\%$ at

$5\,\%$ at ![]() $Re _\tau \approx 80\,000$ (fuselage). In the present work, the use of the minimal channel does not allow the use of

$Re _\tau \approx 80\,000$ (fuselage). In the present work, the use of the minimal channel does not allow the use of ![]() $U_\delta ^+$ to estimate the velocity shift. Nevertheless, the Hama roughness function is constant above the roughness sublayer at matched

$U_\delta ^+$ to estimate the velocity shift. Nevertheless, the Hama roughness function is constant above the roughness sublayer at matched ![]() $Re_\tau$ and Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015) showed that minimal-channel mean profiles match those of full channel up to the critical height

$Re_\tau$ and Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015) showed that minimal-channel mean profiles match those of full channel up to the critical height ![]() $z_c^+=0.4L_y^+$ in the log region. Therefore, we measure the velocity shift at

$z_c^+=0.4L_y^+$ in the log region. Therefore, we measure the velocity shift at ![]() $z_c^+$,

$z_c^+$,

The second identity in (3.3) is accurate only if the smooth and rough velocity profiles are approximately parallel above the roughness sublayer and below ![]() $z_c$, such that the Hama roughness function is constant in this region, indicating that it would be constant even further up if a wider channel domain were used. In minimal-channel flow

$z_c$, such that the Hama roughness function is constant in this region, indicating that it would be constant even further up if a wider channel domain were used. In minimal-channel flow ![]() $L_y<\delta$ and the critical height

$L_y<\delta$ and the critical height ![]() $z_c=0.4L_y$, therefore one typically has

$z_c=0.4L_y$, therefore one typically has ![]() $z_c\ll \delta$. This does not impact the accuracy of the second identity in (3.3), which only depends on the flatness of the Hama roughness function between

$z_c\ll \delta$. This does not impact the accuracy of the second identity in (3.3), which only depends on the flatness of the Hama roughness function between ![]() $z_c$ and

$z_c$ and ![]() $\delta$. At low Reynolds numbers, such as the ones typically achieved in DNS, these conditions depend on knowing the location of the virtual origin of the flow (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991).

$\delta$. At low Reynolds numbers, such as the ones typically achieved in DNS, these conditions depend on knowing the location of the virtual origin of the flow (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991).

Simulations were conducted with matched fluid volumes (i.e. the nominal origin from which ![]() $\delta$ is measured is the riblet mean height, located

$\delta$ is measured is the riblet mean height, located ![]() $\ell _g^2/s$ below the crest). The riblet mean height is the location at which a smooth channel with the same cross-sectional area

$\ell _g^2/s$ below the crest). The riblet mean height is the location at which a smooth channel with the same cross-sectional area ![]() $A_c$ would be located. This choice corresponds to the location where the extrapolated total stress equals

$A_c$ would be located. This choice corresponds to the location where the extrapolated total stress equals ![]() $\tau _w$, but in general the location of the equivalent wall perceived by the turbulent flow might be at a different height. Moreover, the velocity shift obtained with riblets is typically small, in the range

$\tau _w$, but in general the location of the equivalent wall perceived by the turbulent flow might be at a different height. Moreover, the velocity shift obtained with riblets is typically small, in the range ![]() $\Delta U^+\approx -1$ to

$\Delta U^+\approx -1$ to ![]() $1$, making the measurement of

$1$, making the measurement of ![]() $\Delta U^+$ rather sensitive to the wall-normal location. For these reasons, a correct estimation of the location of the virtual origin of the riblet wall is necessary. Several methods have been proposed to estimate the virtual origin of the flow: the centroid of the total stress (Thom Reference Thom1971; Jackson Reference Jackson1981), the virtual origin of the Stokes spanwise flow (Luchini et al. Reference Luchini, Manzo and Pozzi1991), using the Fukagata–Iwamoto–Kasagi (FIK) identity (Bannier et al. Reference Bannier, Garnier and Sagaut2015), or where the turbulent stress vanishes (Nepf et al. Reference Nepf, Ghisalberti, White and Murphy2007; MacDonald et al. Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018). In this work we follow the latter, the physical idea being that the main effect of riblets is to lift up the turbulent eddies in the viscous sublayer, thus reducing the turbulent stress. This concept is only strictly valid for small riblets, for which the effect of the texture reduces to an origin shift (García-Mayoral et al. Reference García-Mayoral, Gómez-de-Segura and Fairhall2019). Consistently with this interpretation we identify the location of the equivalent smooth wall by shifting the turbulent stress profile,

$\Delta U^+$ rather sensitive to the wall-normal location. For these reasons, a correct estimation of the location of the virtual origin of the riblet wall is necessary. Several methods have been proposed to estimate the virtual origin of the flow: the centroid of the total stress (Thom Reference Thom1971; Jackson Reference Jackson1981), the virtual origin of the Stokes spanwise flow (Luchini et al. Reference Luchini, Manzo and Pozzi1991), using the Fukagata–Iwamoto–Kasagi (FIK) identity (Bannier et al. Reference Bannier, Garnier and Sagaut2015), or where the turbulent stress vanishes (Nepf et al. Reference Nepf, Ghisalberti, White and Murphy2007; MacDonald et al. Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018). In this work we follow the latter, the physical idea being that the main effect of riblets is to lift up the turbulent eddies in the viscous sublayer, thus reducing the turbulent stress. This concept is only strictly valid for small riblets, for which the effect of the texture reduces to an origin shift (García-Mayoral et al. Reference García-Mayoral, Gómez-de-Segura and Fairhall2019). Consistently with this interpretation we identify the location of the equivalent smooth wall by shifting the turbulent stress profile, ![]() $\langle \overline {u'w'}\rangle =\langle \overline {uw}\rangle -\langle \bar {u}\,\bar {w}\rangle$ of the smallest riblet geometries (TI310, TI615, TI919, AT15, BL20, TA18) to match the smooth wall. We interpret this length, measured downward from the riblet crest, as the virtual origin of turbulence and we denote it with

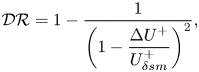

$\langle \overline {u'w'}\rangle =\langle \overline {uw}\rangle -\langle \bar {u}\,\bar {w}\rangle$ of the smallest riblet geometries (TI310, TI615, TI919, AT15, BL20, TA18) to match the smooth wall. We interpret this length, measured downward from the riblet crest, as the virtual origin of turbulence and we denote it with ![]() $\ell _T$. The virtual origin of the larger cases is then obtained by fixing the ratio between the origin of turbulence and the riblet height

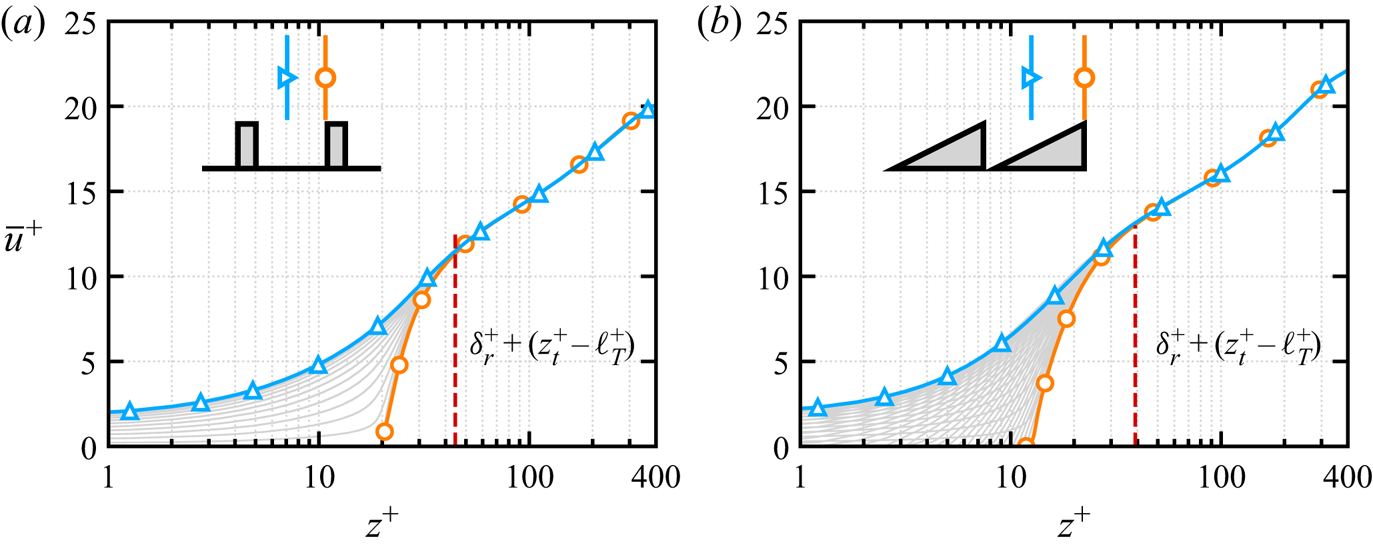

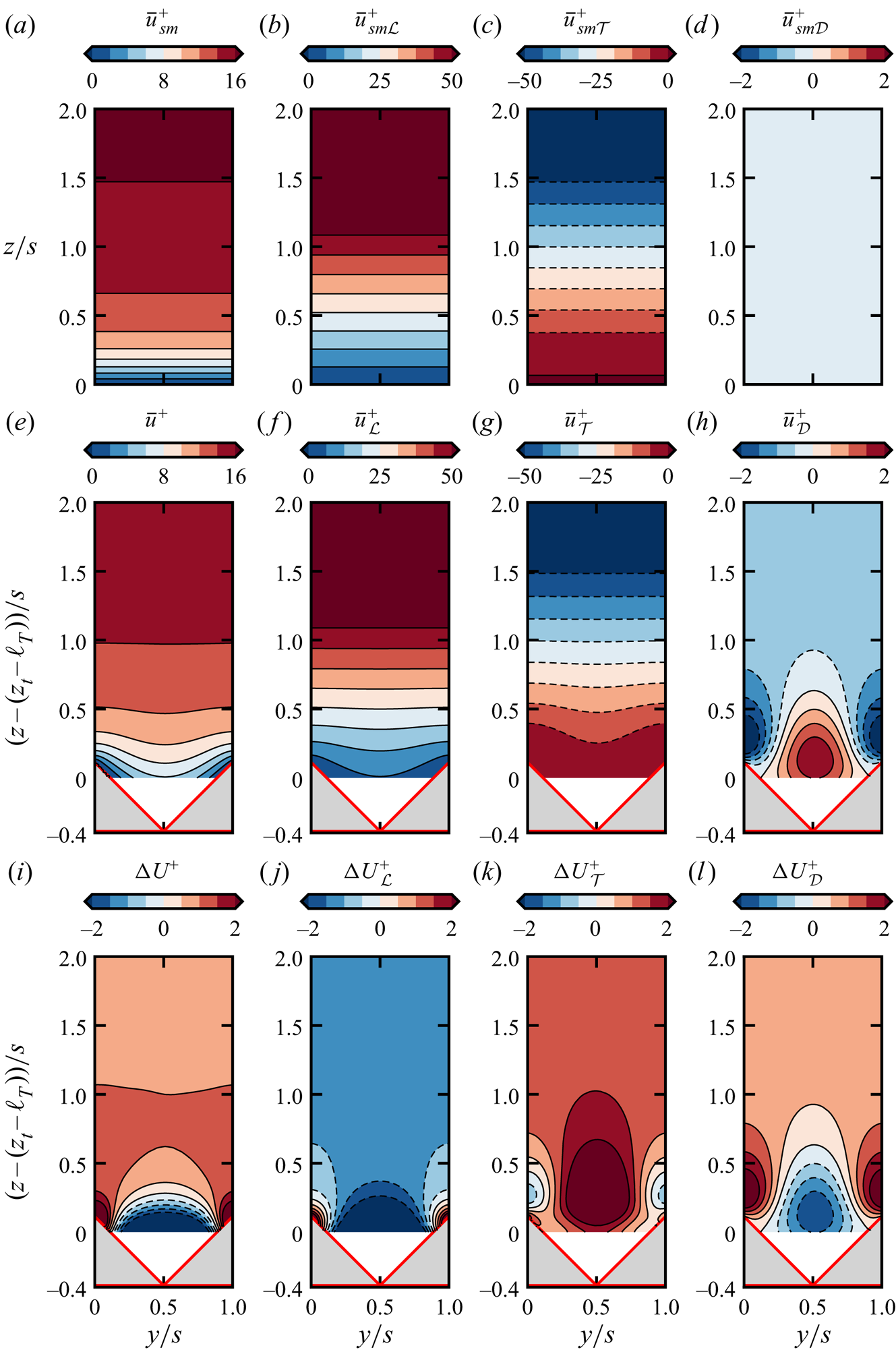

$\ell _T$. The virtual origin of the larger cases is then obtained by fixing the ratio between the origin of turbulence and the riblet height ![]() $\ell _T/k$ for geometries of the same family (triangular with fixed tip angle, asymmetric triangular, blade and trapezoidal). Figure 4(a,c,e,g) shows the original turbulent stress profiles (solid lines) and the shifted ones (dashed lines) for all flow cases. The shifted Reynolds stress profiles match the smooth wall with good agreement, whereas minor differences are observed for increasing riblet size. The effect of the virtual origin shift on the Hama roughness function is reported in figure 4(b,d,f,h), which shows that

$\ell _T/k$ for geometries of the same family (triangular with fixed tip angle, asymmetric triangular, blade and trapezoidal). Figure 4(a,c,e,g) shows the original turbulent stress profiles (solid lines) and the shifted ones (dashed lines) for all flow cases. The shifted Reynolds stress profiles match the smooth wall with good agreement, whereas minor differences are observed for increasing riblet size. The effect of the virtual origin shift on the Hama roughness function is reported in figure 4(b,d,f,h), which shows that ![]() $\langle u\rangle _{sm}^+-\langle u\rangle ^+$ becomes substantially flatter with respect to the original profile, when the virtual origin correction is taken into account, allowing us to measure

$\langle u\rangle _{sm}^+-\langle u\rangle ^+$ becomes substantially flatter with respect to the original profile, when the virtual origin correction is taken into account, allowing us to measure ![]() $\Delta U^+$ as in (3.3) with more confidence, reducing the aforementioned low-Reynolds-number effects. The virtual origin shift relative to the mean height is typically small, in the range

$\Delta U^+$ as in (3.3) with more confidence, reducing the aforementioned low-Reynolds-number effects. The virtual origin shift relative to the mean height is typically small, in the range ![]() $z_t^+-\ell _T^+\approx 2$–

$z_t^+-\ell _T^+\approx 2$–![]() $20$ depending on the riblet size and geometry, but at this relatively low Reynolds number the effect on the mean velocity profile is relevant.

$20$ depending on the riblet size and geometry, but at this relatively low Reynolds number the effect on the mean velocity profile is relevant.

Figure 4. Turbulent stress ![]() $\langle \overline {u'w'}\rangle ^+$ (a,c,e,g) and Hama roughness function

$\langle \overline {u'w'}\rangle ^+$ (a,c,e,g) and Hama roughness function ![]() $\langle u^+\rangle _{sm}-\langle u^+\rangle$ (b,d,f,h), for triangular (a,b), asymmetric triangular (c,d), blade (e, f) and (g,h) trapezoidal riblets. Profiles are reported with respect to the constant volume origin at

$\langle u^+\rangle _{sm}-\langle u^+\rangle$ (b,d,f,h), for triangular (a,b), asymmetric triangular (c,d), blade (e, f) and (g,h) trapezoidal riblets. Profiles are reported with respect to the constant volume origin at ![]() $z=0$ (black solid line) and with respect to the origin of the turbulent stress at

$z=0$ (black solid line) and with respect to the origin of the turbulent stress at ![]() $z=z_t-\ell _T$ (black dashed line). Colour from light to dark indicates increasing riblets spacing

$z=z_t-\ell _T$ (black dashed line). Colour from light to dark indicates increasing riblets spacing ![]() $s^+$ (table 1). The smooth wall minimal-channel turbulent stress (red dashed dot line thick) is also reported in (a,c,e,g). Profiles are shown from above the crest.

$s^+$ (table 1). The smooth wall minimal-channel turbulent stress (red dashed dot line thick) is also reported in (a,c,e,g). Profiles are shown from above the crest. ![]() $z_c^+=0.4L_y^+\approx 100$ (table 1), represented by the red dashed line, is the critical height at which

$z_c^+=0.4L_y^+\approx 100$ (table 1), represented by the red dashed line, is the critical height at which ![]() $\Delta U^+$ is measured. Here,

$\Delta U^+$ is measured. Here, ![]() $z_t$ indicates the location of the crest and

$z_t$ indicates the location of the crest and ![]() $\ell _T$ the location of the virtual origin, measured downward from the crest.

$\ell _T$ the location of the virtual origin, measured downward from the crest.

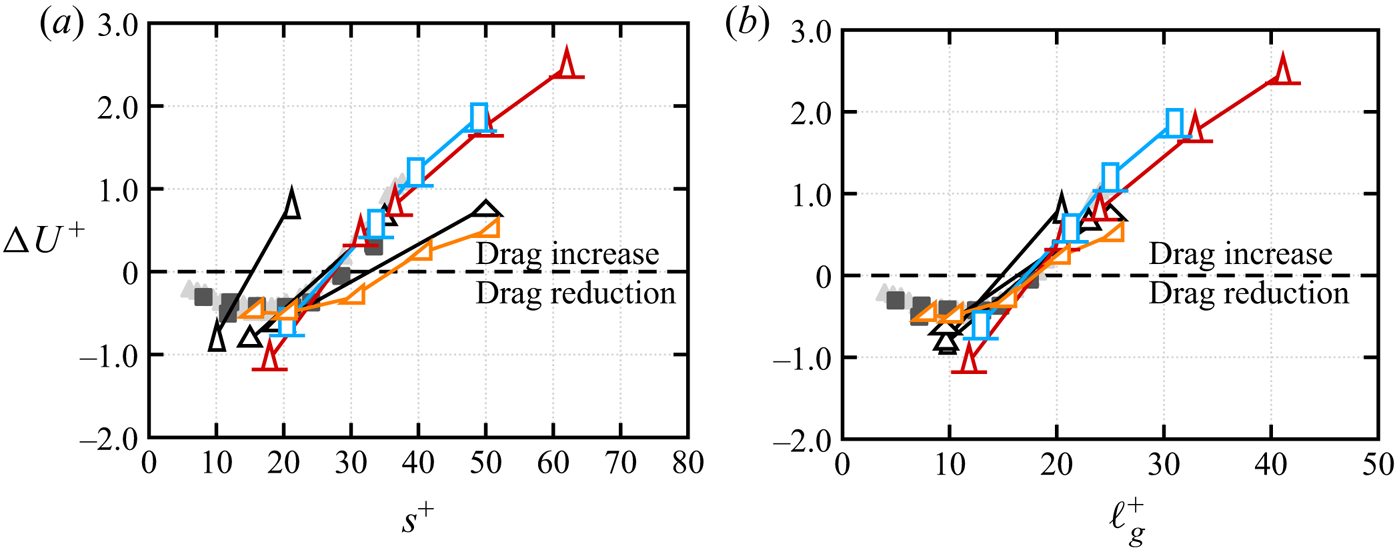

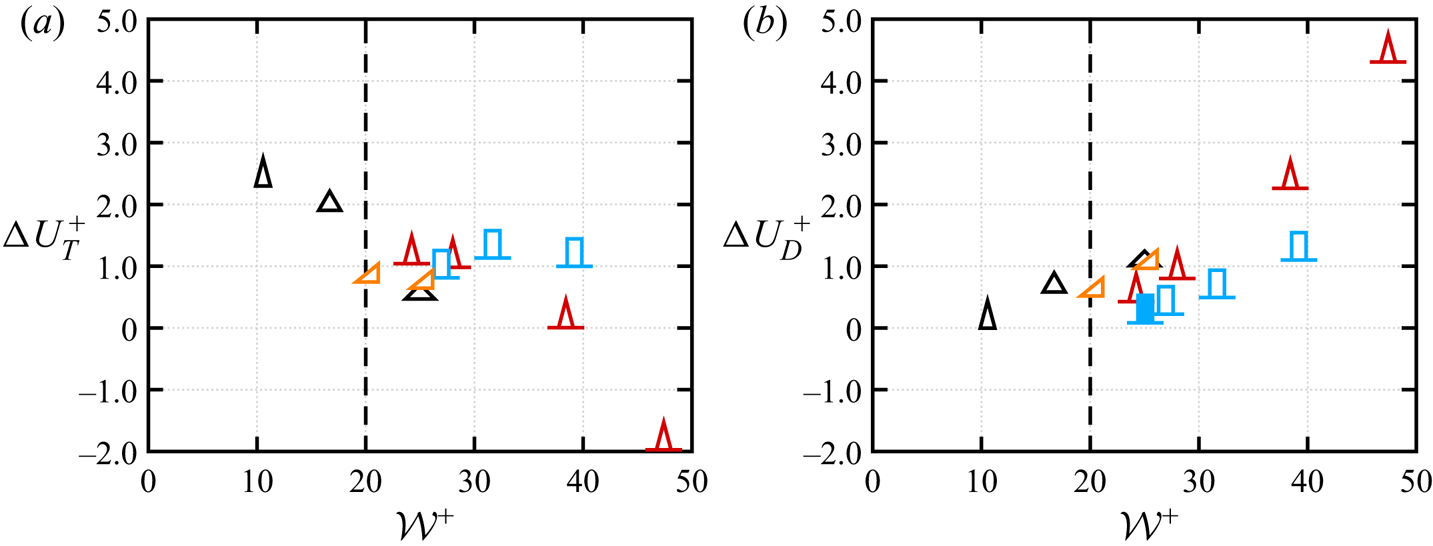

Figures 5(a) and 5(b) show the velocity shift ![]() $\Delta U^+$ as a function of

$\Delta U^+$ as a function of ![]() $s^+$ and

$s^+$ and ![]() $\ell _g^+$, respectively, for different riblet geometries, compared to experimental data for triangles

$\ell _g^+$, respectively, for different riblet geometries, compared to experimental data for triangles ![]() $\alpha =60^\circ$ from (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997) (grey filled triangle) and DNS data for blades

$\alpha =60^\circ$ from (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997) (grey filled triangle) and DNS data for blades ![]() $s/t=4$ from (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011) (grey filled square). DNS data for drag-reducing blades (BL20) and triangles with

$s/t=4$ from (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011) (grey filled square). DNS data for drag-reducing blades (BL20) and triangles with ![]() $\alpha =60^\circ$ (TI615) predict slightly larger drag reduction with respect to previous DNS of blade riblets (grey filled square) and experiments (grey filled triangle). For the blades this can be traced back to the different blade thicknesses,

$\alpha =60^\circ$ (TI615) predict slightly larger drag reduction with respect to previous DNS of blade riblets (grey filled square) and experiments (grey filled triangle). For the blades this can be traced back to the different blade thicknesses, ![]() $s/t=5$ in our case, and

$s/t=5$ in our case, and ![]() $s/t=4$ in García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011), consistent with the idea that thinner blades yield larger drag reduction. As for the triangles, the experimental values of

$s/t=4$ in García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011), consistent with the idea that thinner blades yield larger drag reduction. As for the triangles, the experimental values of ![]() $\Delta U^+$ have been extracted from the drag reduction curves of Bechert et al. (Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997), assuming that the riblet and smooth wall have the same Reynolds number based on bulk velocity (García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011), (3.2) in that paper), which could explain this minor discrepancy. Even though the drag curves are traditionally reported as a function of

$\Delta U^+$ have been extracted from the drag reduction curves of Bechert et al. (Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997), assuming that the riblet and smooth wall have the same Reynolds number based on bulk velocity (García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011), (3.2) in that paper), which could explain this minor discrepancy. Even though the drag curves are traditionally reported as a function of ![]() $s^+$ (Walsh Reference Walsh1982; Luchini et al. Reference Luchini, Manzo and Pozzi1991; Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997), García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011) showed that a better collapse between different geometries can be obtained using the viscous-scaled square root of the groove area,

$s^+$ (Walsh Reference Walsh1982; Luchini et al. Reference Luchini, Manzo and Pozzi1991; Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997), García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011) showed that a better collapse between different geometries can be obtained using the viscous-scaled square root of the groove area, ![]() $\ell _g^+$. In particular, García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011) analysed experimental data for several riblets geometries and showed that

$\ell _g^+$. In particular, García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011) analysed experimental data for several riblets geometries and showed that ![]() $\ell _g^+$ collapses the drag curves of different geometries close to the drag optimum

$\ell _g^+$ collapses the drag curves of different geometries close to the drag optimum ![]() $\ell _g^+\approx 10$–

$\ell _g^+\approx 10$–![]() $11$ and related this scaling to the onset of a Kelvin–Helmholtz-like instability above the riblet crest for blade riblets. Figure 5 shows that the present DNS data also confirm the improved collapse of

$11$ and related this scaling to the onset of a Kelvin–Helmholtz-like instability above the riblet crest for blade riblets. Figure 5 shows that the present DNS data also confirm the improved collapse of ![]() $\Delta U^+$ when this is reported as a function

$\Delta U^+$ when this is reported as a function ![]() $\ell _g^+$ rather than

$\ell _g^+$ rather than ![]() $s^+$. In addition to the previously observed improved collapse near the drag optimum we also note a better agreement between different groove geometries in the drag-increasing regime (i.e. case TI321 triangles at

$s^+$. In addition to the previously observed improved collapse near the drag optimum we also note a better agreement between different groove geometries in the drag-increasing regime (i.e. case TI321 triangles at ![]() $30^{\circ }$, case TI950 triangles at

$30^{\circ }$, case TI950 triangles at ![]() $90^{\circ }$ and cases AT40 and AT50 red asymmetric triangles at

$90^{\circ }$ and cases AT40 and AT50 red asymmetric triangles at ![]() $63.4^{\circ }$).

$63.4^{\circ }$).

Figure 5. (a) Value of ![]() ${\Delta U}^+$ as a function of the viscous-scaled riblet spacing

${\Delta U}^+$ as a function of the viscous-scaled riblet spacing ![]() $s^+$ and (b) as a function of the square root of groove area

$s^+$ and (b) as a function of the square root of groove area ![]() $\ell _g^+=\ell _g/\delta _v$, where

$\ell _g^+=\ell _g/\delta _v$, where ![]() $\ell _g=\sqrt {A_g}$. Symbols represent different flow cases:

$\ell _g=\sqrt {A_g}$. Symbols represent different flow cases:  , triangles

, triangles ![]() $\alpha =30^\circ$;

$\alpha =30^\circ$;  , triangles

, triangles ![]() $\alpha =60^\circ$;

$\alpha =60^\circ$;  , triangles

, triangles ![]() $\alpha =90^\circ$;

$\alpha =90^\circ$;  (red), trapezoids

(red), trapezoids ![]() $\alpha =30^\circ$;

$\alpha =30^\circ$;  (blue), blades

(blue), blades ![]() $s/t=5$;

$s/t=5$;  (orange), asymmetric triangles

(orange), asymmetric triangles ![]() $\alpha =63.4^\circ$;

$\alpha =63.4^\circ$;  (grey), experimental data for triangles

(grey), experimental data for triangles ![]() $\alpha =60^\circ$ (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997);

$\alpha =60^\circ$ (Bechert et al. Reference Bechert, Bruse, Hage, van der Hoeven and Hoppe1997);  , DNS data for blades

, DNS data for blades ![]() $s/t=4$ (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011).

$s/t=4$ (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011).

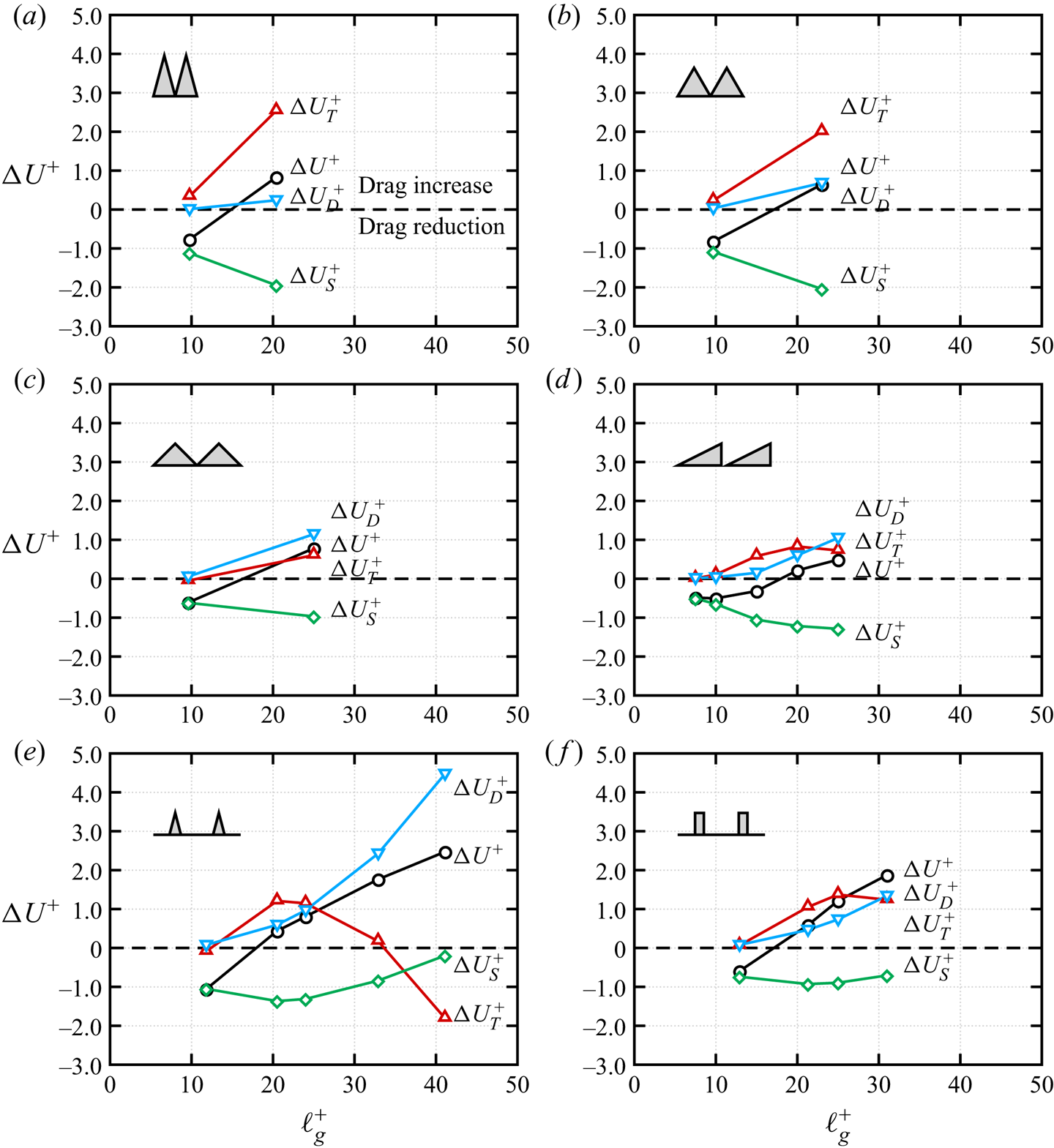

Although reporting the drag curves as a function of ![]() $\ell _g^+$ improves the collapse between different grooves, differences between riblet shapes are still visible. The optimum drag occurs at

$\ell _g^+$ improves the collapse between different grooves, differences between riblet shapes are still visible. The optimum drag occurs at ![]() $\ell _g^+\approx 11$ for all riblet shapes, but

$\ell _g^+\approx 11$ for all riblet shapes, but ![]() $\Delta U^+$ depends on the groove geometry and can be partially predicted from the difference in protrusion heights (Luchini et al. Reference Luchini, Manzo and Pozzi1991). The maximum drag reduction is achieved by the trapezoidal riblets with

$\Delta U^+$ depends on the groove geometry and can be partially predicted from the difference in protrusion heights (Luchini et al. Reference Luchini, Manzo and Pozzi1991). The maximum drag reduction is achieved by the trapezoidal riblets with ![]() $\Delta U^+=-1.06$, whereas the asymmetric triangular riblets have the least drag reduction with

$\Delta U^+=-1.06$, whereas the asymmetric triangular riblets have the least drag reduction with ![]() $\Delta U^+=-0.49$. In the same region, symmetric triangular riblets with

$\Delta U^+=-0.49$. In the same region, symmetric triangular riblets with ![]() $\alpha =30^\circ$,

$\alpha =30^\circ$, ![]() $60\,^\circ$ and

$60\,^\circ$ and ![]() $90^\circ$ achieve

$90^\circ$ achieve ![]() $\Delta U^+=-0.74$,

$\Delta U^+=-0.74$, ![]() $-0.82$ and

$-0.82$ and ![]() $-0.60$, respectively, and blades

$-0.60$, respectively, and blades ![]() $\Delta U^+=-0.60$. The drag curves of large riblets show a different trend and for

$\Delta U^+=-0.60$. The drag curves of large riblets show a different trend and for ![]() $\ell _g^+\approx 20$: asymmetric triangular riblets exhibit the smallest drag increase (

$\ell _g^+\approx 20$: asymmetric triangular riblets exhibit the smallest drag increase (![]() $\Delta U^+\approx 0.2$), compared to trapezoidal (

$\Delta U^+\approx 0.2$), compared to trapezoidal (![]() $\Delta U^+\approx 0.4$), blades (

$\Delta U^+\approx 0.4$), blades (![]() $\Delta U^+\approx 0.6$) and triangular with

$\Delta U^+\approx 0.6$) and triangular with ![]() $\alpha =30^\circ$ (

$\alpha =30^\circ$ (![]() $\Delta U^+\approx 1$),

$\Delta U^+\approx 1$), ![]() $\alpha =60^\circ$ (

$\alpha =60^\circ$ (![]() $\Delta U^+\approx 0.7$) and

$\Delta U^+\approx 0.7$) and ![]() $\alpha =90^\circ$ (

$\alpha =90^\circ$ (![]() $\Delta U^+\approx 0.8$). The drag curves highlight the general idea that sharp riblets provide larger drag reduction, which stems from the Stokes-flow theory (Luchini et al. Reference Luchini, Manzo and Pozzi1991), but this does not hold in the nonlinear regime. For instance at

$\Delta U^+\approx 0.8$). The drag curves highlight the general idea that sharp riblets provide larger drag reduction, which stems from the Stokes-flow theory (Luchini et al. Reference Luchini, Manzo and Pozzi1991), but this does not hold in the nonlinear regime. For instance at ![]() $\ell _g^+\approx 20$, the sharp triangular riblets with

$\ell _g^+\approx 20$, the sharp triangular riblets with ![]() $\alpha =30^\circ$ are the ones providing the largest drag increase, whereas the blunt asymmetric riblets with angle

$\alpha =30^\circ$ are the ones providing the largest drag increase, whereas the blunt asymmetric riblets with angle ![]() $\alpha =63.4^\circ$ are the ones with the smallest drag increase. Hence, the analysis confirms that the linear theory cannot explain the drag curves of large riblets in which inertial flow penetrates the riblet grooves.

$\alpha =63.4^\circ$ are the ones with the smallest drag increase. Hence, the analysis confirms that the linear theory cannot explain the drag curves of large riblets in which inertial flow penetrates the riblet grooves.

4. Roughness sublayer and secondary velocities

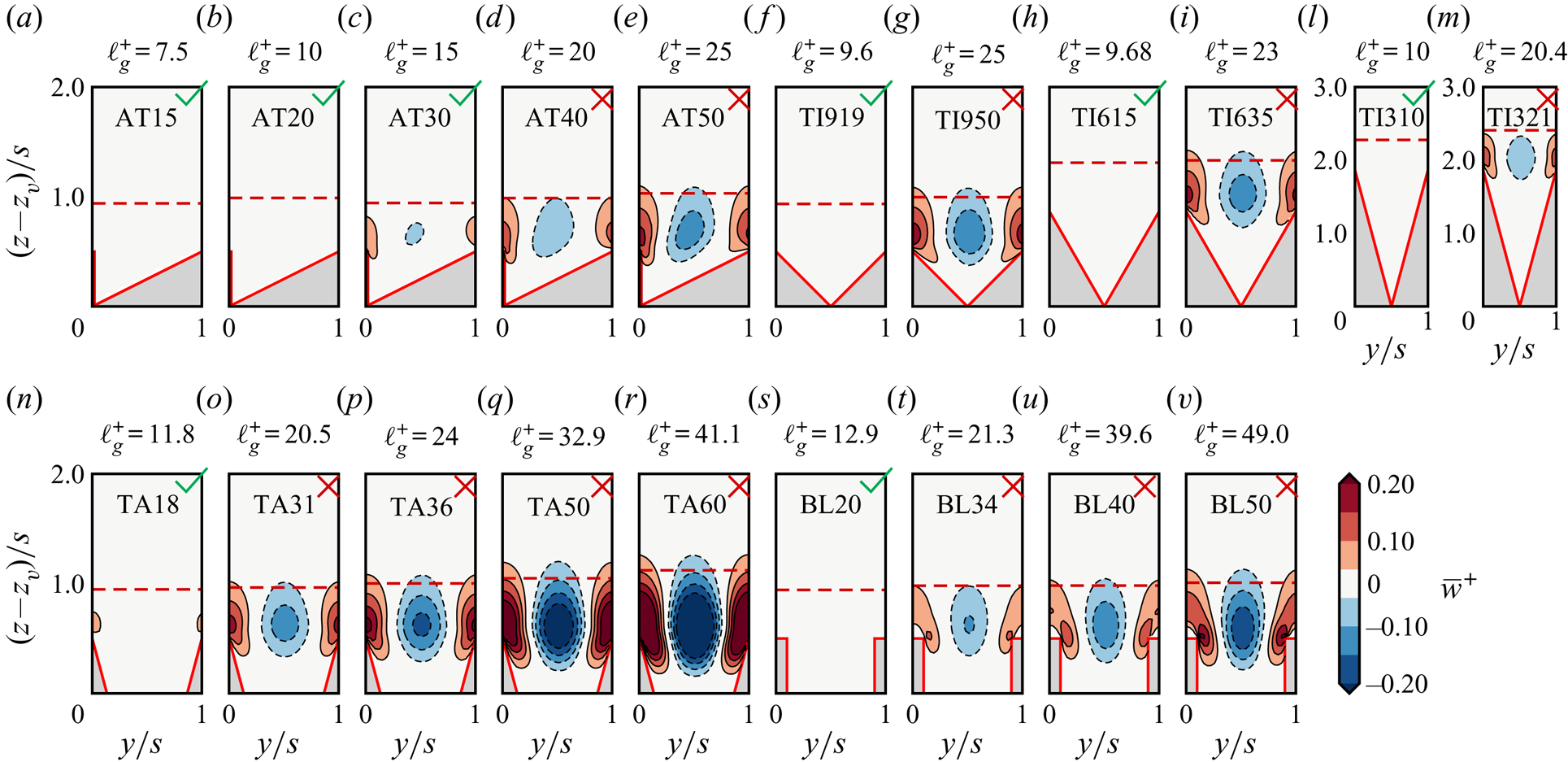

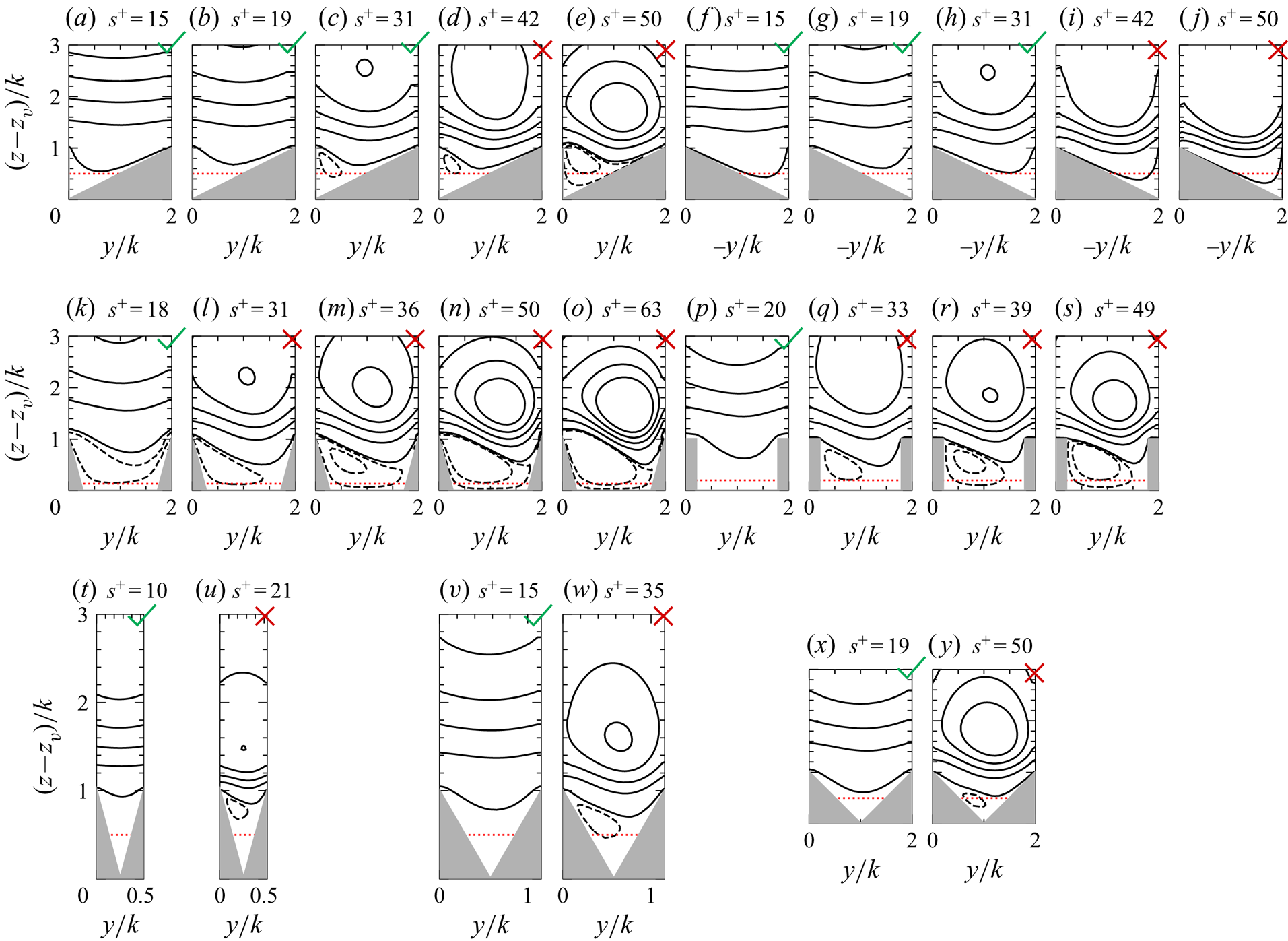

A relevant length scale in rough-wall turbulence is the roughness or riblet sublayer ![]() $\delta _r$, representing the region of direct influence of the riblets in the wall-normal direction, namely the wall-normal distance between the virtual origin and the location at which the flow becomes statistically homogeneous in the wall-parallel directions, (figure 6). Although the notion of roughness sublayer is rather intuitive, many definitions are available in the literature. Raupach et al. (Reference Raupach, Antonia and Rajagopalan1991) identify the roughness sublayer as the region in the range

$\delta _r$, representing the region of direct influence of the riblets in the wall-normal direction, namely the wall-normal distance between the virtual origin and the location at which the flow becomes statistically homogeneous in the wall-parallel directions, (figure 6). Although the notion of roughness sublayer is rather intuitive, many definitions are available in the literature. Raupach et al. (Reference Raupach, Antonia and Rajagopalan1991) identify the roughness sublayer as the region in the range ![]() $2k$–

$2k$–![]() $5k$, where

$5k$, where ![]() $k$ is the roughness height. Nikora et al. (Reference Nikora, Goring, McEwan and Griffiths2001) and Pokrajac et al. (Reference Pokrajac, Campbell, Nikora, Manes and McEwan2007) relate the roughness sublayer to the dispersive velocities, whereas Cheng & Castro (Reference Cheng and Castro2002) define the roughness sublayer as the wall-normal distance at which the ensemble-averaged velocity profile becomes homogeneous in the wall-parallel directions. In the present work we follow the approach of Cheng & Castro (Reference Cheng and Castro2002) and we define the riblet sublayer as the wall-normal location at which the ensemble-averaged streamwise velocity above the crest becomes homogeneous in the spanwise direction,

$k$ is the roughness height. Nikora et al. (Reference Nikora, Goring, McEwan and Griffiths2001) and Pokrajac et al. (Reference Pokrajac, Campbell, Nikora, Manes and McEwan2007) relate the roughness sublayer to the dispersive velocities, whereas Cheng & Castro (Reference Cheng and Castro2002) define the roughness sublayer as the wall-normal distance at which the ensemble-averaged velocity profile becomes homogeneous in the wall-parallel directions. In the present work we follow the approach of Cheng & Castro (Reference Cheng and Castro2002) and we define the riblet sublayer as the wall-normal location at which the ensemble-averaged streamwise velocity above the crest becomes homogeneous in the spanwise direction,

We use the threshold ![]() $0.5u_\tau /s$ because the spanwise velocity variation

$0.5u_\tau /s$ because the spanwise velocity variation ![]() $\partial \bar {u}/\partial y\sim u_\tau /s$, and the value

$\partial \bar {u}/\partial y\sim u_\tau /s$, and the value ![]() $0.5$ has been chosen from visual inspection of the spanwise variation in velocity across the span of the riblet. Figure 7 shows the ensemble-averaged streamwise velocity profiles across the riblet span for flow cases BL50 and AT50, highlighting that (4.1) accurately captures the distinct separation between the region of direct influence of the riblet and the overlying spanwise-homogeneous flow. Although the upper limit of the roughness sublayer can be clearly identified in figure 7, the definition of the lower limit is more blurred and multiple choices are possible. In (4.1) we measure the roughness sublayer starting from the virtual origin of turbulence, but in the following we also consider the roughness sublayer measured from the riblet mean height,

$0.5$ has been chosen from visual inspection of the spanwise variation in velocity across the span of the riblet. Figure 7 shows the ensemble-averaged streamwise velocity profiles across the riblet span for flow cases BL50 and AT50, highlighting that (4.1) accurately captures the distinct separation between the region of direct influence of the riblet and the overlying spanwise-homogeneous flow. Although the upper limit of the roughness sublayer can be clearly identified in figure 7, the definition of the lower limit is more blurred and multiple choices are possible. In (4.1) we measure the roughness sublayer starting from the virtual origin of turbulence, but in the following we also consider the roughness sublayer measured from the riblet mean height, ![]() $\delta _r^+-\ell _T^++z_t^+$ (figure 6), as this is easier to calculate in experiments, where

$\delta _r^+-\ell _T^++z_t^+$ (figure 6), as this is easier to calculate in experiments, where ![]() $\ell _T$ might be difficult to estimate. A visual impression of

$\ell _T$ might be difficult to estimate. A visual impression of ![]() $\delta _r^+-\ell _T^++z_t^+$ can be gained from the sketch in figure 6, which shows the position of the mean riblet height and the virtual origin with respect to the smooth wall. The virtual origin can be interpreted as the wall-normal location at which the outer flow perceives the equivalent smooth wall.

$\delta _r^+-\ell _T^++z_t^+$ can be gained from the sketch in figure 6, which shows the position of the mean riblet height and the virtual origin with respect to the smooth wall. The virtual origin can be interpreted as the wall-normal location at which the outer flow perceives the equivalent smooth wall.

Figure 6. Sketch of the roughness sublayer ![]() $\delta _r$, measured from the virtual origin of turbulence. The virtual origin of turbulence is located

$\delta _r$, measured from the virtual origin of turbulence. The virtual origin of turbulence is located ![]() $\ell _T$ downward from the crest. The equivalent smooth wall is also shown for reference.

$\ell _T$ downward from the crest. The equivalent smooth wall is also shown for reference.

Figure 7. Mean velocity profiles over the riblet at all spanwise locations (grey solid lines), from the lower (orange solid line with circles), to the upper (blue solid line with triangles) curve envelope, for flow case (a) BL50 and (b) AT50. The location of the roughness sublayer ![]() $\delta _r^+$ (red dashed line) as defined in (4.1) is also reported. The vertical lines in the riblet sketch refer to the spanwise location of the lower and upper curve envelopes.

$\delta _r^+$ (red dashed line) as defined in (4.1) is also reported. The vertical lines in the riblet sketch refer to the spanwise location of the lower and upper curve envelopes.

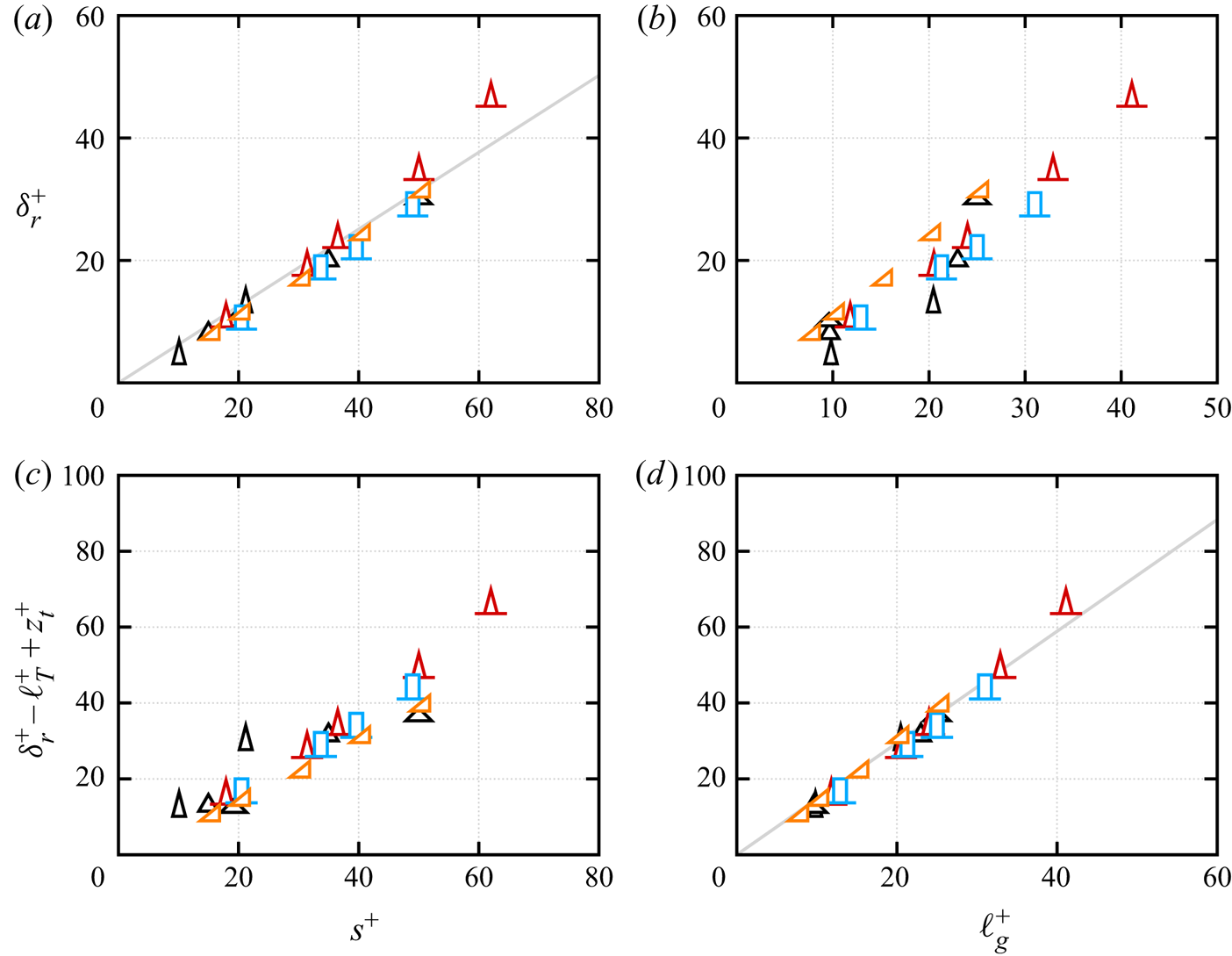

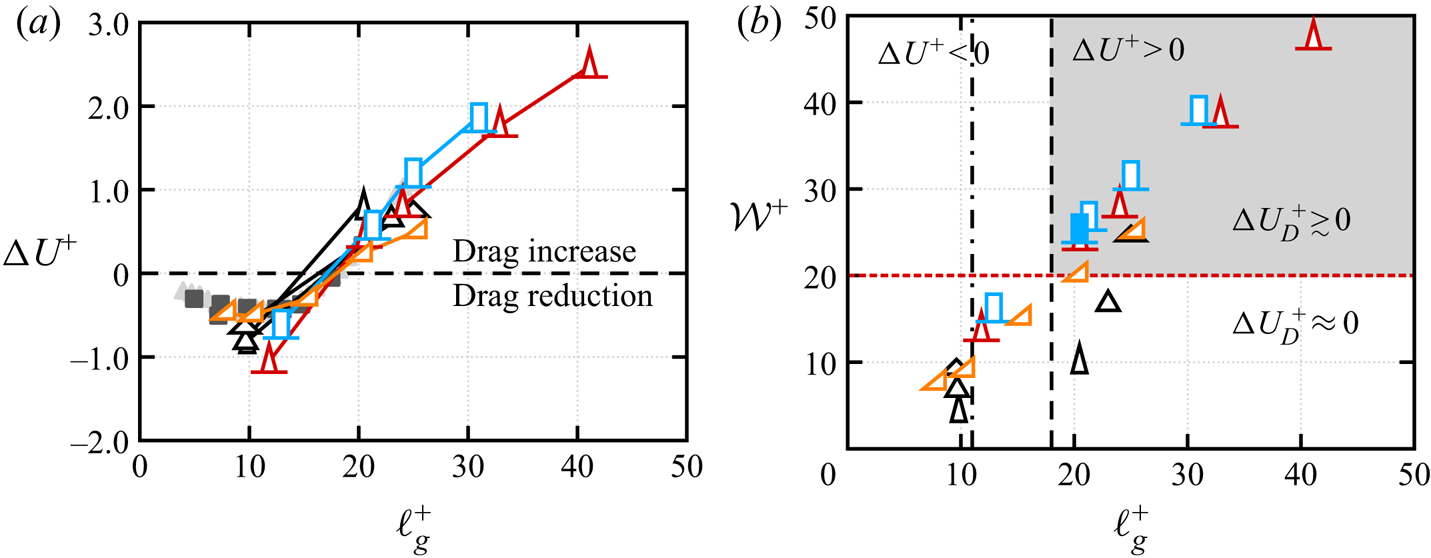

In order to understand the relation between the groove shape and the roughness sublayer, in figure 8 we report ![]() $\delta _r^+$ as a function of

$\delta _r^+$ as a function of ![]() $s^+$ and

$s^+$ and ![]() $\ell _g^+$. Figure 8(a) shows that DNS data for different groove geometries support a linear relationship between the roughness sublayer and the riblet spacing,

$\ell _g^+$. Figure 8(a) shows that DNS data for different groove geometries support a linear relationship between the roughness sublayer and the riblet spacing,

where ![]() $a=0.62$ is the least-squares fitting constant obtained from present DNS data. A slightly larger scatter instead is observed when

$a=0.62$ is the least-squares fitting constant obtained from present DNS data. A slightly larger scatter instead is observed when ![]() $\delta _r^+$ is reported as a function of

$\delta _r^+$ is reported as a function of ![]() $\ell _g^+$ (figure 8b). In the context of roughness, a similar result has been reported by Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2018), who observed that

$\ell _g^+$ (figure 8b). In the context of roughness, a similar result has been reported by Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2018), who observed that ![]() $\delta _r$ is half the spanwise roughness wavelength of egg-carton roughness in fully developed pipe flow. The roughness sublayer can be interpreted as the wall-normal distance above which the flow does not perceive the groove geometry, but rather the mean wall-shear stress induced by the riblets. In this respect (4.2) allows us to relate a flow parameter,

$\delta _r$ is half the spanwise roughness wavelength of egg-carton roughness in fully developed pipe flow. The roughness sublayer can be interpreted as the wall-normal distance above which the flow does not perceive the groove geometry, but rather the mean wall-shear stress induced by the riblets. In this respect (4.2) allows us to relate a flow parameter, ![]() $\delta _r^+$, to a geometrical parameter,

$\delta _r^+$, to a geometrical parameter, ![]() $s^+$, and it shows that the wall-normal location at which the mean flow becomes spanwise homogeneous depends only on the riblet spacing and not on the detailed groove geometry. However, the relation between

$s^+$, and it shows that the wall-normal location at which the mean flow becomes spanwise homogeneous depends only on the riblet spacing and not on the detailed groove geometry. However, the relation between ![]() $\Delta U^+$ and

$\Delta U^+$ and ![]() $\delta _r^+$ is more complex. As also noted by previous authors, there is no fixed relationship between

$\delta _r^+$ is more complex. As also noted by previous authors, there is no fixed relationship between ![]() $\Delta U^+$ and

$\Delta U^+$ and ![]() $s^+$ (and therefore also not between

$s^+$ (and therefore also not between ![]() $\Delta U^+$ and

$\Delta U^+$ and ![]() $\delta _r^+$). Instead,

$\delta _r^+$). Instead, ![]() $\Delta U^+$ of different grooves geometries scales better with

$\Delta U^+$ of different grooves geometries scales better with ![]() $\ell _g^+$ than with

$\ell _g^+$ than with ![]() $s^+$ and (4.3) shows that

$s^+$ and (4.3) shows that ![]() $\ell _g^+$ and

$\ell _g^+$ and ![]() $\delta _r^+$ are related through the mean riblet height. The linear relationship (4.3) can be traced back to the fact that the concept of virtual origin is strictly valid for infinitely small riblets, whereas in the turbulent case inertial flow might penetrate below the virtual origin and measuring the roughness sublayer from the riblet mean height partially accounts for this effect. In this sense